Содержание

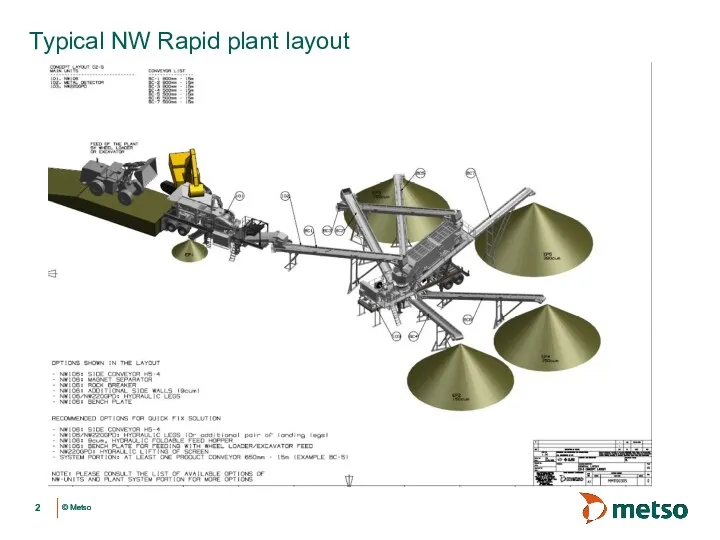

- 2. Typical NW Rapid plant layout

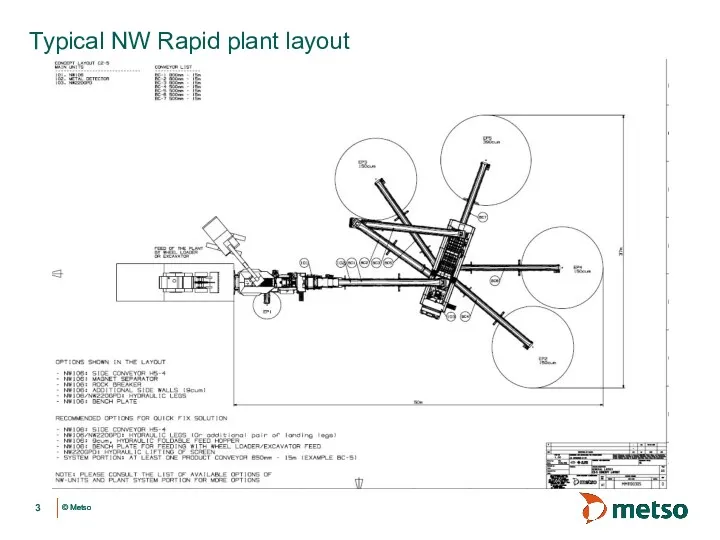

- 3. Typical NW Rapid plant layout

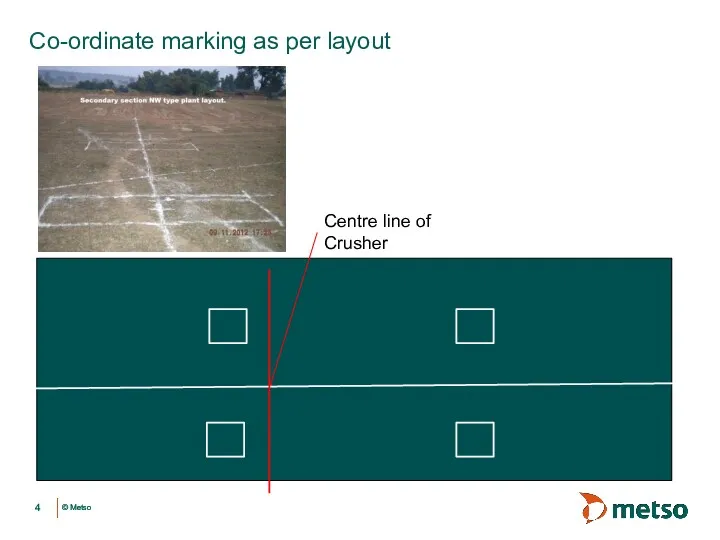

- 4. Co-ordinate marking as per layout Centre line of Crusher

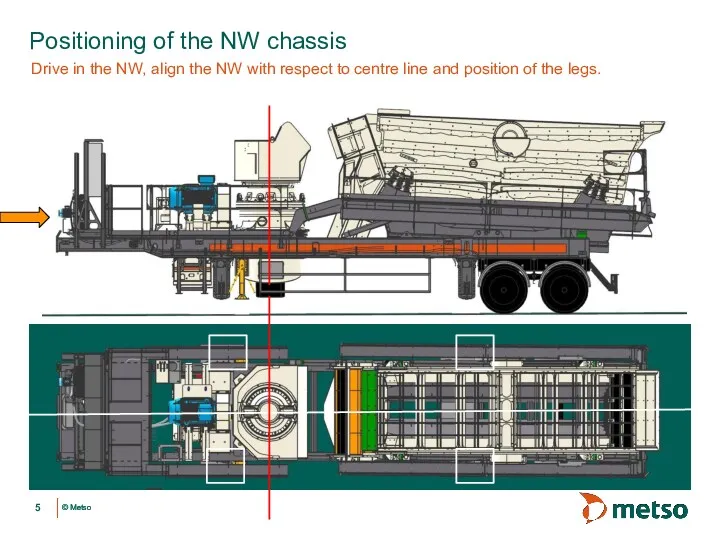

