Содержание

- 2. /62 Course Target 1.GW4D20 Diesel Engine Parameter & Structure 2.GW4D20 Diesel Engine Assembly Operation 3.GW4D20 Diesel

- 3. /62 Topics 一、GW4D20 Diesel Engine General Instruction 二、GW4D20 Diesel Engine Basic Parameter 三、GW4D20 Mechanical System

- 4. /62 Ⅰ.GW4D20 Diesel Engine General Introduction GW4D20 diesel engine with turbocharger system is developed by Great

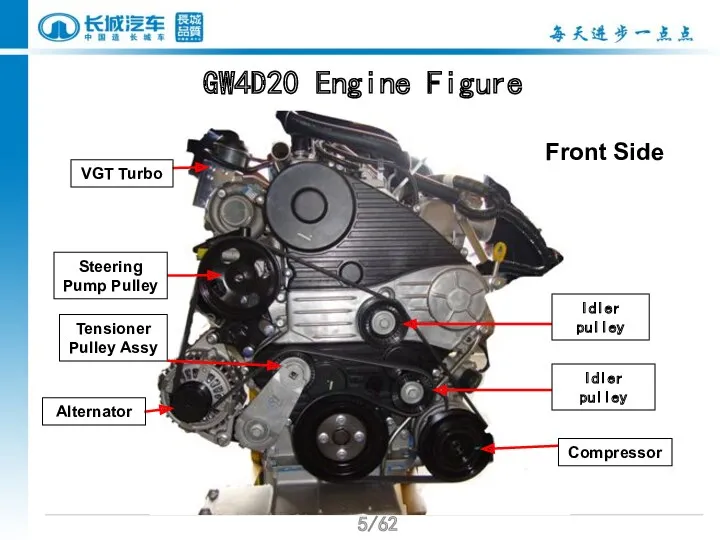

- 5. /62 GW4D20 Engine Figure Tensioner Pulley Assy Alternator Steering Pump Pulley VGT Turbo Idler pulley Idler

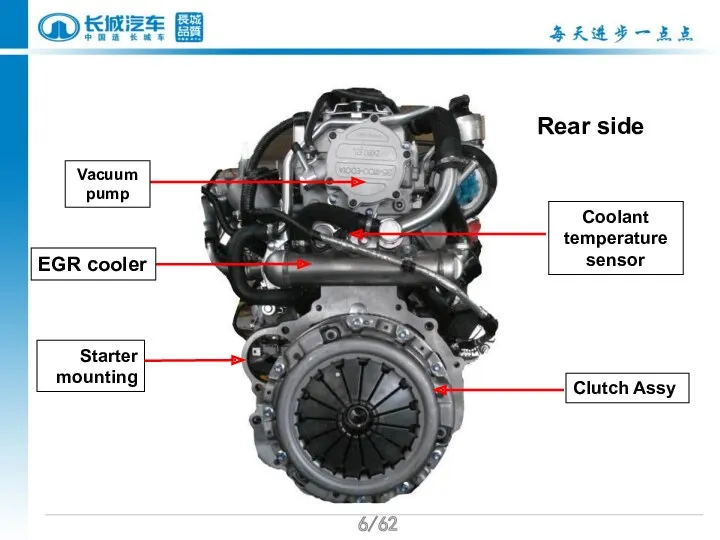

- 6. /62 Starter mounting Coolant temperature sensor Vacuum pump EGR cooler Rear side Clutch Assy

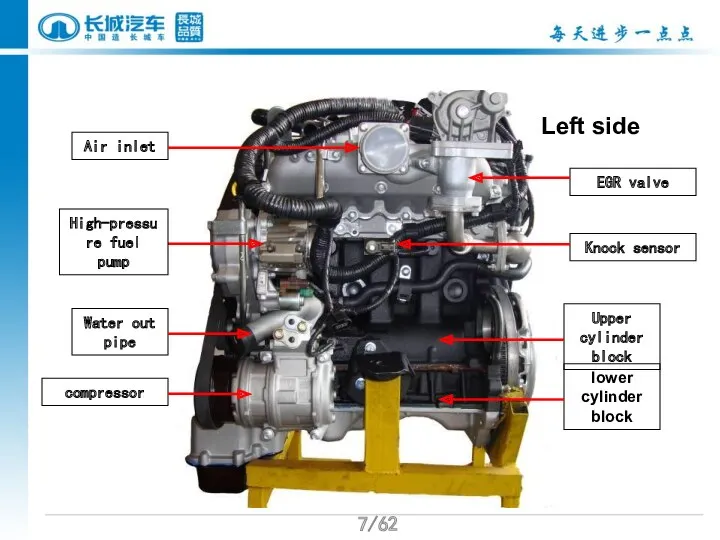

- 7. /62 EGR valve Water out pipe High-pressure fuel pump Knock sensor Upper cylinder block lower cylinder

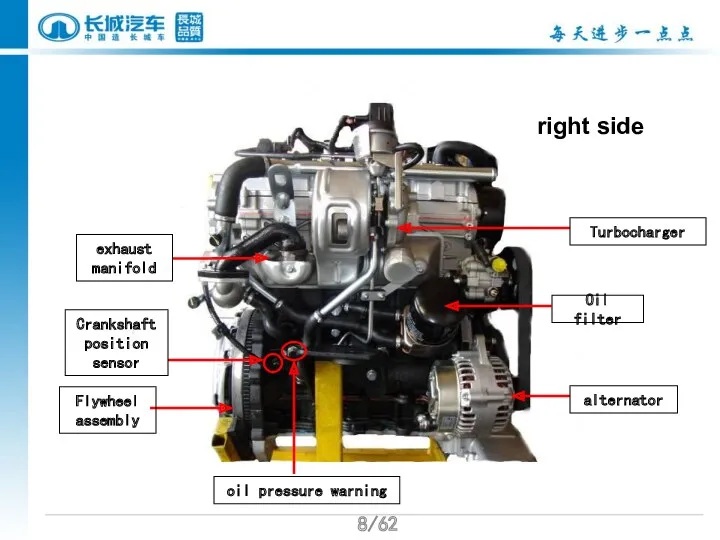

- 8. /62 exhaust manifold Oil filter oil pressure warning Turbocharger alternator Flywheel assembly Crankshaft position sensor right

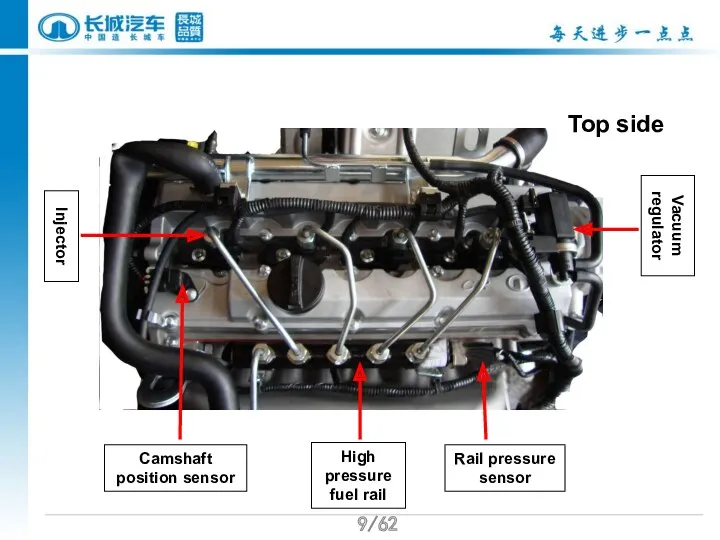

- 9. /62 Injector Vacuum regulator Rail pressure sensor High pressure fuel rail Camshaft position sensor Top side

