Содержание

- 2. Positioning 1 Features 2 Functions 3 Applications 4 CONTENT Models 5

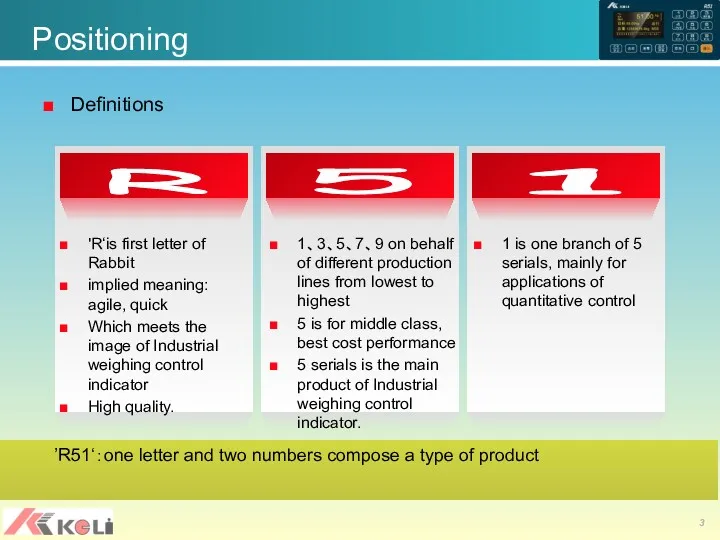

- 3. Positioning R 5 1 Definitions 'R‘is first letter of Rabbit implied meaning: agile, quick Which meets

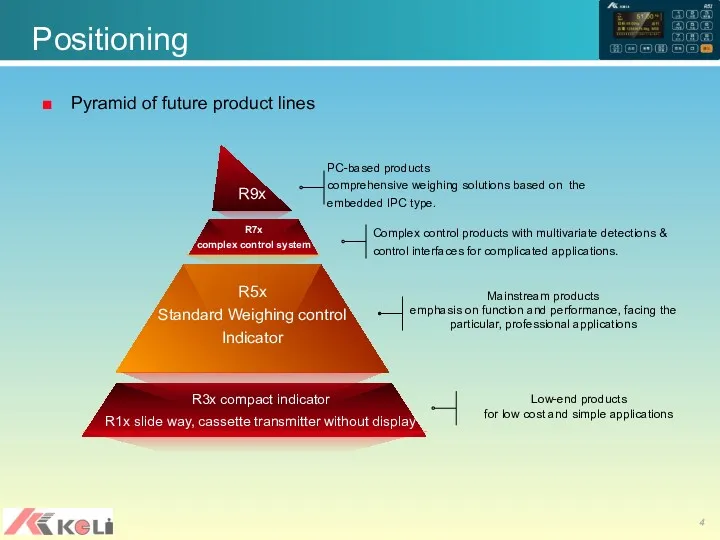

- 4. Positioning Pyramid of future product lines R3x compact indicator R1x slide way, cassette transmitter without display

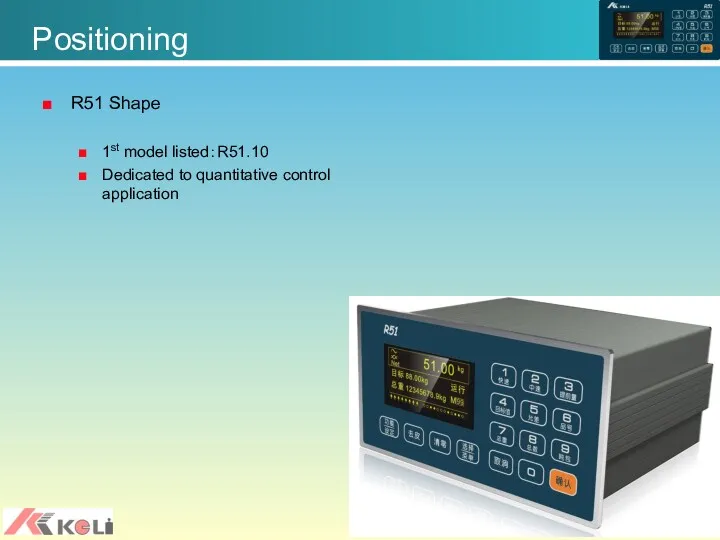

- 5. Positioning R51 Shape 1st model listed:R51.10 Dedicated to quantitative control application