- 5. Positioning of the NW chassis Drive in the NW, align the NW with respect to centre

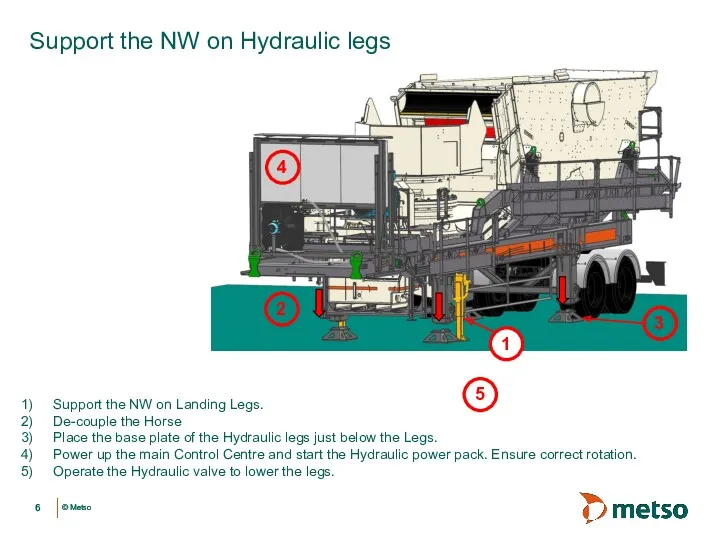

- 6. Support the NW on Hydraulic legs Support the NW on Landing Legs. De-couple the Horse Place

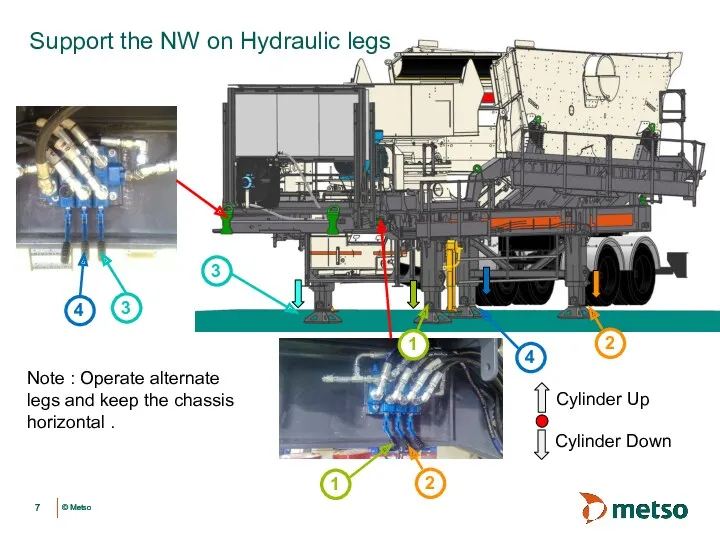

- 7. Support the NW on Hydraulic legs 3 3 Note : Operate alternate legs and keep the