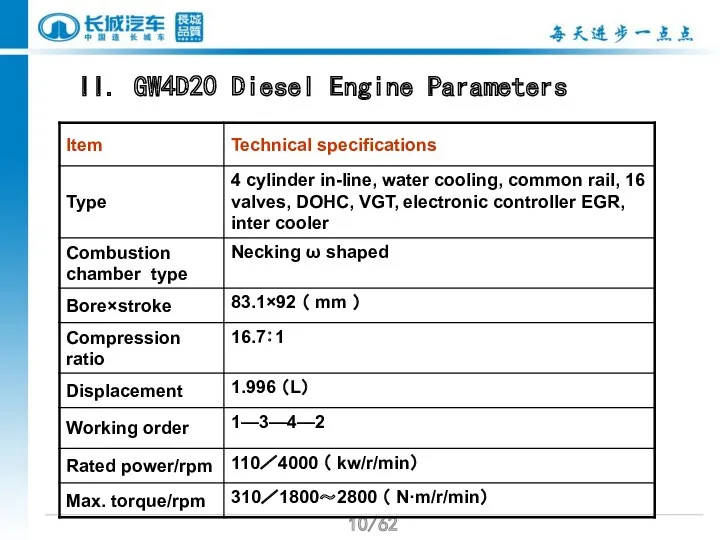

- 10. /62 II. GW4D20 Diesel Engine Parameters

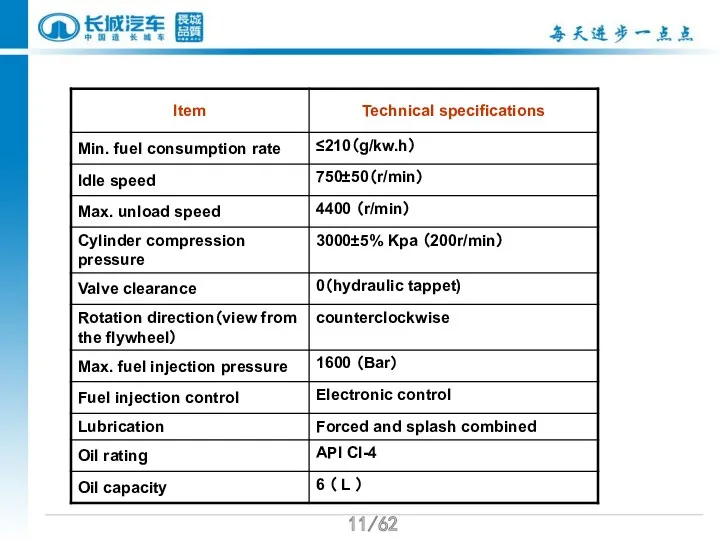

- 11. /62

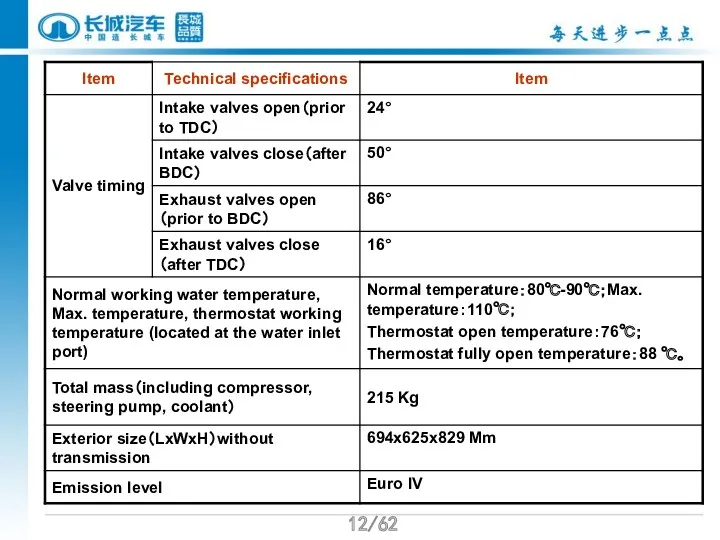

- 12. /62

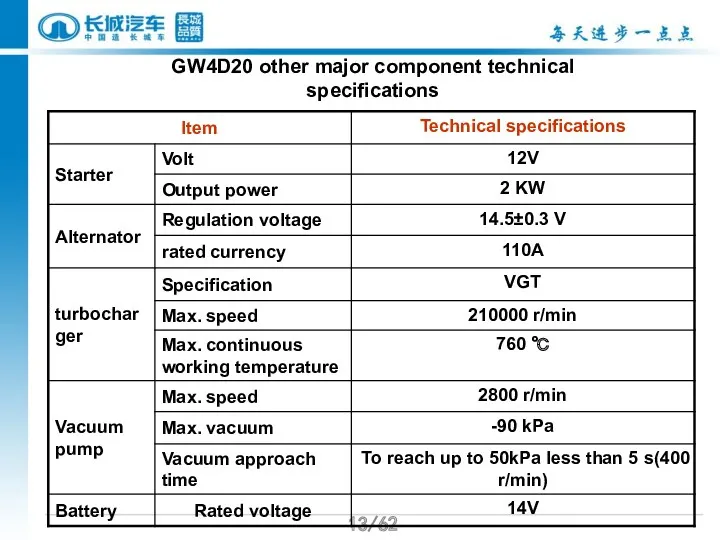

- 13. /62 GW4D20 other major component technical specifications

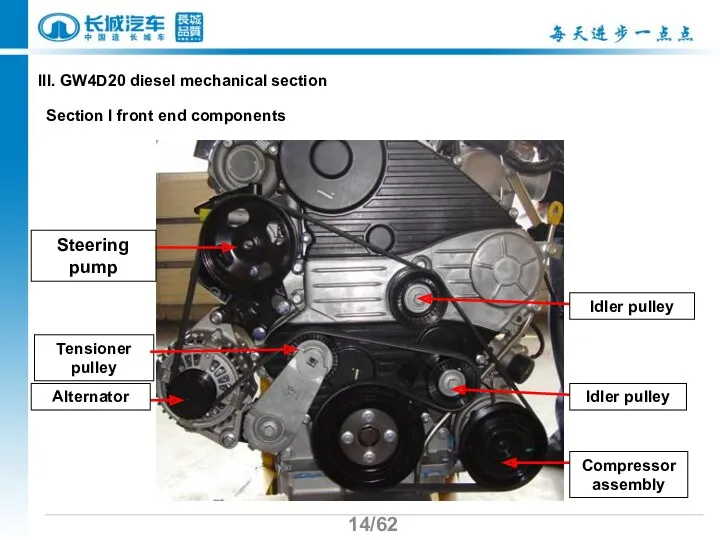

- 14. /62 Tensioner pulley Alternator Steering pump Idler pulley Idler pulley Compressor assembly Section I front end

- 15. /62 II. Notes in removing the alternator belt Remove the belt:turn the tensioner clockwise with torque

