Содержание

- 2. Definition It is concerned with planning, organizing and controlling the flow of materials from their initial

- 3. AIM OF MATERIAL MANAGEMENT To get 1. The Right quality 2. Right quantity of supplies 3.

- 4. PURPOSE OF MATERIAL MANAGEMENT To gain economy in purchasing To satisfy the demand during period of

- 5. Primary Right price High turnover Low procurement & storage cost Continuity of supply Consistency in quality

- 6. Economy in material management Containing the costs Instilling efficiency in all activities

- 7. Four basic needs of Material management To have adequate materials on hand when needed To pay

- 8. Basic principles of material management Effective management & supervision It depends on managerial functions of Planning

- 9. Elements of material management Demand estimation Identify the needed items Calculate from the trends in Consumption

- 10. Functional areas of material management 1. Purchasing 2. Central service supply 3. Central stores 4. The

- 11. PROCUREMENT 1. Directorate general of supply & disposal (DGS & D, Govt. Of India] 2. Medical

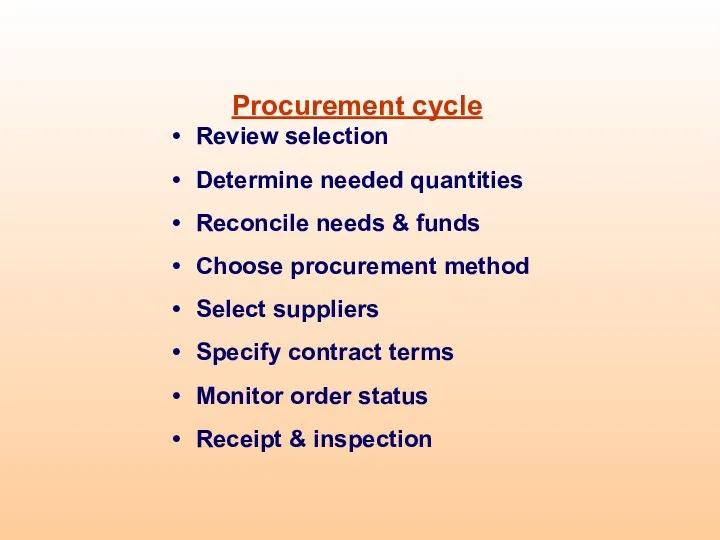

- 12. Procurement cycle Review selection Determine needed quantities Reconcile needs & funds Choose procurement method Select suppliers

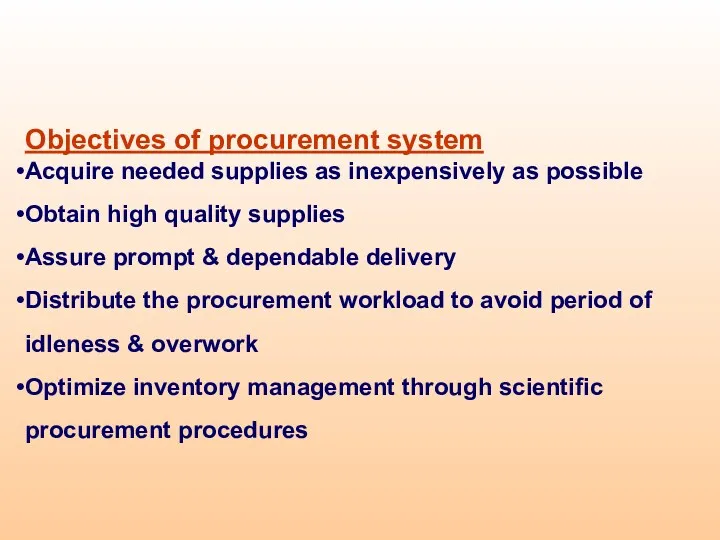

- 13. Objectives of procurement system Acquire needed supplies as inexpensively as possible Obtain high quality supplies Assure

