Содержание

- 2. Lecture content Introduction to automatics – short history, control system and related nations, classification of control

- 3. Automatics derives from Greek word automatos, "acting of one's own will, self-acting, of itself," made up

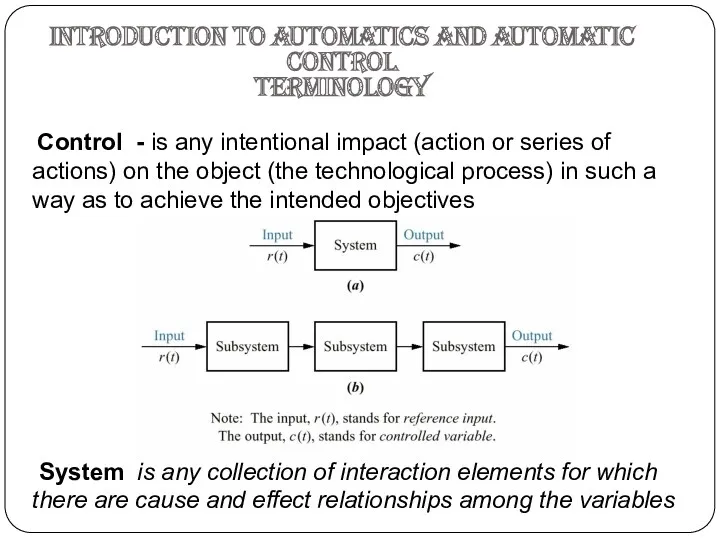

- 4. Control - is any intentional impact (action or series of actions) on the object (the technological

- 5. Controlled variables - these are the variables which quantify the performance or quality of the final

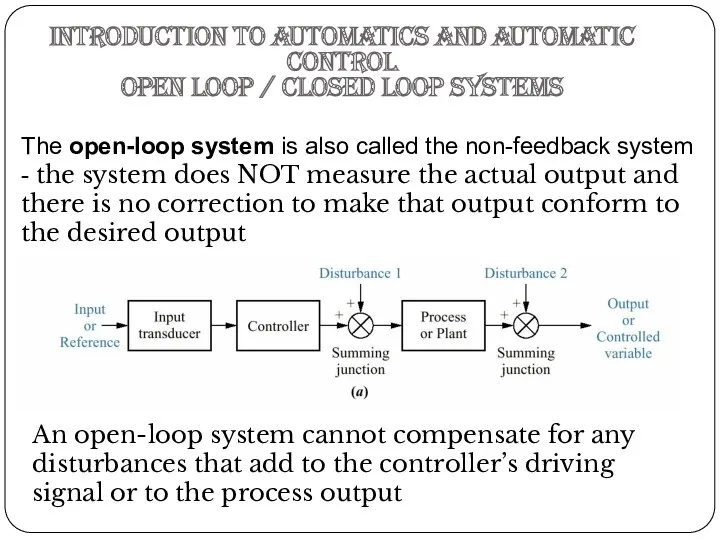

- 6. Introduction to Automatics and automatic control OPEN LOOP / CLOSED LOOP SYSTEMS The open-loop system is

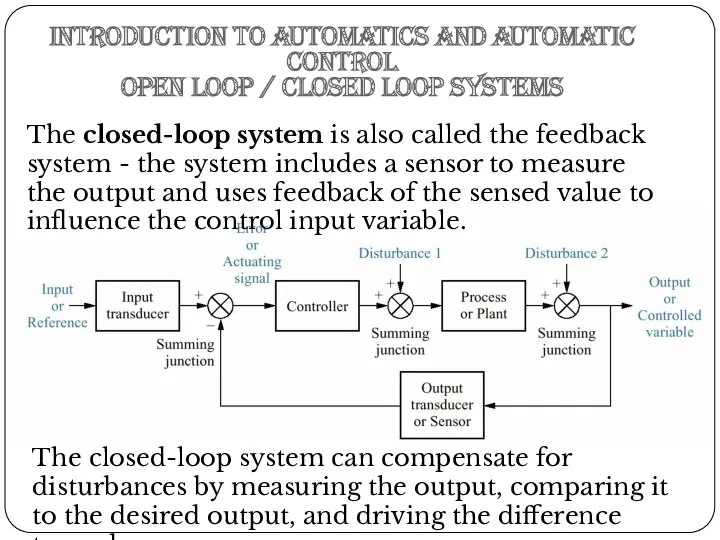

- 7. Introduction to Automatics and automatic control OPEN LOOP / CLOSED LOOP SYSTEMS The closed-loop system is

