Содержание

- 2. Our people is our most important assets Our objectives are no accidents, injuries or losses, by

- 3. Global Footprint Head office in Ireland Region Main Office in Moscow 900+ service bases in 100+

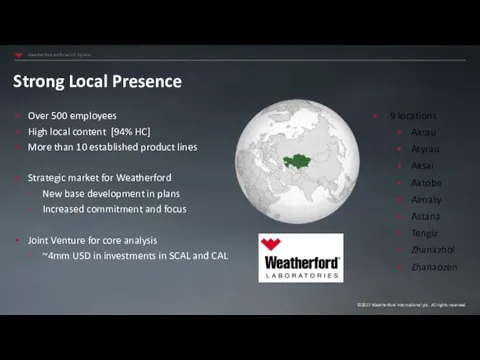

- 4. Strong Local Presence Over 500 employees High local content [94% HC] More than 10 established product

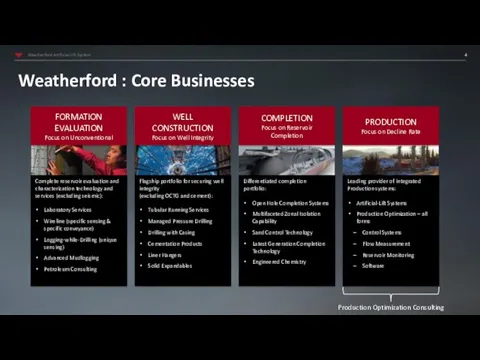

- 5. Weatherford : Core Businesses Production Optimization Consulting

- 6. WEATHERFORD is the ONLY supplier of All Lift Technologies ES pump Plunger Lift Rod Lift Gas

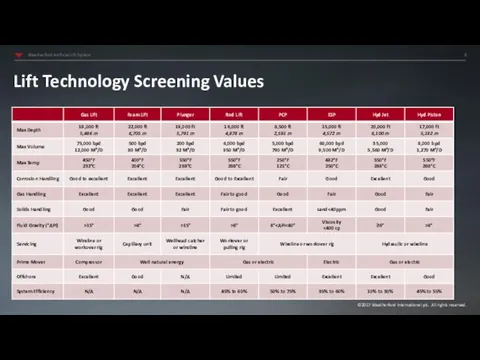

- 7. Lift Technology Screening Values

- 8. Considered to be one of the oldest form of Artificial Lift…….

- 9. Weatherford Pumping Units Broadest pumping unit offering in the industry Conventional Ampscot® and Maximizer® Enhanced geometry

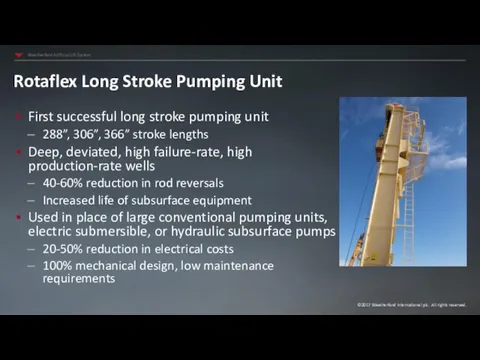

- 10. Rotaflex Long Stroke Pumping Unit First successful long stroke pumping unit 288”, 306”, 366” stroke lengths

- 11. Strapjack – Low Profile VSH2 – Nitrogen-over-Hydraulic Portable Pumping Unit Specialty Pumping Units

- 12. VSH2 – What is the VSH2 PU Reciprocating rod pumping unit Strokes conventional sucker rods or

- 13. VSH2 – Why is it different Greater rod loads requiring less horse power Unit has three

