Содержание

- 2. Ceramics A wide-ranging group of materials whose ingredients are clays, sand and felspar.

- 3. Clays Contain some of the following: Silicon & Aluminium as silicates Potassium compounds Magnesium compounds Calcium

- 4. Types of Ceramics Whitewares Refractories Glasses Abrasives Cements

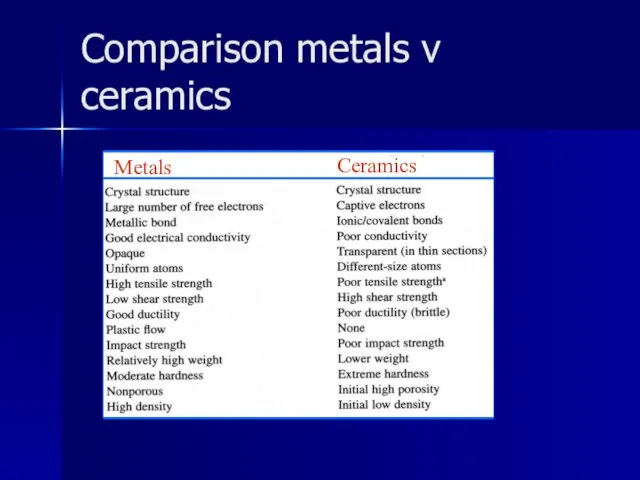

- 5. Comparison metals v ceramics

- 6. Bonded Clay Ceramics Made from natural clays and mixtures of clays and added crystalline ceramics. These

- 7. Whitewares Crockery Floor and wall tiles Sanitary-ware Electrical porcelain Decorative ceramics

- 8. Whiteware: Bathrooms

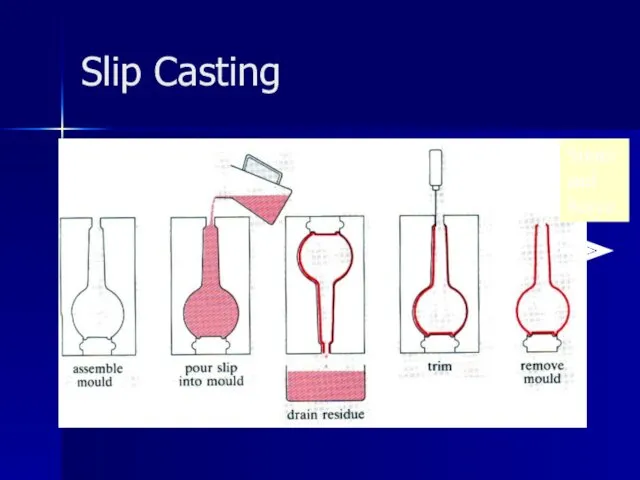

- 9. Slip Casting Sinter and Serve

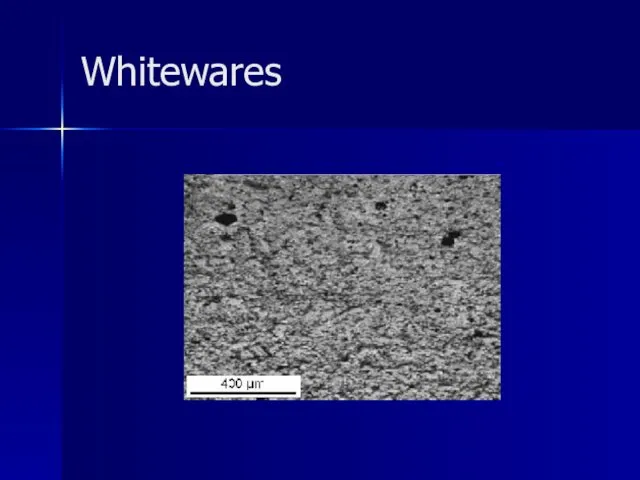

- 10. Whitewares

- 11. Refractories Firebricks for furnaces and ovens. Have high Silicon or Aluminium oxide content. Brick products are

- 12. Refractories Used to provide thermal protection of other materials in very high temperature applications, such as

- 13. Refractory Brick

- 14. Amorphous Ceramics (Glasses) Main ingredient is Silica (SiO2) If cooled very slowly will form crystalline structure.