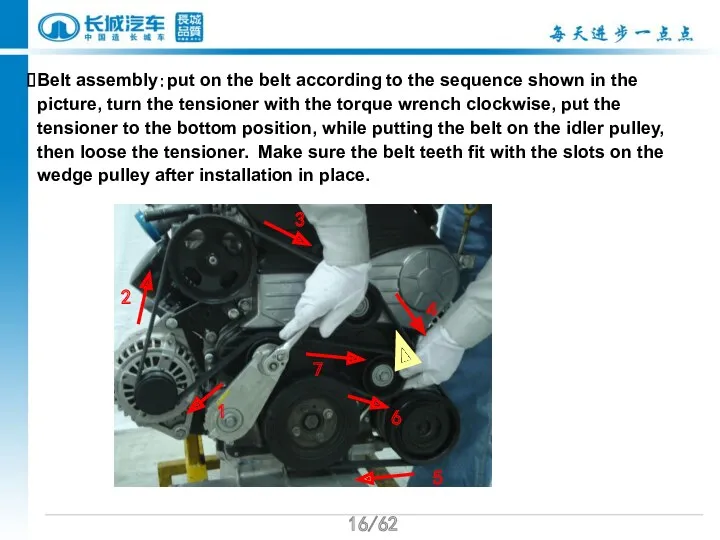

- 16. /62 Belt assembly:put on the belt according to the sequence shown in the picture, turn the

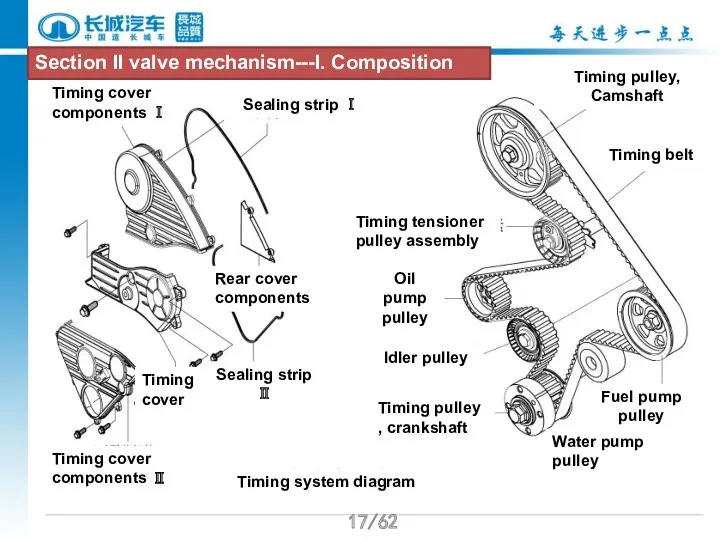

- 17. /62 正时系统示意图 Timing cover components Ⅰ Sealing strip Ⅰ Rear cover components Timing cover components Ⅱ

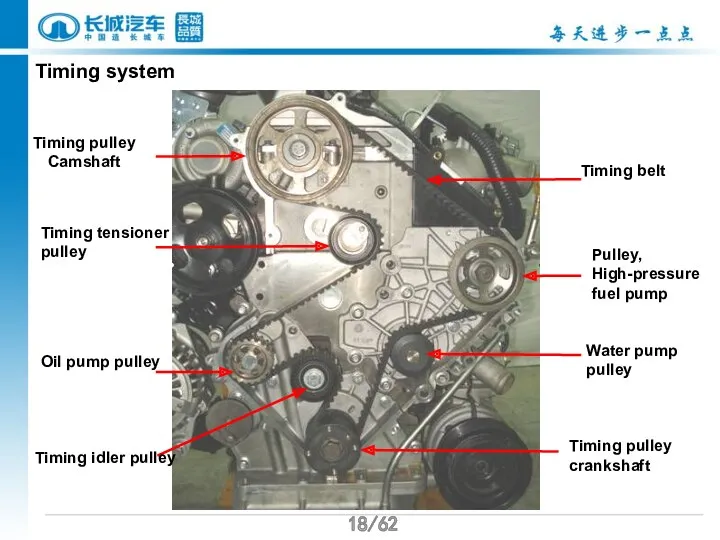

- 18. /62 /62 Timing system Timing pulley Camshaft Timing tensioner pulley Oil pump pulley Timing idler pulley

- 19. /62 /62 The features of timing system: There are totally 7 pulleys in the timing system,

- 20. /62 /62 Timing tensioner pulley Timing idler pulley Timing belt Timing belt have to be changed

- 21. /62 /62 II. timing pulley change Important notes in changing timing pulley: environment must be clean

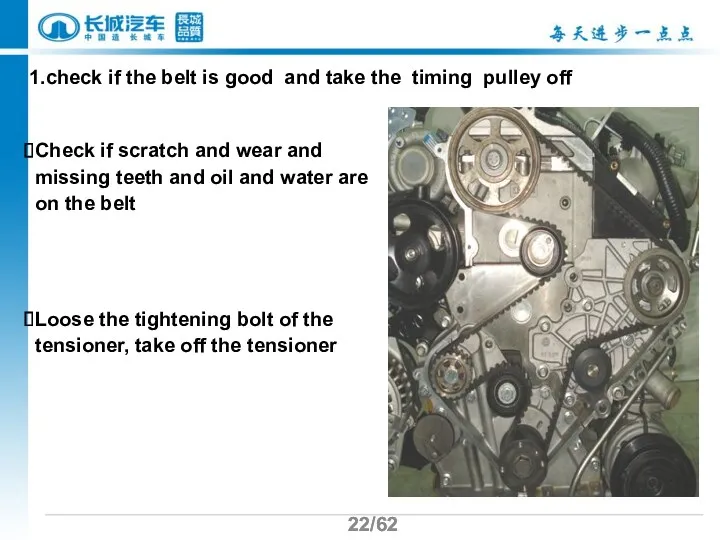

- 22. /62 /62 1.check if the belt is good and take the timing pulley off Check if

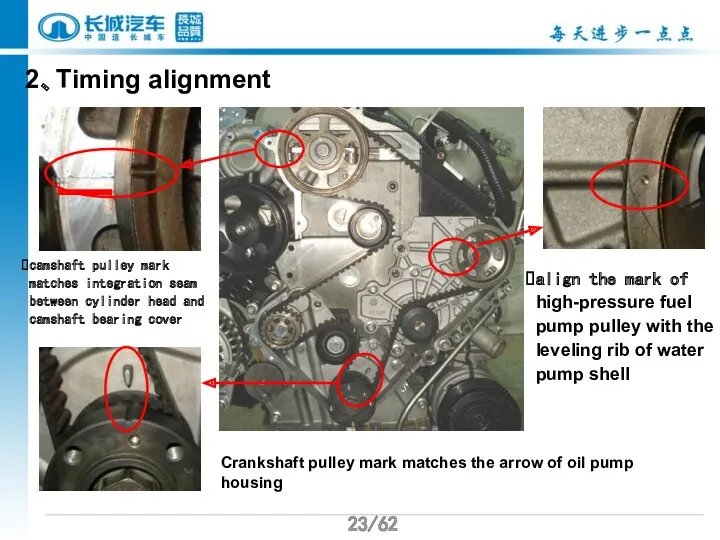

- 23. /62 /62 2、Timing alignment camshaft pulley mark matches integration seam between cylinder head and camshaft bearing

- 24. /62 Press the glue line on this position Glue is prohibited from implementing on the camshaft