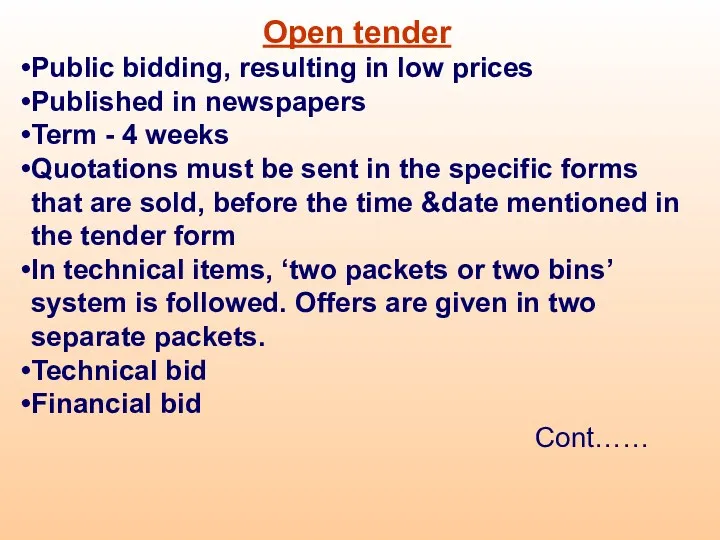

- 15. Open tender Public bidding, resulting in low prices Published in newspapers Term - 4 weeks Quotations

- 16. First technical bid is opened & short listed Then financial bid of selected companies are opened

- 17. Earnest money 2 % of the tender amount or as decided has to be paid along

- 18. Rate contract Firms are asked to supply stores at specified Rates during the period covered by

- 19. Points to remember while purchasing Proper specification Invite quotations from reputed firms Comparison of offers based

- 20. Storage Store must be of adequate space Materials must be stored in an appropriate place in

- 21. Inventory control It means stocking adequate number and kind of stores, so that the materials are

- 22. Functions of inventory control To provide maximum supply service, consistent with maximum efficiency & optimum investment.

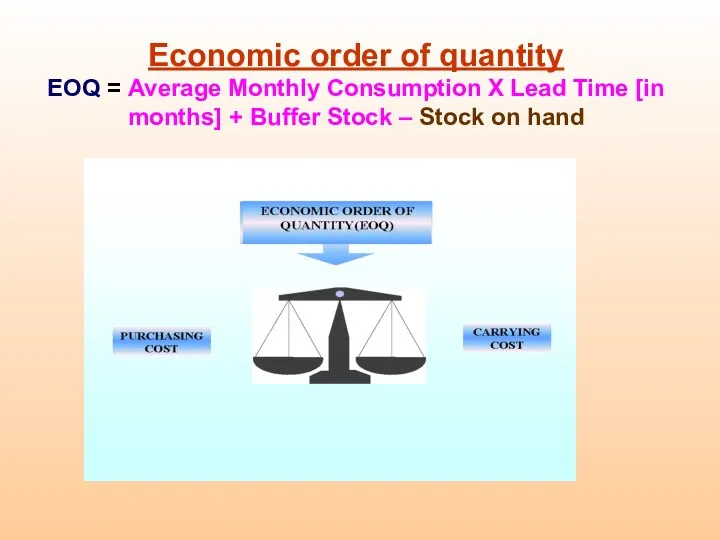

- 23. Economic order of quantity EOQ = Average Monthly Consumption X Lead Time [in months] + Buffer

- 24. Re-order level: stock level at which fresh order is placed. Average consumption per day x lead

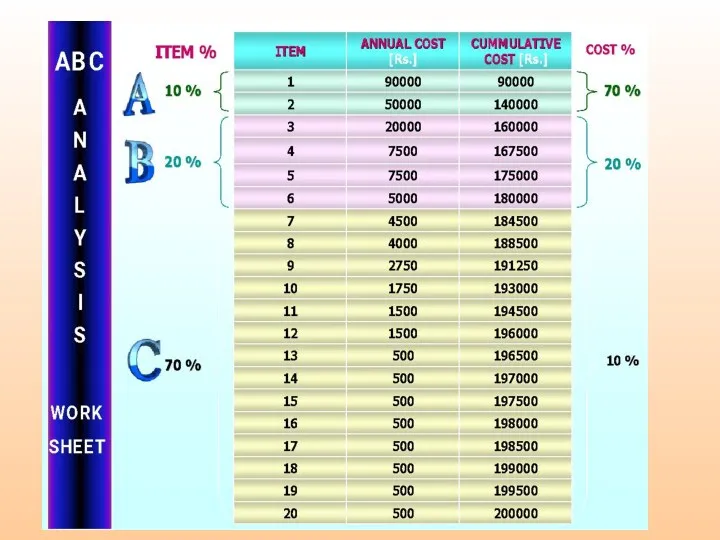

- 25. ABC ANALYSIS (ABC = Always Better Control) This is based on cost criteria. It helps to