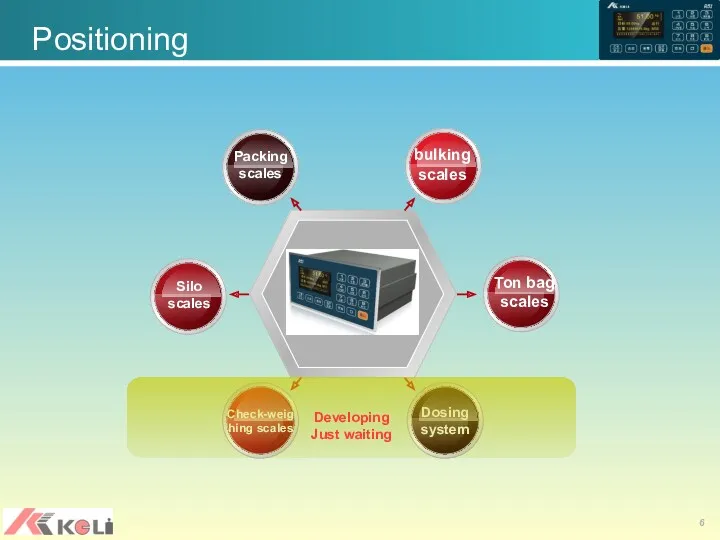

- 6. Positioning 单击此处添加 段落文字内容 Silo scales Packing scales bulking scales Check-weighing scales Dosing system Ton bag scales

- 7. Positioning 1 Features 2 Functions 3 Applications 4 CONTENT Models 5

- 8. Features Integration work mode Good environmental compatibility HMI is simple & clear Flexible communication connection

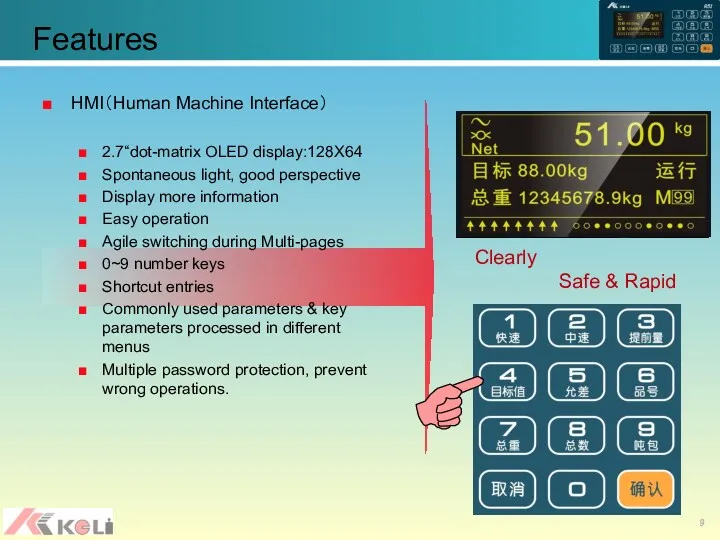

- 9. Features HMI(Human Machine Interface) 2.7“dot-matrix OLED display:128X64 Spontaneous light, good perspective Display more information Easy operation