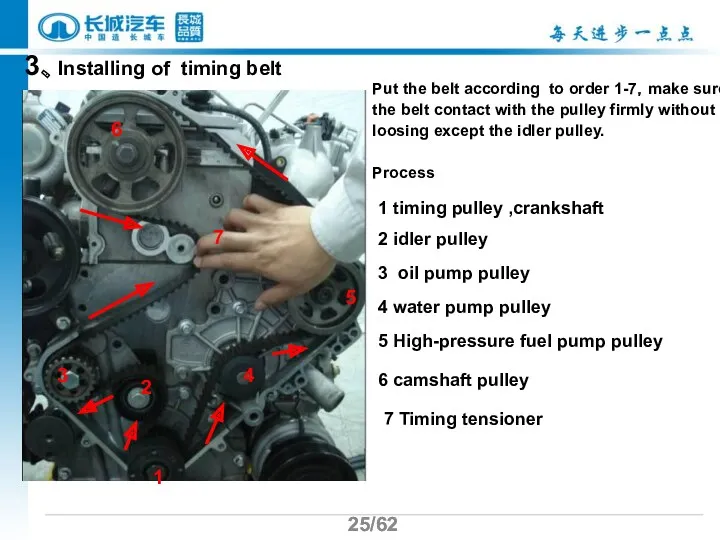

- 25. /62 /62 3、Installing of timing belt Put the belt according to order 1-7,make sure the belt

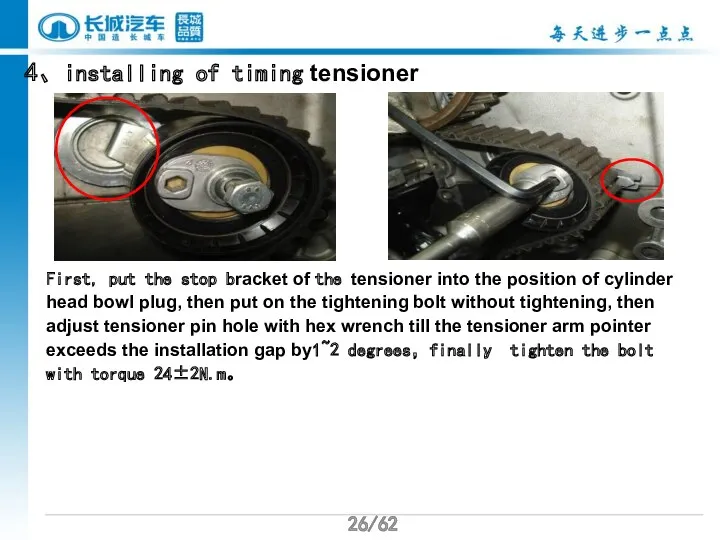

- 26. /62 /62 4、installing of timing tensioner First, put the stop bracket of the tensioner into the

- 27. /62 /62 5 timing check To rotate crankshaft clockwise twice and ensure if timing crankshaft pulley

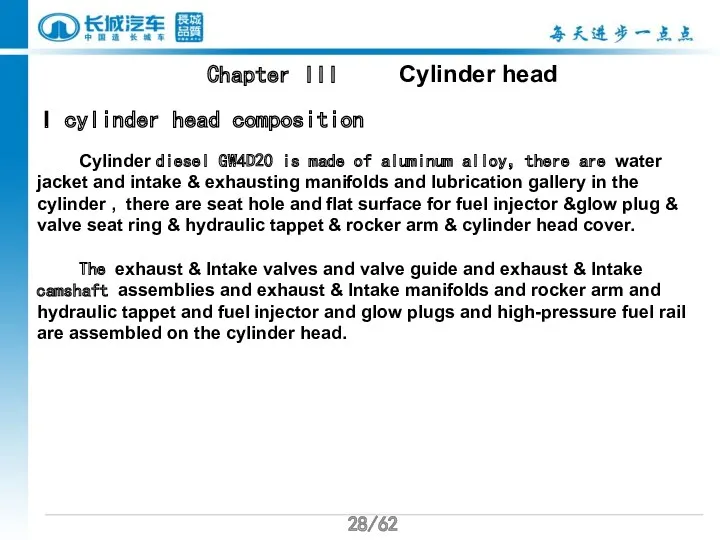

- 28. /62 /62 Chapter III Cylinder head I cylinder head composition Cylinder diesel GW4D20 is made of

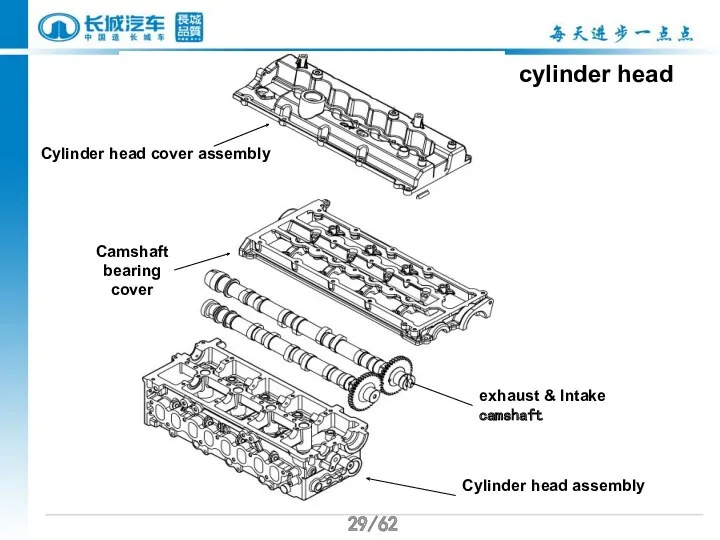

- 29. /62 /62 cylinder head Cylinder head cover assembly Camshaft bearing cover exhaust & Intake camshaft Cylinder

- 30. /62 /62 Oil passage Oil inlet

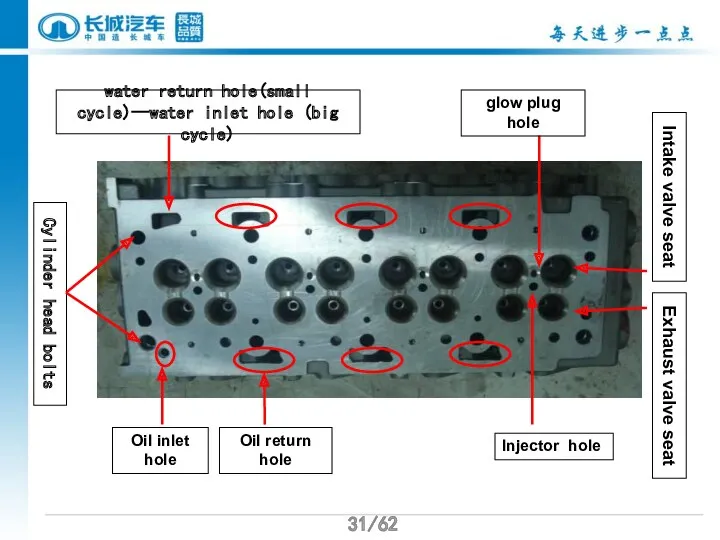

- 31. /62 /62 Intake valve seat water return hole(small cycle)--water inlet hole (big cycle) Exhaust valve seat

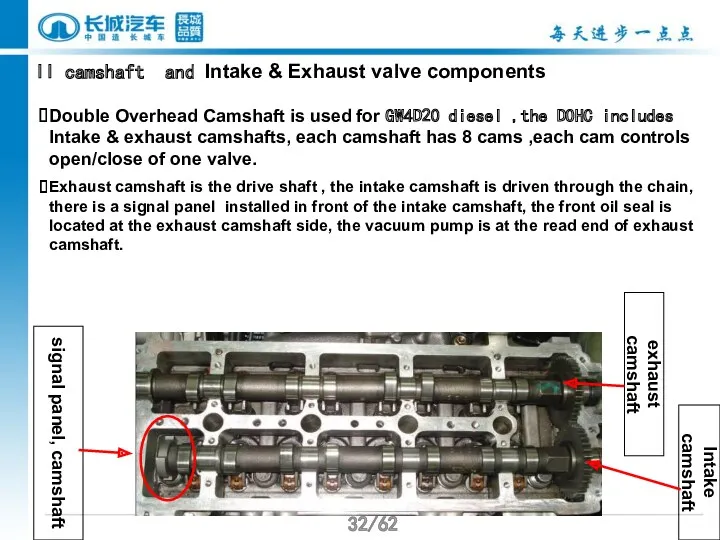

- 32. /62 /62 II camshaft and Intake & Exhaust valve components Double Overhead Camshaft is used for

