ENG 100 Introduction to Engineering. CAD-LAB-2: Surface Design – Rhino Automation – Solid Modeling (CSG & B-Rep) презентация

Содержание

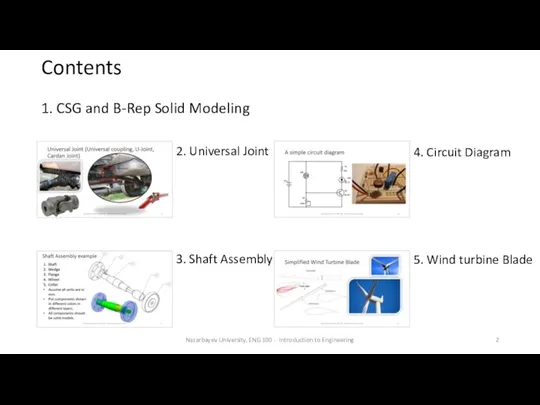

- 2. Contents Nazarbayev University, ENG 100 - Introduction to Engineering 2. Universal Joint 3. Shaft Assembly 4.

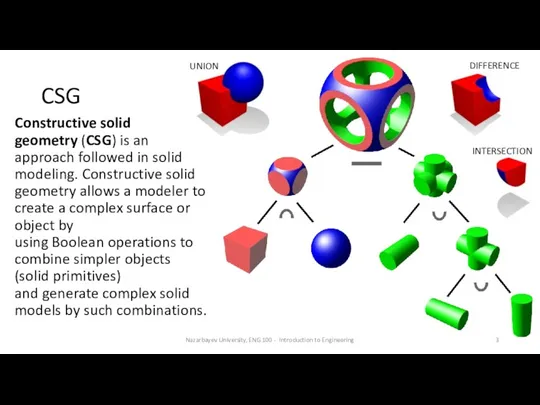

- 3. CSG Constructive solid geometry (CSG) is an approach followed in solid modeling. Constructive solid geometry allows

- 4. B-rep The second and most popular approach in solid modeling and computer-aided design, is the boundary

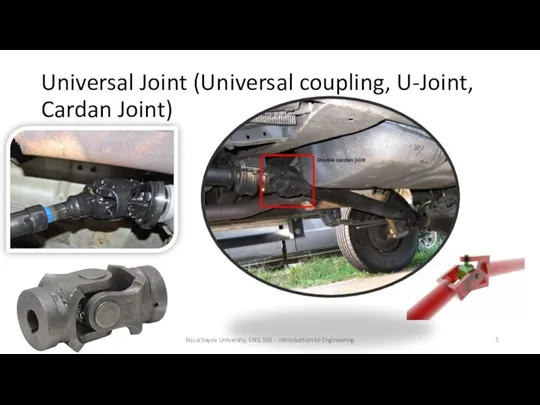

- 5. Universal Joint (Universal coupling, U-Joint, Cardan Joint) Nazarbayev University, ENG 100 - Introduction to Engineering

