Содержание

- 2. ROLLER MILL

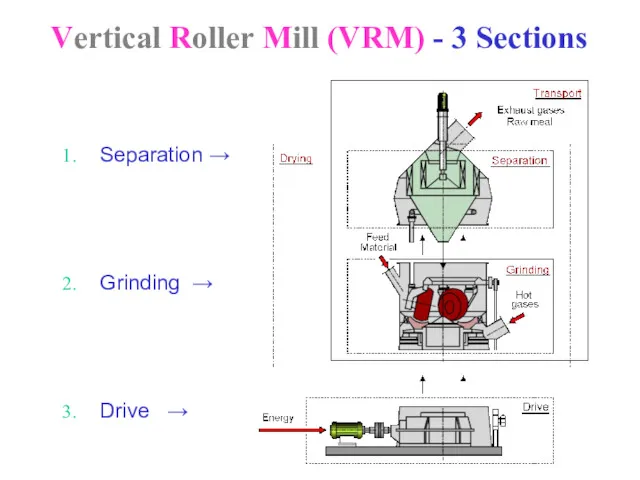

- 3. Vertical Roller Mill (VRM) - 3 Sections Separation → Grinding → Drive →

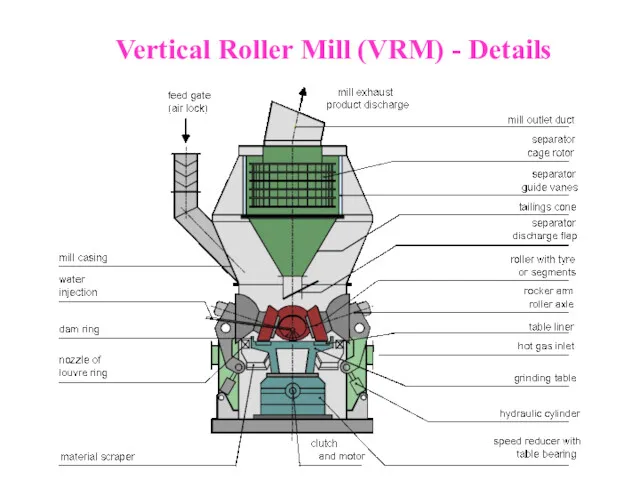

- 4. Vertical Roller Mill (VRM) - Details

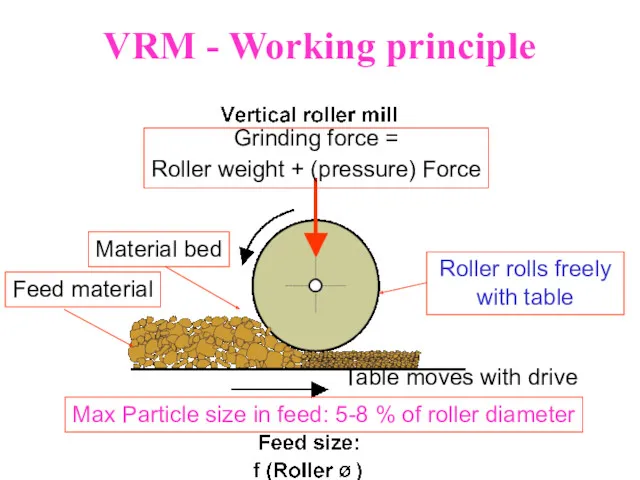

- 5. VRM - Working principle Material bed Feed material Max Particle size in feed: 5-8 % of

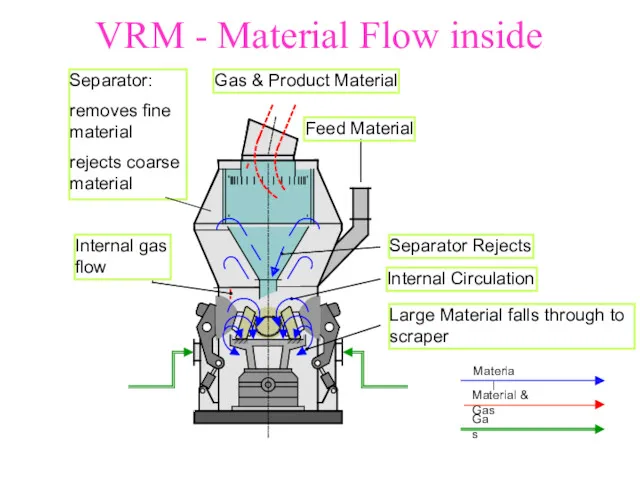

- 6. VRM - Material Flow inside Gas & Product Material Feed Material Separator Rejects Internal Circulation Large