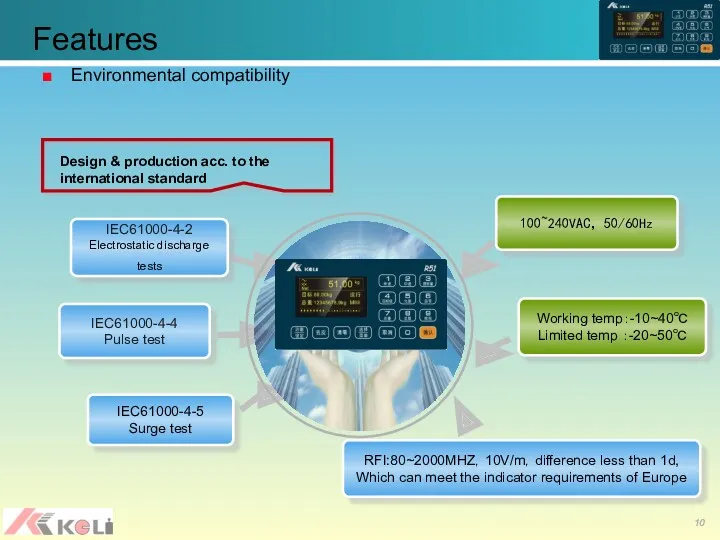

- 10. Features Environmental compatibility IEC61000-4-2 Electrostatic discharge tests IEC61000-4-4 Pulse test IEC61000-4-5 Surge test RFI:80~2000MHZ,10V/m,difference less than

- 11. Features Communication connections Standard with independent RS232 interface Standard with independent RS485 interface Other connections serial

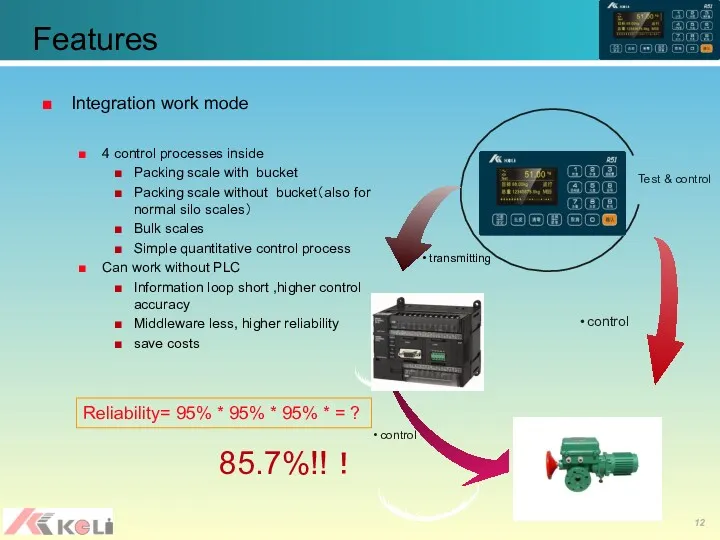

- 12. Features Integration work mode 4 control processes inside Packing scale with bucket Packing scale without bucket(also

- 13. Features General specifications 24 bits high resolution∑-Δconversion with 300Hz sample rate Verification divide:3000e,1μv/e. Max divide:20000d. Min

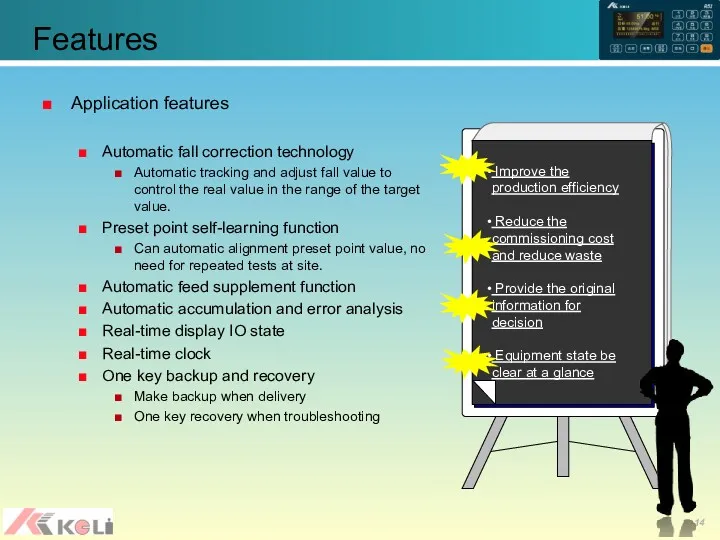

- 14. Features Application features Automatic fall correction technology Automatic tracking and adjust fall value to control the

- 15. R51 Positioning 1 R51 Features 2 Functions 3 Applications 4 CONTENT Model series 5

