Содержание

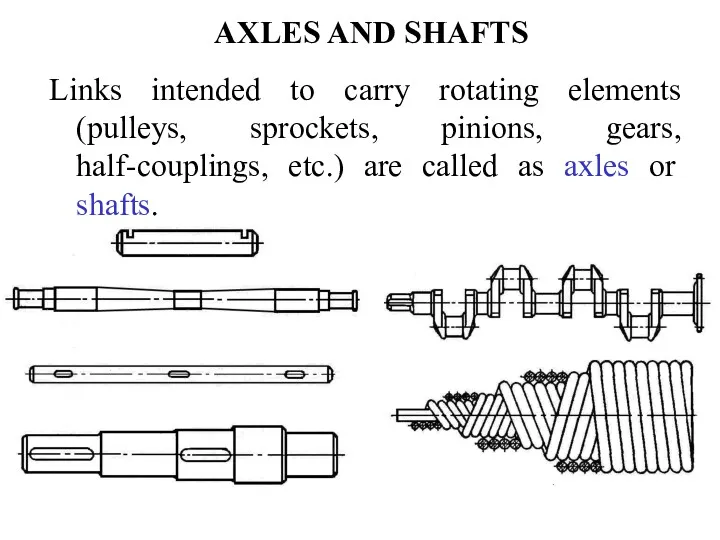

- 2. AXLES AND SHAFTS Links intended to carry rotating elements (pulleys, sprockets, pinions, gears, half-couplings, etc.) are

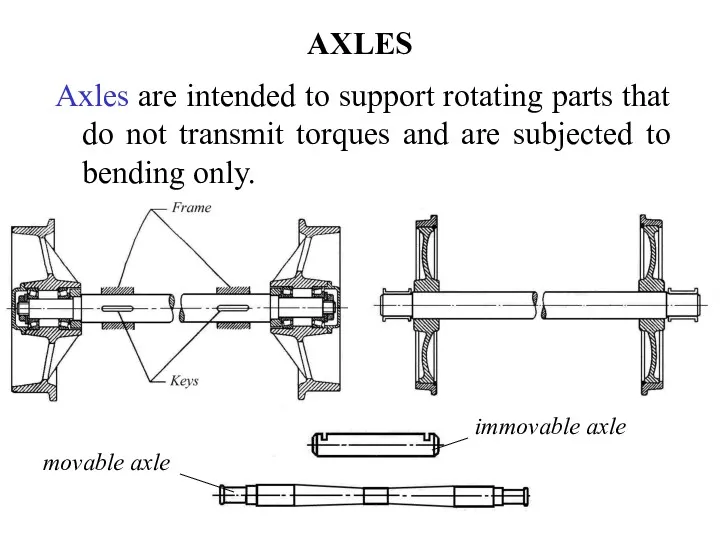

- 3. AXLES Axles are intended to support rotating parts that do not transmit torques and are subjected

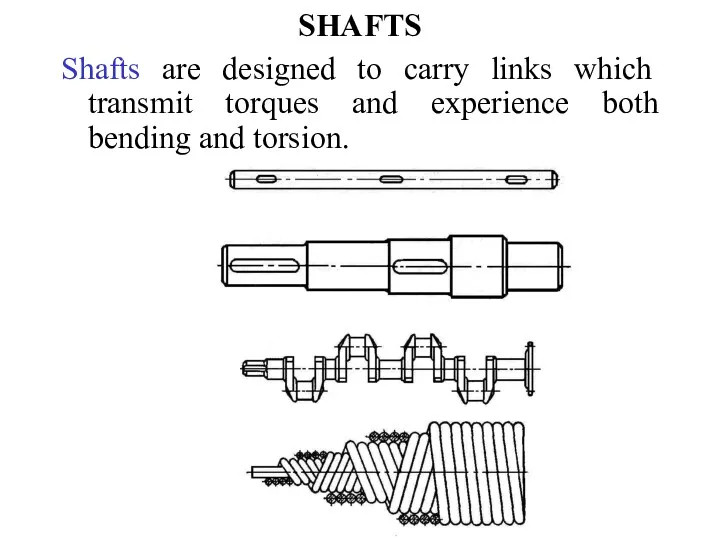

- 4. SHAFTS Shafts are designed to carry links which transmit torques and experience both bending and torsion.

- 5. CLASSIFICATION OF SHAFTS According to purpose Shafts of various drives (gear drives, belt drives, chain drives

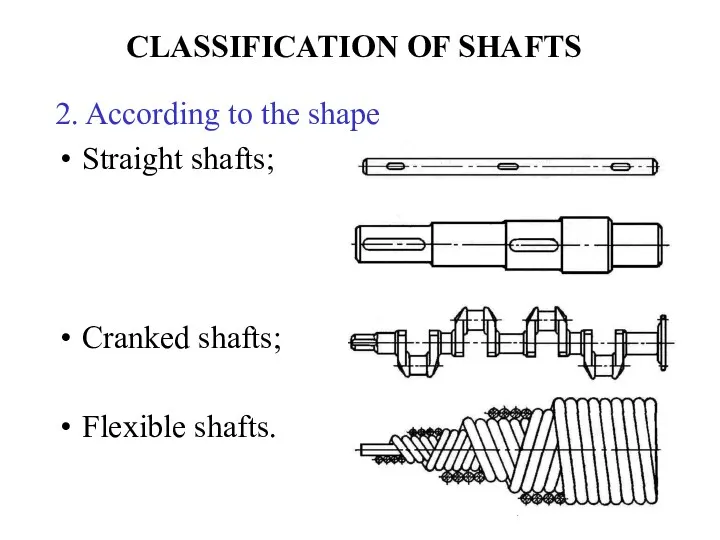

- 6. CLASSIFICATION OF SHAFTS 2. According to the shape Straight shafts; Cranked shafts; Flexible shafts.

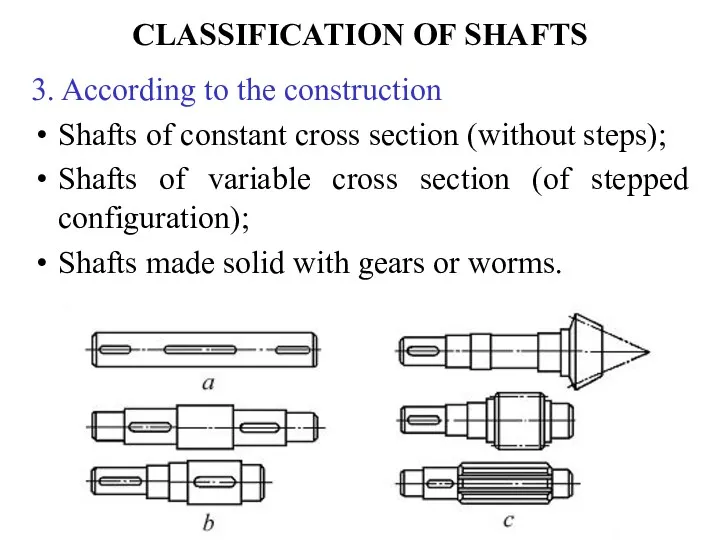

- 7. CLASSIFICATION OF SHAFTS 3. According to the construction Shafts of constant cross section (without steps); Shafts

