Japanese Manufacturing Systems - JIT (Just In Time), known also by names: Stockless Production (HP), Zero Inventories, Kanban презентация

Содержание

- 2. JAP

- 3. JAP Savo-type rowing boat year 1888

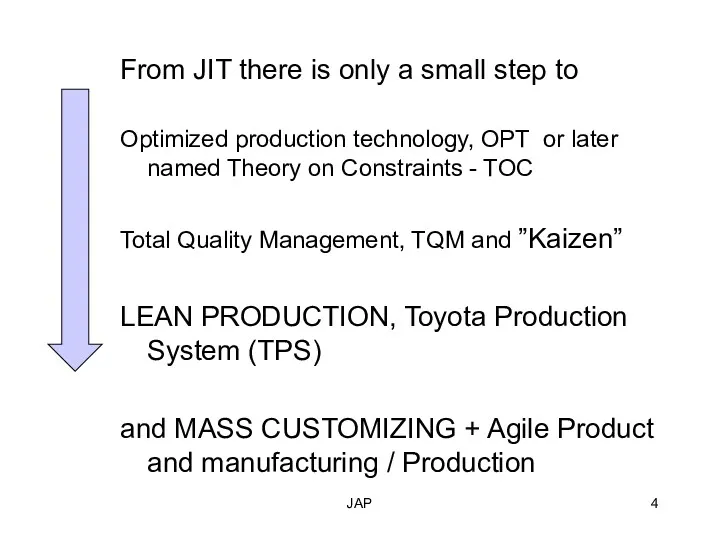

- 4. JAP From JIT there is only a small step to Optimized production technology, OPT or later

- 5. JAP From Traditional JUST IN CASE, JIC, system to modern era of manufacturing – case TPS

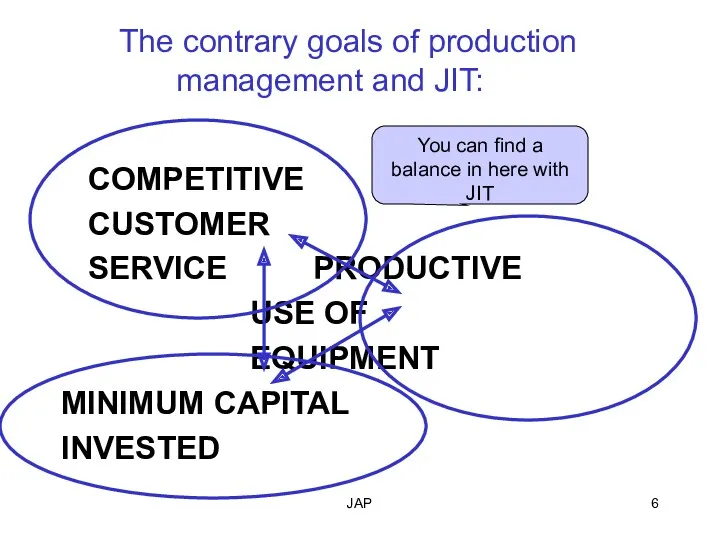

- 6. JAP You can find a balance in here with JIT The contrary goals of production management

- 7. JAP Just in time or Just in case Just in Time by Toyota https://www.youtube.com/watch?v=cAUXHJBB5CM

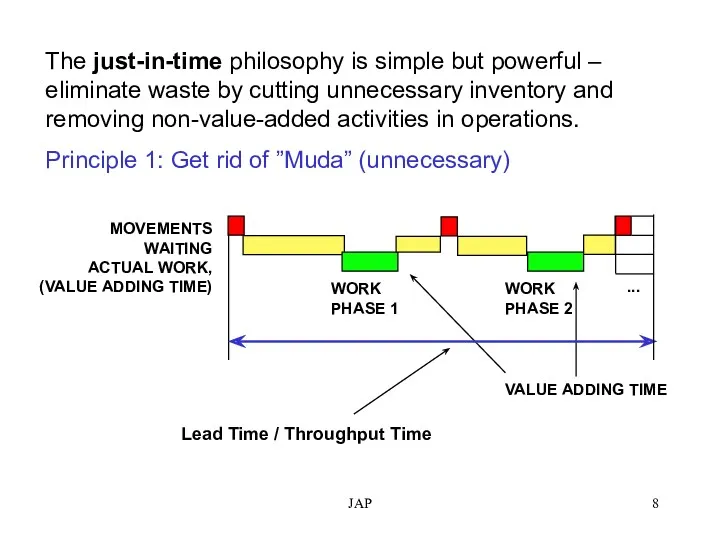

- 8. JAP Lead Time / Throughput Time The just-in-time philosophy is simple but powerful – eliminate waste