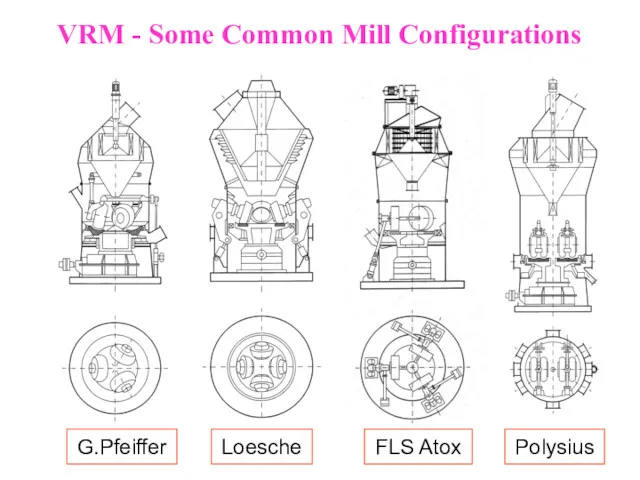

- 7. VRM - Some Common Mill Configurations G.Pfeiffer Loesche FLS Atox Polysius

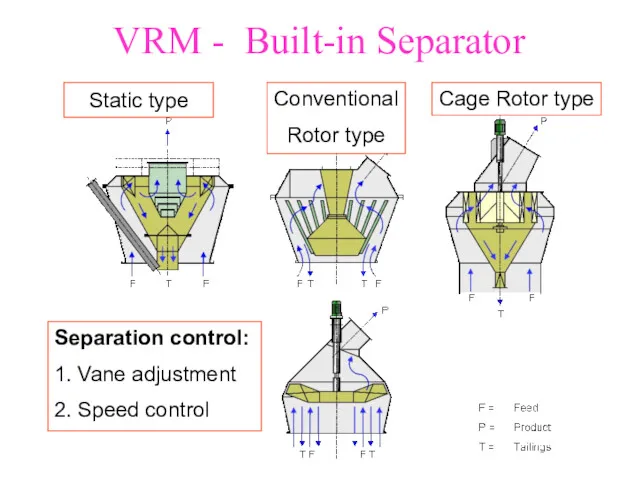

- 8. VRM - Built-in Separator Cage Rotor type Conventional Rotor type Static type Separation control: 1. Vane

- 9. Separators of 3rd Generation (Vertical roller mill) Guide vane system Reject cone Cage rotor

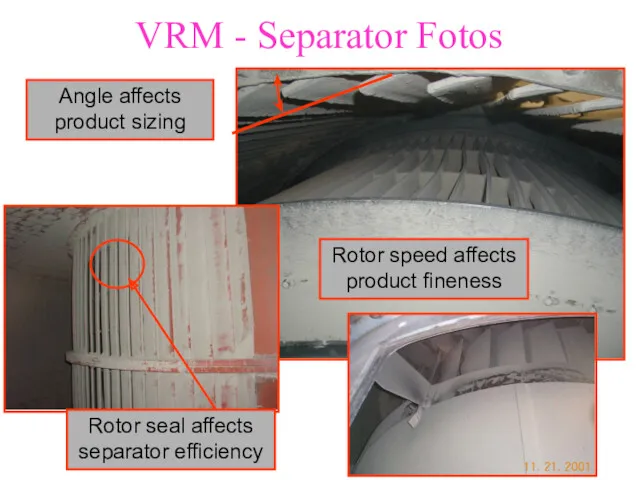

- 10. VRM - Separator Fotos Angle affects product sizing Rotor speed affects product fineness Rotor seal affects

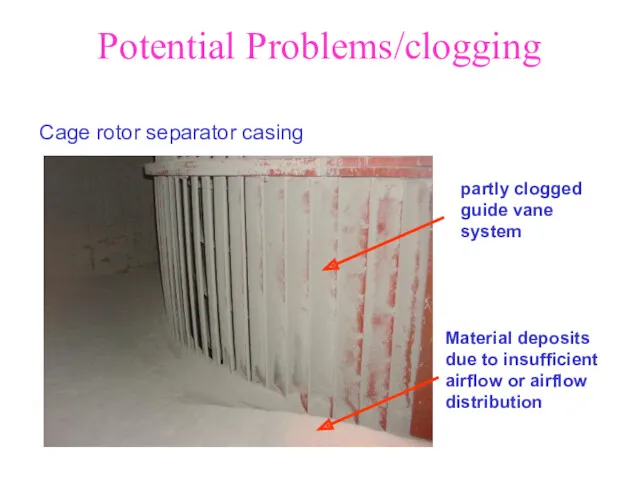

- 11. Potential Problems/clogging Cage rotor separator casing partly clogged guide vane system Material deposits due to insufficient