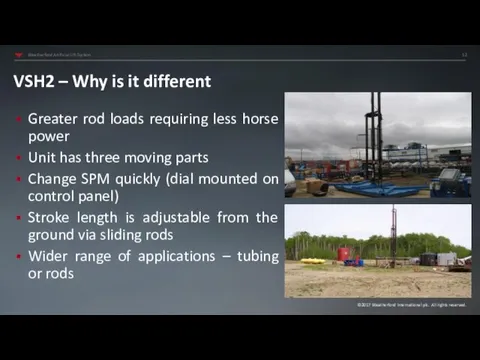

- 14. VSH2 – Theory of Operation Nitrogen gas pushes on the accumulator piston. Hydraulic fluid is forced

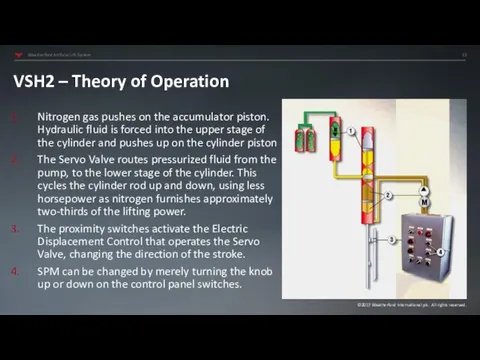

- 15. VSH2 – Nitrogen-over-Hydraulic PU Three Sizes - 60”,120” & 150.” SPM - 0 to 7.5 (depending

- 16. What is COROD® Continuous Rod? Registered name for “Continuous Sucker Rod” Superior alternative to conventional sucker

- 17. Current COROD® Continuous Rod Installations Installed in 25,000+ wells worldwide Deepest Well on Record: 14,028 ft

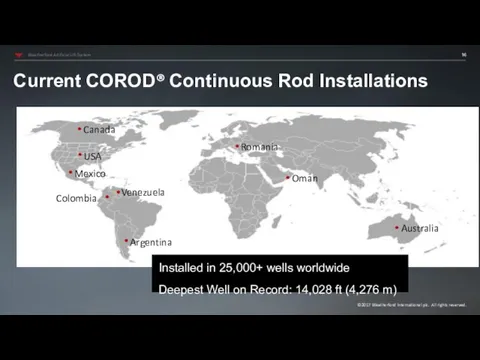

- 18. Why is COROD® Continuous Rod a Solution? RRP/ PCP Applications 1. Deep wells 2. Slant wells

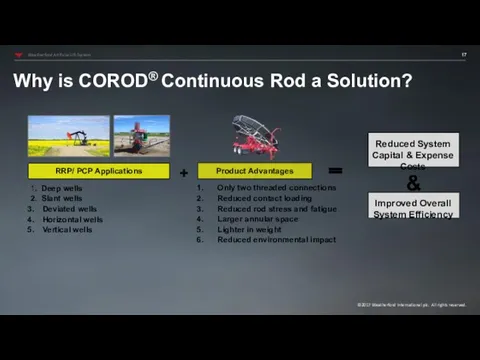

- 19. Product Advantages Fewer Threaded Connections COROD continuous rod only requires two couplings, regardless of well depth

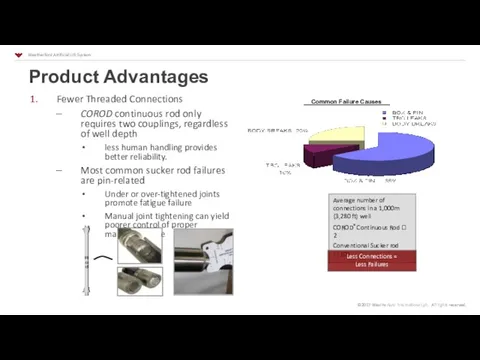

- 20. Sucker Rod Product Advantages Reduced Contact Loading Concentrated contact loads cause tubing & rod wear Under

- 21. Product Advantages Reduced Rod Stress and Fatigue Bending stresses are magnified near rod-coupling connections due to