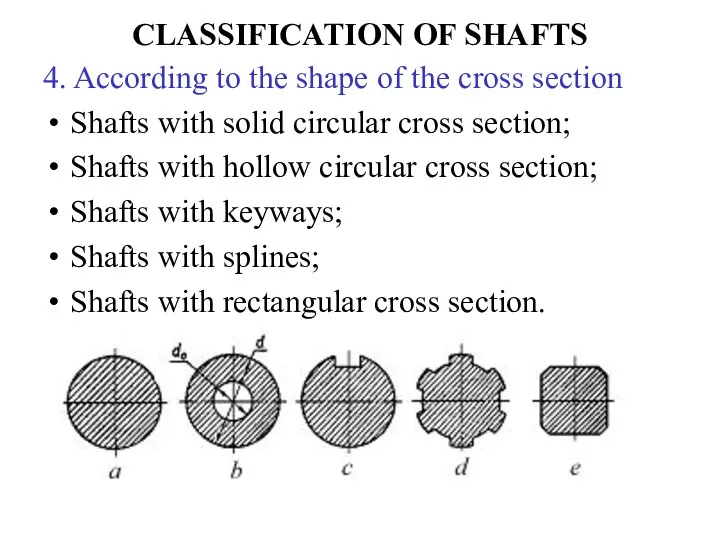

- 8. CLASSIFICATION OF SHAFTS 4. According to the shape of the cross section Shafts with solid circular

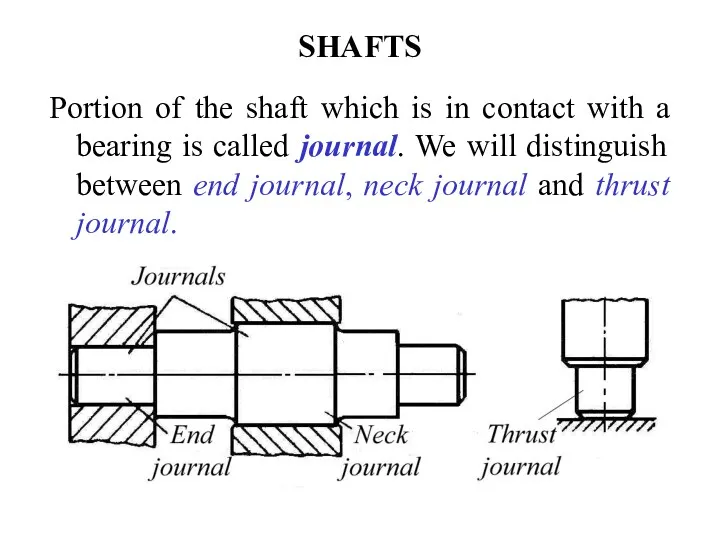

- 9. SHAFTS Portion of the shaft which is in contact with a bearing is called journal. We

- 10. CALCULATION OF SHAFTS Strength; Rigidity; Oscillations. Shafts may be calculated for:

- 11. CALCULATION OF SHAFTS FOR STRENGTH Determination of the minimum diameter of the shaft; Designing the shaft

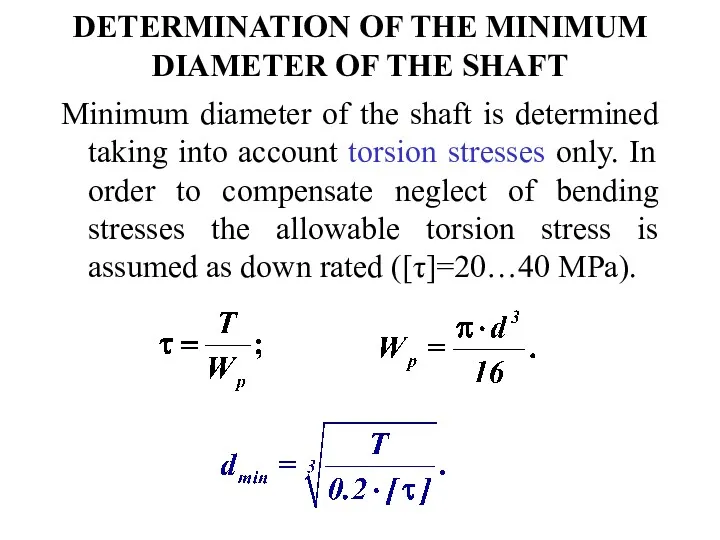

- 12. DETERMINATION OF THE MINIMUM DIAMETER OF THE SHAFT Minimum diameter of the shaft is determined taking

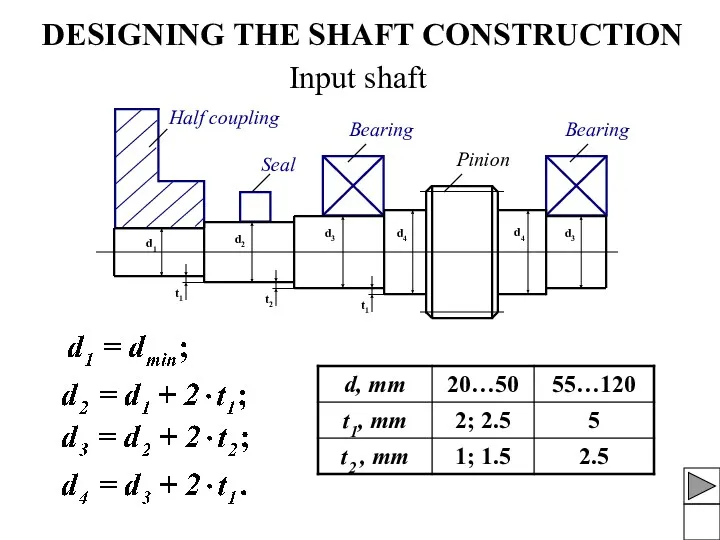

- 13. DESIGNING THE SHAFT CONSTRUCTION Input shaft Half coupling Seal Bearing Bearing Pinion

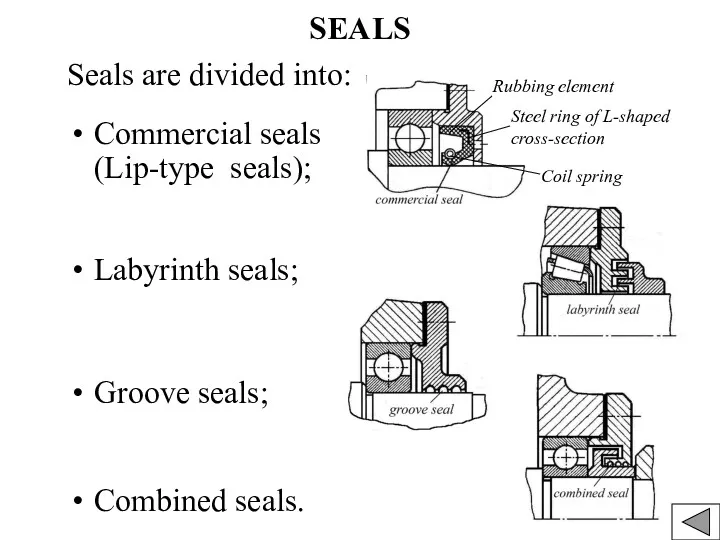

- 14. SEALS Seals are divided into: Commercial seals (Lip-type seals); Labyrinth seals; Groove seals; Combined seals. Rubbing