- 8. A blind person driving a car: open loop control Driving a car by using vision: feedback

- 9. Central heating system in house/room: without temperature sensor - open loop control with temperature sensor –

- 10. HİSTORY Automatic control systems were first developed more than two thousand years ago. The first feedback

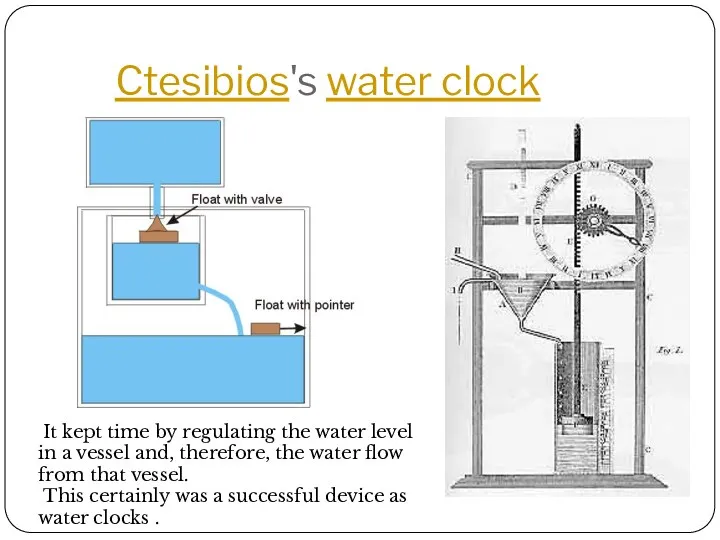

- 11. Ctesibios's water clock It kept time by regulating the water level in a vessel and, therefore,

- 12. HİSTORY In the 17th and 18th centuries were popular in Europe, automata equipped with dancing figures

- 13. HİSTORY James Watt fly-ball governor Rotational velocity stablilization of the steam engine – 1769 Reduced steam

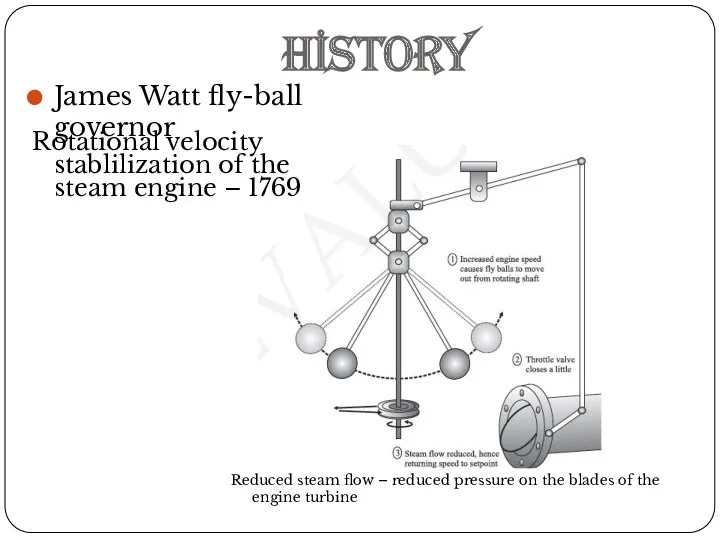

- 14. 1868 Governor control analysis (Maxwell) 1927 Telephone amplifier analysis (Bode - frequency domain analysis) 1932 Stability

- 15. CLASIFICATION OF CONTROL SYTEMS The classification can be carried out in many different ways, by taking

- 16. CLASIFICATION OF CONTROL SYTEMS 2. With respect to the task performed by the system: Systems of

- 17. CLASIFICATION OF CONTROL SYTEMS 2. With respect to the task performed by the system: Programmed control

- 18. CLASIFICATION OF CONTROL SYTEMS 2. With respect to the task performed by the system: Tracking systems

- 19. CLASIFICATION OF CONTROL SYTEMS 2. With respect to the task performed by the system: Systems having

- 20. CLASIFICATION OF CONTROL SYTEMS 3. With respect to the instants of supervision: Continous-time control systems Discrete-time