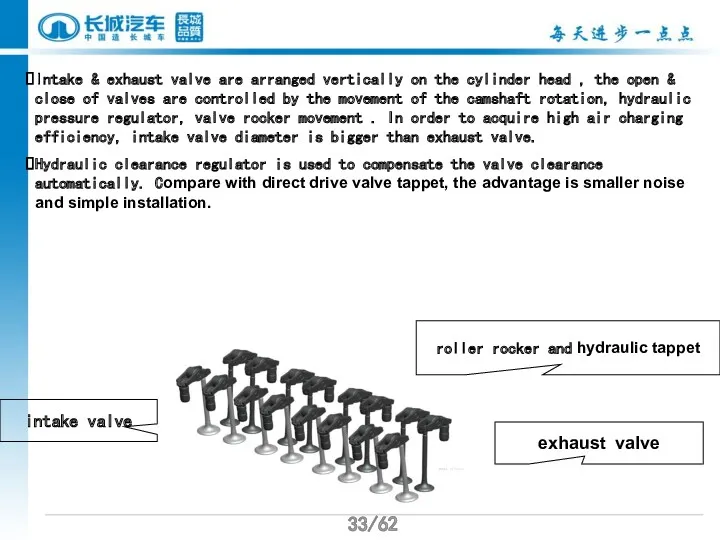

- 33. /62 /62 Intake & exhaust valve are arranged vertically on the cylinder head , the open

- 34. /62 /62 roller rocker hydraulic tappet Lock clamp

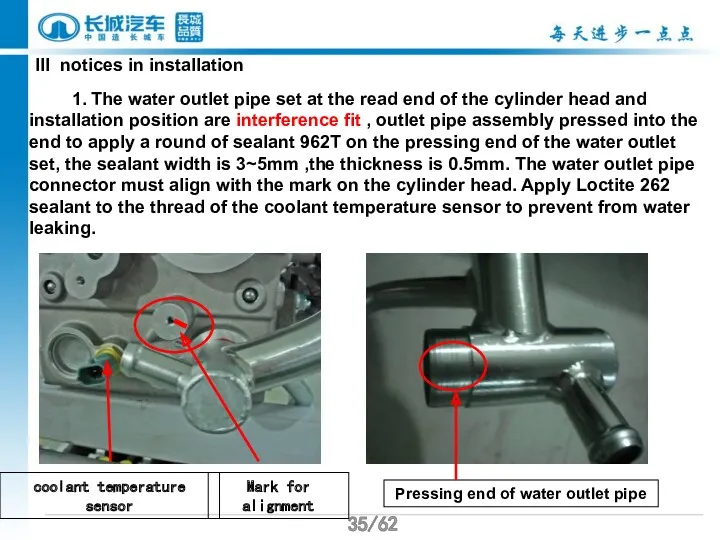

- 35. /62 /62 III notices in installation 1. The water outlet pipe set at the read end

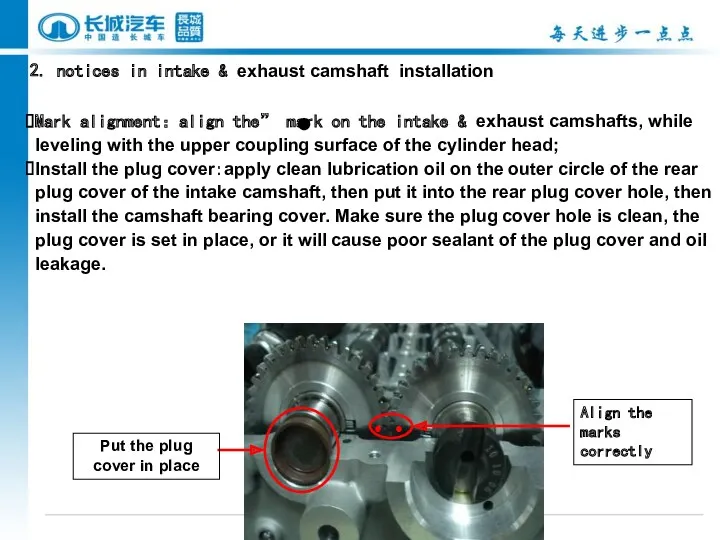

- 36. /62 /62 2. notices in intake & exhaust camshaft installation Mark alignment:align the” mark on the

- 37. /62 /62 Notices in installing the front oil seal of the camshaft : as there is

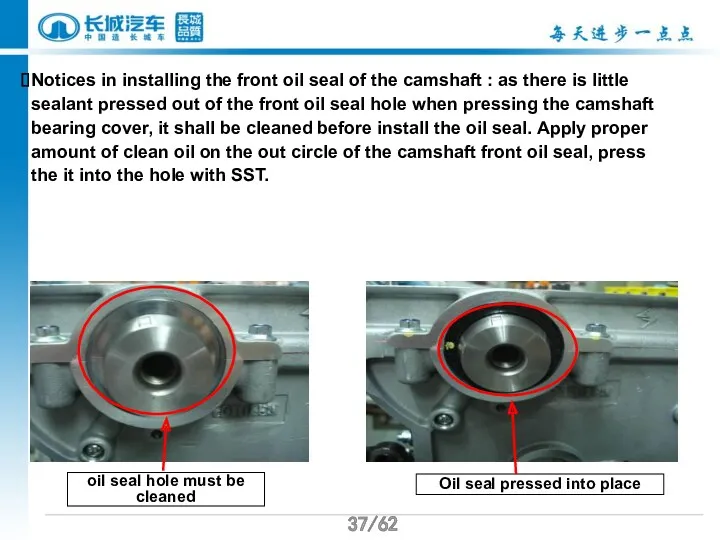

- 38. /62 /62 3.notices in applying the glue on the camshaft bearing cover Clean the camshaft bearing