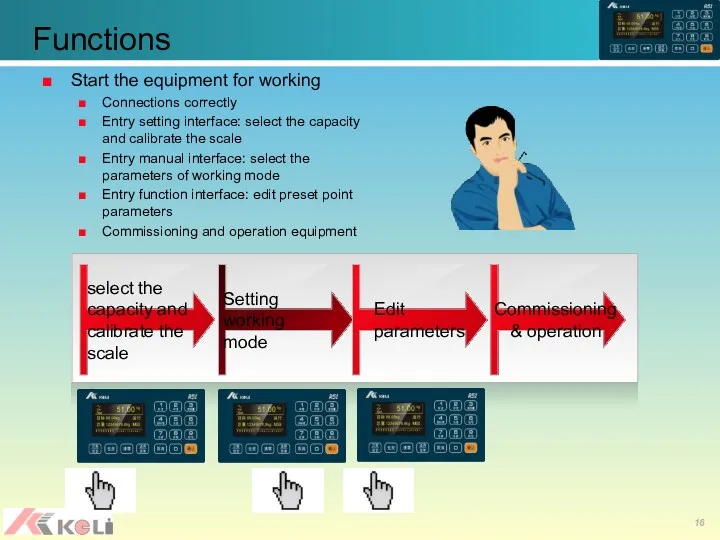

- 16. Functions Start the equipment for working Connections correctly Entry setting interface: select the capacity and calibrate

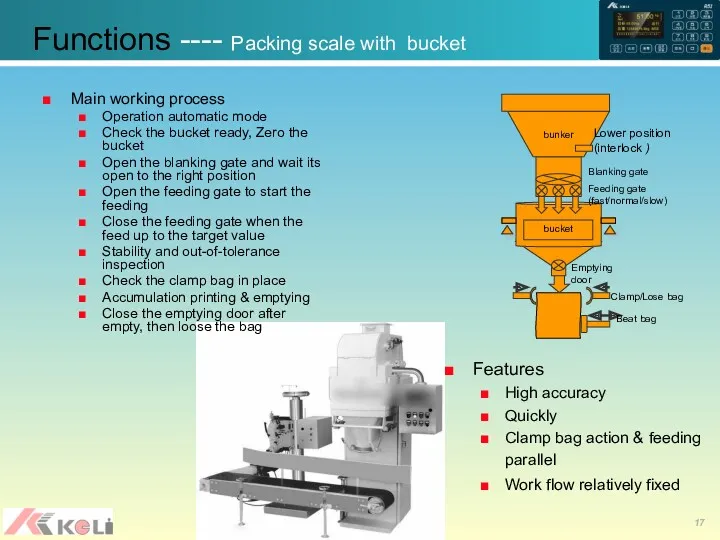

- 17. Functions ---- Packing scale with bucket Main working process Operation automatic mode Check the bucket ready,

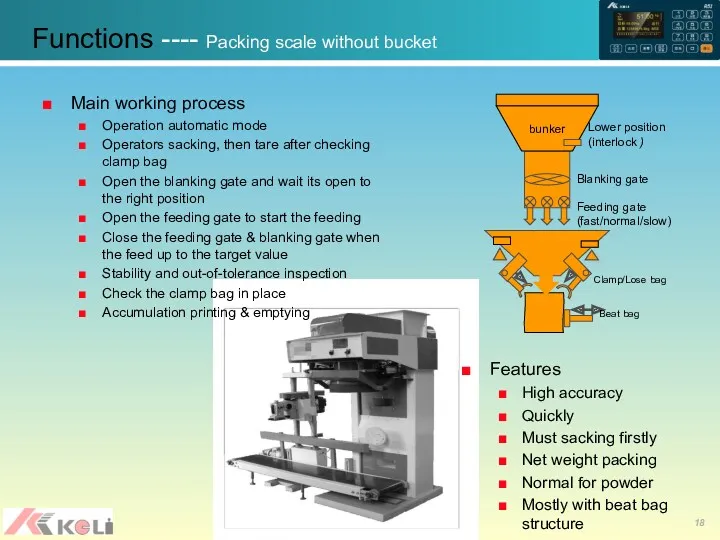

- 18. Functions ---- Packing scale without bucket Main working process Operation automatic mode Operators sacking, then tare