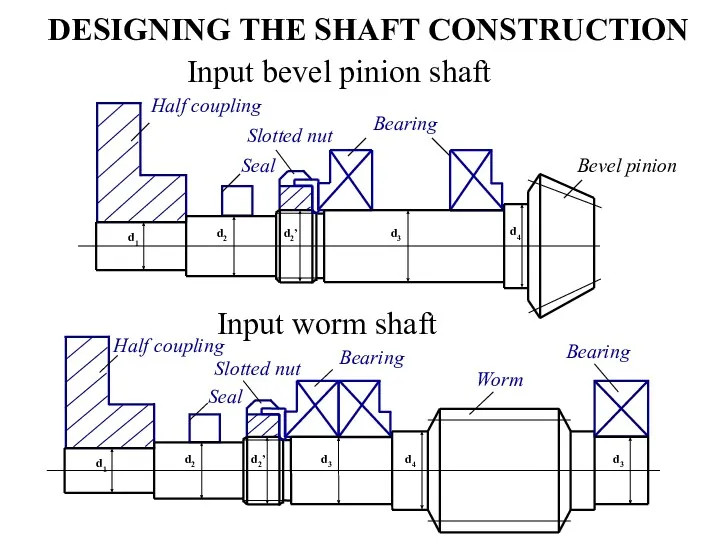

- 15. DESIGNING THE SHAFT CONSTRUCTION Input bevel pinion shaft Input worm shaft

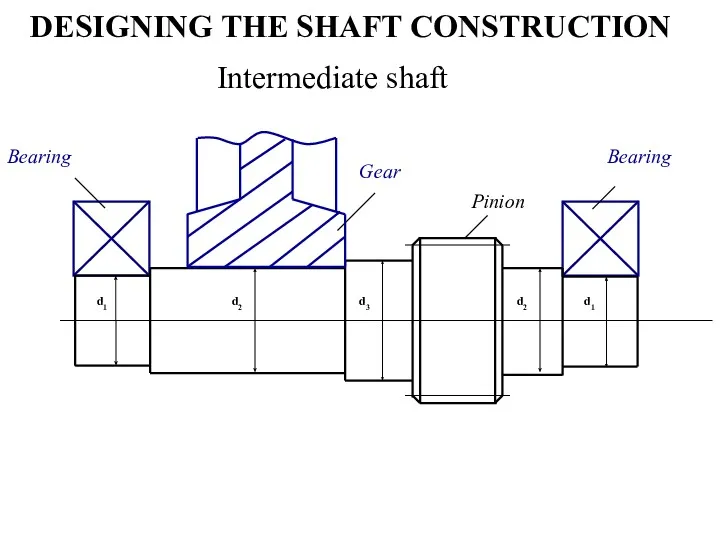

- 16. DESIGNING THE SHAFT CONSTRUCTION Intermediate shaft d1 d2 d2 d1 Bearing Bearing Pinion d3 Gear

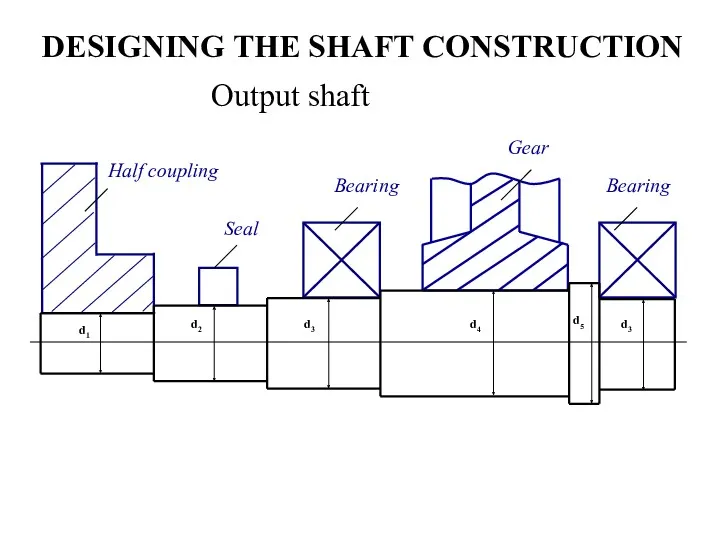

- 17. DESIGNING THE SHAFT CONSTRUCTION Output shaft Bearing

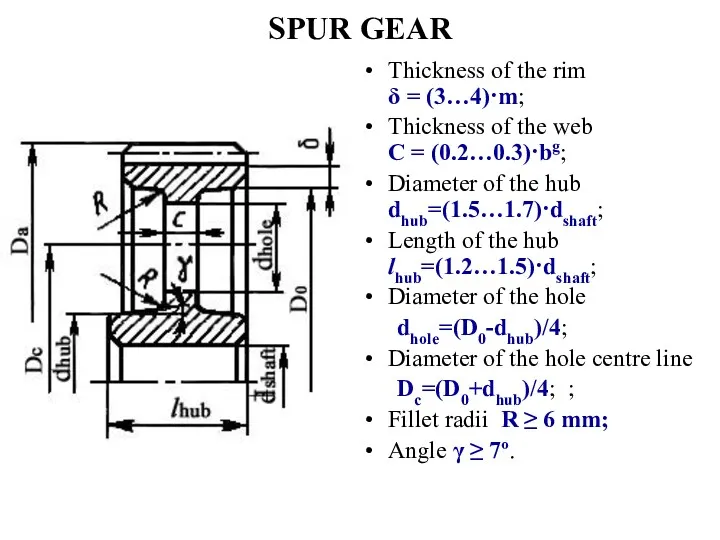

- 18. SPUR GEAR Thickness of the rim δ = (3…4)·m; Thickness of the web C = (0.2…0.3)·bg;