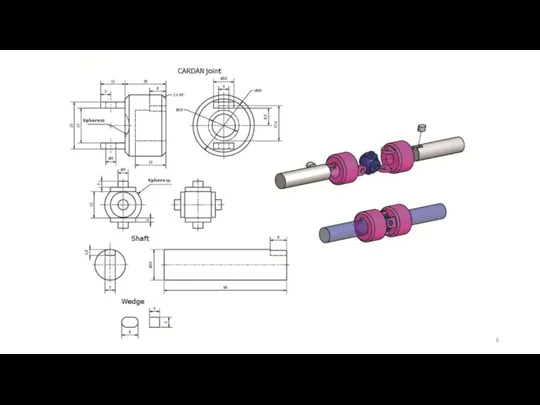

- 6. Nazarbayev University, ENG 100 - Introduction to Engineering

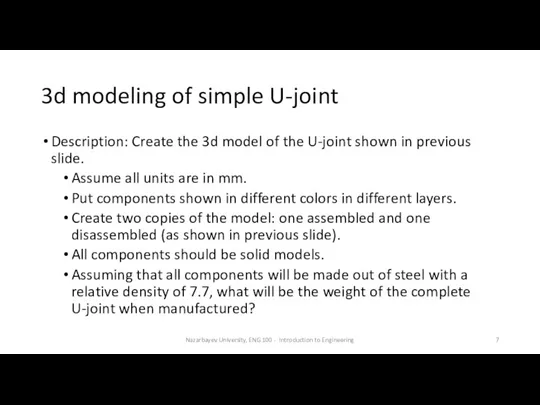

- 7. 3d modeling of simple U-joint Description: Create the 3d model of the U-joint shown in previous

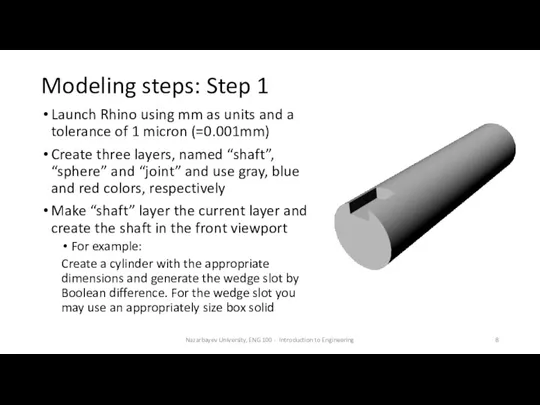

- 8. Modeling steps: Step 1 Launch Rhino using mm as units and a tolerance of 1 micron

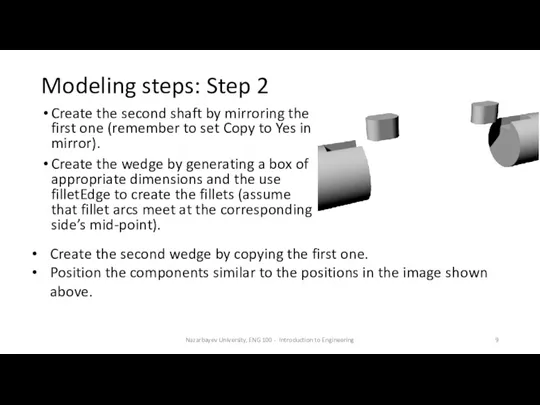

- 9. Modeling steps: Step 2 Create the second shaft by mirroring the first one (remember to set

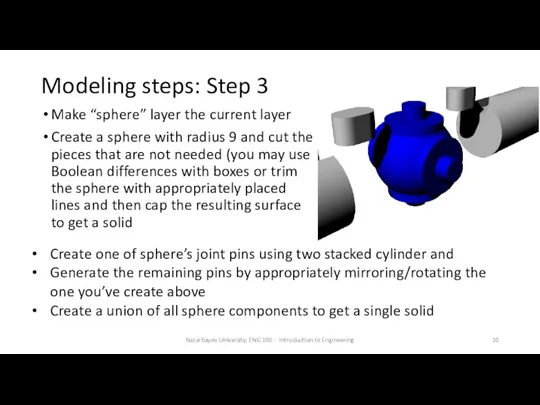

- 10. Modeling steps: Step 3 Make “sphere” layer the current layer Create a sphere with radius 9

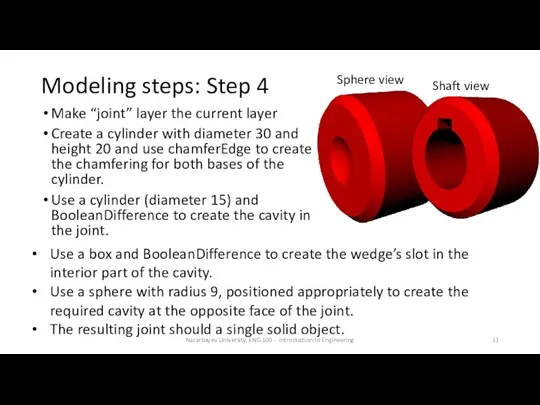

- 11. Modeling steps: Step 4 Make “joint” layer the current layer Create a cylinder with diameter 30