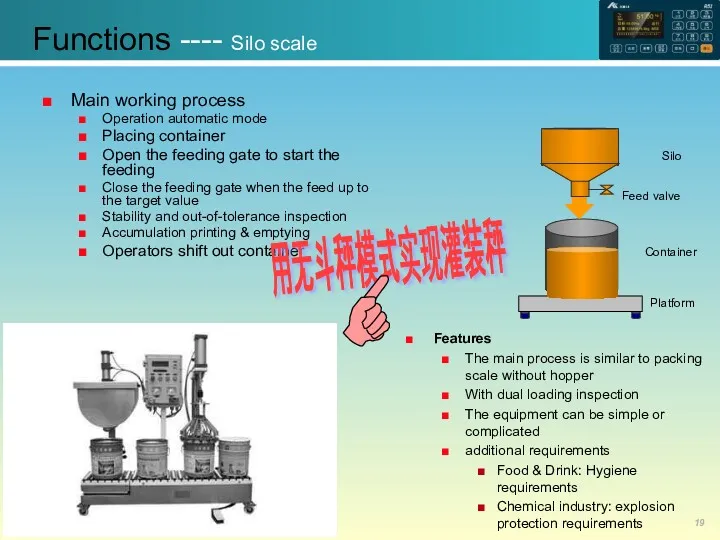

- 19. Functions ---- Silo scale Main working process Operation automatic mode Placing container Open the feeding gate

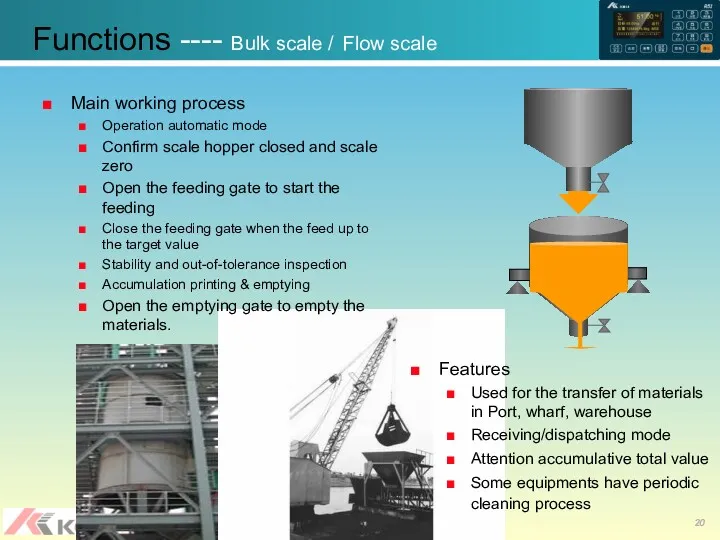

- 20. Functions ---- Bulk scale / Flow scale Main working process Operation automatic mode Confirm scale hopper

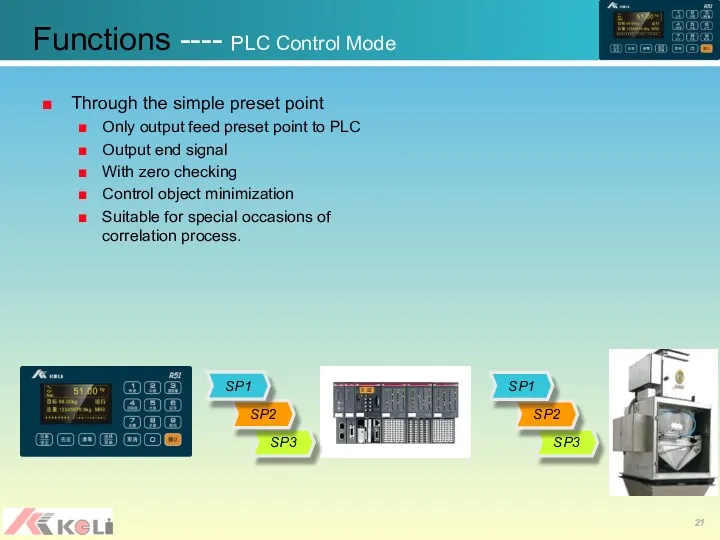

- 21. Functions ---- PLC Control Mode Through the simple preset point Only output feed preset point to