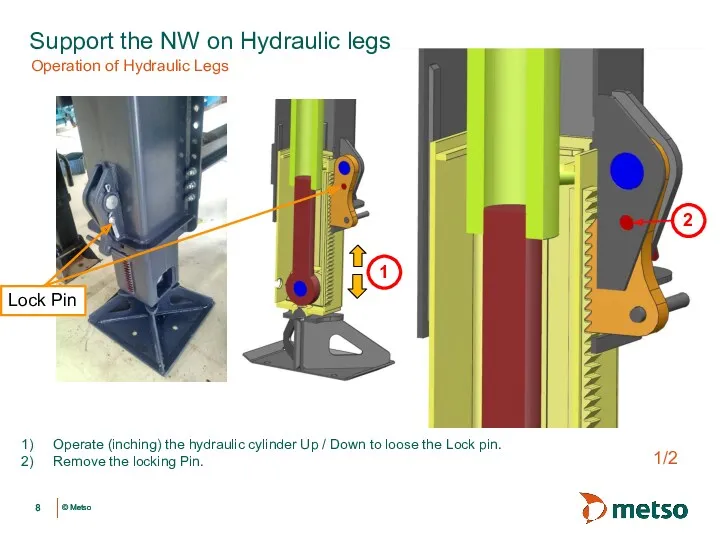

- 8. Support the NW on Hydraulic legs Operation of Hydraulic Legs Lock Pin Operate (inching) the hydraulic

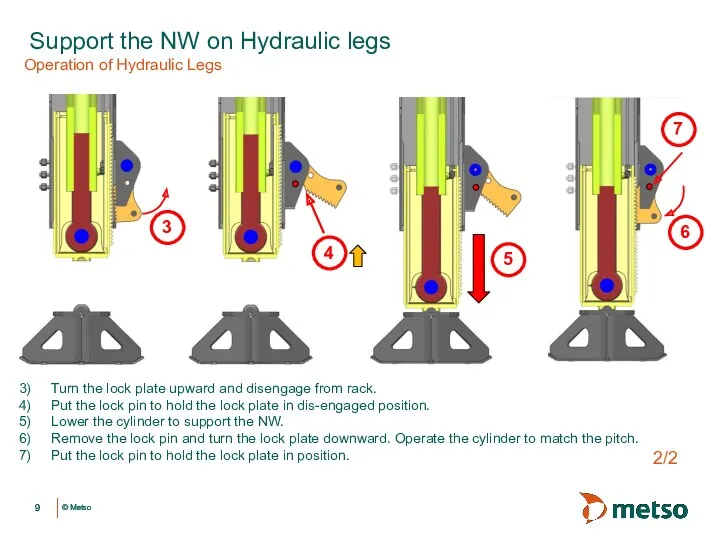

- 9. Support the NW on Hydraulic legs Turn the lock plate upward and disengage from rack. Put