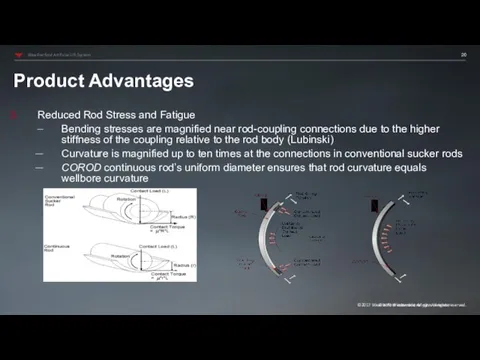

- 22. Product Advantages Larger Annular Space Reduced pressure losses COROD continuous rod reduces pressure losses typically by

- 23. Larger Annular Space Product Advantages 7/8” 1” 11/8” 7/8” 23/8 Tubing 23/8 Tubing 27/8 Tubing 27/8

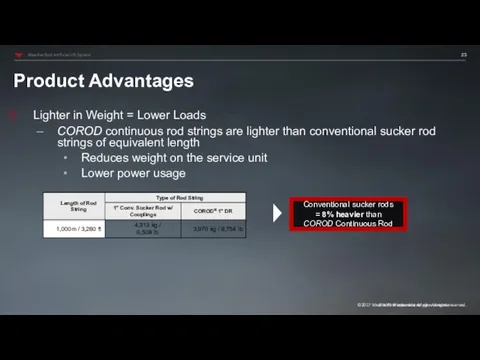

- 24. Product Advantages Lighter in Weight = Lower Loads COROD continuous rod strings are lighter than conventional

- 25. COROD® Continuous Rod Properties DWR SWR DR D DER DE SER SE

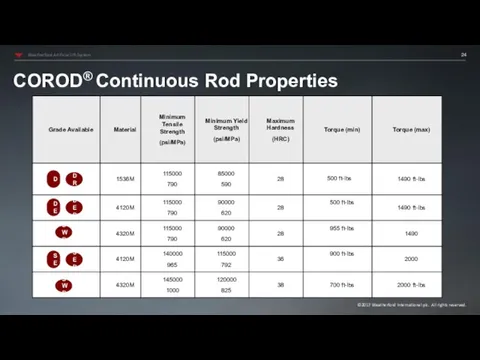

- 26. Mobile Gripper™ Unit (MG™) Compact, truck-mounted rod injector with integral hydraulic power source, BOP, knuckle picker,

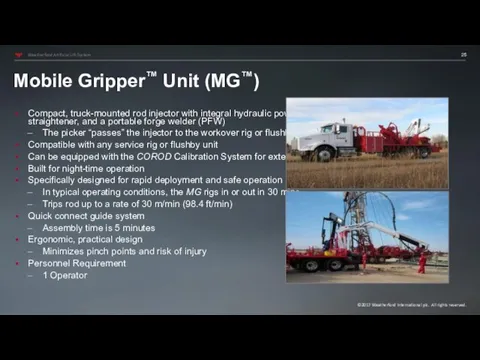

- 27. The Gripper The basis of all COROD® continuous rod service operations Mobile Gripper™

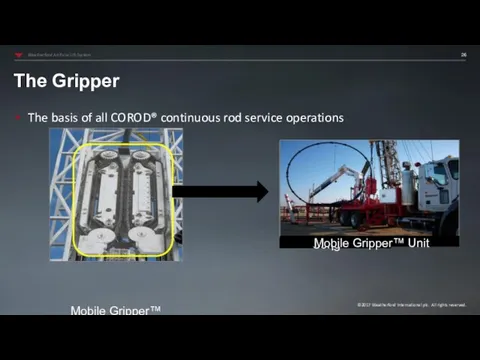

- 28. Corig™ Unit (COROD® Rig) Personnel Requirements One operator One rig assistant Applications All COROD continuous rod