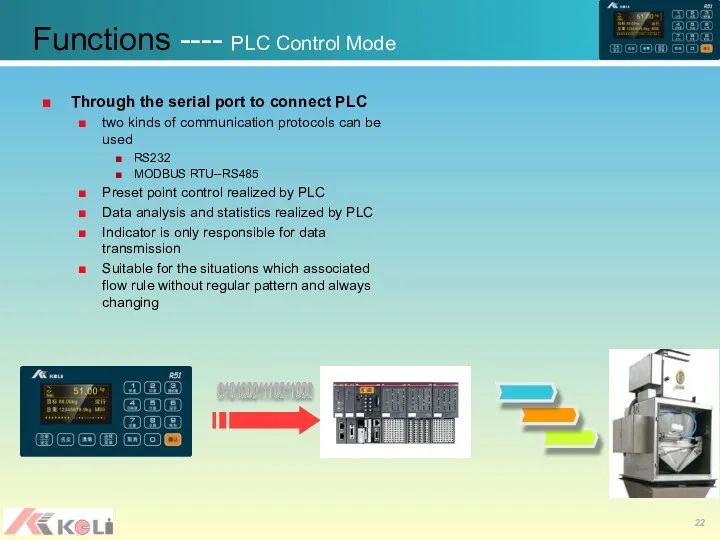

- 22. Functions ---- PLC Control Mode Through the serial port to connect PLC two kinds of communication

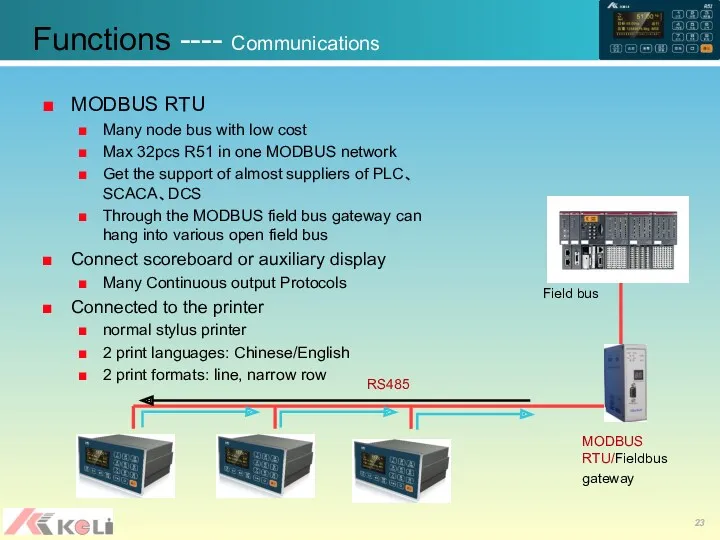

- 23. MODBUS RTU/Fieldbus gateway Functions ---- Communications MODBUS RTU Many node bus with low cost Max 32pcs

- 24. R51 Positioning 1 R51 Features 2 Functions 3 Applications 4 CONTENT Model series 5

- 25. Applications Applicable processes Packaging, filling Ingredients, bulk and packaging … Applications and industries Chemical (petrochemical, refining)

- 26. R51 Positioning 1 R51 Features 2 Functions 3 Applications 4 CONTENT Model series 5

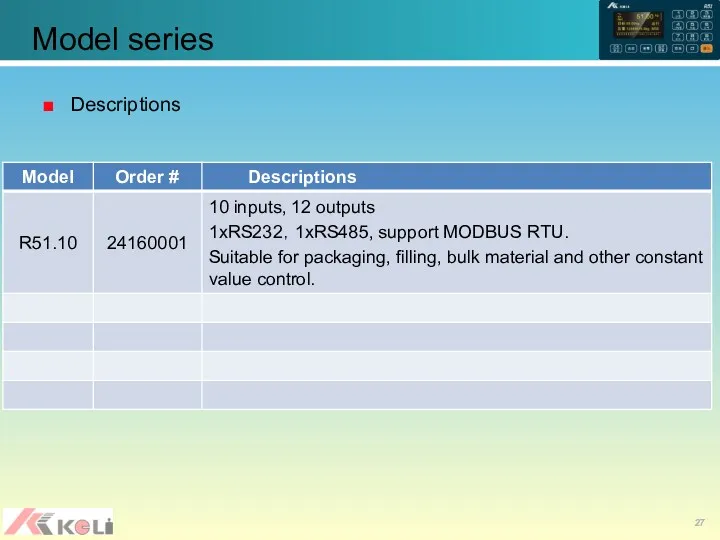

- 27. Model series Descriptions

- 28. Q&A

- 30. Скачать презентацию

О цифровизации земель сельскохозяйственного назначения муниципальных райнов Челябинской области