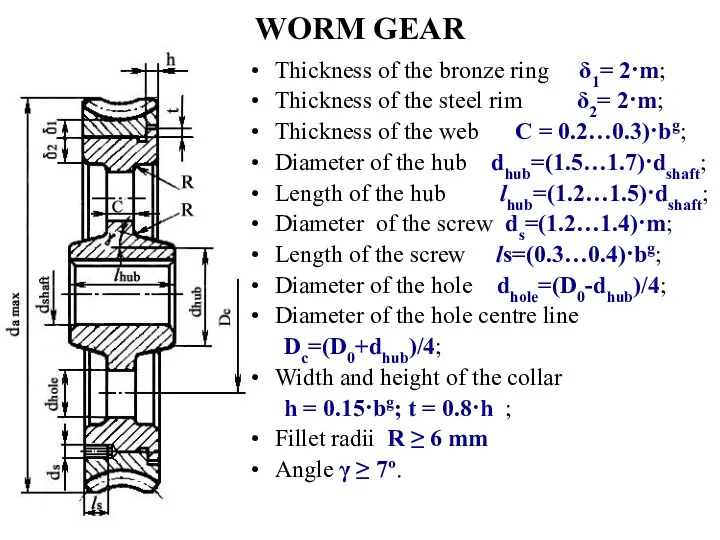

- 19. WORM GEAR Thickness of the bronze ring δ1= 2·m; Thickness of the steel rim δ2= 2·m;

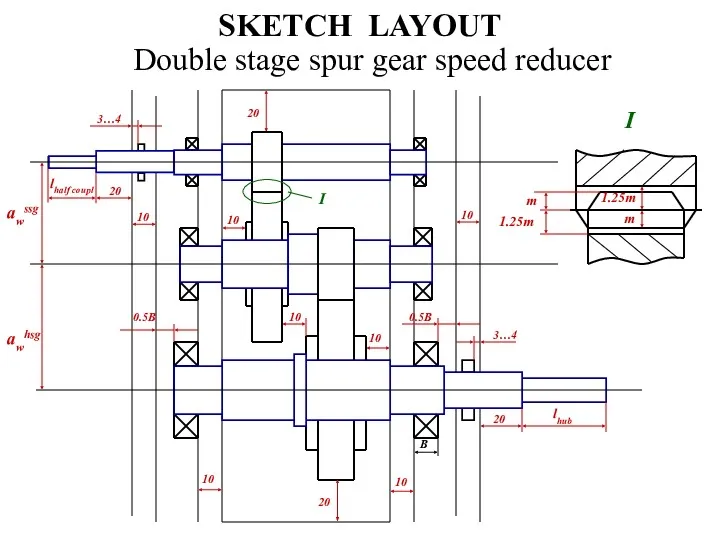

- 20. SKETCH LAYOUT Double stage spur gear speed reducer I I

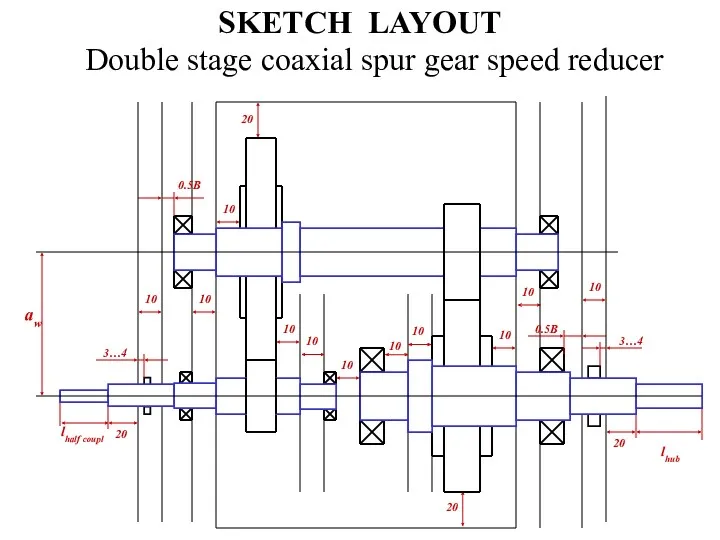

- 21. SKETCH LAYOUT Double stage coaxial spur gear speed reducer

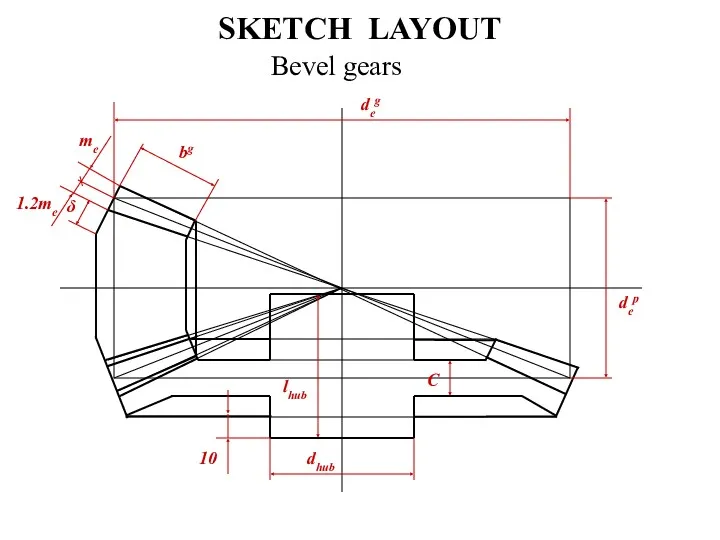

- 22. SKETCH LAYOUT Bevel gears

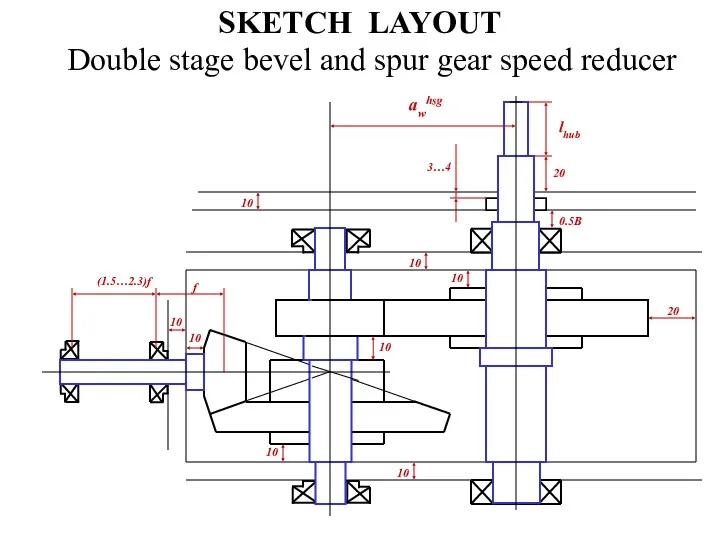

- 23. SKETCH LAYOUT Double stage bevel and spur gear speed reducer

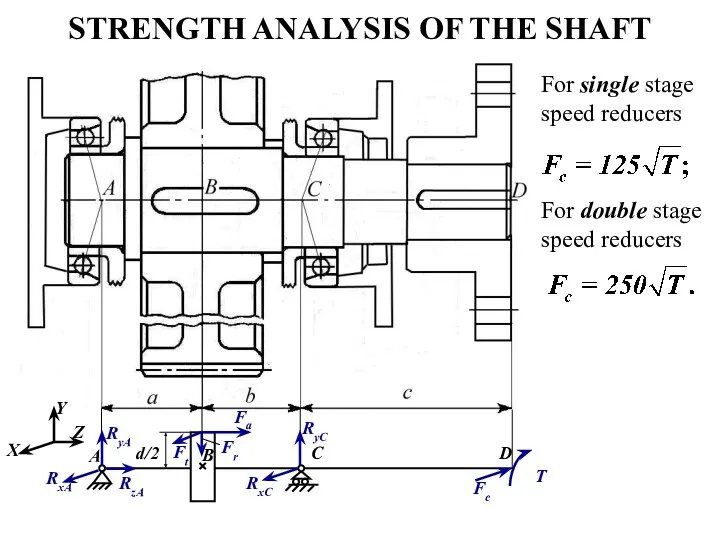

- 24. STRENGTH ANALYSIS OF THE SHAFT For single stage speed reducers For double stage speed reducers