- 26. ‘A’ ITEMS Small in number, but consume large amount of resources Must have: Tight control Rigid

- 27. ‘C’ ITEMS Larger in number, but consume lesser amount of resources Must have: Ordinary control measures

- 29. ‘B’ ITEM Intermediate Must have: Moderate control Purchase based on rigid requirements Reasonably strict watch &

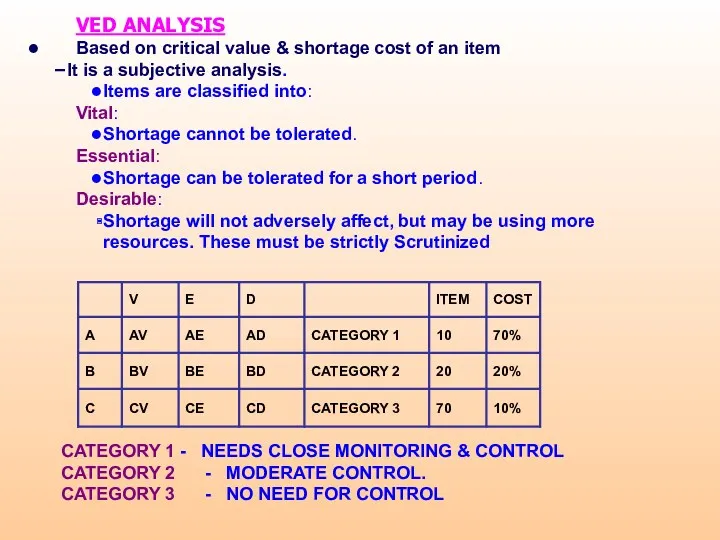

- 30. VED ANALYSIS Based on critical value & shortage cost of an item It is a subjective

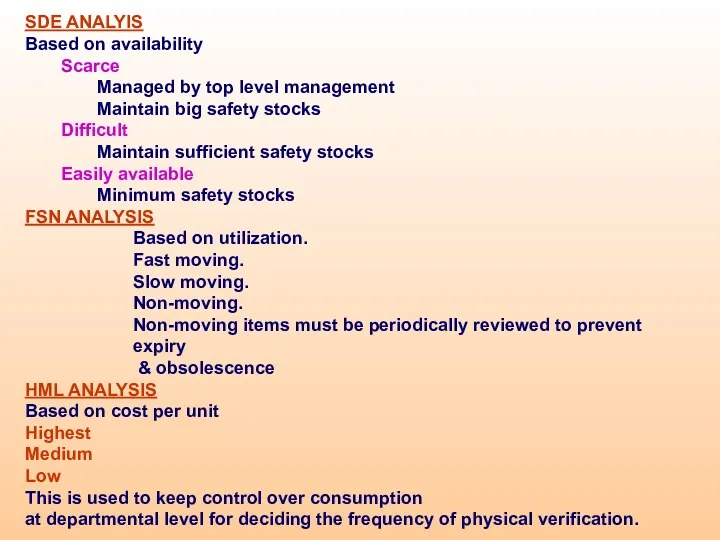

- 31. SDE ANALYIS Based on availability Scarce Managed by top level management Maintain big safety stocks Difficult

- 32. PROCURMENT OF EQUIPMENT Points to be noted before purchase of an equipment: Latest technology Availability of

