Содержание

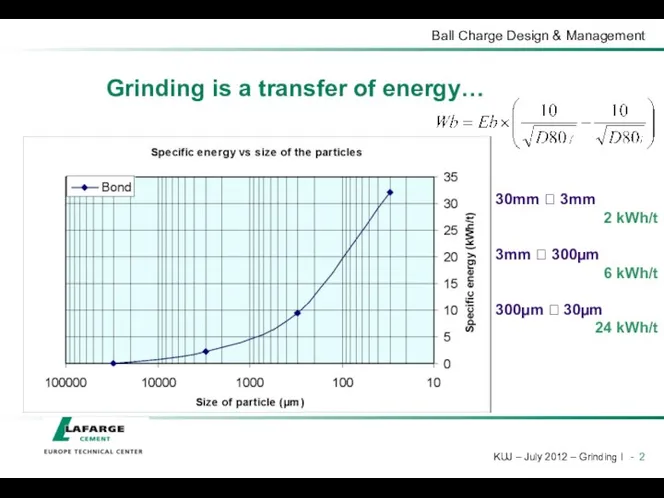

- 2. Grinding is a transfer of energy… 30mm ? 3mm 2 kWh/t 3mm ? 300µm 6 kWh/t

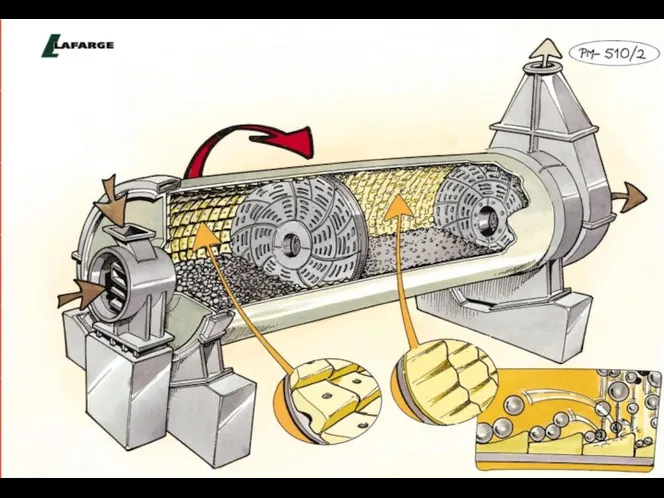

- 3. … from a mill to particles… (mill motors = 85% of the power absorbed in the

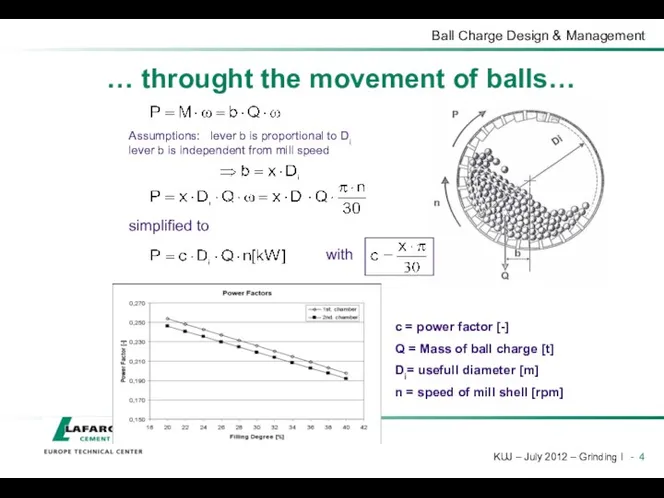

- 4. Assumptions: lever b is proportional to Di lever b is independent from mill speed c =