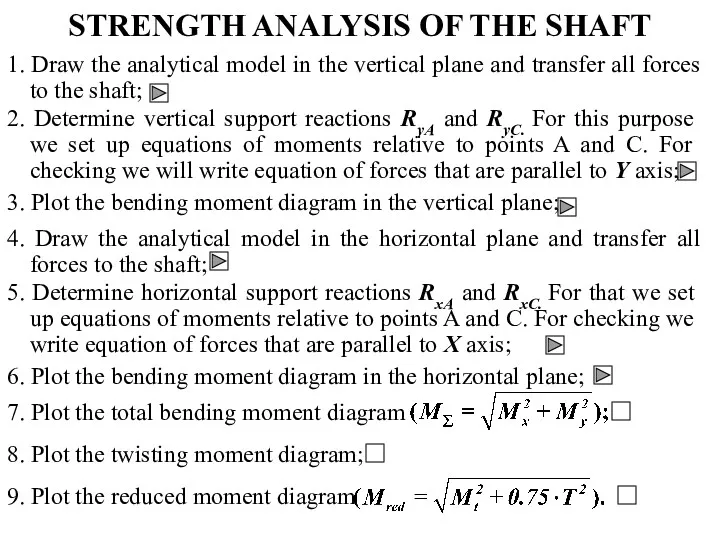

- 25. STRENGTH ANALYSIS OF THE SHAFT 1. Draw the analytical model in the vertical plane and transfer

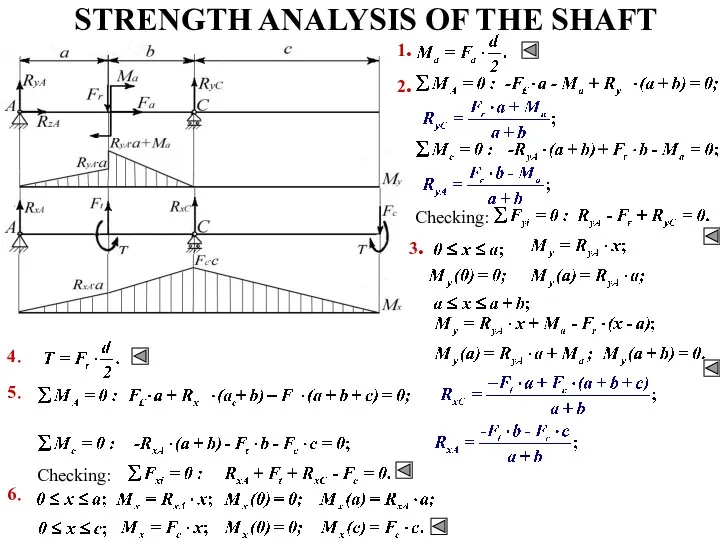

- 26. STRENGTH ANALYSIS OF THE SHAFT Checking: 1. 2. 3. 5. Checking: 6. 4.

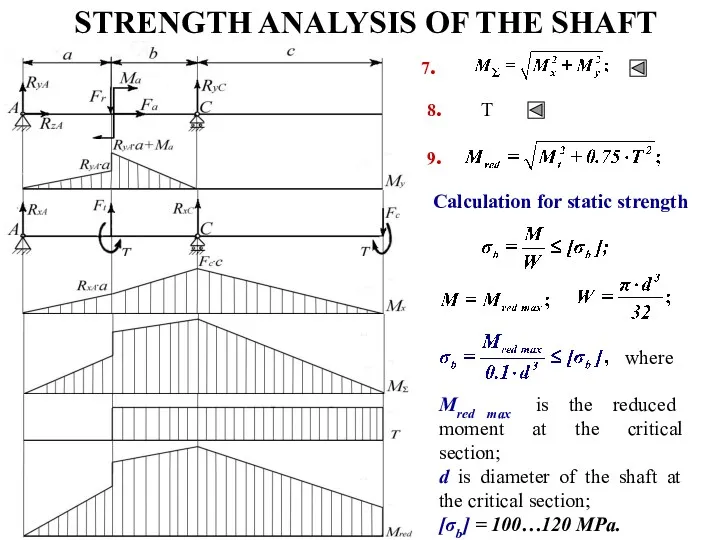

- 27. STRENGTH ANALYSIS OF THE SHAFT T 7. 8. 9. Calculation for static strength Mred max is

- 28. STRENGTH ANALYSIS OF THE SHAFT Calculation of the shaft for fatigue strength Changing of bending stresses

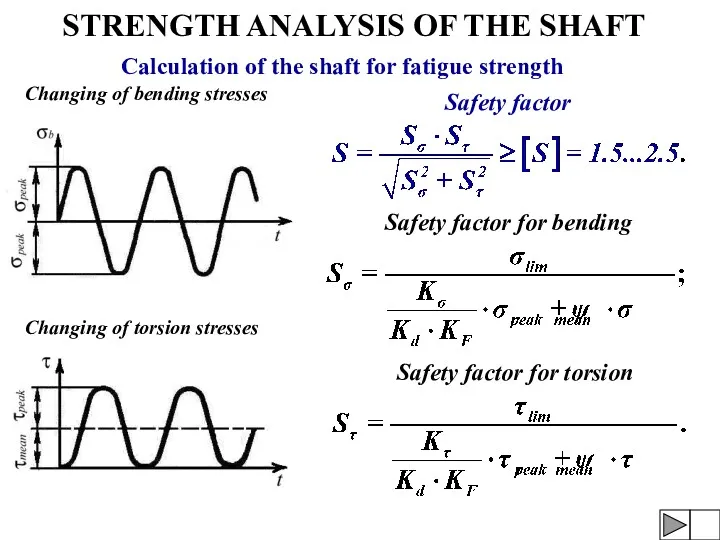

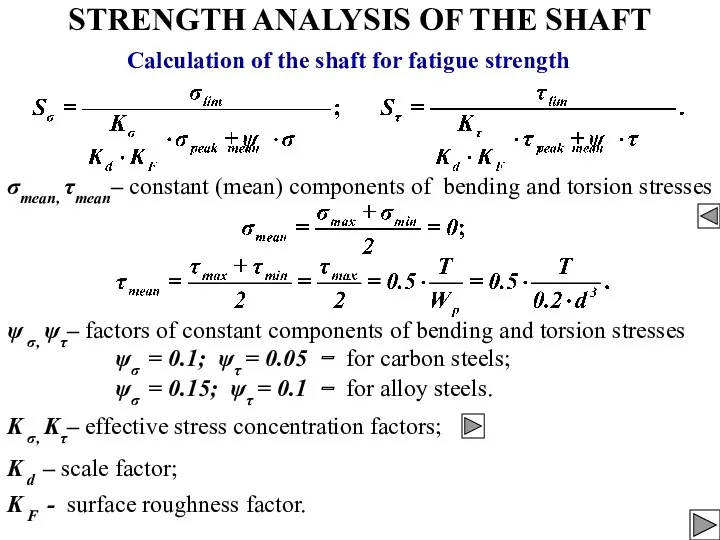

- 29. STRENGTH ANALYSIS OF THE SHAFT Calculation of the shaft for fatigue strength σlim, τlim – limit