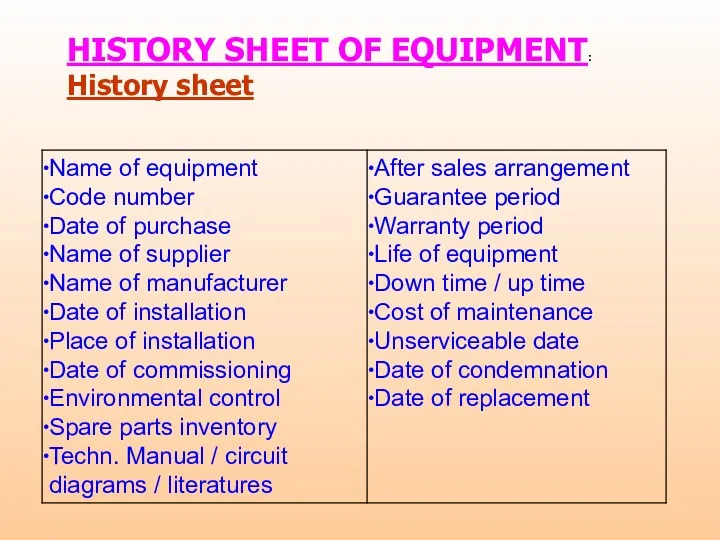

- 33. HISTORY SHEET OF EQUIPMENT: History sheet

- 34. Maintenance sheet: Annual maintenance contract [AMC] Starting date Expiry date Service / repair description Materials /

- 35. EQUIPMENT MAINTENANCE & CONDEMNATION Maintenance & repairs: Preventive maintenance Master maintenance plan Repair of equipment

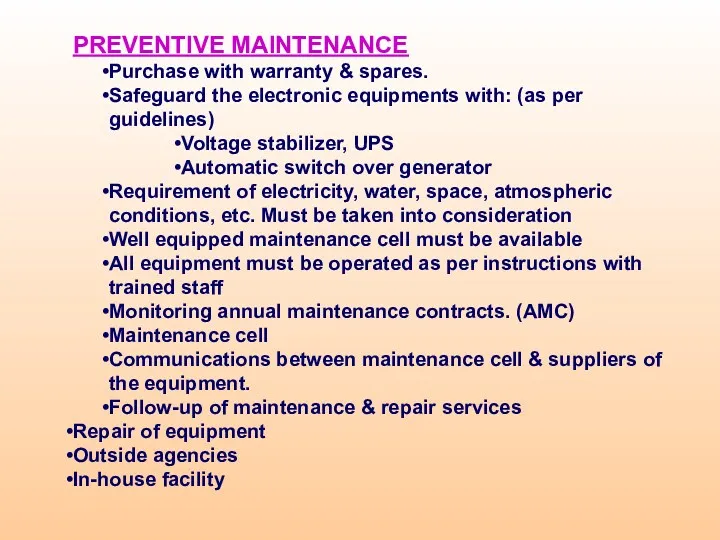

- 36. PREVENTIVE MAINTENANCE Purchase with warranty & spares. Safeguard the electronic equipments with: (as per guidelines) Voltage

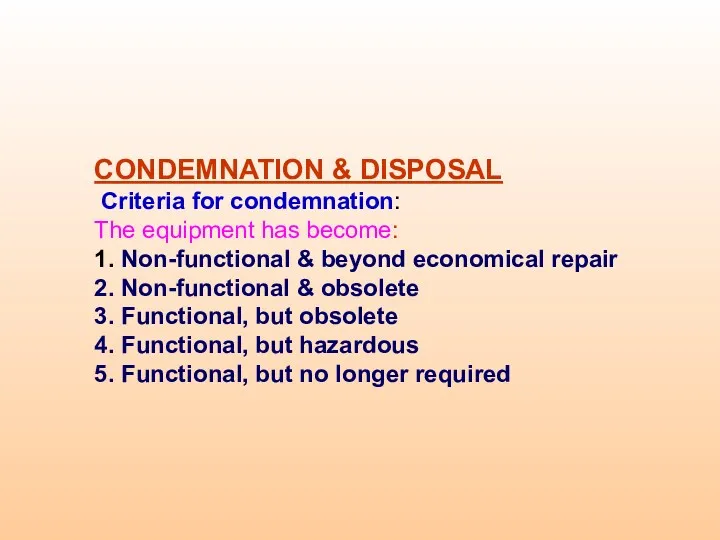

- 37. CONDEMNATION & DISPOSAL Criteria for condemnation: The equipment has become: 1. Non-functional & beyond economical repair