- 5. … with a poor efficiency (95% lost in heat) 50mm ? ~ 0,5mm Crushing is more

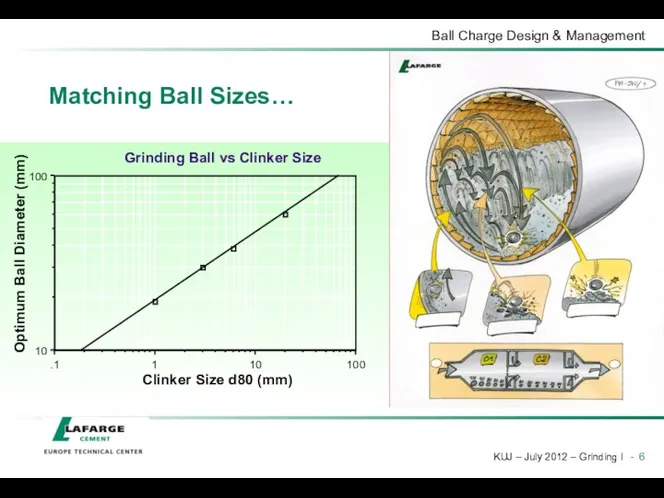

- 6. Matching Ball Sizes…

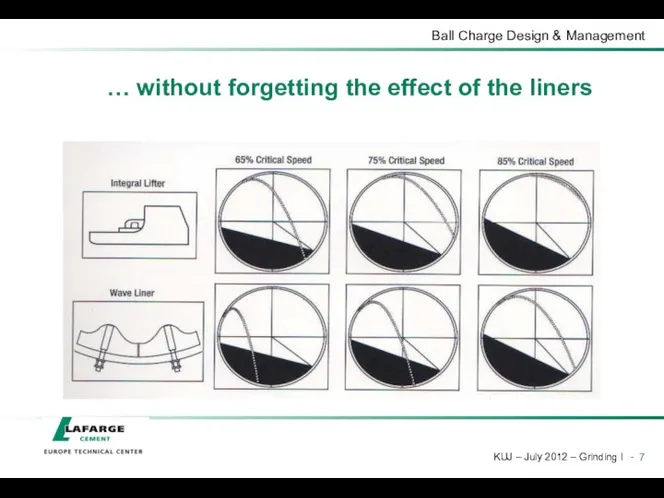

- 7. … without forgetting the effect of the liners

- 8. Porosity Average ball weight total charge weight / total number of balls kg/ball Specific surface area

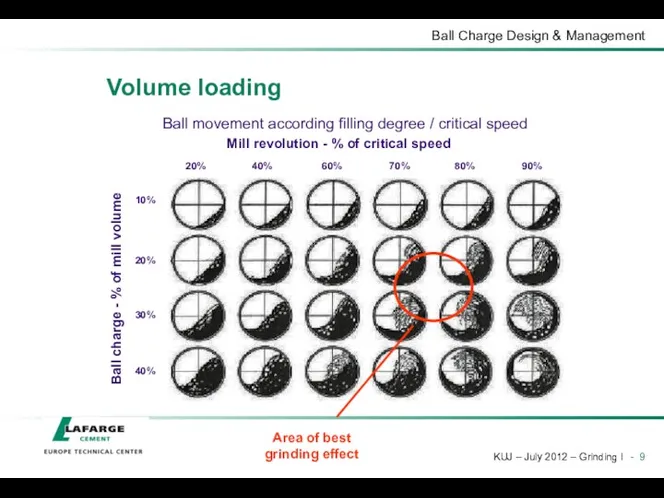

- 9. Ball movement according filling degree / critical speed Ball charge - % of mill volume Area

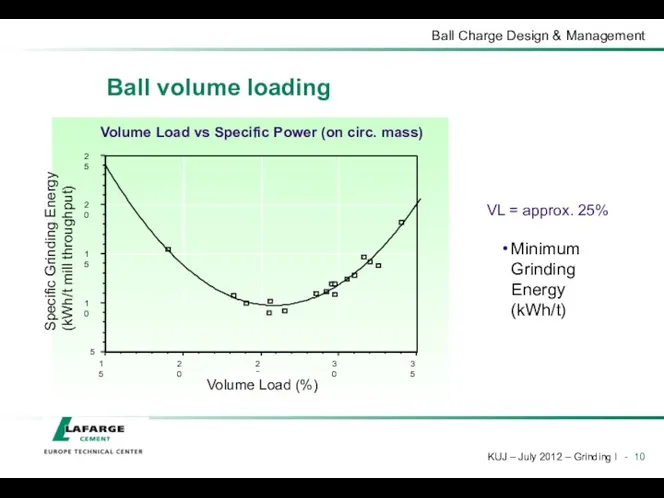

- 10. Ball volume loading Minimum Grinding Energy (kWh/t) VL = approx. 25%

- 11. A = Free surface S = Surface area of charge The required surface area [S] can