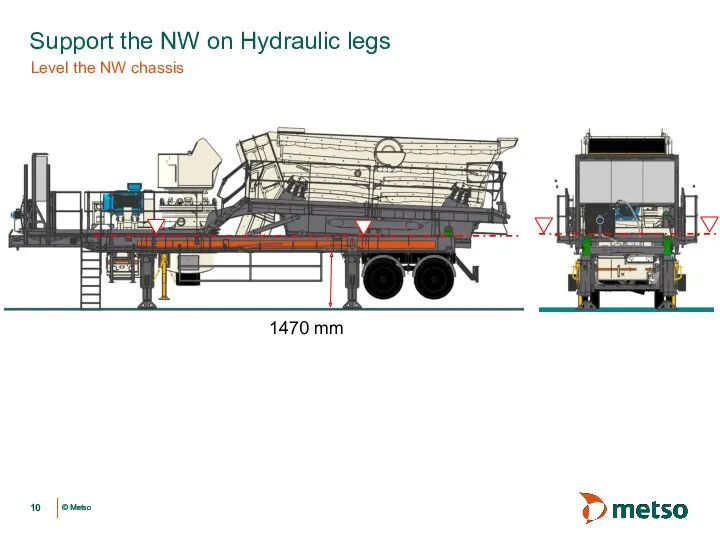

- 10. Support the NW on Hydraulic legs Level the NW chassis 1470 mm

- 11. Unfold the hand rails

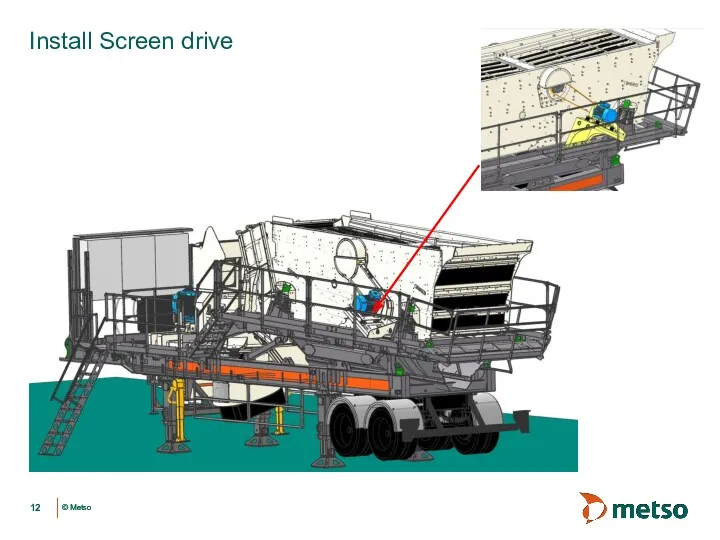

- 12. Install Screen drive

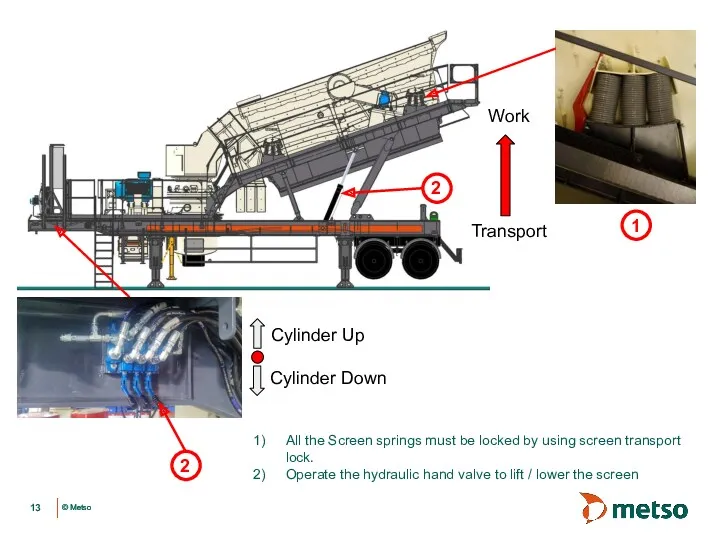

- 13. Lift the screen Transport Work All the Screen springs must be locked by using screen transport

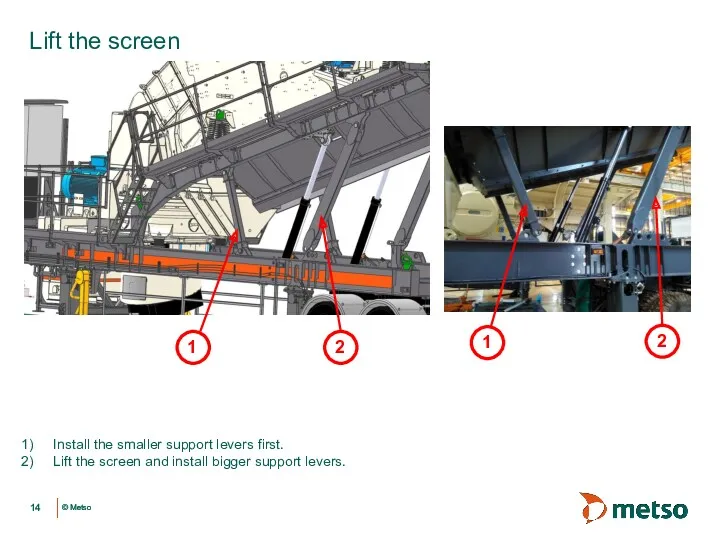

- 14. Lift the screen Install the smaller support levers first. Lift the screen and install bigger support