- 15. Glass Types Three common types of glass: Soda-lime glass - 95% of all glass, windows containers

- 16. Glasses Flat glass (windows) Container glass (bottles) Pressed and blown glass (dinnerware) Glass fibres (home insulation)

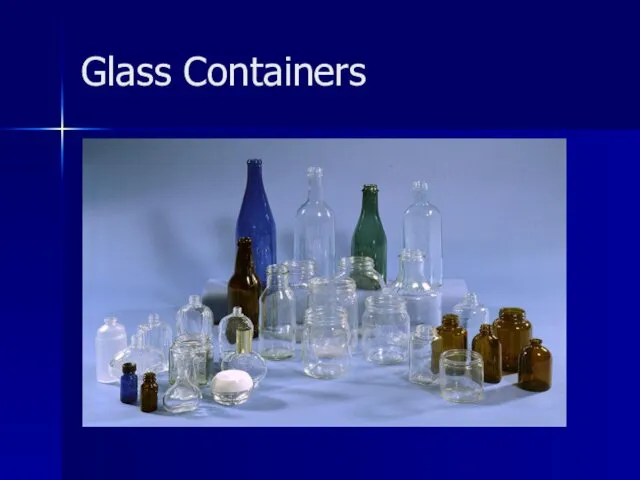

- 17. Glass Containers

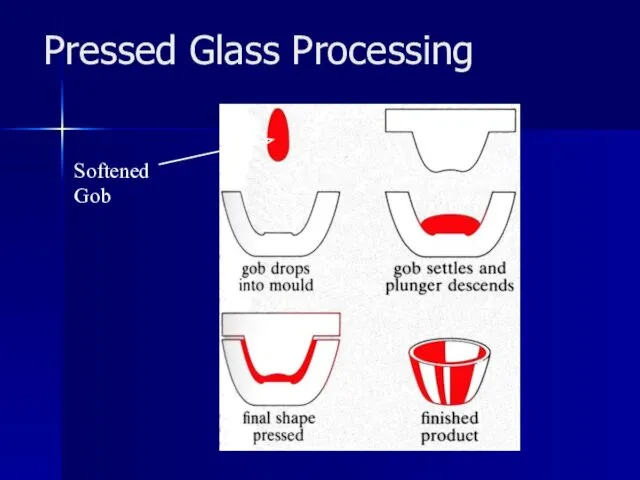

- 18. Pressed Glass Processing Softened Gob

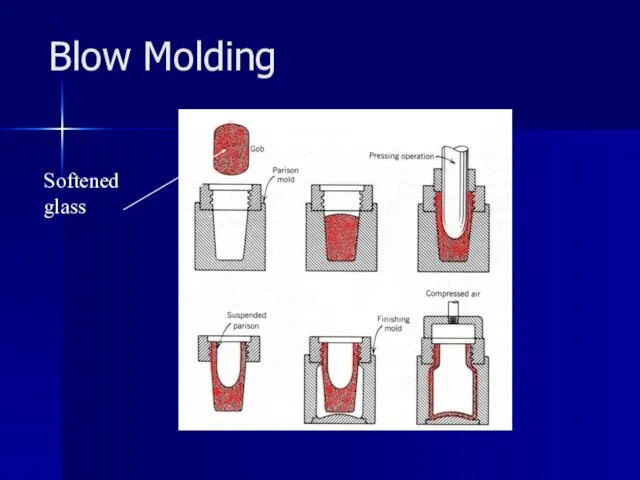

- 19. Blow Molding Softened glass

- 20. Glass in Buildings

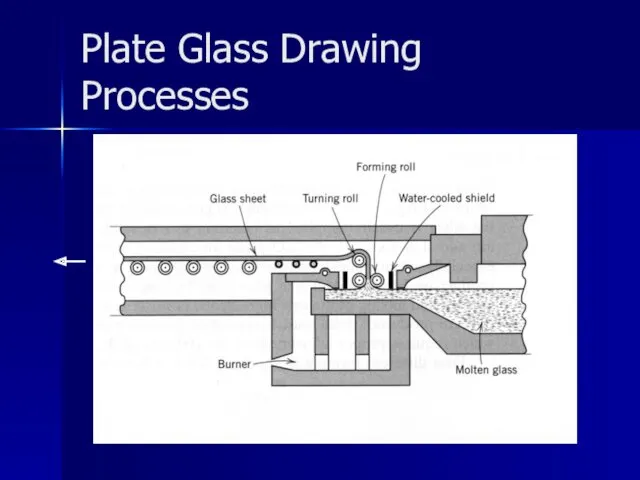

- 21. Plate Glass Drawing Processes

- 22. Tempered Glass The strength of glass can be enhanced by inducing compressive residual stresses at the