- 9. JAP Basic principles of JIT - minimizing the material Reduction of lot / batch sizes to

- 10. JAP Basic principles of JIT - developing the production system Product and production cells Small Group

- 11. JAP Basic principles of JIT - developing the supply chain JIT purchasing means Long-Term stable relationships

- 12. JAP Basic principles of JIT - managing people Z-theory Lifetime employment - means safety and positive

- 13. JAP “Why are we here ? We are here to come alive, to have fun, to

- 14. JAP Shortening the set-up-times is essential for smaller lot and batch sizes Possibilities / technologies: JIGS

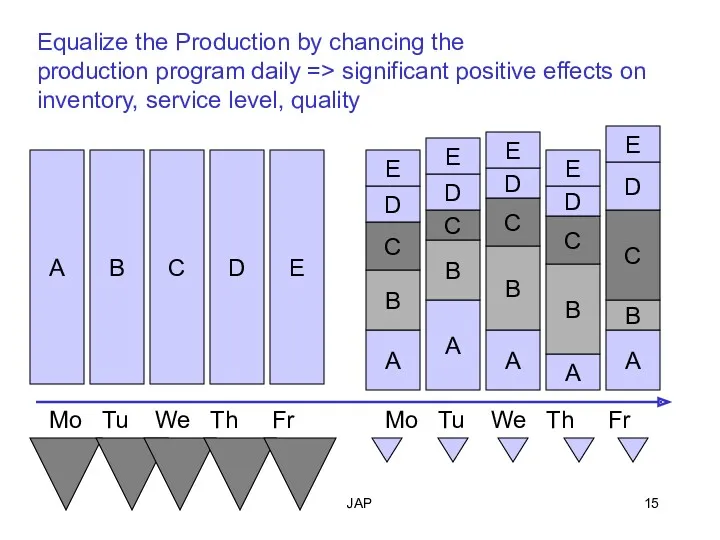

- 15. JAP Equalize the Production by chancing the production program daily => significant positive effects on inventory,

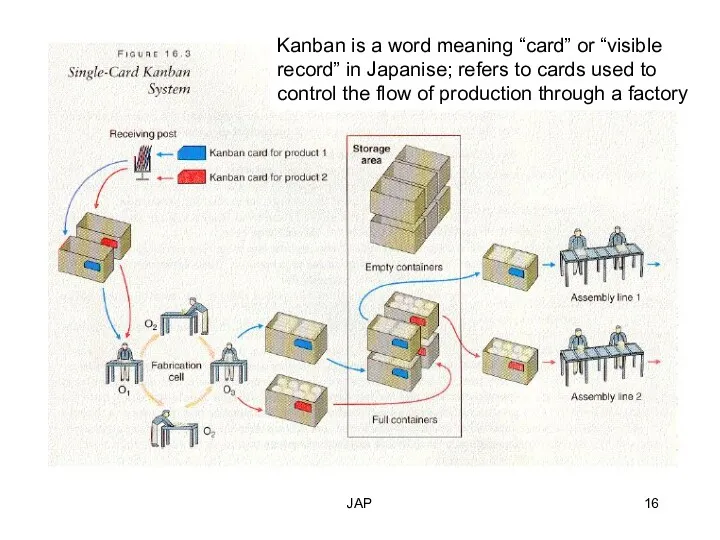

- 16. JAP Kanban is a word meaning “card” or “visible record” in Japanise; refers to cards used

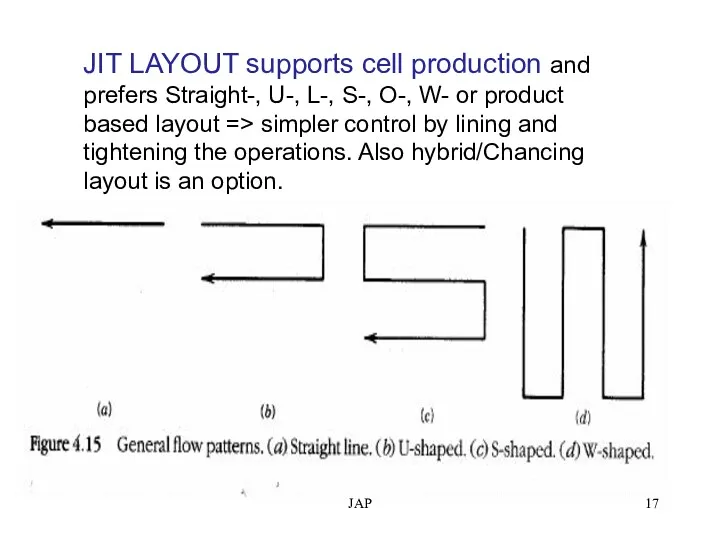

- 17. JAP JIT LAYOUT supports cell production and prefers Straight-, U-, L-, S-, O-, W- or product