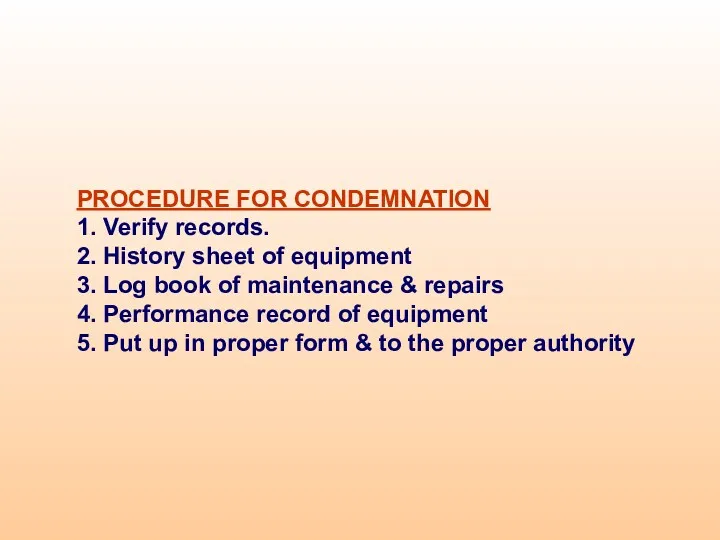

- 38. PROCEDURE FOR CONDEMNATION 1. Verify records. 2. History sheet of equipment 3. Log book of maintenance

- 39. DISPOSAL 1. Circulate to other units, where it is needed 2. Return to the vendor, if

- 40. CONCLUSION Material management is an important management tool which will be very useful in getting the

- 42. Скачать презентацию

![Maintenance sheet: Annual maintenance contract [AMC] Starting date Expiry date](/_ipx/f_webp&q_80&fit_contain&s_1440x1080/imagesDir/jpg/365270/slide-33.jpg)

Организация складского хозяйства предприятия

Организация складского хозяйства предприятия Складское хозяйство

Складское хозяйство Функції менеджменту, як відособлені види управлінської діяльності

Функції менеджменту, як відособлені види управлінської діяльності Совершенствование логистической системы предприятия ООО МЕТРО Кэш энд Кэрри

Совершенствование логистической системы предприятия ООО МЕТРО Кэш энд Кэрри Менеджмент информационных систем

Менеджмент информационных систем Правило 1-10-100

Правило 1-10-100 Программирование и конфигурирование в корпоративных ИС. Система 1С:Предприятие. (Лекция 1)

Программирование и конфигурирование в корпоративных ИС. Система 1С:Предприятие. (Лекция 1) Установление системы целей

Установление системы целей Мотивация Без ручной оценки

Мотивация Без ручной оценки Инновация и реинжениринг; их использование в управлении проектами

Инновация и реинжениринг; их использование в управлении проектами Контроллинг как система управления современным предприятием

Контроллинг как система управления современным предприятием Организационная динамика. (Тема 2)

Организационная динамика. (Тема 2) Регулювання трудової діяльності персоналу

Регулювання трудової діяльності персоналу Системные характеристики, функции, структура в СМИ. (Тема 3)

Системные характеристики, функции, структура в СМИ. (Тема 3) Základy řízení - TŘOS

Základy řízení - TŘOS Стили руководства. Определение стилей. Классические стили. Многомерные стили

Стили руководства. Определение стилей. Классические стили. Многомерные стили STEP- анализ

STEP- анализ Понятие и причины текучести кадров

Понятие и причины текучести кадров Ценность бренда и стратегическое позиционирование. Эффективное управление отношениями с основными стейкхолдерами НКО

Ценность бренда и стратегическое позиционирование. Эффективное управление отношениями с основными стейкхолдерами НКО Коммуникации. Структура коммуникационного процесса

Коммуникации. Структура коммуникационного процесса Экономическая эффективность в IT. Кризисное управление в IT

Экономическая эффективность в IT. Кризисное управление в IT Профессиональная мотивация и удовлетворенность трудом сотрудников салонов красоты с разным стажем работы

Профессиональная мотивация и удовлетворенность трудом сотрудников салонов красоты с разным стажем работы Методы исследования в менеджменте. Система научных учреждений Российской Федерации

Методы исследования в менеджменте. Система научных учреждений Российской Федерации Совершенствование организации перевозки асфальта транспортными средствами ОАО ТАТК

Совершенствование организации перевозки асфальта транспортными средствами ОАО ТАТК Ұйымдағы билік және коммуникация

Ұйымдағы билік және коммуникация Організація взаємодії керівника і секретаря

Організація взаємодії керівника і секретаря Лидерство и стиль управления

Лидерство и стиль управления Лидерство и управление: кто может быть лидером

Лидерство и управление: кто может быть лидером