Содержание

- 2. Plan Introduction; Main features of the process; Conclusion;

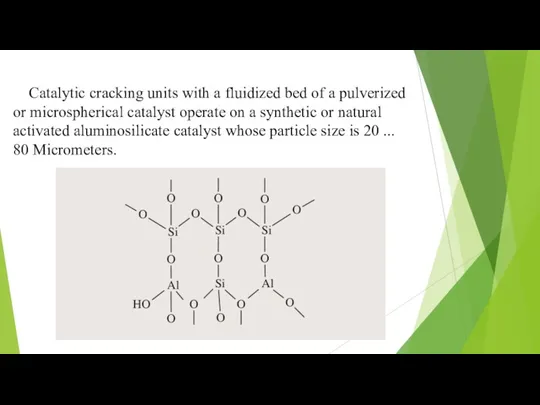

- 3. Catalytic cracking units with a fluidized bed of a pulverized or microspherical catalyst operate on a

- 4. The advantages of this type of cracking compared to cracking, which uses a ball catalyst, are:

- 5. The disadvantage of cracking in a fluidized bed is that due to the intensive mixing of

- 6. There are four main schemes of the reactor unit: The scheme with a double rise of

- 7. Scheme with the location of the reactor and regenerator on the same level. The catalyst is

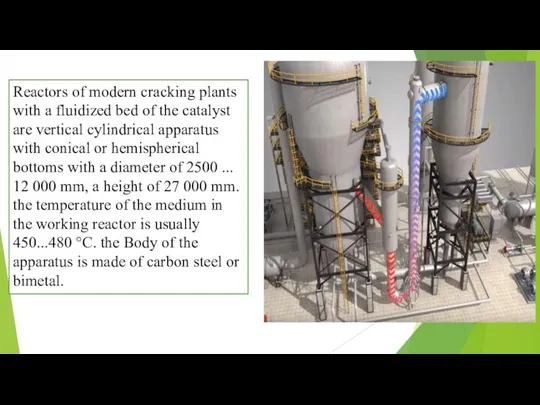

- 8. Reactors of modern cracking plants with a fluidized bed of the catalyst are vertical cylindrical apparatus

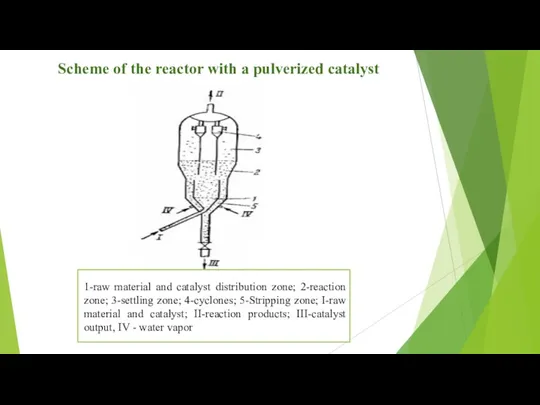

- 9. 1-raw material and catalyst distribution zone; 2-reaction zone; 3-settling zone; 4-cyclones; 5-Stripping zone; I-raw material and

- 11. Скачать презентацию

Социальная работа с детьми, имеющими ограниченные возможности здоровья

Социальная работа с детьми, имеющими ограниченные возможности здоровья Сварка металлов. Общие сведения. Физическая сущность сварочной дуги. Тепловое действие сварочной дуги

Сварка металлов. Общие сведения. Физическая сущность сварочной дуги. Тепловое действие сварочной дуги Художественная картина мира. Анализ рассказов В. Шаламова Стланик и Воскрешение лиственницы

Художественная картина мира. Анализ рассказов В. Шаламова Стланик и Воскрешение лиственницы Les Types de Phrases

Les Types de Phrases Презенация Социально-личностное развитие дошкольника с учётом гендерных особенностей

Презенация Социально-личностное развитие дошкольника с учётом гендерных особенностей Обеспечение химической защиты

Обеспечение химической защиты Внеклассное мероприятие Знайте правила движения как таблицу умножения!

Внеклассное мероприятие Знайте правила движения как таблицу умножения! Отрезок. Длина отрезка. Прямая. Луч. 5 класс

Отрезок. Длина отрезка. Прямая. Луч. 5 класс Землеройно-транспортные машины. Классификация, устройство, назначение

Землеройно-транспортные машины. Классификация, устройство, назначение Споживання кормів та його регуляція. Лекція 7

Споживання кормів та його регуляція. Лекція 7 о-е после шип в наречиях

о-е после шип в наречиях Оператор комп’ютерного набору

Оператор комп’ютерного набору Классный час Берегите глаза

Классный час Берегите глаза Результаты метапредметной диагностической работы

Результаты метапредметной диагностической работы Особенности педагогической деятельности с обучающимися с интеллектуальными нарушениями

Особенности педагогической деятельности с обучающимися с интеллектуальными нарушениями Тағамды сақтау жолы консервілеу

Тағамды сақтау жолы консервілеу ДопускКпеддеят.ОткрУрок03.12.2020

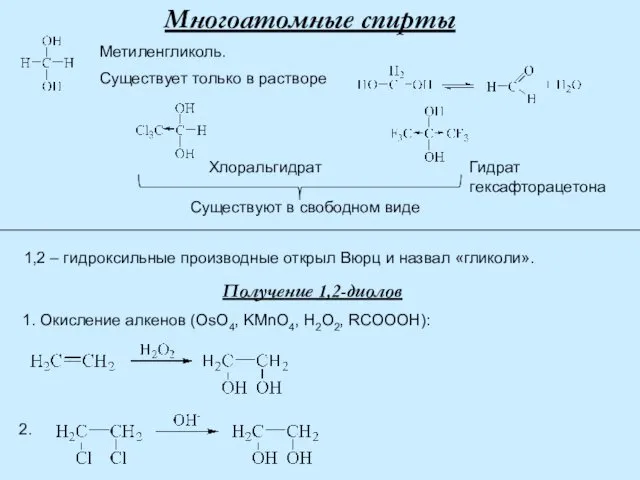

ДопускКпеддеят.ОткрУрок03.12.2020 Многоатомные спирты

Многоатомные спирты GP2 BCM SVC bulletin Document 4.01.00

GP2 BCM SVC bulletin Document 4.01.00 Coffee Zavod. Доходная кофейня самообслуживания

Coffee Zavod. Доходная кофейня самообслуживания Путешествие в Иерусалим

Путешествие в Иерусалим Автоматизация звука Ш в словах

Автоматизация звука Ш в словах Акты действия (бездействия) ОГВ и ОМС, направленные на ограничение конкуренции

Акты действия (бездействия) ОГВ и ОМС, направленные на ограничение конкуренции Склад та властивості нафти

Склад та властивості нафти Презентация к празднику Победой кончилась война. Диск

Презентация к празднику Победой кончилась война. Диск phppb0sz2_Madame-Tussauds

phppb0sz2_Madame-Tussauds Окислительно-восстановительные реакции

Окислительно-восстановительные реакции Биоритмология

Биоритмология