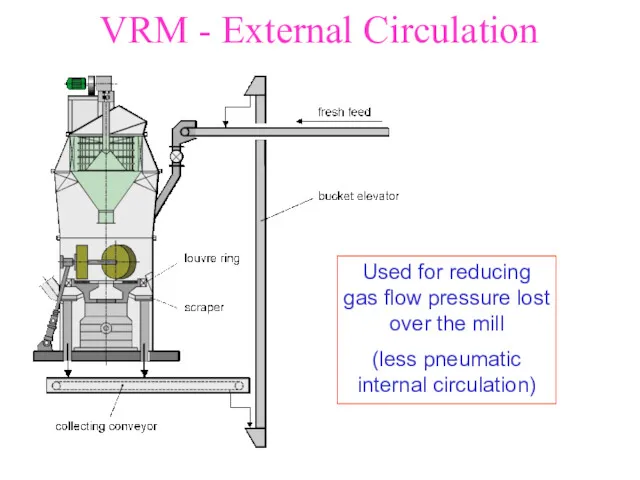

- 12. VRM - External Circulation Used for reducing gas flow pressure lost over the mill (less pneumatic

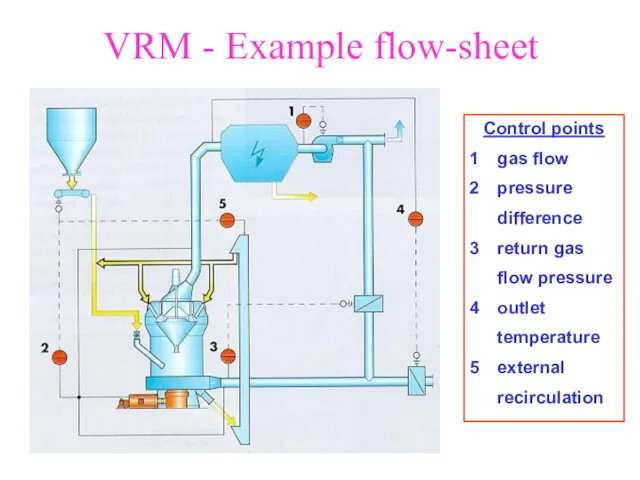

- 13. VRM - Example flow-sheet Control points gas flow pressure difference return gas flow pressure outlet temperature

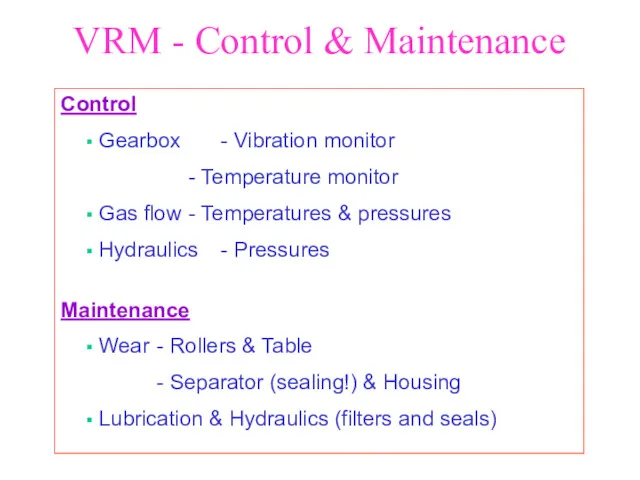

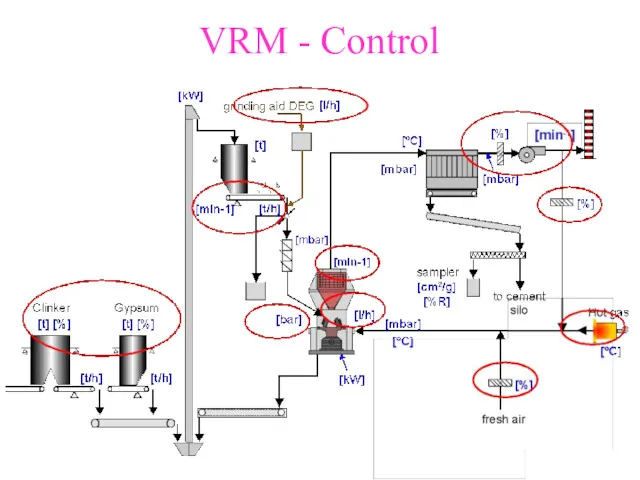

- 14. VRM - Control & Maintenance Control Gearbox - Vibration monitor - Temperature monitor Gas flow -

