Слайд 2

Слайд 3

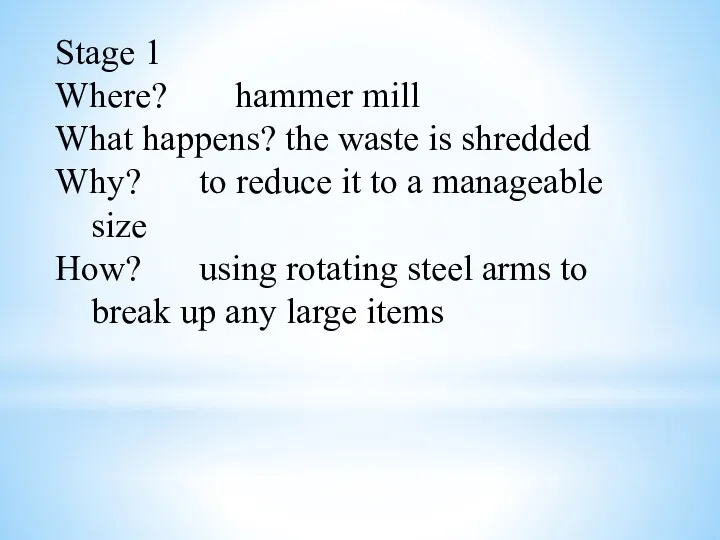

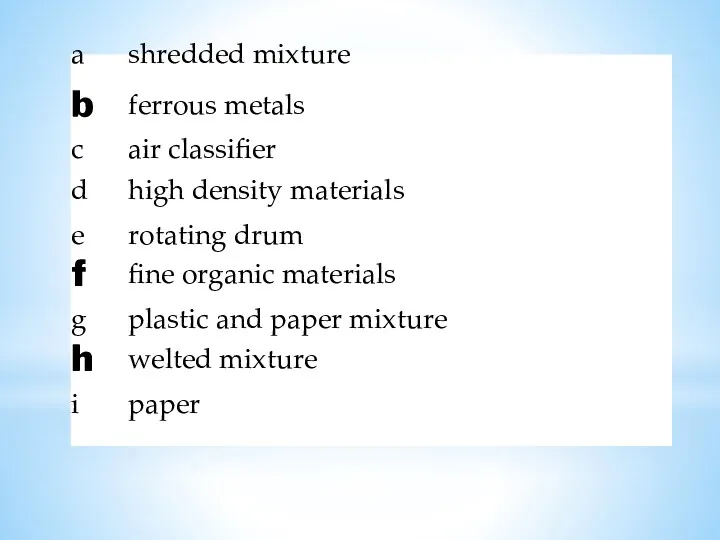

Stage 1

Where? hammer mill

What happens? the waste is shredded

Why? to reduce it

to a manageable size

How? using rotating steel arms to break up any large items

Слайд 4

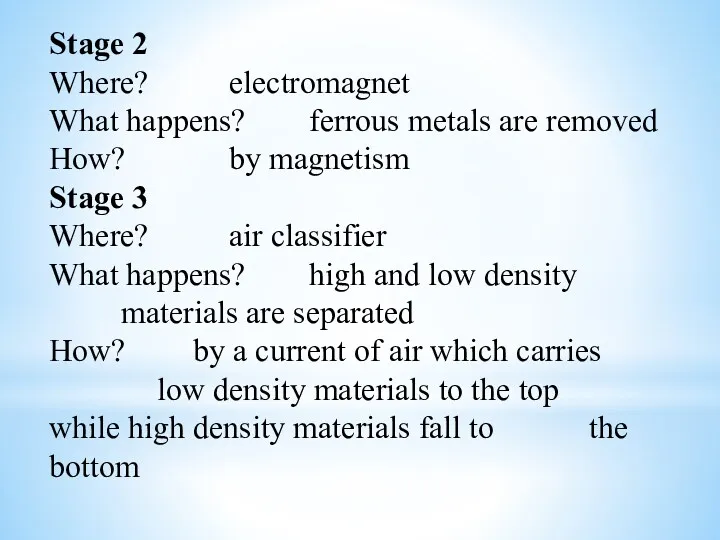

Stage 2

Where? electromagnet

What happens? ferrous metals are removed

How? by magnetism

Stage 3

Where? air classifier

What happens?