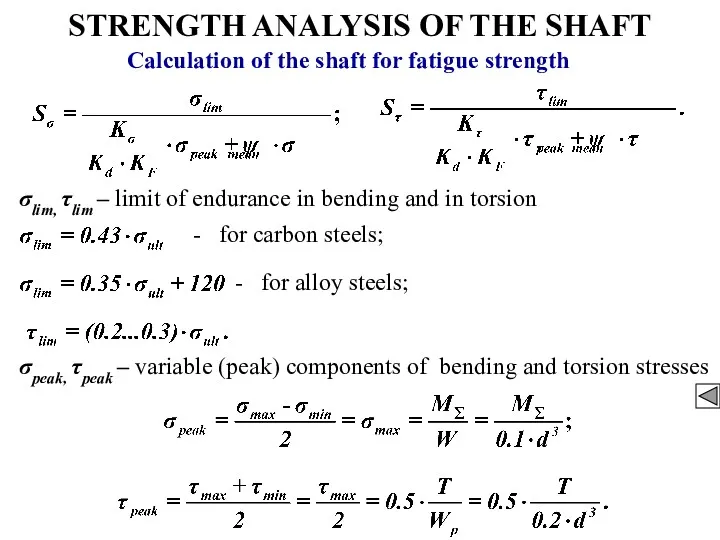

- 30. STRENGTH ANALYSIS OF THE SHAFT ψσ = 0.1; ψτ = 0.05 − for carbon steels; ψσ

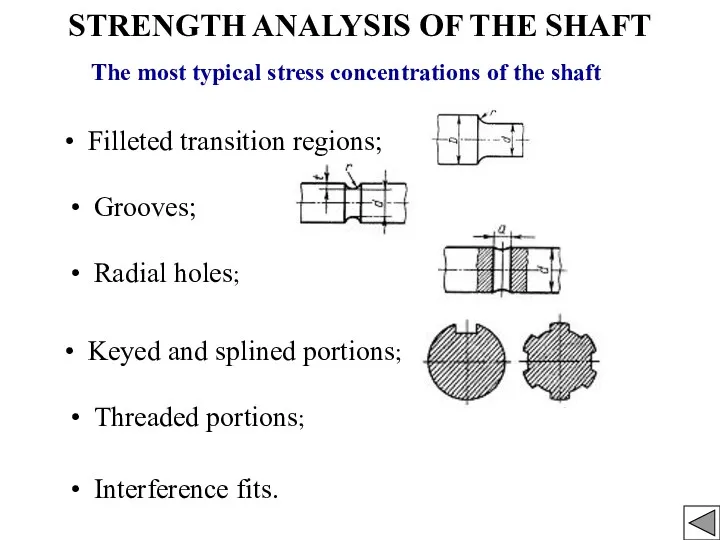

- 31. STRENGTH ANALYSIS OF THE SHAFT The most typical stress concentrations of the shaft Filleted transition regions;

- 32. RIGIDITY ANALYSIS OF THE SHAFT Flexural rigidity Basic criteria of flexural rigidity are: Maximum deflection (sag)

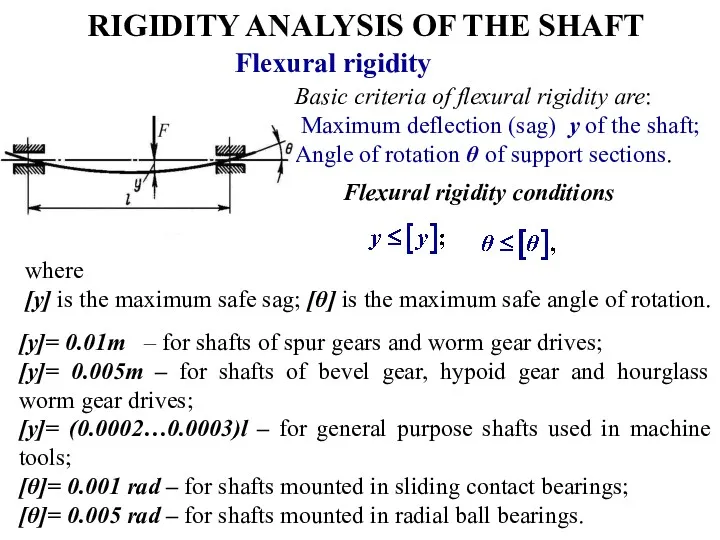

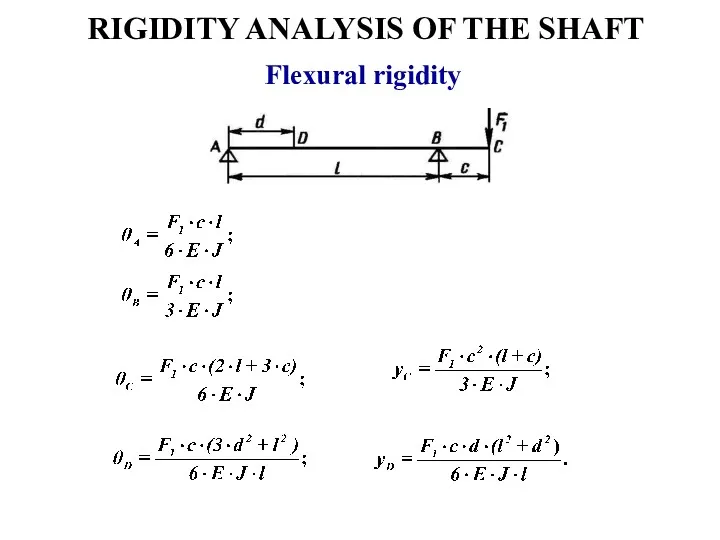

- 33. RIGIDITY ANALYSIS OF THE SHAFT Flexural rigidity E is modulus of elasticity of the shaft material;