- 15. VRM - Control

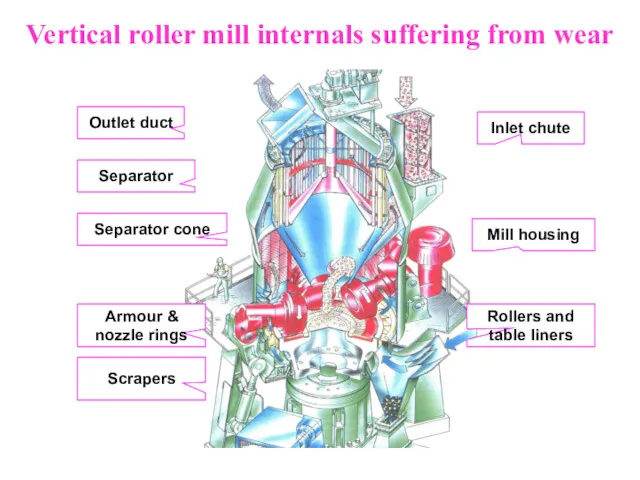

- 16. Outlet duct Inlet chute Mill housing Armour & nozzle rings Rollers and table liners Separator cone

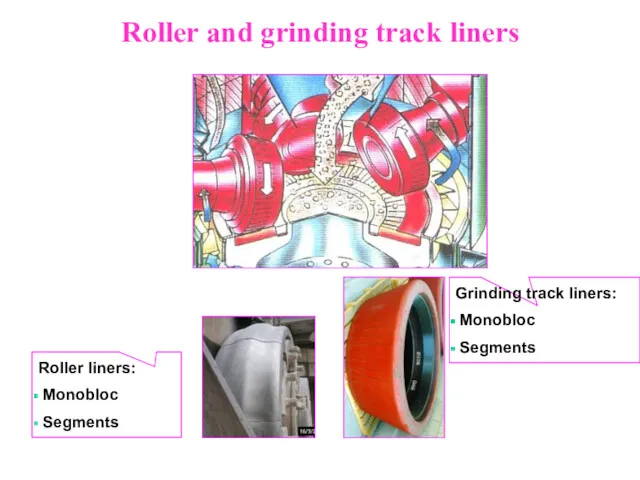

- 17. Roller and grinding track liners Roller liners: Monobloc Segments Grinding track liners: Monobloc Segments

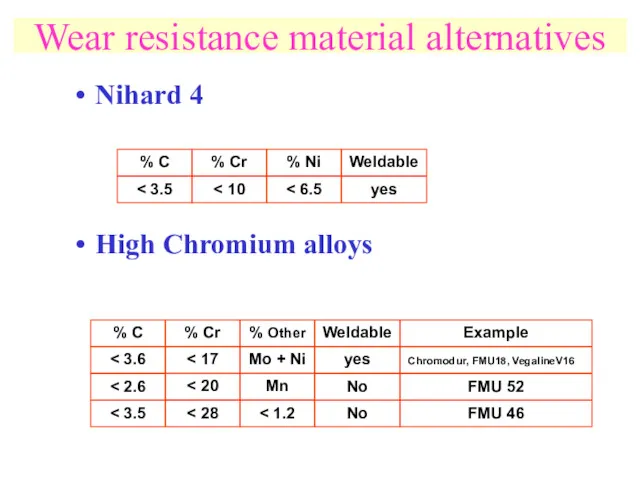

- 18. Nihard 4 High Chromium alloys Wear resistance material alternatives % C % Cr % Ni Weldable

- 19. Wear resistance material alternatives Metallic inserts roller liner Hard metallic insert Soft material base

- 20. Ceramic inserts roller and grinding track liners Wear resistance material alternatives Metallic base (High Cr) Ceramic

- 21. Wear rate monitoring Minimum allowed thickness 2’500 [h] = 50 [mm] 40 [mm] = ~ 2’000