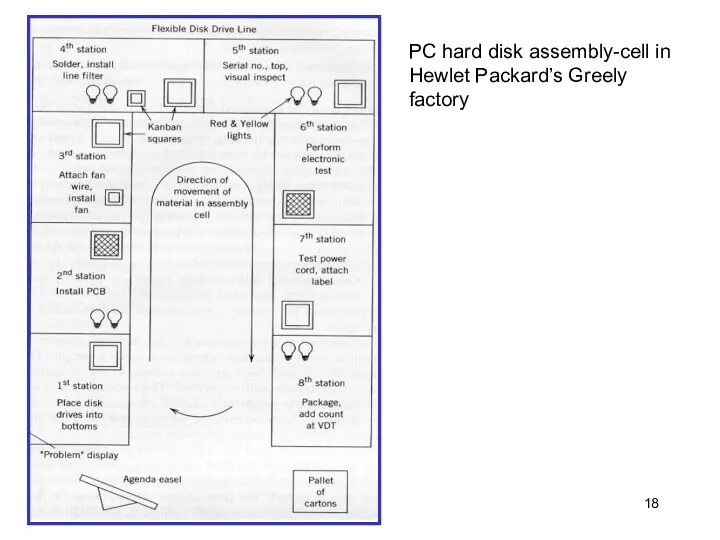

- 18. JAP PC hard disk assembly-cell in Hewlet Packard’s Greely factory

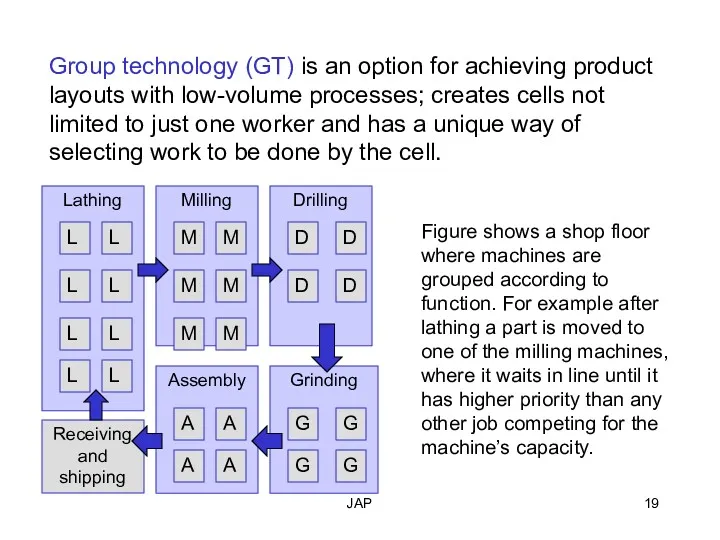

- 19. JAP Assembly Grinding Drilling Milling Lathing Group technology (GT) is an option for achieving product layouts

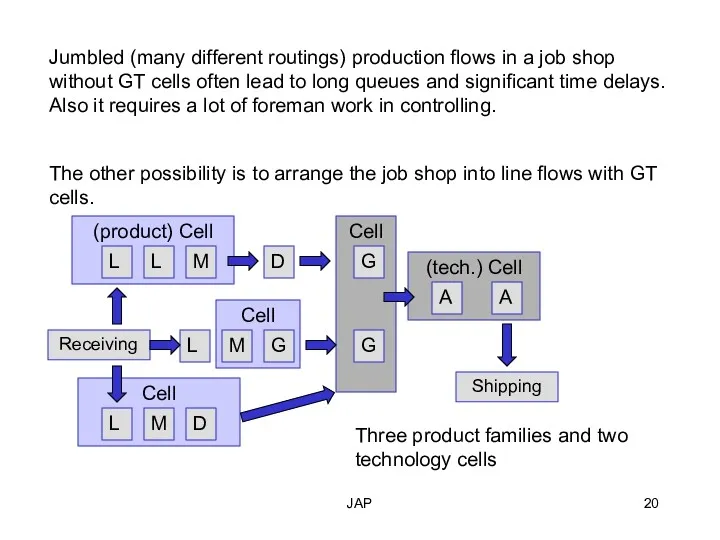

- 20. JAP Cell (tech.) Cell Cell Cell (product) Cell Jumbled (many different routings) production flows in a