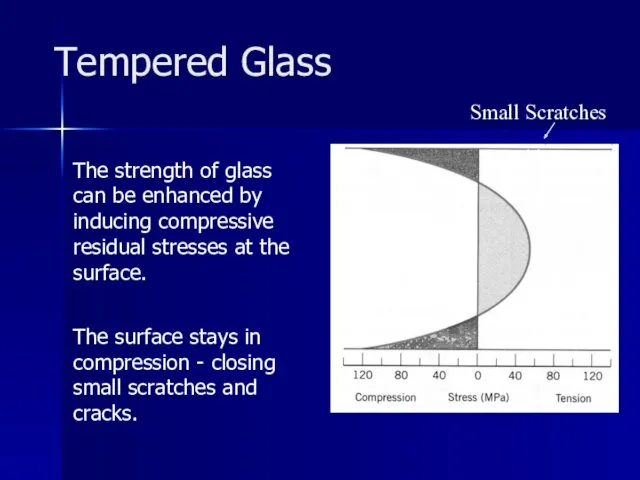

- 23. Hardening Processes Tempering: Glass heated above Tg but below the softening point Cooled to room temp

- 24. Armoured Glass Many have tried to gain access with golf clubs and baseball bats but obviously

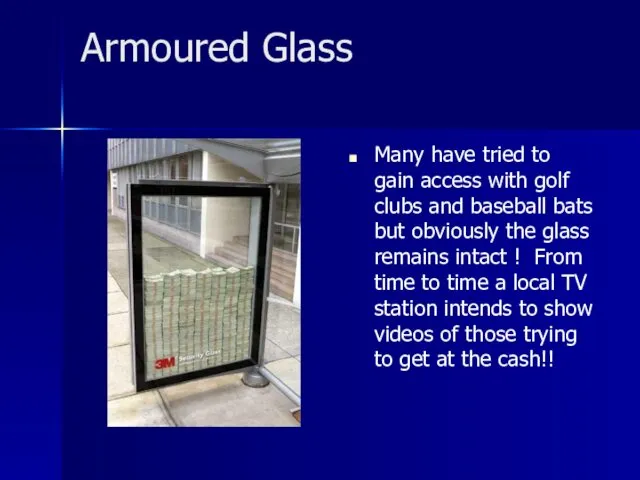

- 25. Leaded Glass

- 26. Crystalline Ceramics Good electrical insulators and refractories. Magnesium Oxide is used as insulation material in heating

- 27. Abrasives Natural (garnet, diamond, etc.) Synthetic abrasives (silicon carbide, diamond, fused alumina, etc.) are used for

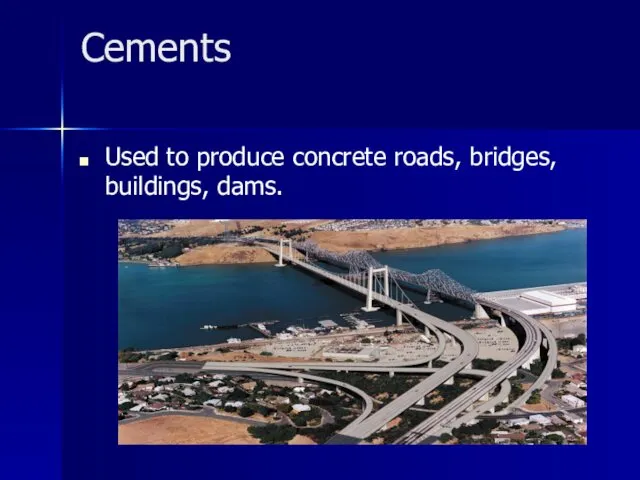

- 28. Cements Used to produce concrete roads, bridges, buildings, dams.