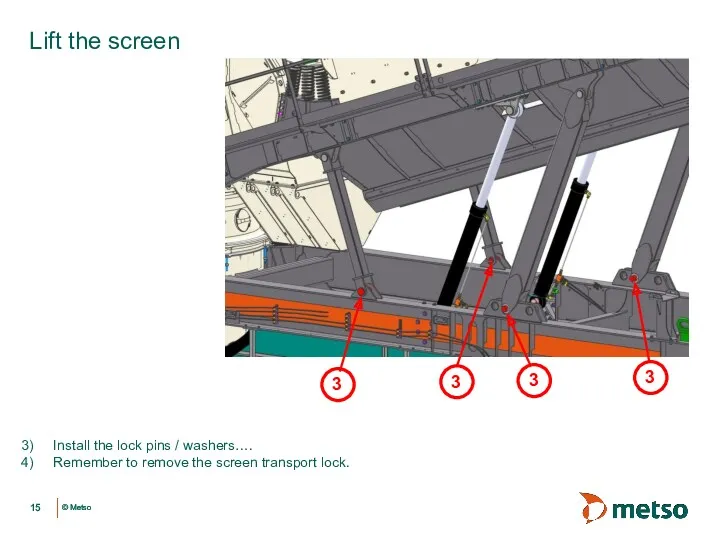

- 15. Lift the screen Install the lock pins / washers…. Remember to remove the screen transport lock.

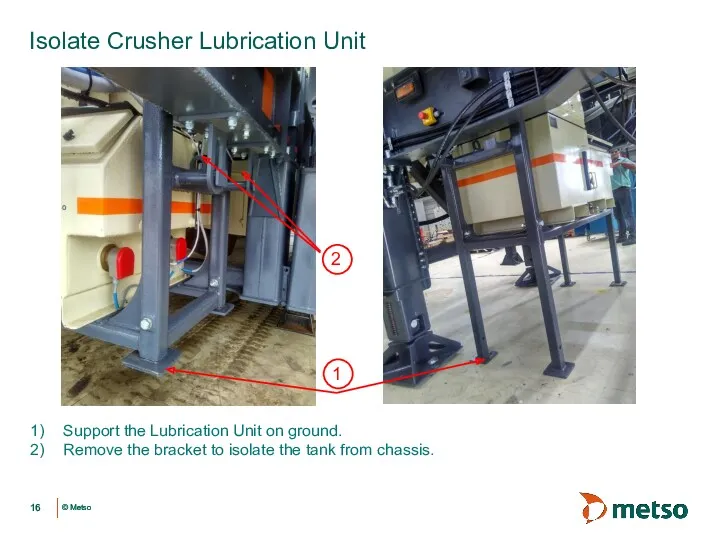

- 16. Isolate Crusher Lubrication Unit Support the Lubrication Unit on ground. Remove the bracket to isolate the