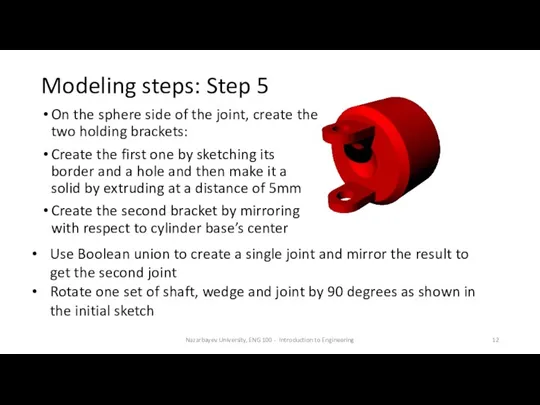

- 12. Modeling steps: Step 5 On the sphere side of the joint, create the two holding brackets:

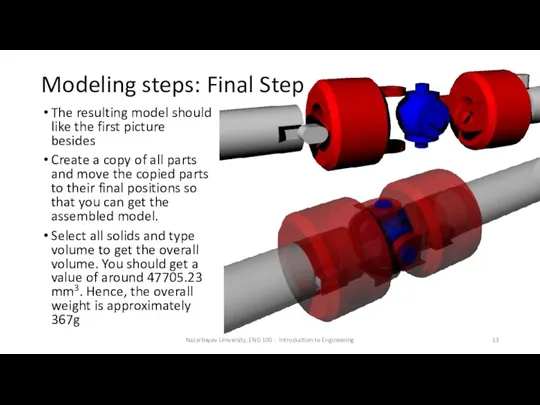

- 13. Modeling steps: Final Step The resulting model should like the first picture besides Create a copy

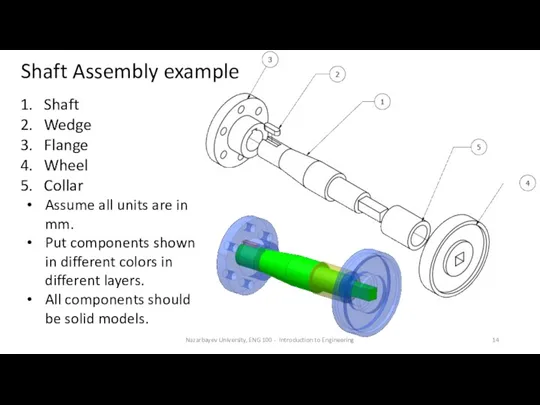

- 14. Shaft Assembly example Nazarbayev University, ENG 100 - Introduction to Engineering Shaft Wedge Flange Wheel Collar