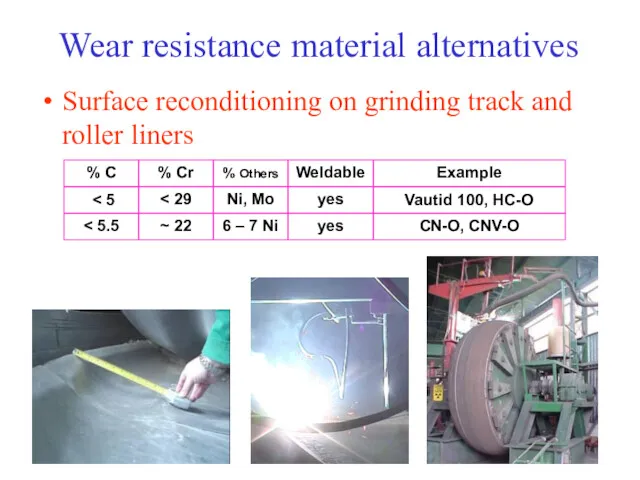

- 22. Wear resistance material alternatives Surface reconditioning on grinding track and roller liners % C % Cr

- 24. Скачать презентацию

![Wear rate monitoring Minimum allowed thickness 2’500 [h] = 50](/_ipx/f_webp&q_80&fit_contain&s_1440x1080/imagesDir/jpg/137392/slide-20.jpg)

Көз, мұрын, құлақ қуысын күту іс-әрекеттері

Көз, мұрын, құлақ қуысын күту іс-әрекеттері Разметка, рубка металла, гибка труб

Разметка, рубка металла, гибка труб Линии влияния в плоских статически определимых фермах

Линии влияния в плоских статически определимых фермах Арт-терапия

Арт-терапия День Петра и Февронии

День Петра и Февронии Интеллектуально-развивающая игра Говорун-шоу

Интеллектуально-развивающая игра Говорун-шоу ЗДОЛ Исетские Зори г. Каменск-Уральский. Лагерь Профессии будущего

ЗДОЛ Исетские Зори г. Каменск-Уральский. Лагерь Профессии будущего Экологическое право

Экологическое право Методы организации послепродажного обслуживания

Методы организации послепродажного обслуживания Родителям пятиклассников. Проблемы адаптации

Родителям пятиклассников. Проблемы адаптации Пожарная безопасность, организация противопожарной защиты учреждения

Пожарная безопасность, организация противопожарной защиты учреждения Music and TV by Ukrainian Americans

Music and TV by Ukrainian Americans Устройство ЭВМ

Устройство ЭВМ Пенсійна реформа в Україні

Пенсійна реформа в Україні Количество информации как мера уменьшения неопределенности знания

Количество информации как мера уменьшения неопределенности знания Личность и ее характеристики

Личность и ее характеристики Анализ финансово-хозяйственной деятельности компании

Анализ финансово-хозяйственной деятельности компании нормативная система оценки риска (часть 2)

нормативная система оценки риска (часть 2) Основной капитал организации. Тема 7

Основной капитал организации. Тема 7 История села Усть-Золиха ( Мессер)

История села Усть-Золиха ( Мессер) Російський балет ХХ століття

Російський балет ХХ століття Рабочие программы

Рабочие программы Бережливое производство в производственной системе АО ВИС. Группа ОАТ

Бережливое производство в производственной системе АО ВИС. Группа ОАТ Классный час на тему Дружба крепкая…

Классный час на тему Дружба крепкая… Планирование, подготовка и организация дипломатических переговоров

Планирование, подготовка и организация дипломатических переговоров Сложение и вычитание десятичных дробей

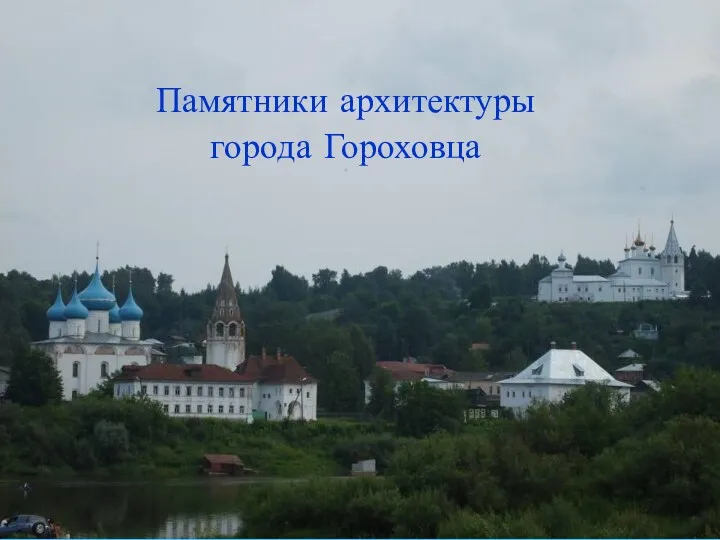

Сложение и вычитание десятичных дробей Памятники архитектуры города Гороховца

Памятники архитектуры города Гороховца Что мы знаем о происхождении шахматной игры?

Что мы знаем о происхождении шахматной игры?