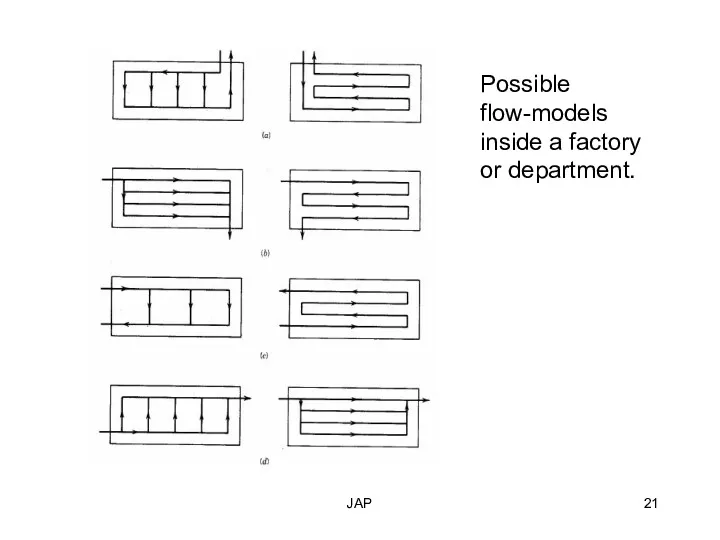

- 21. JAP Possible flow-models inside a factory or department.

- 22. JAP Just in Time (JIT) supplies JIT is not a technique. It's a management philosophy, now

- 23. JAP Among JIT requirements are: improving your own sales forecast and, where appropriate, your production planning

- 24. JAP TQM and DR. DEMINGS FOURTEEN POINTS; the viewpoint of JIT and LEAN 1. Achieve constancy

- 25. JAP CONSTANCY OF PURPOSE Create constancy of purpose for continual improvement of products and service, allocating

- 26. JAP Do they answer to their consciences? Do they answer to a built-in institution? Do they

- 27. JAP THE NEW PHILOSOPHY Adopt the new philosophy. We are in a new economic age, created

- 28. JAP Cease dependence on mass inspection Eliminate the need for mass inspection as a way to

- 29. JAP End lowest-tender contracts End the practice of awarding business solely on the basis of price

- 30. JAP Improve every process Improve constantly and forever every process for planning, production, and service. Search

- 31. JAP Institute training on the job Institute modern methods of training on the job for all,

- 32. JAP Institute leadership Adopt and institute leadership aimed at helping people to do a better job.

- 33. JAP Drive out fear Encourage effective two-way communication and other means to drive out fear throughout

- 34. JAP ”Figures, like fear, have in many cases become a weapon of conventional management. Indeed, figures

- 35. JAP Break down barriers Break down barriers between departments and staff areas. People in different areas,

- 36. JAP Eliminate exhortations Eliminate the use of slogans, posters, and exhortations for the work-force, demanding zero

- 37. JAP Eliminate arbitrary numerical targets Eliminate work standards that prescribe quotas for the workforce and numerical

- 38. JAP Permit pride of workmanship Remove the barriers that rob hourly workers, and people in management,

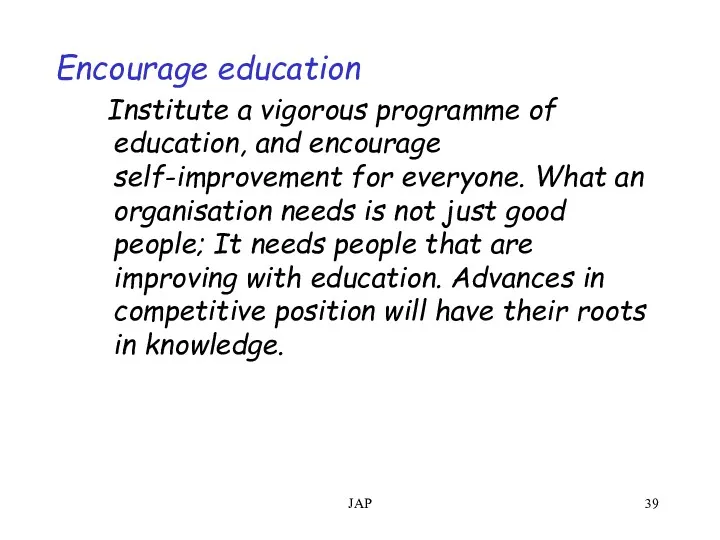

- 39. JAP Encourage education Institute a vigorous programme of education, and encourage self-improvement for everyone. What an