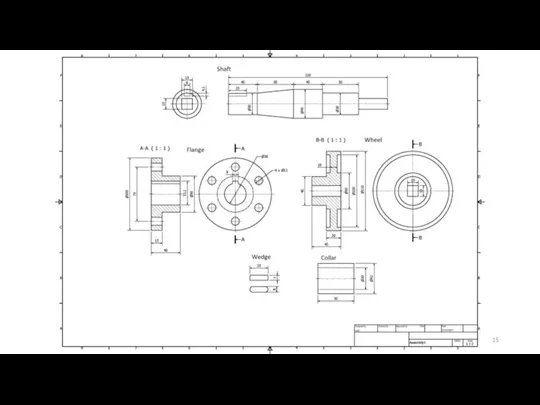

- 15. Nazarbayev University, ENG 100 - Introduction to Engineering

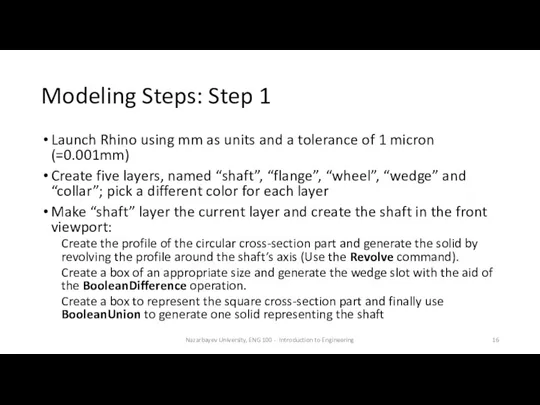

- 16. Modeling Steps: Step 1 Launch Rhino using mm as units and a tolerance of 1 micron

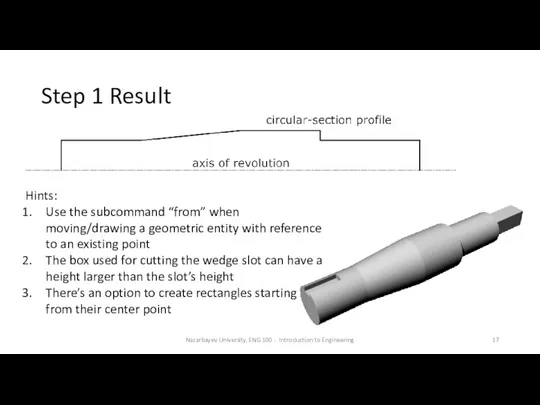

- 17. Step 1 Result Nazarbayev University, ENG 100 - Introduction to Engineering Hints: Use the subcommand “from”

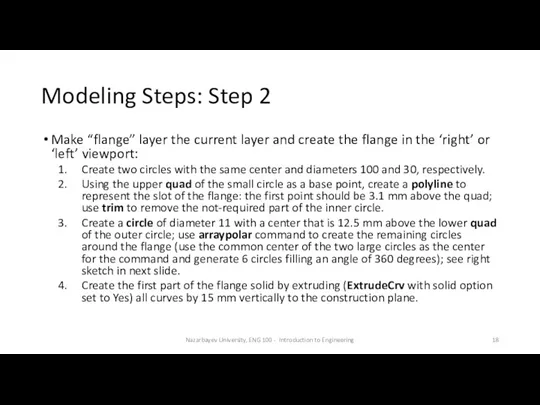

- 18. Modeling Steps: Step 2 Make “flange” layer the current layer and create the flange in the

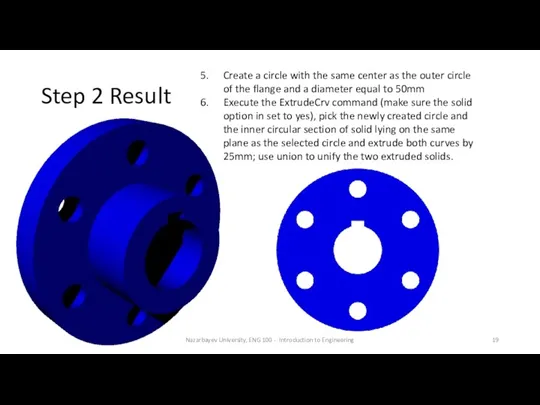

- 19. Step 2 Result Nazarbayev University, ENG 100 - Introduction to Engineering Create a circle with the

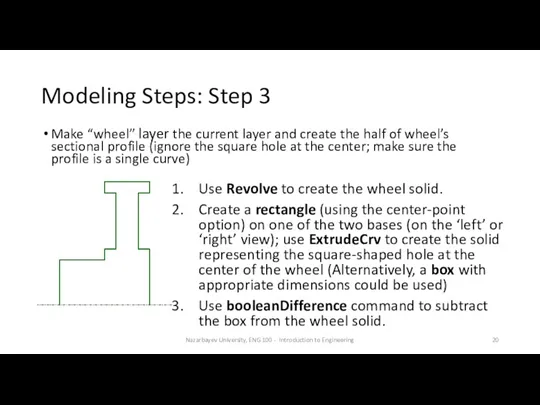

- 20. Modeling Steps: Step 3 Make “wheel” layer the current layer and create the half of wheel’s