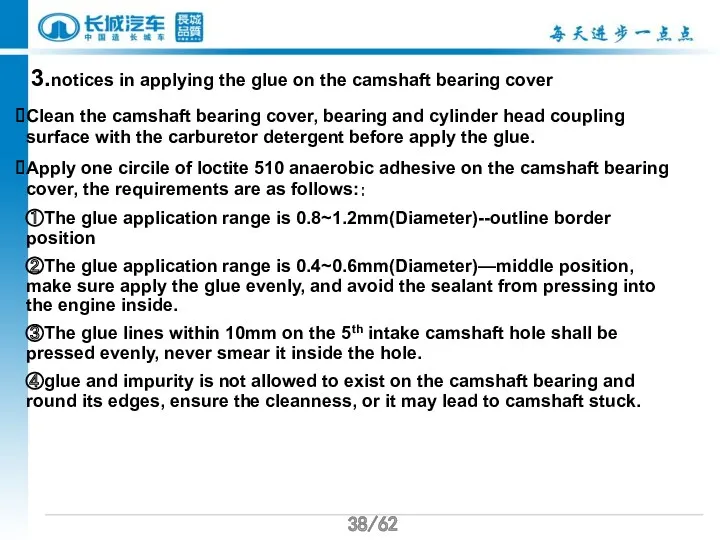

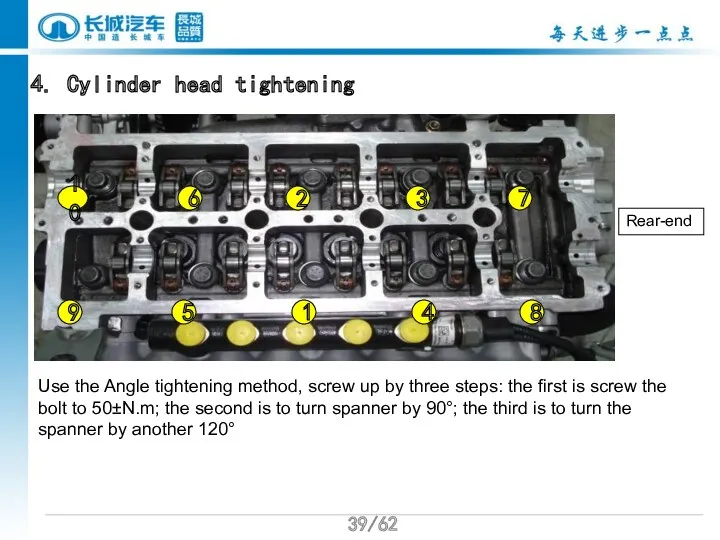

- 39. /62 4. Cylinder head tightening 1 2 4 3 5 6 8 9 Use the Angle

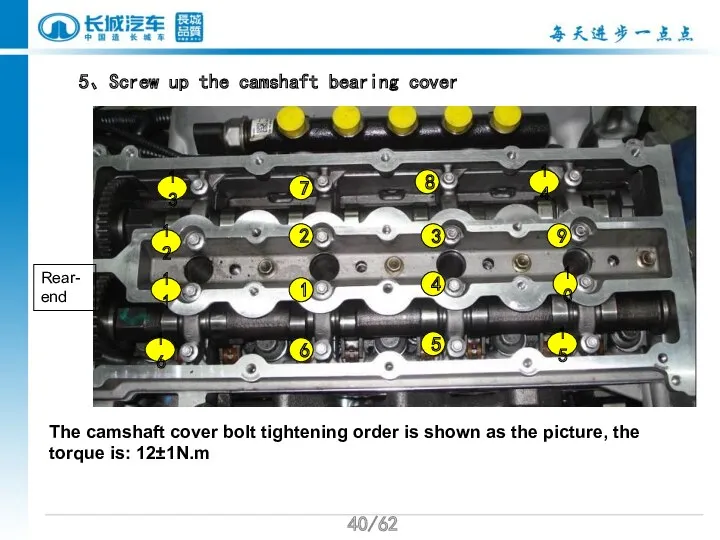

- 40. /62 5、Screw up the camshaft bearing cover 1 2 6 3 4 5 7 9 The

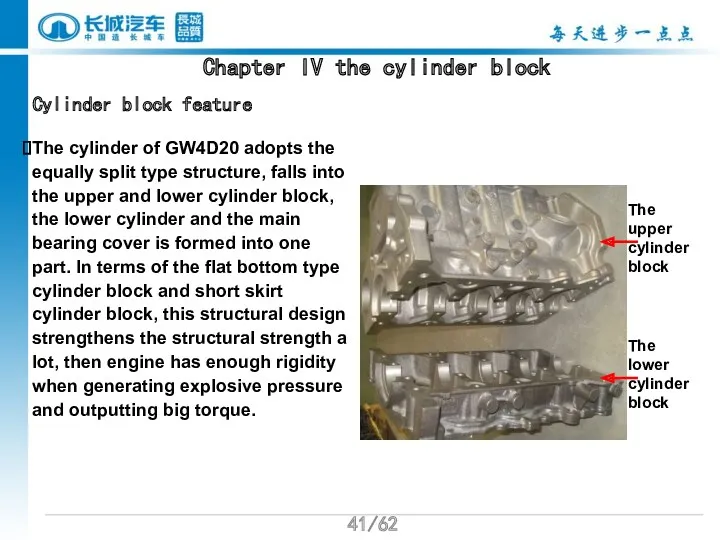

- 41. /62 Chapter IV the cylinder block Cylinder block feature The cylinder of GW4D20 adopts the equally

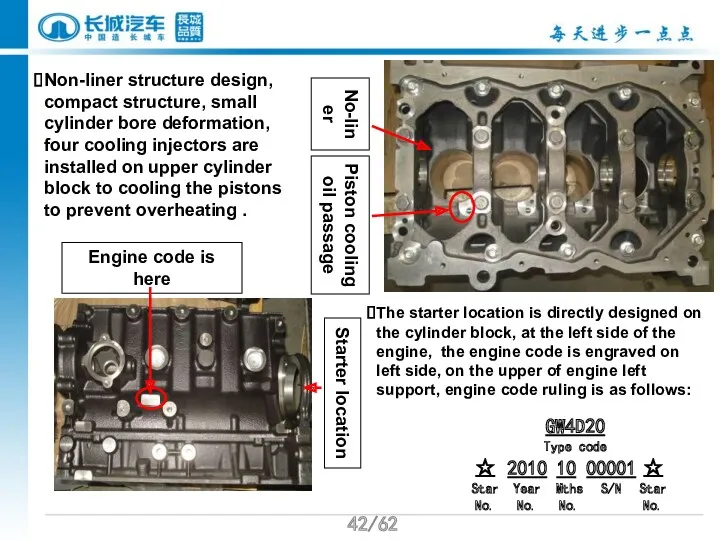

- 42. /62 Starter location No-liner Piston cooling oil passage Non-liner structure design, compact structure, small cylinder bore

- 43. /62 Oil cooler seat Rotor oil pump, oil pump and the cylinder integrated into one part,

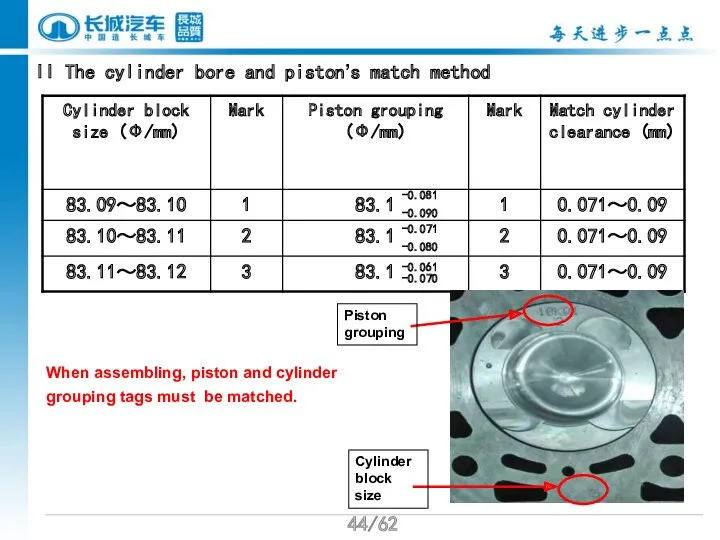

- 44. /62 II The cylinder bore and piston’s match method When assembling, piston and cylinder grouping tags