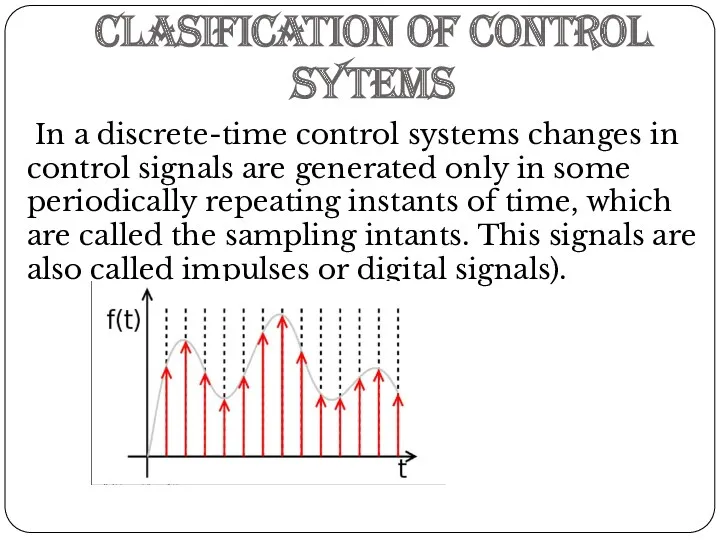

- 21. CLASIFICATION OF CONTROL SYTEMS In a discrete-time control systems changes in control signals are generated only

- 22. CLASIFICATION OF CONTROL SYTEMS 4. With respect to the possibility of application of the superposition principle

- 23. THANK YOU

- 25. Скачать презентацию

Религия. Готовимся к ЕГЭ

Религия. Готовимся к ЕГЭ Налоги

Налоги Игра как активная форма развития воображения у детей дошкольного возраста

Игра как активная форма развития воображения у детей дошкольного возраста Силы взаимодействия винта, руля и корпуса судна

Силы взаимодействия винта, руля и корпуса судна Презентация Опыт работы Формирование эмоциональной отзывчивости дошкольников в театрализованной деятельности

Презентация Опыт работы Формирование эмоциональной отзывчивости дошкольников в театрализованной деятельности Специальные гидравлические машины пищевых производств, компрессоры и вакуум-насосы

Специальные гидравлические машины пищевых производств, компрессоры и вакуум-насосы Презентация Пудель

Презентация Пудель Зооветеринарный аудит в скотоводстве

Зооветеринарный аудит в скотоводстве Презентация Петров (1)

Презентация Петров (1) Роль притч в самоопределении личности учащихся в процессе преподавания курса ОРКСЭ

Роль притч в самоопределении личности учащихся в процессе преподавания курса ОРКСЭ Смутное время (1598 - 1613)

Смутное время (1598 - 1613) Семинар-практикум Синквейн в ознакомлении дошкольников с трудом взрослых

Семинар-практикум Синквейн в ознакомлении дошкольников с трудом взрослых Инфинит от ФОРЕВЕР

Инфинит от ФОРЕВЕР Индивидуально - типологические подходы на уроках математики.

Индивидуально - типологические подходы на уроках математики. Схема запуска преобразователя электропоезда ЭД2Т

Схема запуска преобразователя электропоезда ЭД2Т 20240201_postroyka_bashni

20240201_postroyka_bashni Транссибирская магистраль

Транссибирская магистраль Презентация Строение цветковых растений

Презентация Строение цветковых растений Принтер. Понятие

Принтер. Понятие Елементна база комп‘ютерної електроніки та аналогові електронні пристрої. Напівпровідникові діоди. (Тема 1.1)

Елементна база комп‘ютерної електроніки та аналогові електронні пристрої. Напівпровідникові діоди. (Тема 1.1) Масленица. Сказка

Масленица. Сказка Вероятностные методы обработки информации

Вероятностные методы обработки информации Классный час Наша первая отметка

Классный час Наша первая отметка Рождество в русской поэзии

Рождество в русской поэзии Состав и структура ракетно-космического комплекса. Лекция № 3

Состав и структура ракетно-космического комплекса. Лекция № 3 Синтоизм - национальная религия Японии

Синтоизм - национальная религия Японии Экологический мониторинг

Экологический мониторинг Кожевенное производство. Энерго- и ресурсосбережение

Кожевенное производство. Энерго- и ресурсосбережение