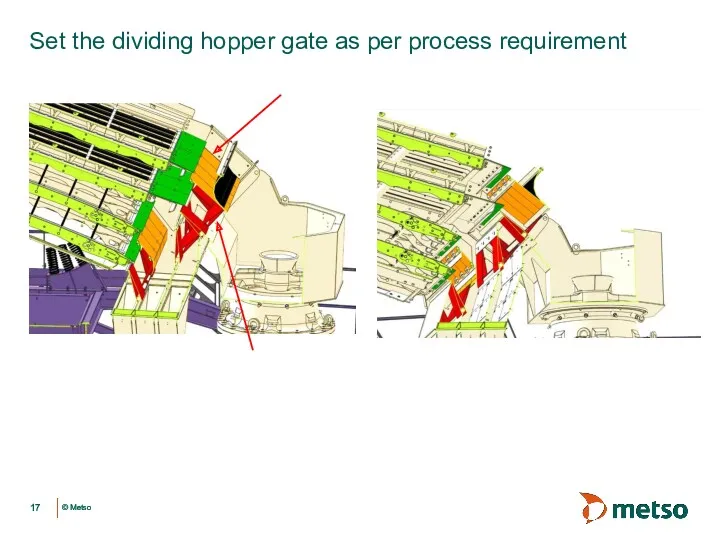

- 17. Set the dividing hopper gate as per process requirement

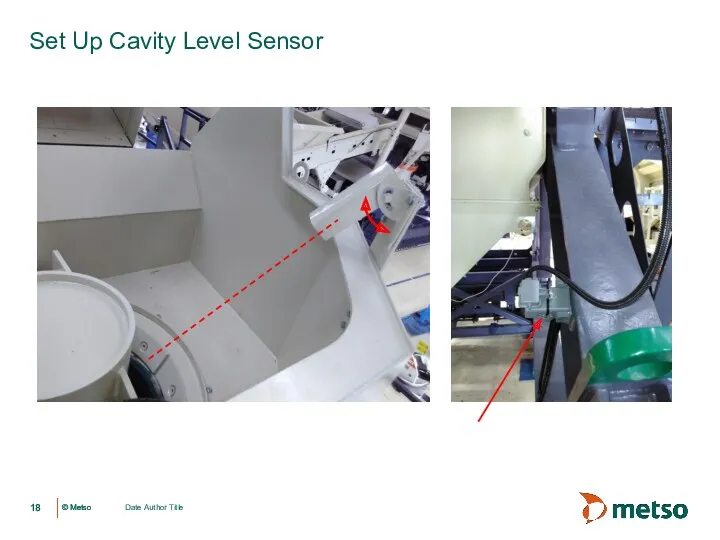

- 18. Date Author Title Set Up Cavity Level Sensor

- 19. Date Author Title Isolate the Control Centre from NW chassis. Remove the mounting bolts and support

- 20. Electrical Installation

- 21. Date Author Title Electrical Installation Connect Screen motor power cable.

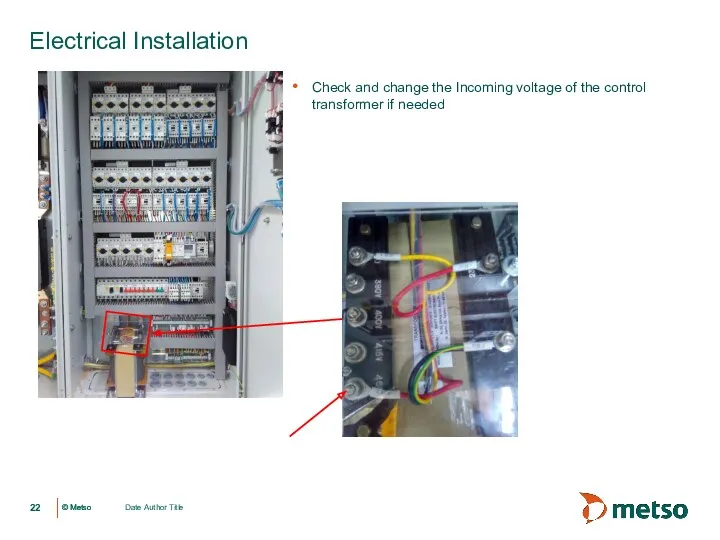

- 22. Date Author Title Electrical Installation Check and change the Incoming voltage of the control transformer if

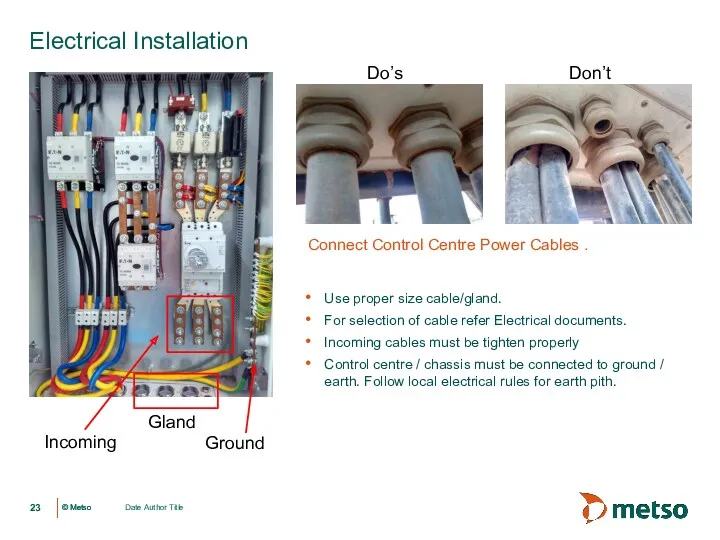

- 23. Date Author Title Connect Control Centre Power Cables . Do’s Don’t Use proper size cable/gland. For