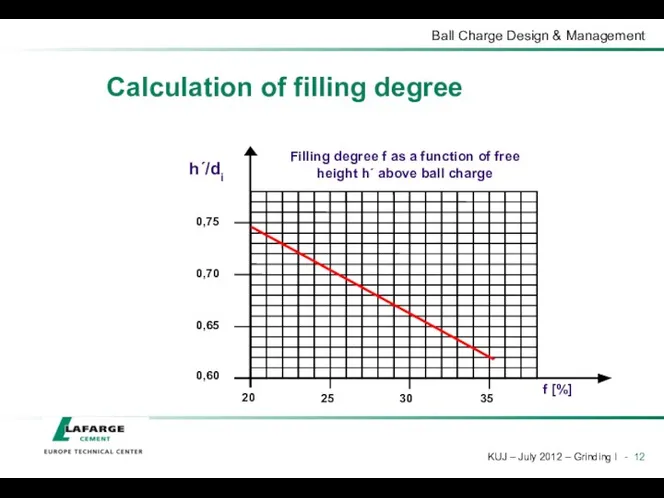

- 12. Calculation of filling degree

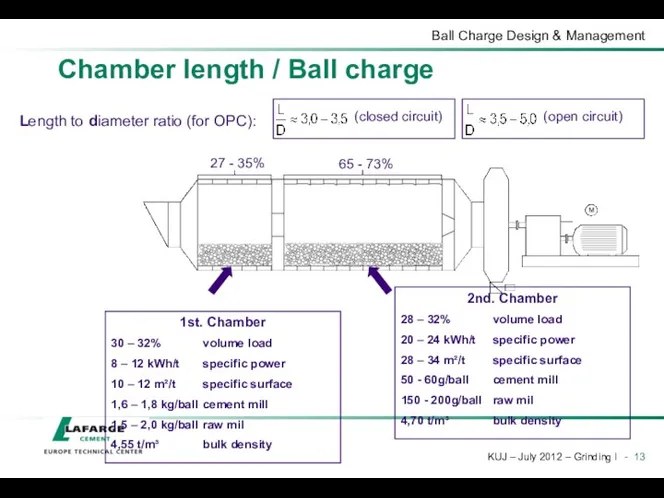

- 13. 27 - 35% 65 - 73% Length to diameter ratio (for OPC): 1st. Chamber 30 –

- 14. Ball Charge Fundamentals In a ball mill, the balls grind the material Match the charge to

- 15. How to design a ball charge and manage it? Calculation of a theoretical ball charge (always

- 16. Theoretical ball charge Parameters Product: type, composition, fineness, throughput… the ball charge design must produce the

- 17. Design methodology Numerous attempts to make the process more scientific and rigorous Slegten, Polysius Models Lafarge