high and low density materials are separated

How? by a current of air which carries

low density materials to the top while high density materials fall to the bottom

Слайд 5

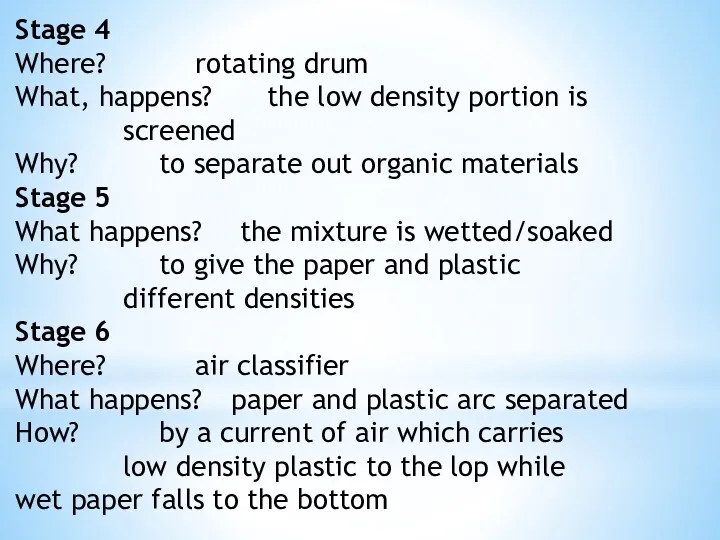

Stage 4

Where? rotating drum

What, happens? the low density portion is screened

Why? to separate

out organic materials

Stage 5

What happens? the mixture is wetted/soaked

Why? to give the paper and plastic

different densities

Stage 6

Where? air classifier

What happens? paper and plastic arc separated

How? by a current of air which carries

low density plastic to the lop while wet paper falls to the bottom

Слайд 6

1 could/can. Could is the better choice because we do not yet

recycle most waste although it is theoretically possible.

2 can/could. Can is the better choice because this is the practice in some countries. It is not just a theoretical possibility.

3 could (because we do not do this).

4 can (because this describes something real).

5 can (because this describes the state of affairs at this time).

Слайд 7

Stage 2 The shredded waste next passes to an electromagnet where

ferrous metals are removed (by magnetism).

Stage 3 The waste then passes through an air classifier where high and low density materials are separated by a current of air which carries low density materials to the top while high density materials fall to the bottom.

Stage 4 After that, the waste passes through a rotating drum where the low density portion is screened to separate out organic materials.

Stage 5 Next, the mixture is wetted to give the paper and plastic different densities.

Stage 6 Finally, the wetted mixture passes

through a second air classifier where paper and plastic are separated by a current of air which carries low density plastic lo the top while wet paper falls to the bottom

Слайд 8

Слайд 9

Out of the ordinary

Out of the ordinary How do you feel. English together

How do you feel. English together Вестминстерское аббатство

Вестминстерское аббатство Secret letter

Secret letter Teaching Grammar & Vocabulary for CAE

Teaching Grammar & Vocabulary for CAE American sport

American sport Читаем по-английски. Гласные A, E, I, O, U

Читаем по-английски. Гласные A, E, I, O, U Halloween

Halloween Collection of tests

Collection of tests English in European integration

English in European integration The place we live in

The place we live in Canadian English

Canadian English Тест: Местоимения somebody, anybody, something, anything, somewhere, anywhere

Тест: Местоимения somebody, anybody, something, anything, somewhere, anywhere English grammar. The passive voice

English grammar. The passive voice Говорение. Стратегия выполнения, полный разбор задания, схема ответа

Говорение. Стратегия выполнения, полный разбор задания, схема ответа Food in my life. Lesson 3. Vegetables

Food in my life. Lesson 3. Vegetables Animals. Hidden Pictures

Animals. Hidden Pictures Future tenses

Future tenses My Family

My Family Загадки для малышей

Загадки для малышей How to shop properly

How to shop properly 50 States Fun Facts & Questions

50 States Fun Facts & Questions Подготовка к ВПР. Устная часть (7 класс)

Подготовка к ВПР. Устная часть (7 класс) Модальный глагол Can

Модальный глагол Can Christmas in the UK

Christmas in the UK Урок з англійської мови для 6 класу. Одяг. Пори року

Урок з англійської мови для 6 класу. Одяг. Пори року Your future, our future. Environment quiz

Your future, our future. Environment quiz Модальные глаголы can / could

Модальные глаголы can / could