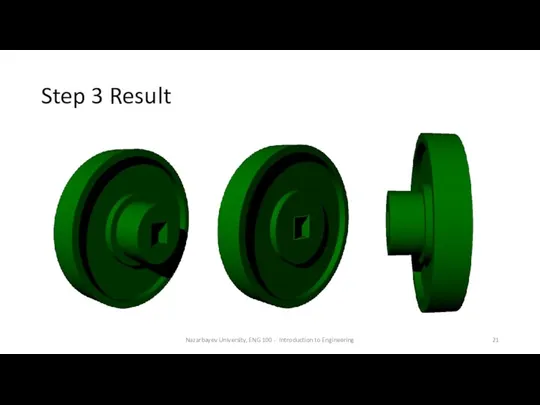

- 21. Step 3 Result Nazarbayev University, ENG 100 - Introduction to Engineering

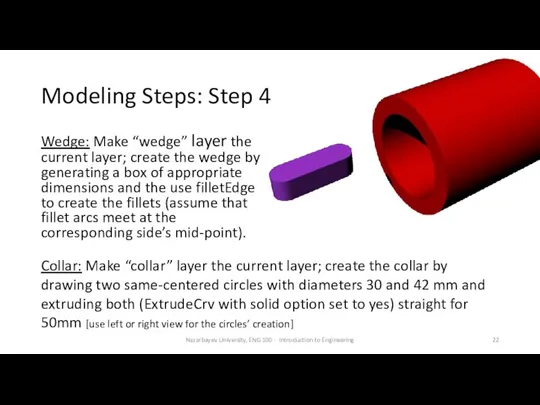

- 22. Modeling Steps: Step 4 Wedge: Make “wedge” layer the current layer; create the wedge by generating

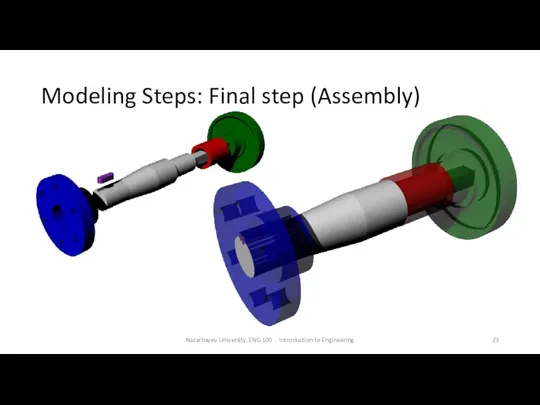

- 23. Modeling Steps: Final step (Assembly) Nazarbayev University, ENG 100 - Introduction to Engineering

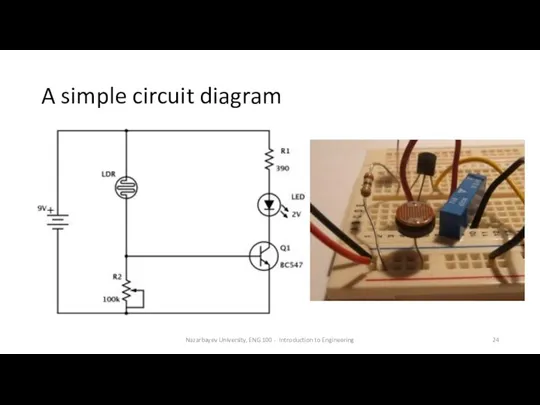

- 24. A simple circuit diagram Nazarbayev University, ENG 100 - Introduction to Engineering