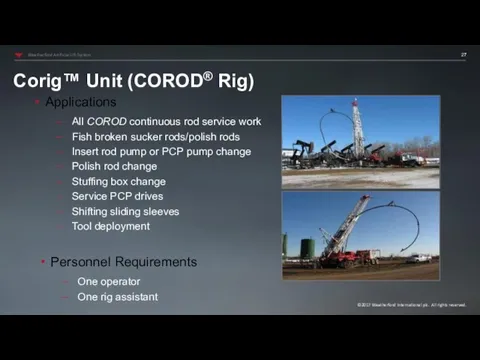

- 30. Скачать презентацию

Логистика производства

Логистика производства Корпоративный кодекс ГК Вектор

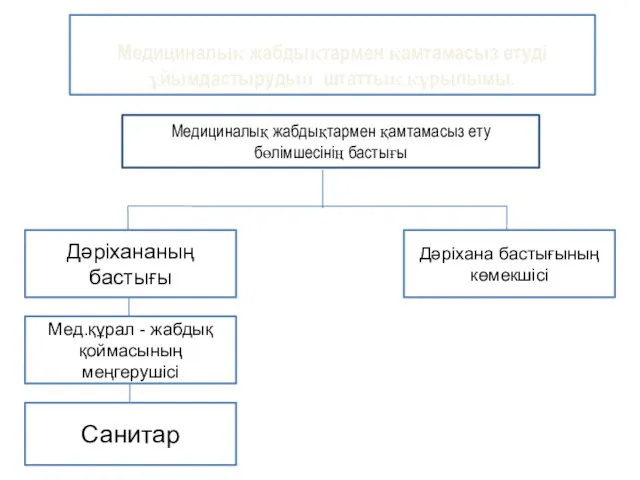

Корпоративный кодекс ГК Вектор Медициналық жабдықтармен қамтамасыз ету бөлімшесінің бастығы

Медициналық жабдықтармен қамтамасыз ету бөлімшесінің бастығы Методика проведения swot – анализа

Методика проведения swot – анализа Оценка эффективности транспортно-технологических систем; принципы исследования эффективности, критерии оценки эффективности

Оценка эффективности транспортно-технологических систем; принципы исследования эффективности, критерии оценки эффективности Нормативно-методическое и документационное обеспечение системы управления персоналом

Нормативно-методическое и документационное обеспечение системы управления персоналом The FSC CoC Auditor’s Training: New templates of documents and procedures

The FSC CoC Auditor’s Training: New templates of documents and procedures Planowanie. Plany taktyczne

Planowanie. Plany taktyczne Базисные условия поставки

Базисные условия поставки Управление персоналом. Индивидуальный план

Управление персоналом. Индивидуальный план Персоналға деген қажеттілікті жоспарлау

Персоналға деген қажеттілікті жоспарлау Предмет и метод управленческого консультирования

Предмет и метод управленческого консультирования Социально-психологический климат в коллективе

Социально-психологический климат в коллективе Функції управління охороною праці

Функції управління охороною праці Менеджмент риска. Метод анализа видов и последствий отказов

Менеджмент риска. Метод анализа видов и последствий отказов Принципы обеспечения качества и управление качеством

Принципы обеспечения качества и управление качеством Теория X и Y МакГрегора

Теория X и Y МакГрегора Анализ управления внутренними рисками организации

Анализ управления внутренними рисками организации Использование логико-структурного подхода в современной практике проектного планирования. Тема 4

Использование логико-структурного подхода в современной практике проектного планирования. Тема 4 Разработка бизнес-плана по увеличению производственных мощностей предприятия

Разработка бизнес-плана по увеличению производственных мощностей предприятия Контрольная функция управления, его развитие

Контрольная функция управления, его развитие Логистика закупок. Определение оптимального размера заказа

Логистика закупок. Определение оптимального размера заказа Методы деловой оценки сотрудников

Методы деловой оценки сотрудников Введение. Классификация и характеристика основных типов предприятий общественного питания

Введение. Классификация и характеристика основных типов предприятий общественного питания Менеджмент в государственных организациях

Менеджмент в государственных организациях Система менеджмента качества. Премии по качеству

Система менеджмента качества. Премии по качеству Система внутреннего контроля современного предприятия

Система внутреннего контроля современного предприятия Chapter 5. Foundations of business intelligence: databases and information management

Chapter 5. Foundations of business intelligence: databases and information management