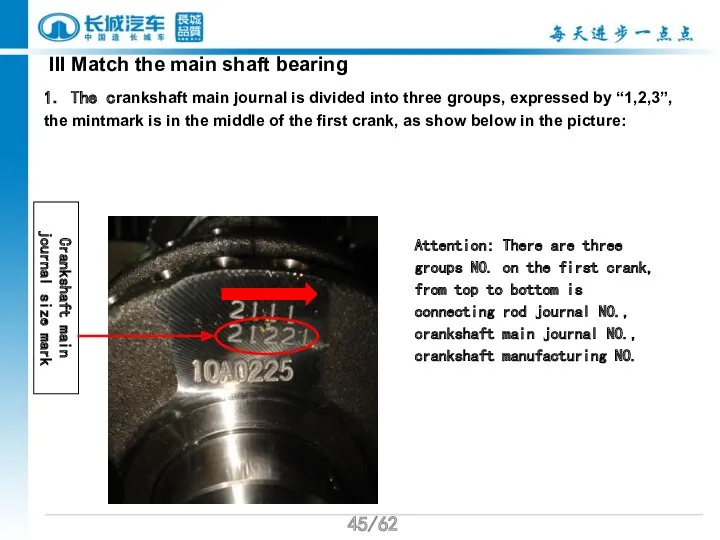

- 45. /62 III Match the main shaft bearing 1. The crankshaft main journal is divided into three

- 46. /62 2.The cylinders bore diameter is divided into three groups, expressed by “1,2,3” Marks on the

- 47. /62 3. The crankshaft main bearing bearings are divided into three groups, expressed by “yellow colorless

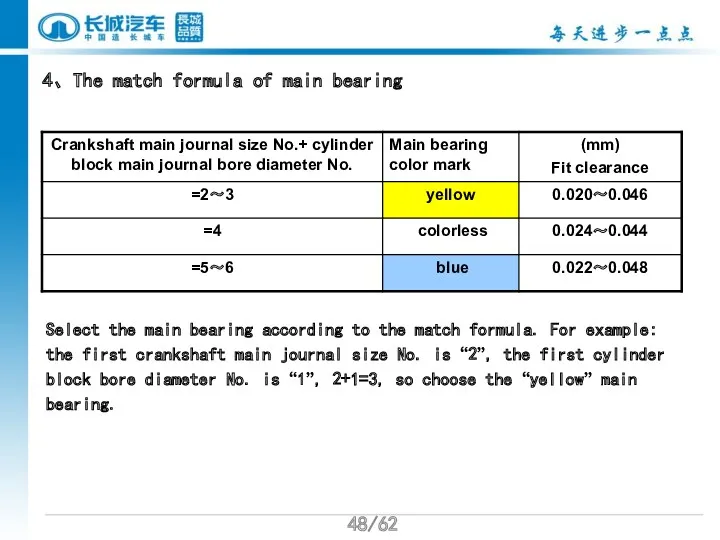

- 48. /62 4、The match formula of main bearing Select the main bearing according to the match formula.

- 49. /62 IV Match the connecting rod bearing 1.The crankshaft rod journal is divided into three groups,

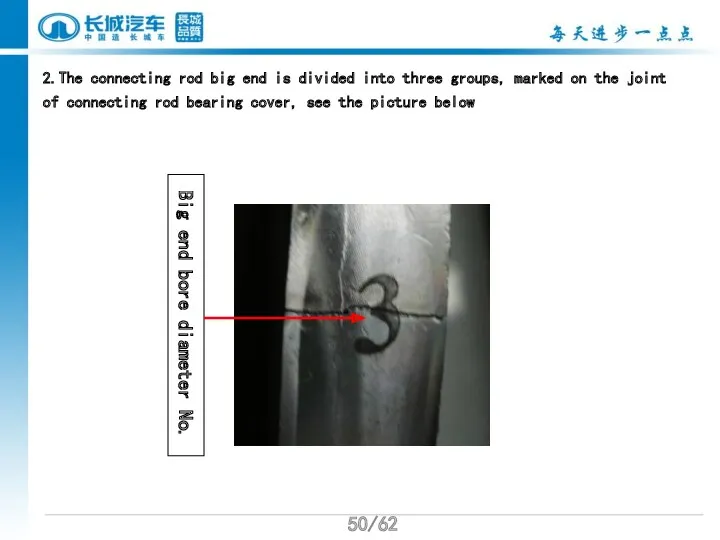

- 50. /62 2.The connecting rod big end is divided into three groups, marked on the joint of

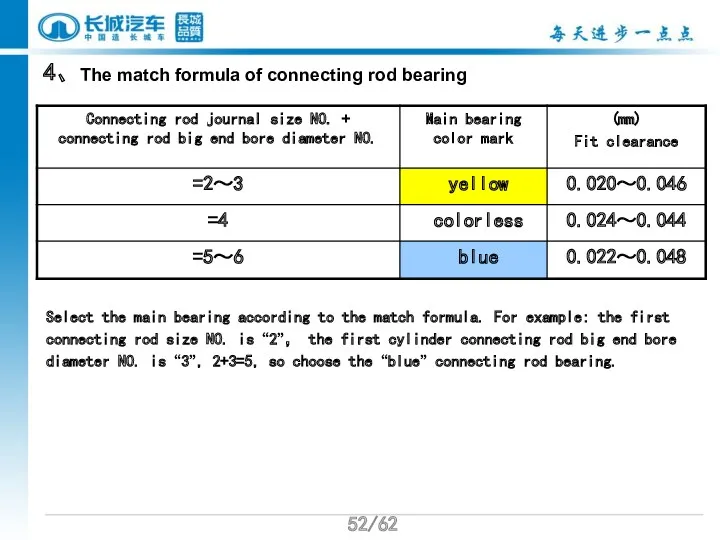

- 51. /62 3. The connecting rod bearings are divided into three groups, expressed by “yellow, colorless and

- 52. /62 4、The match formula of connecting rod bearing Select the main bearing according to the match

- 53. /62 V. Notices in installation 1、The notices in installing the piston and connecting rod. According to

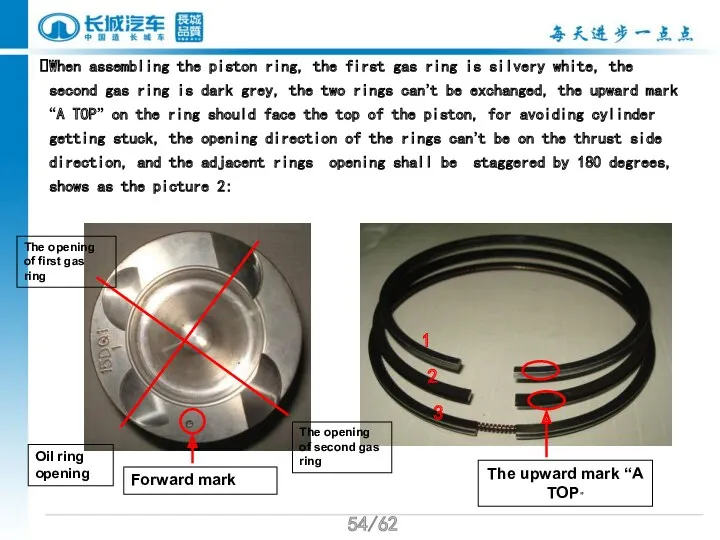

- 54. /62 When assembling the piston ring, the first gas ring is silvery white, the second gas

- 55. /62 2. The notices in assembling the lower cylinder block apply the glue: before install the

