Содержание

- 2. Content Size reduction mechanism Release point and internal dynamics 1st and 2nd chamber 1st chamber liners

- 3. Content Size reduction mechanism Release point and internal dynamics 1st and 2nd chamber 1st chamber liners

- 4. 3 mechanisms of size reduction Fractures Crushing Chipping Crushing and some fines Abrasion Fine grinding

- 5. Internal ball dynamics Cataracting Free fall of the balls Emphasis on crushing Cascading Tumbles along charge

- 6. Content Size reduction mechanism Release point and internal dynamics 1st and 2nd chamber 1st chamber liners

- 7. Release points and grinding Position depends on three main factors % of critical speed Liner’s design

- 8. Release point and mill critical speed Speed of rotation at which centrifugal forces overcome gravity forces

- 9. Release points and liners design Different liners design can give different release points and therefore different

- 10. Internal dynamics in first chamber Primary grinding of coarse material with large grinding media (Ø 90-60

- 11. Internal dynamics in second chamber Development of a high fineness with small grinding media (Ø 50-15

- 12. Content Size reduction mechanism Release point and internal dynamics 1st and 2nd chamber 1st chamber liners

- 13. Purpose of a liner’s design Each liner is designed to ensure: Lowest specific energy consumption Highest

- 15. Activator liners Step liner Wave liner type “Duolift” Step liner tpe “Xlift” Step liner with wave

- 16. Step liner Only for first compartments Better wear characteristics Moderate lift Designed for DIN drilled shell

- 17. Single wave & Duolift liners Only for first compartments Single wave Negative back slope induces sliding

- 18. Installed Duolift liners

- 19. First chamber - Reminders Be careful of the appropriate ratio between Critical speed Liner lifting action

- 20. Content Size reduction mechanism Release point and internal dynamics 1st and 2nd chamber 1st chamber liners

- 21. Second chamber liners Classifying lining with activator profile Conventional classifying lining with wave profile Wave lining

- 22. Purpose of classifying liners Match ball size to particle size (Bond Formula) without partitions

- 23. Examples of classifying liners

- 24. Classifying liners - issues Causes of poor classification Liner’s step wear Lifting of the charge too

- 25. Classifying liner design and mill shell size

- 26. Other types of liners : grooved liners

- 27. Other types of liners : Danula or Dam Rings Where we find it Long mills, in

- 28. Second chamber - Reminders Classifying liners Causes for poor classification Liner step wear Lifting of the

- 29. Liner material selection: Breakage resistance Wear resistance LOW CHROMIUM ALLOY 3% Cr 0,5% C 45-50 HRC

- 30. Content Size reduction mechanism Release point and internal dynamics 1st and 2nd chamber 1st chamber liners

- 31. Fastening types Bolted Requires a drilling in the mill tube for every plate Easy handling during

- 32. Semi-bolted Minimum two bolted rows in total Requires special tools and experienced fitters Fastening types

- 33. Fastening types Boltless Plates are forced-fitted with positive locking without any bolts Requires precise preparation, special

- 34. Liners’ wear management Liner wear optimisation Avoid metal / metal contact Minimise purge duration Look for

- 35. Content Size reduction mechanism Release point and internal dynamics 1st and 2nd chamber 1st chamber liners

- 36. Balls wear

- 37. Content Size reduction mechanism Release point and internal dynamics 1st and 2nd chamber 1st chamber liners

- 38. Mill head lining Conical design Conical head lining plates on a conical mill head are exposed

- 39. Mill head lining Straight design (with structure) Straight head lining plates on a conical mill head

- 40. Content Size reduction mechanism Release point and internal dynamics 1st and 2nd chamber 1st chamber liners

- 41. Mass transport Reason for mass transport in the mill shell Mill inlet feed pushes the material

- 42. Material filling ratio Definition (In practice, it is evaluated with the level of material above or

- 43. Grinding vs. filling Interparticle grinding occurs when the voids space is properly filled The collision of

- 44. Mill bypass Ball charge expands when overloaded In the extreme, a stream of material “bypass” the