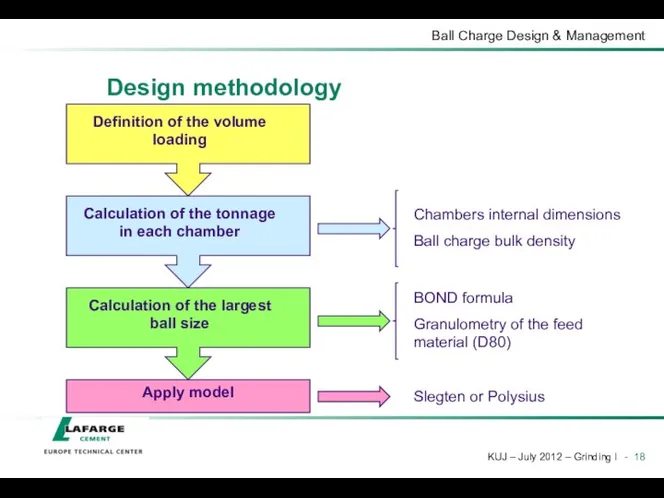

- 18. Design methodology

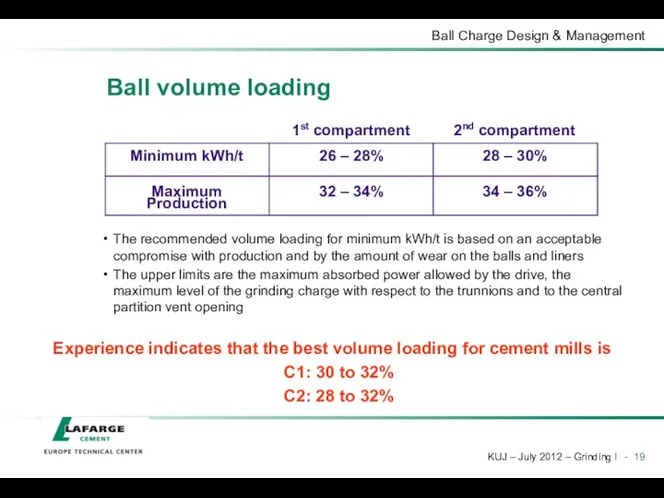

- 19. Ball volume loading The recommended volume loading for minimum kWh/t is based on an acceptable compromise

- 20. Biggest ball where, Ømax = biggest ball diameter, mm D20 = sieve dimension where 20% is

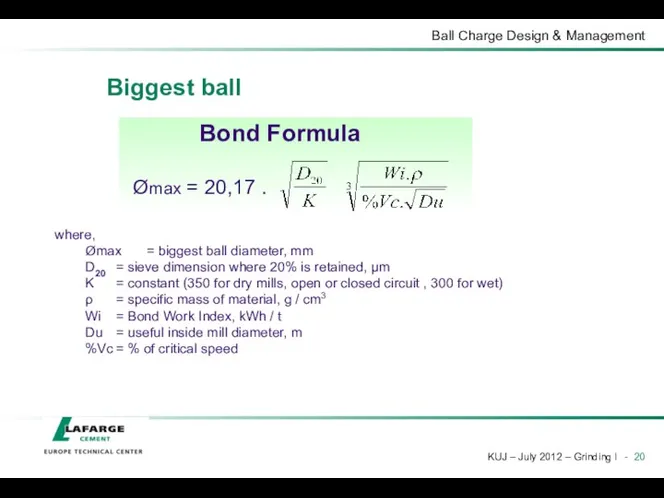

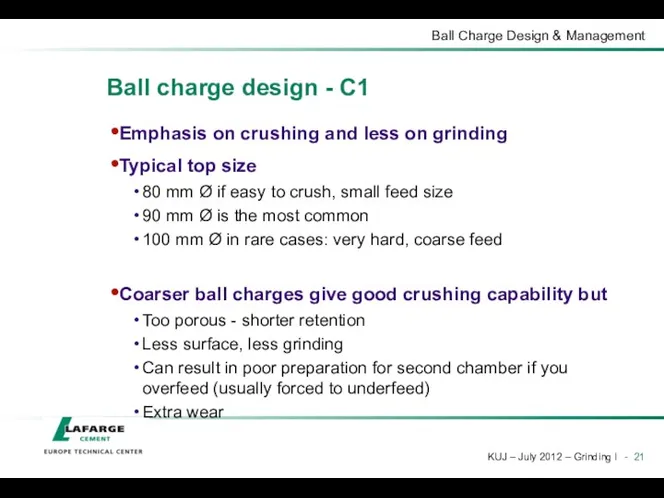

- 21. Ball charge design - C1 Emphasis on crushing and less on grinding Typical top size 80

- 22. Ball charge design - C2 Emphasis on attrition grinding Cement grinding wants maximum fines generation (Blaine)

- 23. Effective length curves Convert the % weight to equivalent % length Plot effective mill length vs.