О цифровизации земель сельскохозяйственного назначения муниципальных райнов Челябинской области Основы логики

Основы логики Работа с файлами в Паскале

Работа с файлами в Паскале Растровая графика. (Лекция 2)

Растровая графика. (Лекция 2) Программа түсінігі. Құрылымы. Шамаларды сипаттау

Программа түсінігі. Құрылымы. Шамаларды сипаттау Дистанционный урок – урок с использованием учебного материала либо полностью размещенного в Интернете

Дистанционный урок – урок с использованием учебного материала либо полностью размещенного в Интернете Программирование на языке Паскаль. Массивы, часть 2

Программирование на языке Паскаль. Массивы, часть 2 Интернет-магазины, за и против

Интернет-магазины, за и против Язык С++: новые возможности. (Лекция 1)

Язык С++: новые возможности. (Лекция 1) Уровни изоляции транзакций. Свойства транзакций

Уровни изоляции транзакций. Свойства транзакций Теория принятия решений в научно-исследовательской работе

Теория принятия решений в научно-исследовательской работе Информационные ресурсы БИБЛИОТЕКИ Университета для программы MBA Управление в здравоохранении

Информационные ресурсы БИБЛИОТЕКИ Университета для программы MBA Управление в здравоохранении Бірлескен желілерді бағыттау. 4 лекция

Бірлескен желілерді бағыттау. 4 лекция Регистрация в WealTcom

Регистрация в WealTcom Войти в IT

Войти в IT Информационные ресурсы сети Интернет

Информационные ресурсы сети Интернет Компьютерная графика и анимация. Векторная графика

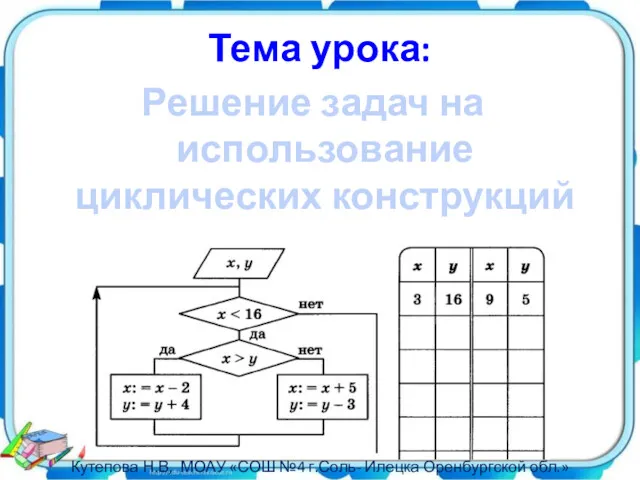

Компьютерная графика и анимация. Векторная графика Решение задач на использование циклических конструкций

Решение задач на использование циклических конструкций Определение и проблемы языков программирования

Определение и проблемы языков программирования Среда Visual Basic. Основные понятия VB

Среда Visual Basic. Основные понятия VB Field programmable gate arrays

Field programmable gate arrays Обработка исключений

Обработка исключений Вступне практичне завдання на курси 2015 QAP INT. Технічні вимоги•SPA

Вступне практичне завдання на курси 2015 QAP INT. Технічні вимоги•SPA Мультимедиа: Microsoft, PowerPoint

Мультимедиа: Microsoft, PowerPoint Глобальная сеть интернет

Глобальная сеть интернет Работа с программой Power Point

Работа с программой Power Point Вирусы. Классификация вирусов

Вирусы. Классификация вирусов Электронная почта и телеконференции

Электронная почта и телеконференции