- 46. Скачать презентацию

Изобретение радио А.С. Поповым

Изобретение радио А.С. Поповым Конденсаторы

Конденсаторы Фотолитография. Практическое занятие 4

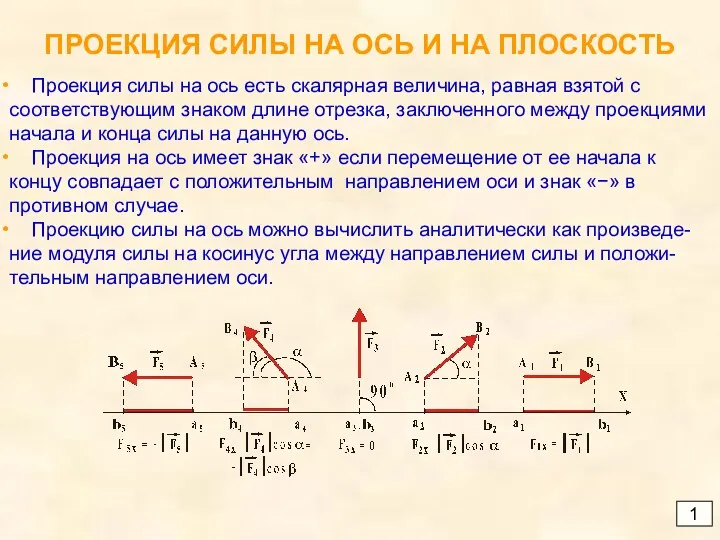

Фотолитография. Практическое занятие 4 Проекция силы на ось и на плоскость

Проекция силы на ось и на плоскость Мастер-класс по теме Использование системно-деятельностного подхода для повышения качества на уроках физики

Мастер-класс по теме Использование системно-деятельностного подхода для повышения качества на уроках физики Теплове випромінювання

Теплове випромінювання История возникновения спектроскопии

История возникновения спектроскопии Звуковые волны. Скорость звука.

Звуковые волны. Скорость звука. Термодинамика. Изменение агрегатных состояний вещества

Термодинамика. Изменение агрегатных состояний вещества История изобретения велосипеда. 2 класс

История изобретения велосипеда. 2 класс Естественное и искусственное освещение

Естественное и искусственное освещение Прилади спін-хвильової електроніки

Прилади спін-хвильової електроніки Кинематические схемы

Кинематические схемы Самоанализ учителя физики

Самоанализ учителя физики Эксперимент – как метод активизации мыслительной деятельности учащихся на уроках физики

Эксперимент – как метод активизации мыслительной деятельности учащихся на уроках физики MATLAB 程式設計入門篇 音訊讀寫、錄製與播放

MATLAB 程式設計入門篇 音訊讀寫、錄製與播放 Timing recovery in baseband transmission. (Lecture 8)

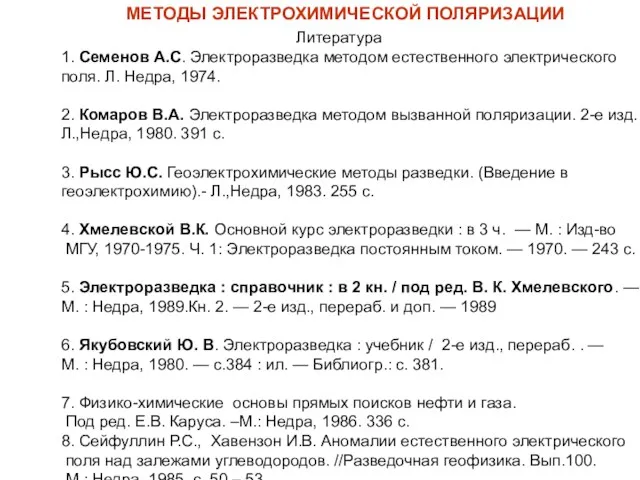

Timing recovery in baseband transmission. (Lecture 8) Методы электрохимической поляризации

Методы электрохимической поляризации Ферродинамические приборы

Ферродинамические приборы Жидкостная система охлаждения. Урок № 32

Жидкостная система охлаждения. Урок № 32 Проявление сил в живой природе

Проявление сил в живой природе Производственно-техническая база предприятий автосервиса (Лекция № 5)

Производственно-техническая база предприятий автосервиса (Лекция № 5) Сила трения. Трение в природе и технике. 9 класс

Сила трения. Трение в природе и технике. 9 класс Проект производственного участка по ТО и ремонту приборов системы питания автомобилей с дизельными двигателями

Проект производственного участка по ТО и ремонту приборов системы питания автомобилей с дизельными двигателями Классический метод расчета переходных процессов. Переходные процессы в цепях с r и L, r и C при постоянных напряжениях. Лекция 8

Классический метод расчета переходных процессов. Переходные процессы в цепях с r и L, r и C при постоянных напряжениях. Лекция 8 ФИЗИКА 8 класс Изменение агрегатных состояний вещества

ФИЗИКА 8 класс Изменение агрегатных состояний вещества Виртуальный музей радиосвязи

Виртуальный музей радиосвязи Электронный парамагнитный резонанс

Электронный парамагнитный резонанс