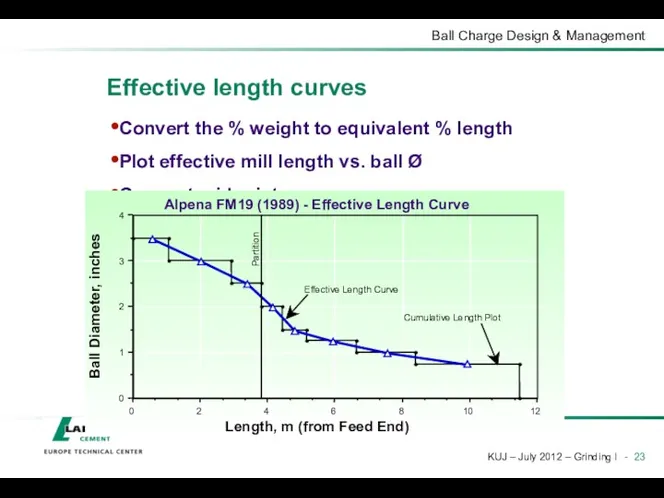

- 24. Why use a curve? Only so much grinding can be done over a given length of

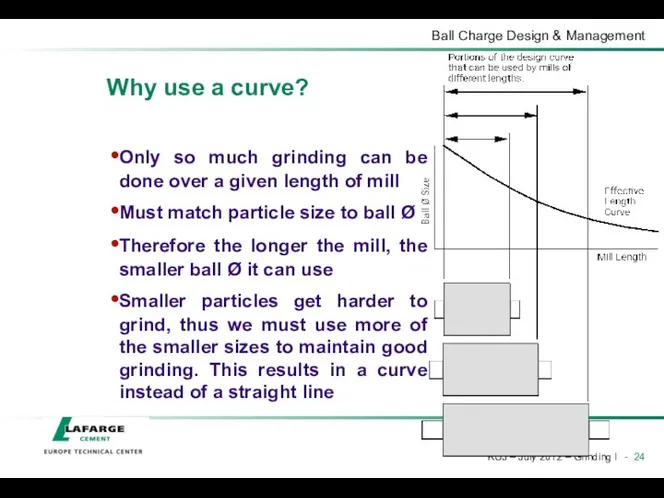

- 25. Polysius design Use exponential curve Start with 90mm top size Result depends on compartment length @

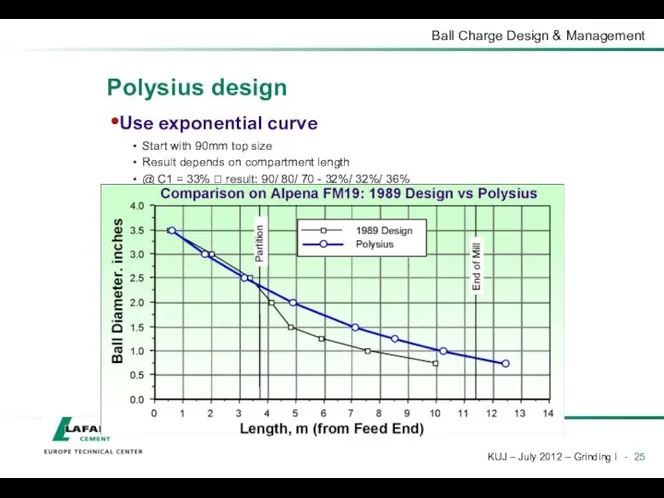

- 26. Slegten Model Divides the mill into 3 parts Preparation in the 1st Compartment Same quantity of