- 29. Advanced Ceramics Advanced ceramic materials have been developed over the past half century Applied as thermal

- 30. Advanced Ceramics Structural: Wear parts, bioceramics, cutting tools, engine components, armour. Electrical: Capacitors, insulators, integrated circuit

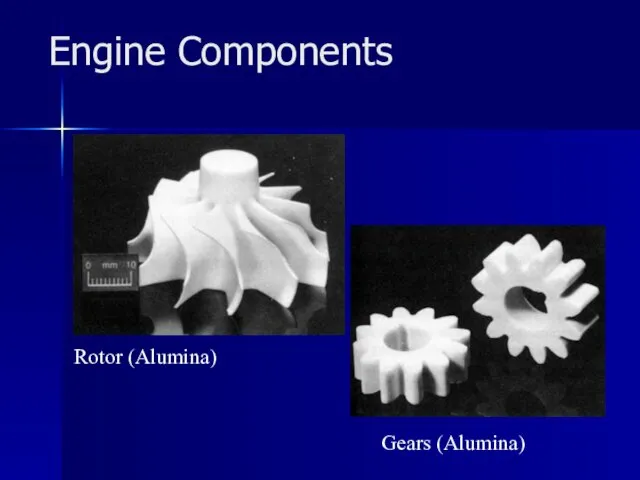

- 31. Engine Components Rotor (Alumina) Gears (Alumina)

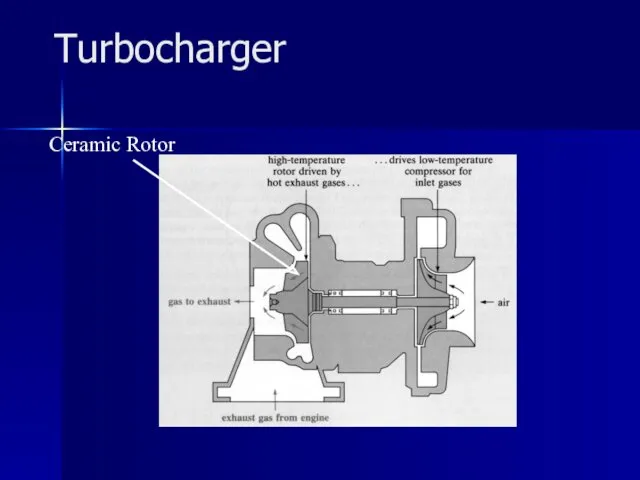

- 32. Turbocharger Ceramic Rotor

- 33. Ceramic Brake Discs

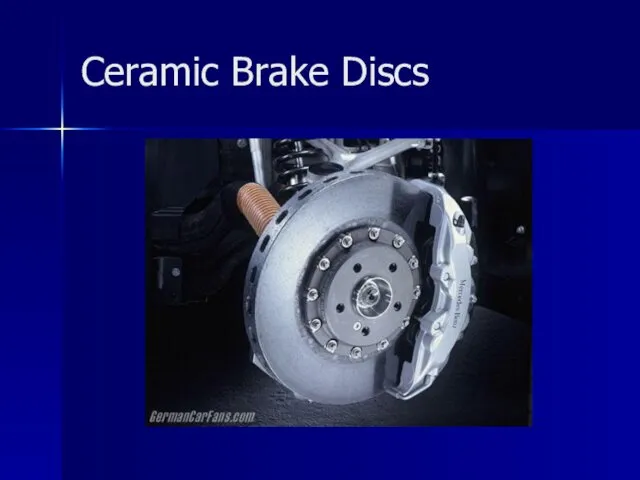

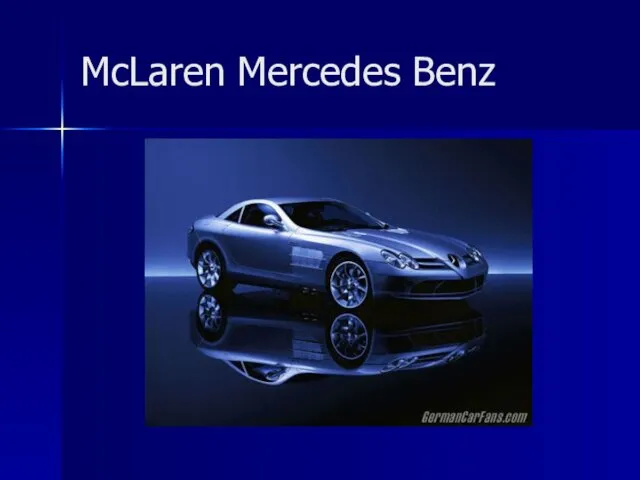

- 34. McLaren Mercedes Benz

- 35. Silicon Carbide Automotive Components in Silicon Carbide Chosen for its heat and wear resistance