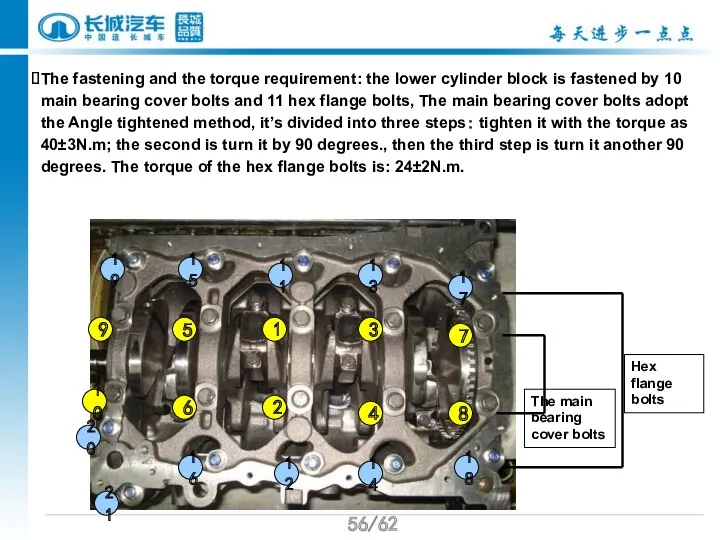

- 56. /62 The fastening and the torque requirement: the lower cylinder block is fastened by 10 main

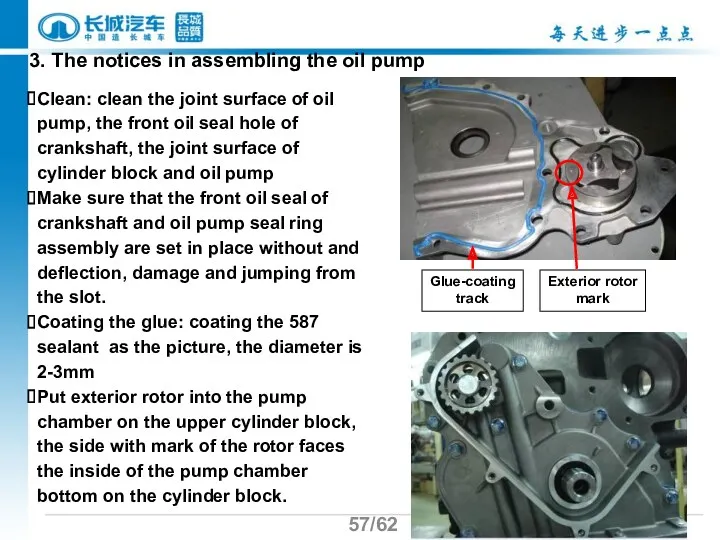

- 57. /62 3. The notices in assembling the oil pump Clean: clean the joint surface of oil

- 59. Скачать презентацию

Энергия связи. Дефект масс. Решение задач

Энергия связи. Дефект масс. Решение задач Динамика. Основные понятия

Динамика. Основные понятия Сила тока. Измерение силы тока.

Сила тока. Измерение силы тока. Цветные вопросы по физике

Цветные вопросы по физике Chapter 20 Thermodynamics

Chapter 20 Thermodynamics Многоточечный электронный впрыск

Многоточечный электронный впрыск Динаміка матеріальної точки

Динаміка матеріальної точки Тепловые двигатели и нагнетатели. Компрессоры

Тепловые двигатели и нагнетатели. Компрессоры Презентация к уроку

Презентация к уроку Электрический ток в полупроводниках

Электрический ток в полупроводниках Волновое уравнение для электромагнитных волн. Электричество и магнетизм

Волновое уравнение для электромагнитных волн. Электричество и магнетизм Устойчивость к скачкам потока. Лекция 8

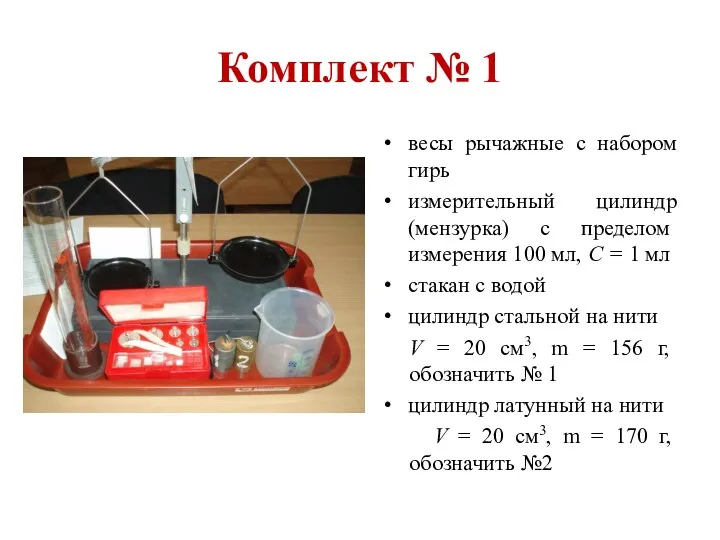

Устойчивость к скачкам потока. Лекция 8 Комплекты для экспериментальных заданий ОГЭ по физике

Комплекты для экспериментальных заданий ОГЭ по физике Методы атомной спектроскопии

Методы атомной спектроскопии Разработка диаграмм управления пневматическими приводами

Разработка диаграмм управления пневматическими приводами Берегите тепло в доме

Берегите тепло в доме Элементы механики жидкостей и газов

Элементы механики жидкостей и газов Температура

Температура Artificial communication satellites

Artificial communication satellites Aльтернативна энергетика. Геотермальні електростанції

Aльтернативна энергетика. Геотермальні електростанції Электромагнитные волны

Электромагнитные волны Кинетическая энергия

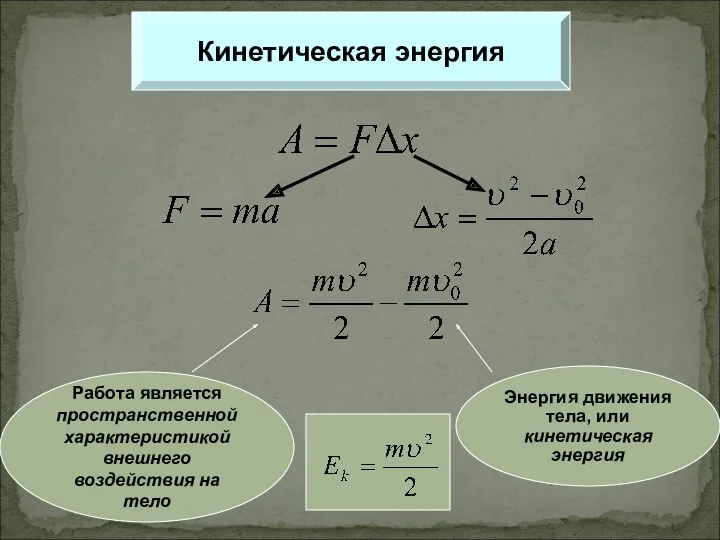

Кинетическая энергия Электромагнитные зондирования (ВЭЗ, ДЭЗ, ВЭЗ-ВП, ЧЗ, ЗС, МТЗ)

Электромагнитные зондирования (ВЭЗ, ДЭЗ, ВЭЗ-ВП, ЧЗ, ЗС, МТЗ) Электростатика. Закон Кулона

Электростатика. Закон Кулона Система впрыска VAG

Система впрыска VAG Свободное падение

Свободное падение ТО и ремонт системы питания двигателя автомобиля УРАЛ-NEXT

ТО и ремонт системы питания двигателя автомобиля УРАЛ-NEXT Электрическое поле в вакууме. (Тема 13)

Электрическое поле в вакууме. (Тема 13)