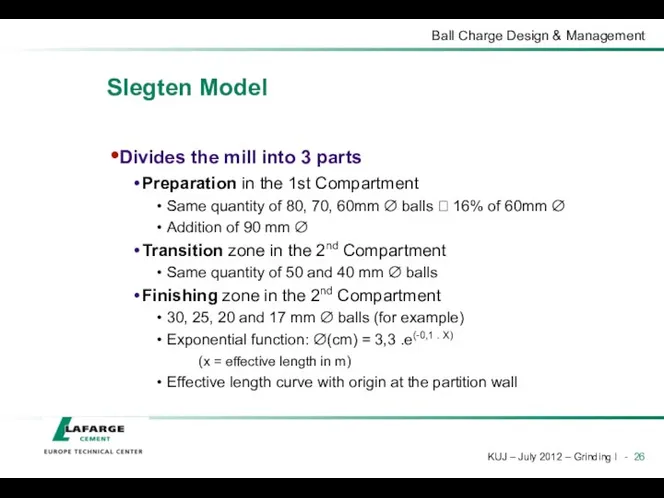

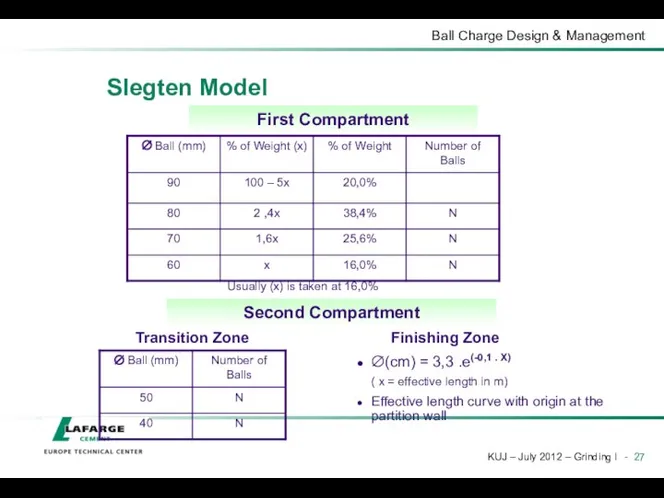

- 27. Slegten Model First Compartment Usually (x) is taken at 16,0% Second Compartment Transition Zone Finishing Zone

- 28. Slegten model example calculation Material characteristics Clinker D80 = 15 mm Wi = 13,49 kWh/t ρ

- 29. Slegten model example calculation Closed circuit cement mill L/D = 3 Du = 3,65 m Lu