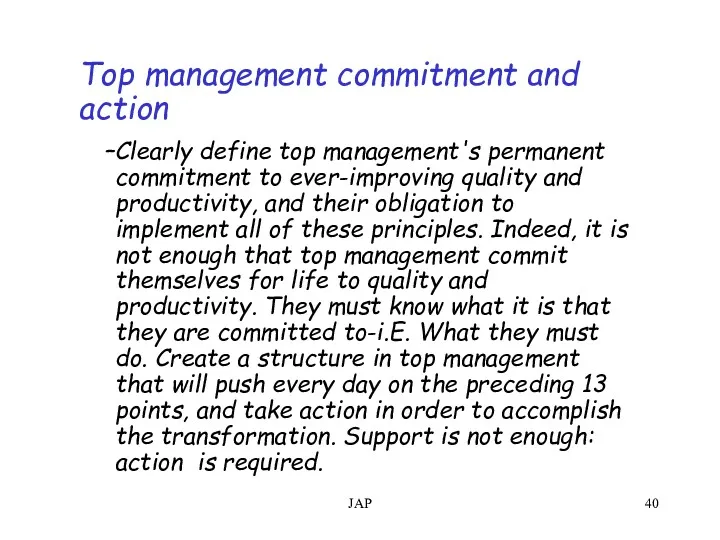

- 40. JAP Top management commitment and action Clearly define top management's permanent commitment to ever-improving quality and

- 42. Скачать презентацию

Исследование внутренней и внешней среды организации с целью формирования стратегии развития (на примере ООО Винсо СВ)

Исследование внутренней и внешней среды организации с целью формирования стратегии развития (на примере ООО Винсо СВ) Карьерные траектории в современном мире

Карьерные траектории в современном мире Сущность и функции производственного менеджмента

Сущность и функции производственного менеджмента Управление рисками проекта (часть 1)

Управление рисками проекта (часть 1) Метод Дельфи (Delphi)

Метод Дельфи (Delphi) Планирование работы в сфере ЖКХ товариществами на примере ТСЖ Полёт

Планирование работы в сфере ЖКХ товариществами на примере ТСЖ Полёт Критерии успешных управленческих решений

Критерии успешных управленческих решений Природа мотивации работника. Теории мотивации (содержательные, процессуальные)

Природа мотивации работника. Теории мотивации (содержательные, процессуальные) Персонал организации как объект управления

Персонал организации как объект управления Analiza opskrbnog lanca uz pomoć mapiranja toka vrijednosti

Analiza opskrbnog lanca uz pomoć mapiranja toka vrijednosti Стратегический менеджмент. Стратегии тоже нужна стратегия

Стратегический менеджмент. Стратегии тоже нужна стратегия Международная организация по стандартизации

Международная организация по стандартизации Профессия Туризм

Профессия Туризм Аудит качества

Аудит качества Planning as a function of management

Planning as a function of management Логистический подход к управлению МП в сфере обращения

Логистический подход к управлению МП в сфере обращения Кадровое планирование

Кадровое планирование Расширение ассортимента продукции ООО Устьянская перерабатывающая компания

Расширение ассортимента продукции ООО Устьянская перерабатывающая компания Типизация технологических процессов

Типизация технологических процессов Программа прохождения стажировки по специальности продавец бытовой техники

Программа прохождения стажировки по специальности продавец бытовой техники Особенности мотивации поведения людей в организации

Особенности мотивации поведения людей в организации Стратегия Голубого Океана. Консалтинговый Центр Игоря Балобанова Решение есть

Стратегия Голубого Океана. Консалтинговый Центр Игоря Балобанова Решение есть Монетный двор

Монетный двор Time management

Time management New program development

New program development Выявление профессиональных компетенций инновационного менеджера

Выявление профессиональных компетенций инновационного менеджера Системы менеджмента качества в российских IT компаниях

Системы менеджмента качества в российских IT компаниях Совершенствование организации сбыта хлебобулочных изделий в ООО Губахахлеб г. Губаха Пермского края

Совершенствование организации сбыта хлебобулочных изделий в ООО Губахахлеб г. Губаха Пермского края