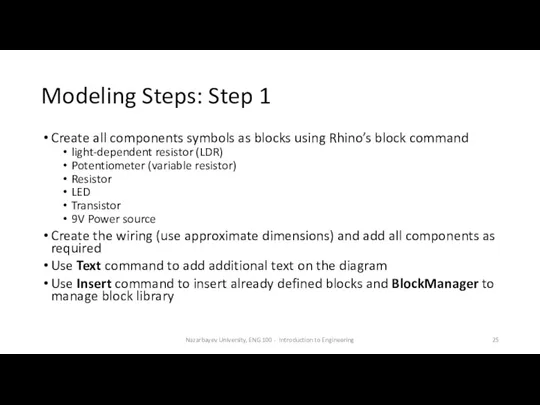

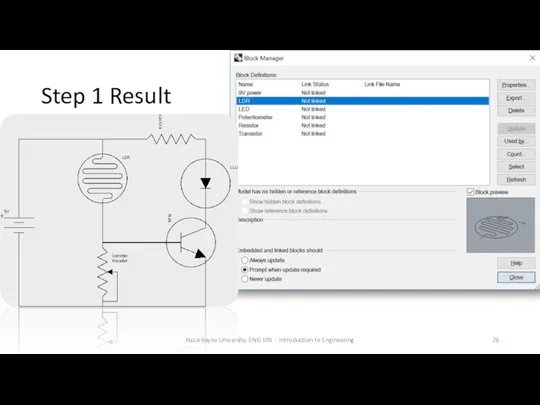

- 25. Modeling Steps: Step 1 Create all components symbols as blocks using Rhino’s block command light-dependent resistor

- 26. Step 1 Result Nazarbayev University, ENG 100 - Introduction to Engineering

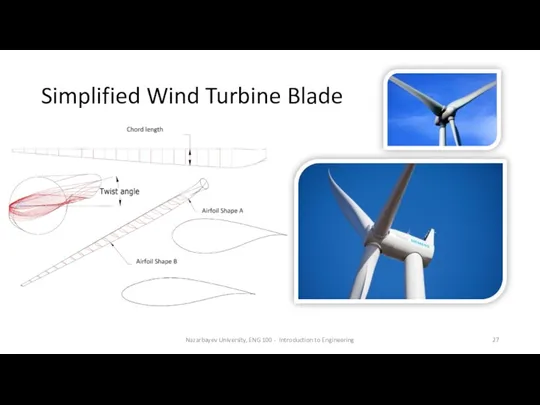

- 27. Simplified Wind Turbine Blade Nazarbayev University, ENG 100 - Introduction to Engineering

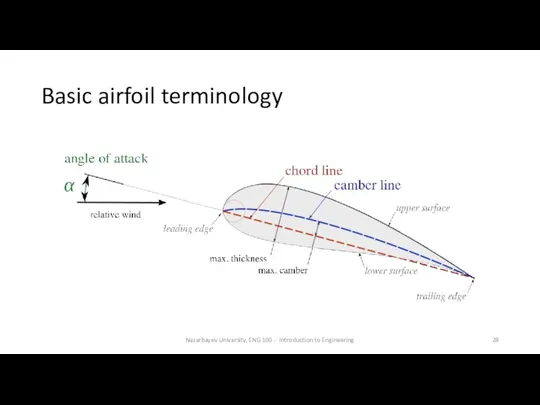

- 28. Basic airfoil terminology Nazarbayev University, ENG 100 - Introduction to Engineering

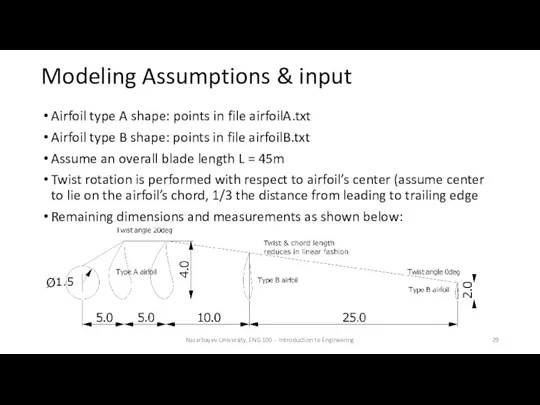

- 29. Modeling Assumptions & input Airfoil type A shape: points in file airfoilA.txt Airfoil type B shape:

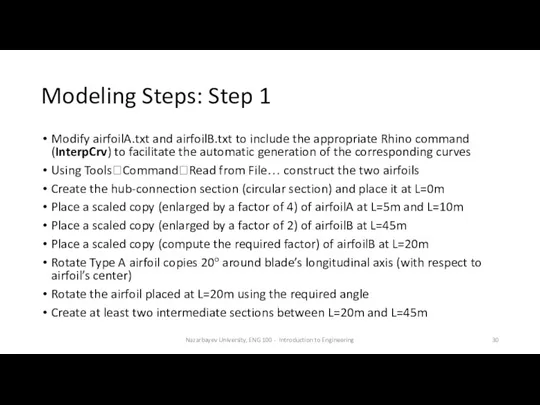

- 30. Modeling Steps: Step 1 Modify airfoilA.txt and airfoilB.txt to include the appropriate Rhino command (InterpCrv) to

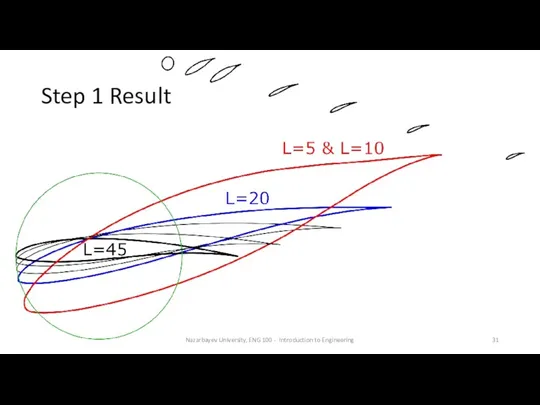

- 31. Step 1 Result Nazarbayev University, ENG 100 - Introduction to Engineering

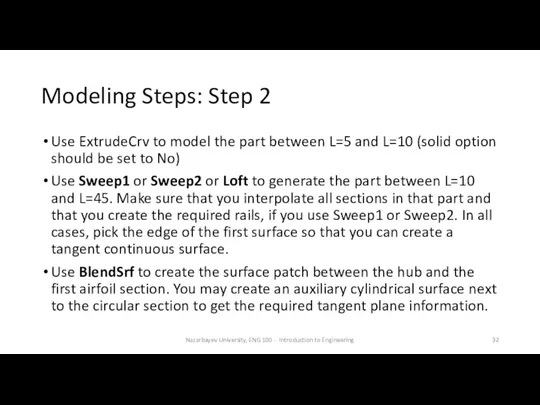

- 32. Modeling Steps: Step 2 Use ExtrudeCrv to model the part between L=5 and L=10 (solid option

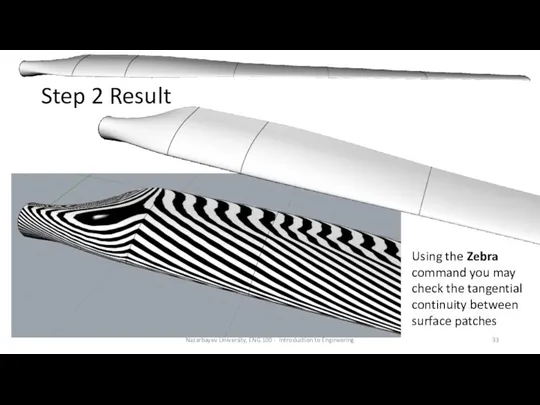

- 33. Step 2 Result Nazarbayev University, ENG 100 - Introduction to Engineering Using the Zebra command you

- 34. Modeling Steps: Step 3 Join all surfaces together using the join command Use the cap command