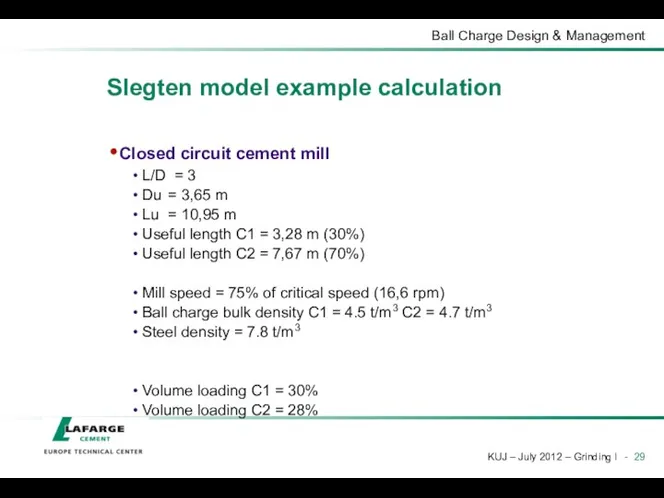

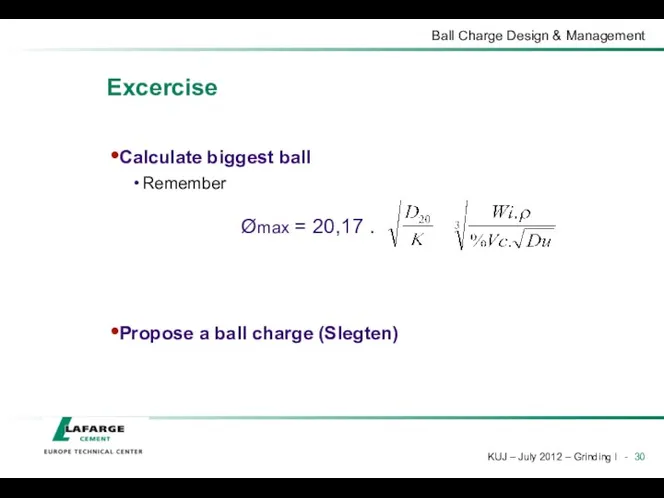

- 30. Excercise Calculate biggest ball Remember Propose a ball charge (Slegten)

- 31. Ball charge optimization (existing mill) Calculate theoretical ball charge as a reference Perform a mill audit

- 32. Ball charge management Having a well-designed ball charge is one thing… … but you need to

- 33. Top-ups Follow-up at least every month Check mill power consumption (same product every time) Free height

- 34. Ball charge sorting Objective Eliminate scrap, broken and undersize balls scrap = foreign metallic elements polluting

- 35. Sorting method Purge mill, take everything out of the compartment Sort, weigh and record By size

- 37. Скачать презентацию

Адаптированная программа дошкольного образования для детей с задержкой психического развития

Адаптированная программа дошкольного образования для детей с задержкой психического развития Материалы к Празднику знаний -1сентября Диск

Материалы к Празднику знаний -1сентября Диск Внеклассное мероприятие Вежливые слова

Внеклассное мероприятие Вежливые слова Своя игра (игра-соревнование)

Своя игра (игра-соревнование) Мировая экономика

Мировая экономика Азбука безопасности. Словарик

Азбука безопасности. Словарик هوش مصنوعی

هوش مصنوعی 20231026_osobennosti_organizatsii_olimpiad_po_informatike

20231026_osobennosti_organizatsii_olimpiad_po_informatike Презентация к практическому занятию по химии в 5 классе.

Презентация к практическому занятию по химии в 5 классе. D элементтеріне жалпы сипаттама

D элементтеріне жалпы сипаттама Разработка системы автоматического регулирования питания барабанного котельного агрегата водой (на материалах АО ССГПО)

Разработка системы автоматического регулирования питания барабанного котельного агрегата водой (на материалах АО ССГПО) Русь в правление Ивана Грозного (1533 - 1584)

Русь в правление Ивана Грозного (1533 - 1584) Медико-демографические проблемы населения России

Медико-демографические проблемы населения России Мультибрендовая платформа FROZA. Автозапчасти и аксессуары для авто, мото, грузовой и спецтехники

Мультибрендовая платформа FROZA. Автозапчасти и аксессуары для авто, мото, грузовой и спецтехники Modern construction technologies

Modern construction technologies Новая система обращения с твердыми коммунальными отходами

Новая система обращения с твердыми коммунальными отходами Социальная сеть Facebook

Социальная сеть Facebook Интеллектуальная игра Пентагон

Интеллектуальная игра Пентагон Загадки про грибы

Загадки про грибы Понятие и сущность международного права. (Лекция 1)

Понятие и сущность международного права. (Лекция 1) Подготовка деталей перед сборкой и сваркой. Сборка и сварка

Подготовка деталей перед сборкой и сваркой. Сборка и сварка Великобритания во второй половине XX века

Великобритания во второй половине XX века презентация №Фенол

презентация №Фенол Индекс экономической безопасности

Индекс экономической безопасности Балалардағы экг ерекшеліктері.Жүрек тондарының пайда болу механизмдері

Балалардағы экг ерекшеліктері.Жүрек тондарының пайда болу механизмдері Определение надежности, безотказности, работоспособности, долговечности, ремонтопригодности

Определение надежности, безотказности, работоспособности, долговечности, ремонтопригодности Семья.Семейные ценности.

Семья.Семейные ценности. Возбудитель коклюша Bordetella pertussis

Возбудитель коклюша Bordetella pertussis