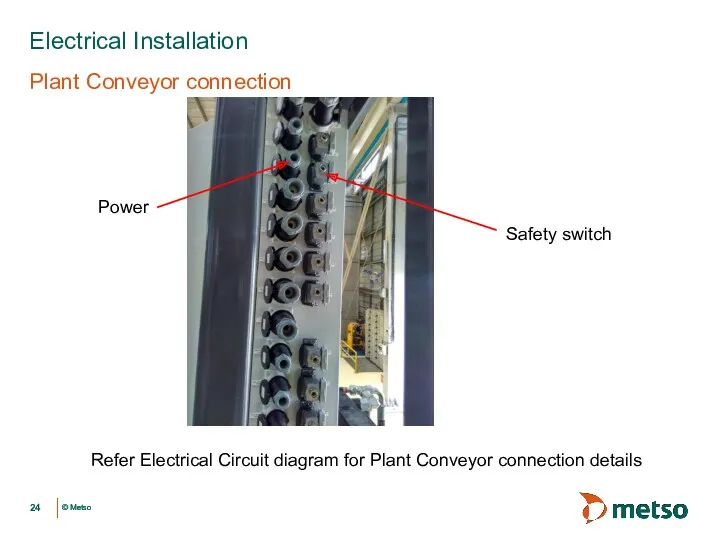

- 24. Plant Conveyor connection Electrical Installation Power Safety switch Refer Electrical Circuit diagram for Plant Conveyor connection

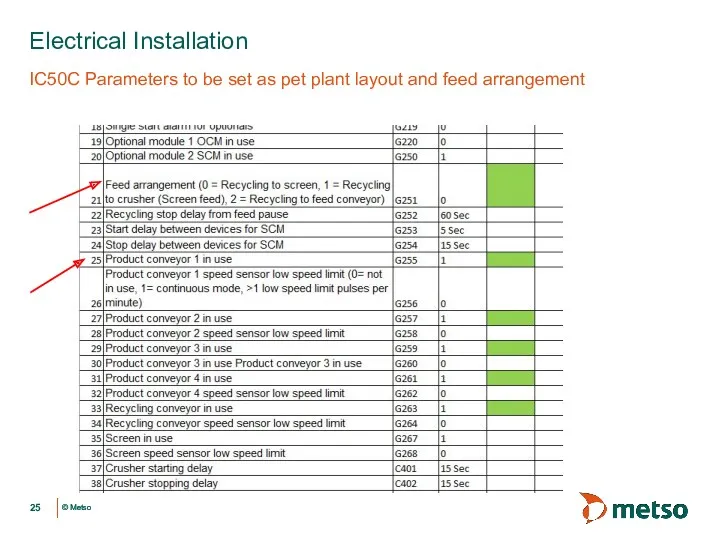

- 25. IC50C Parameters to be set as pet plant layout and feed arrangement Electrical Installation

- 27. Скачать презентацию

Инженерно-авиационное обеспечение безопасности полётов

Инженерно-авиационное обеспечение безопасности полётов Двигатель внутреннего сгорания

Двигатель внутреннего сгорания Хроматографические методы анализа и их применение для контроля качества лекарственных средств (продолжение)

Хроматографические методы анализа и их применение для контроля качества лекарственных средств (продолжение) Тормозная система КамАЗа

Тормозная система КамАЗа Тюнинг двигателя

Тюнинг двигателя Электромагнитная пушка – основа космической транспортной системы. 7 класс

Электромагнитная пушка – основа космической транспортной системы. 7 класс Презентация Проектное обучение

Презентация Проектное обучение ОГЭ - 2016. Физика.