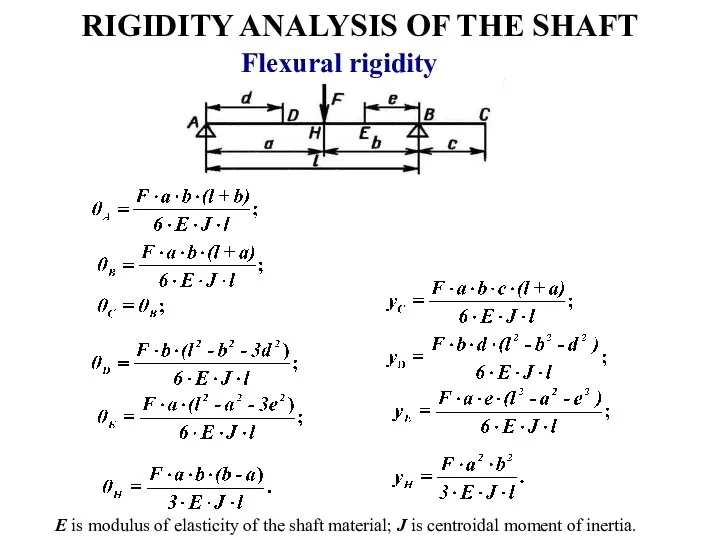

- 34. RIGIDITY ANALYSIS OF THE SHAFT Flexural rigidity

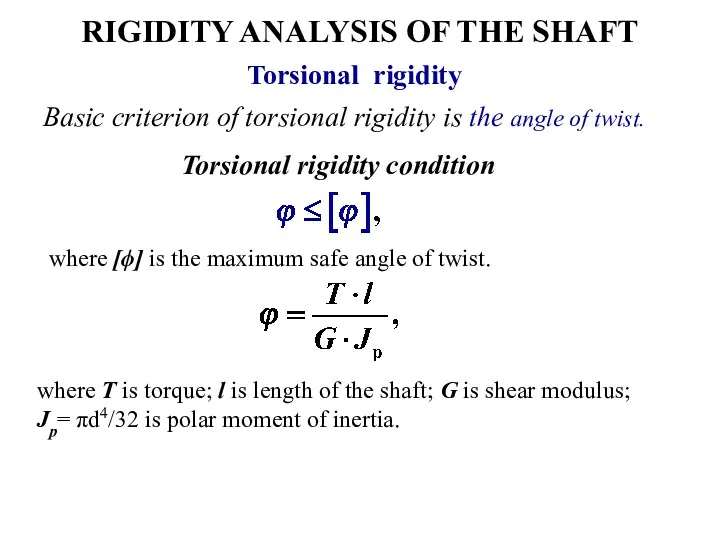

- 35. RIGIDITY ANALYSIS OF THE SHAFT Basic criterion of torsional rigidity is the angle of twist. Torsional

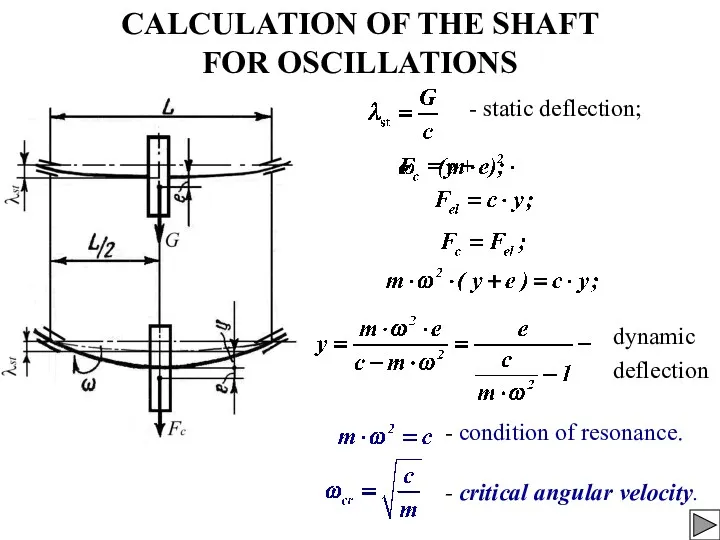

- 36. CALCULATION OF THE SHAFT FOR OSCILLATIONS - static deflection; dynamic deflection - condition of resonance. -

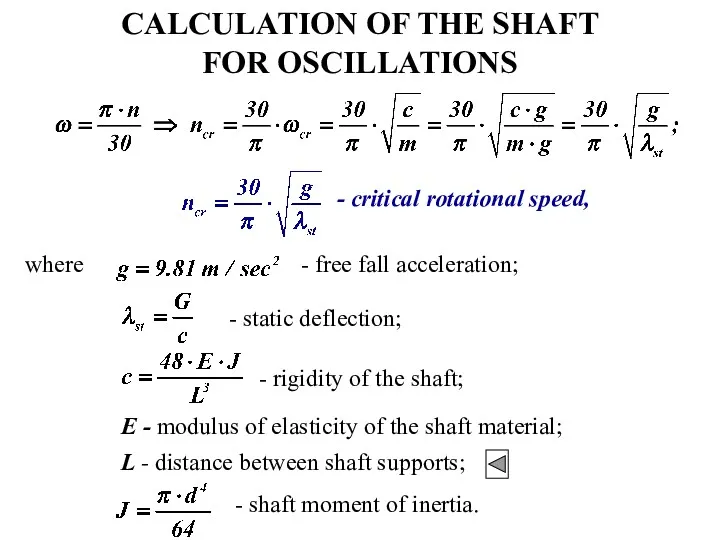

- 37. CALCULATION OF THE SHAFT FOR OSCILLATIONS - critical rotational speed, where - free fall acceleration; -

- 39. Скачать презентацию

Истечение из отверстий и насадок

Истечение из отверстий и насадок Законы постоянного тока Тема урока: Электрический ток. Сила тока.

Законы постоянного тока Тема урока: Электрический ток. Сила тока. Способы соединения жил кабелей

Способы соединения жил кабелей Квантовая физика. Фотоэффект

Квантовая физика. Фотоэффект Схематизация опор. Определение реакций

Схематизация опор. Определение реакций Изготовление столярного соединения УС-1

Изготовление столярного соединения УС-1 Проводники в электрическом поле. Диэлектрики в электрическом поле

Проводники в электрическом поле. Диэлектрики в электрическом поле Механические колебания. 11 класс

Механические колебания. 11 класс Магнит өрісіндегі тогы бар контур

Магнит өрісіндегі тогы бар контур Кванттық теорияның бастаулары

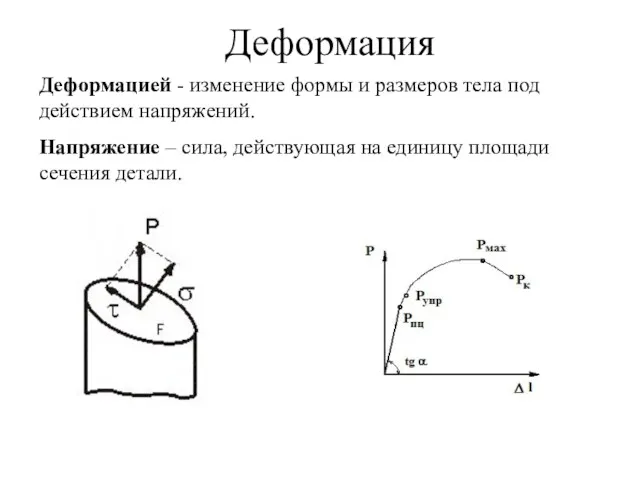

Кванттық теорияның бастаулары Деформация. Механизмы пластической деформации

Деформация. Механизмы пластической деформации Химические источники тока гальванические элементы, аккумуляторы