- 36. Скачать презентацию

Algebra relacyjna. Wprowadzenie do systemów baz danych

Algebra relacyjna. Wprowadzenie do systemów baz danych Знакомство с ТРИК Студией

Знакомство с ТРИК Студией Использование информационно-коммуникационных технологий в преподавании физики

Использование информационно-коммуникационных технологий в преподавании физики Метод побудови раціональної архітектури мережі 5G на основі існуючих 4G мереж

Метод побудови раціональної архітектури мережі 5G на основі існуючих 4G мереж Автоматизированные рабочие места автоматизированного управления (тема 9)

Автоматизированные рабочие места автоматизированного управления (тема 9) Технологии 3Dпечати, применяемые на АО НПК Уралвагонзавод

Технологии 3Dпечати, применяемые на АО НПК Уралвагонзавод Анализ публикаций в этно-СМИ Московская немецкая газета. Итоговый исследовательский проект по дисциплине Этножурналистика

Анализ публикаций в этно-СМИ Московская немецкая газета. Итоговый исследовательский проект по дисциплине Этножурналистика Компьютерные презентации. Мультимедиа

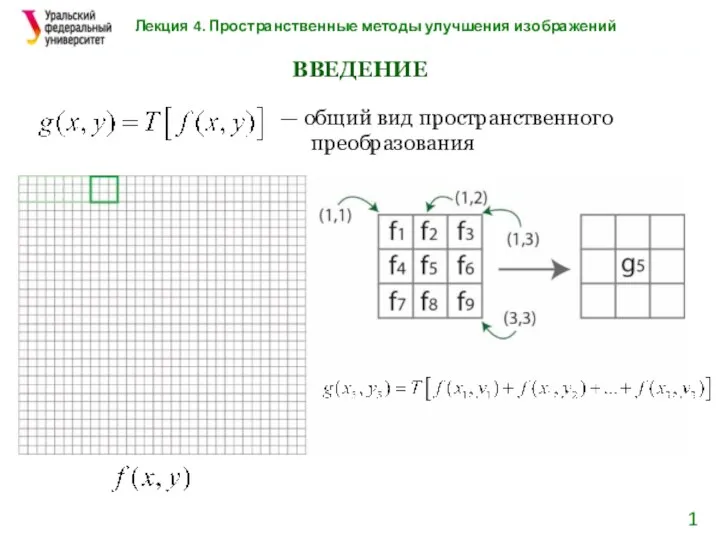

Компьютерные презентации. Мультимедиа Пространственные методы улучшения изображений

Пространственные методы улучшения изображений Интегрированный урок Математика - информатика

Интегрированный урок Математика - информатика How to install Java

How to install Java Нейронна мережа Джордана

Нейронна мережа Джордана Разграничение прав доступа в сети. Общее дисковое пространство в локальной сети

Разграничение прав доступа в сети. Общее дисковое пространство в локальной сети Массивы. Лекция 2

Массивы. Лекция 2 Математичні функцій в С++

Математичні функцій в С++ Презентация Безопасный Интернет

Презентация Безопасный Интернет Информационная безопасность и кибербезопасность

Информационная безопасность и кибербезопасность Лекция 2 – Основы языка C#

Лекция 2 – Основы языка C# Медиасистемы. Основы терминологического анализа. Основные типологические характеристики

Медиасистемы. Основы терминологического анализа. Основные типологические характеристики Управление памятью в ОСС

Управление памятью в ОСС Стандарты в области компьютерной графики

Стандарты в области компьютерной графики 1. Обработка символьной информации. Символьные переменные

1. Обработка символьной информации. Символьные переменные презентация Информационные технологии

презентация Информационные технологии Представление (кодирование) чисел

Представление (кодирование) чисел Графический дизайн

Графический дизайн Розробка системи обміну повідомленнями для Twitter, на базі мобільних технологій

Розробка системи обміну повідомленнями для Twitter, на базі мобільних технологій Кодирование графической информации

Кодирование графической информации BIM: Междисциплинарная координация

BIM: Междисциплинарная координация