- 36. Ceramic Armour Ceramic armour systems are used to protect military personnel and equipment. Advantage: low density

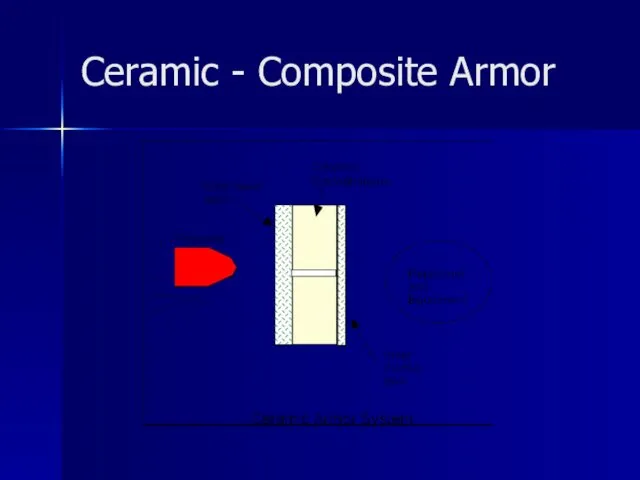

- 37. Most of the impact energy is absorbed by the fracturing of the ceramic and any remaining

- 38. Ceramic - Composite Armor

- 40. Скачать презентацию

Common suffixes for nouns

Common suffixes for nouns Презентация Преображение Господне

Презентация Преображение Господне Плоскостная разметка металла

Плоскостная разметка металла Растения. Заготовка и сушка семян

Растения. Заготовка и сушка семян Кроссворд по информатике

Кроссворд по информатике Презентация Зимующие птицы

Презентация Зимующие птицы Визитная карточка участницы конкурса Воспитатель года 2010 Быстровой С.В.

Визитная карточка участницы конкурса Воспитатель года 2010 Быстровой С.В. Налог на прибыль. Налогоплательщики налога на прибыль

Налог на прибыль. Налогоплательщики налога на прибыль МЕТОДИЧЕСКИЕ РАЗРАБОТКИ ПО ЛОГОПЕДИИ. ИГРА-ПРЕЗЕНТАЦИЯ Доскажи словечко

МЕТОДИЧЕСКИЕ РАЗРАБОТКИ ПО ЛОГОПЕДИИ. ИГРА-ПРЕЗЕНТАЦИЯ Доскажи словечко Разработка приложения для обмена текстовыми сообщениями по сетям TCP/IP в защищенном исполнении

Разработка приложения для обмена текстовыми сообщениями по сетям TCP/IP в защищенном исполнении 20231204_itogovyy_individualnyy_proekt_kak_forma_itogovoy_attestatsii_dostizheniy

20231204_itogovyy_individualnyy_proekt_kak_forma_itogovoy_attestatsii_dostizheniy Острый насморк (ринит)

Острый насморк (ринит) День памяти Неизвестному солдату.

День памяти Неизвестному солдату. Дыхательная гимнастика

Дыхательная гимнастика Дәрігердің қоғамда алатын орны

Дәрігердің қоғамда алатын орны Предмет и объект социальной педагогики

Предмет и объект социальной педагогики Роботы. Понятие о принципах работы роботов

Роботы. Понятие о принципах работы роботов Метод учебного проекта

Метод учебного проекта Классный час О вреде курения

Классный час О вреде курения Память. Триггеры и защелки

Память. Триггеры и защелки івномірний прямолінійний рух. Шлях і переміщення. Швидкість руху. Рівняння рівномірного прямолінійного руху

івномірний прямолінійний рух. Шлях і переміщення. Швидкість руху. Рівняння рівномірного прямолінійного руху Логика предикатов. ДМ.13

Логика предикатов. ДМ.13 Сущность понятия Педагогическая технология и его научные аспекты

Сущность понятия Педагогическая технология и его научные аспекты Tooth structure

Tooth structure Презентация к уроку ИЗО

Презентация к уроку ИЗО Конструкционные функциональные волокнистые композиты. Полимерные матричные материалы

Конструкционные функциональные волокнистые композиты. Полимерные матричные материалы Презентация Приобщение детей к народному творчеству

Презентация Приобщение детей к народному творчеству 20231009_otkrytyy_urok_v_10_klasse

20231009_otkrytyy_urok_v_10_klasse