ОГЭ - 2016. Физика. Основы расчета элементов стальных конструкций

Основы расчета элементов стальных конструкций Урок Механическая работа 7 класс

Урок Механическая работа 7 класс Коррозия металлов

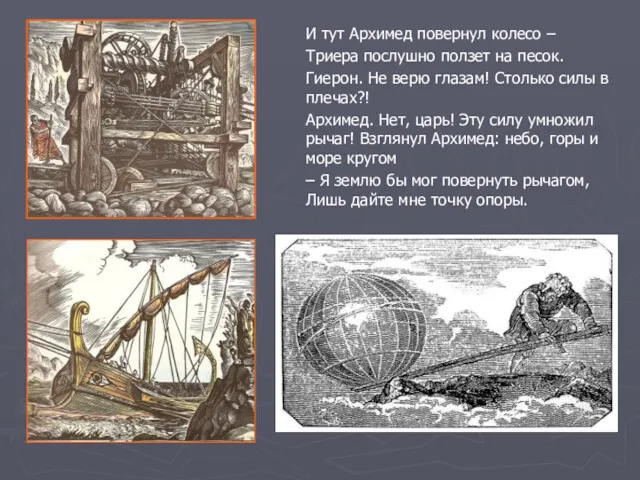

Коррозия металлов Простые механизмы

Простые механизмы Основные неисправности и нормы ТОиР. Лекция 6

Основные неисправности и нормы ТОиР. Лекция 6 Біртекті емес электр өрісі кезіндегі разрядтың пайда болуы

Біртекті емес электр өрісі кезіндегі разрядтың пайда болуы Открытый урок по физике 7 класс. Сила давления

Открытый урок по физике 7 класс. Сила давления Полупроводники. Собственная проводимость полупроводников. Полупроводниковые приборы

Полупроводники. Собственная проводимость полупроводников. Полупроводниковые приборы Конвективный теплообмен. Глава 2

Конвективный теплообмен. Глава 2 Инструментальные методы качественного анализа органических веществ

Инструментальные методы качественного анализа органических веществ Инерция

Инерция Делимость электрического заряда. Электрон. Строение атома

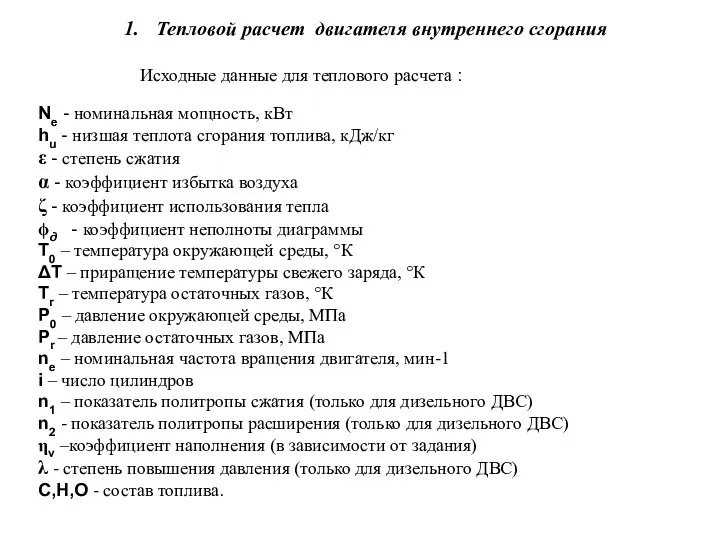

Делимость электрического заряда. Электрон. Строение атома Тепловой расчет двигателя внутреннего сгорания

Тепловой расчет двигателя внутреннего сгорания Магнитное поле в вакууме

Магнитное поле в вакууме Интеллектуальная игра по физике Умники и умницы

Интеллектуальная игра по физике Умники и умницы Индикаторные и эффективные показатели ДВС. Тема 8

Индикаторные и эффективные показатели ДВС. Тема 8 Применение аккумуляторов

Применение аккумуляторов Водяной пар

Водяной пар Технологии выращивания кристаллов. Технология полупроводниковых материалов

Технологии выращивания кристаллов. Технология полупроводниковых материалов Возникновение радио

Возникновение радио