Химические источники тока гальванические элементы, аккумуляторы Квантовые постулаты Бора

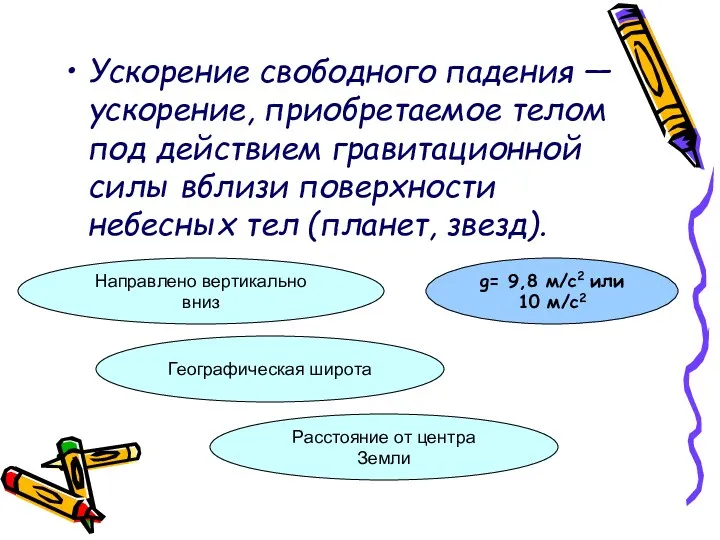

Квантовые постулаты Бора Ускорение свободного падения

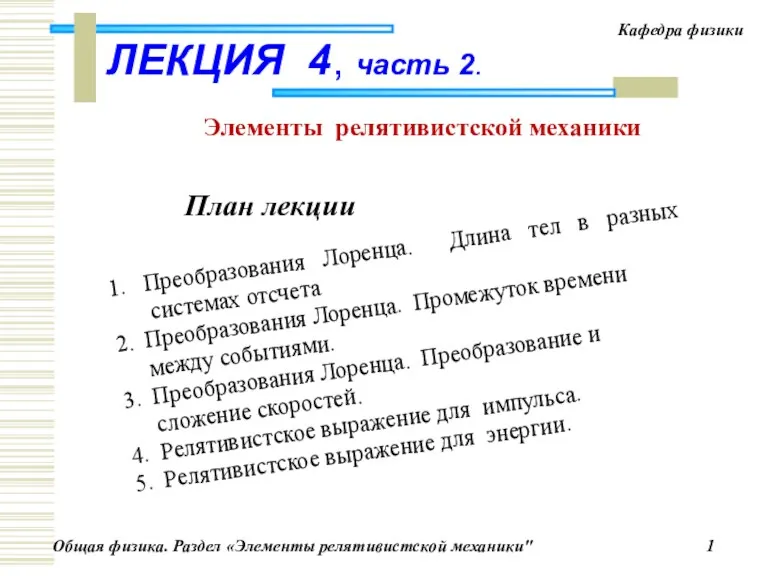

Ускорение свободного падения Элементы релятивистской механики. Специальная теория относительности. (Лекция 4.2)

Элементы релятивистской механики. Специальная теория относительности. (Лекция 4.2) Зависимость давления насыщенного пара от температуры. Кипение

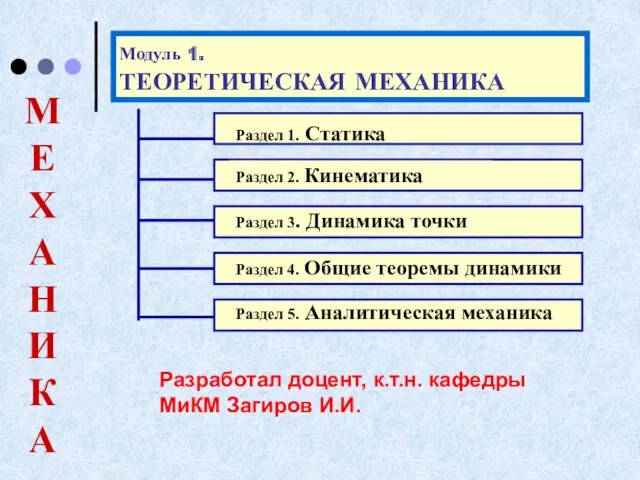

Зависимость давления насыщенного пара от температуры. Кипение ЛЕКЦИИ термех. модуль 1

ЛЕКЦИИ термех. модуль 1 Презентация по теме: Газовые законы

Презентация по теме: Газовые законы Механические волны

Механические волны Презентация по физике для 8 класса - своя игра по теме Электричество

Презентация по физике для 8 класса - своя игра по теме Электричество Зачем физика повару?

Зачем физика повару? Использование электронных образовательных ресурсов в преподавании физики

Использование электронных образовательных ресурсов в преподавании физики Плавление и отвердевание кристаллических тел

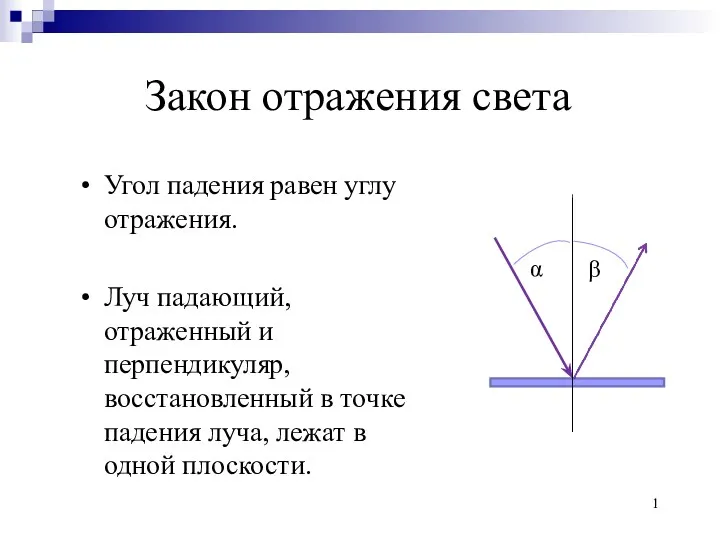

Плавление и отвердевание кристаллических тел Преломление и полное внутреннее отражение света

Преломление и полное внутреннее отражение света Простые механизмы. Зубчатая передача

Простые механизмы. Зубчатая передача электродинамика 11 класс

электродинамика 11 класс презентация Введение в предмет

презентация Введение в предмет Основы теории напряженного состояния. Лекция 9

Основы теории напряженного состояния. Лекция 9