Содержание

- 2. content Well concept evolution Case for charge testing Test set-up / test conditions Charge test results

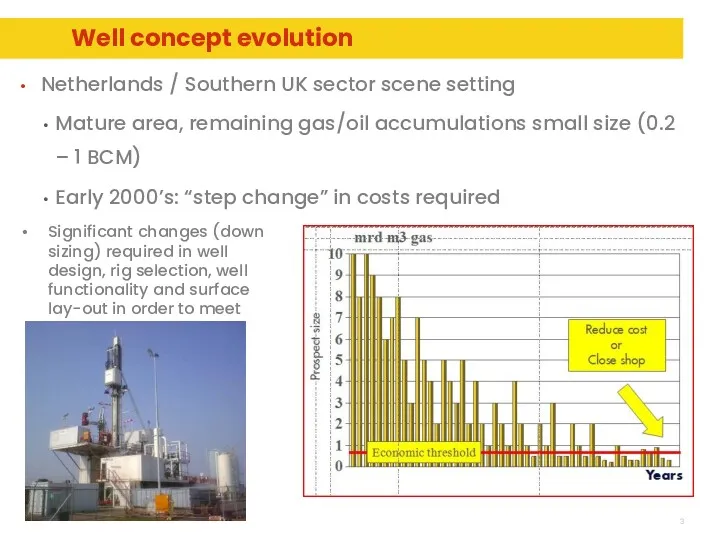

- 3. Well concept evolution Netherlands / Southern UK sector scene setting Mature area, remaining gas/oil accumulations small

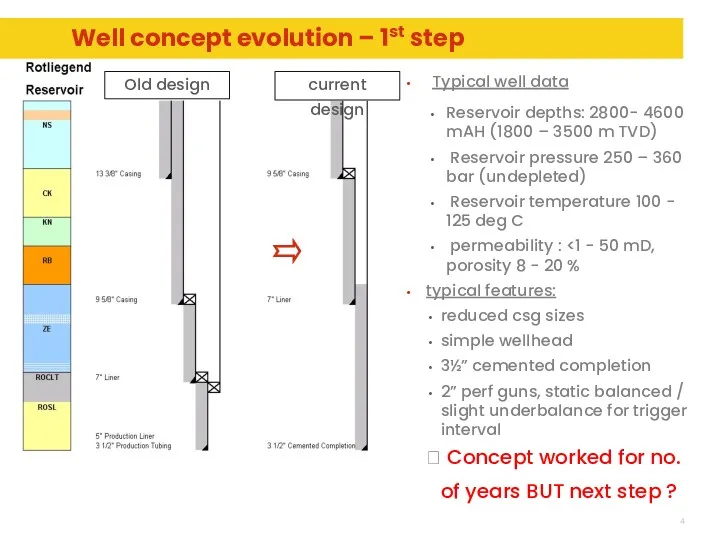

- 4. Well concept evolution – 1st step Typical well data Reservoir depths: 2800- 4600 mAH (1800 –

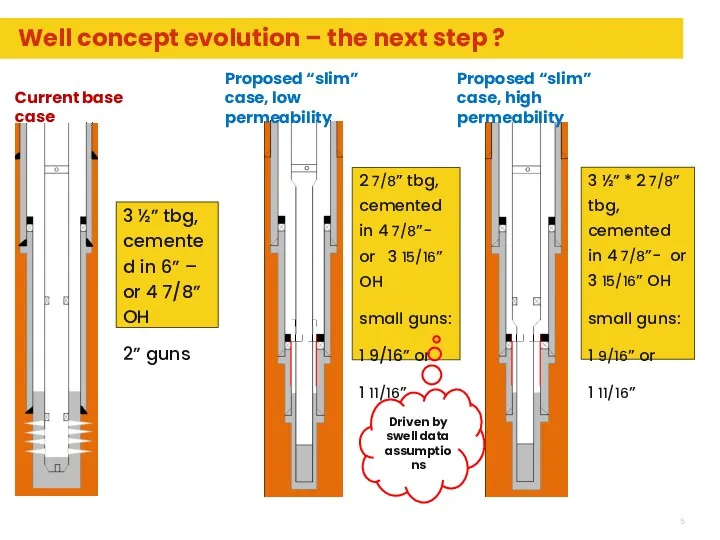

- 5. Well concept evolution – the next step ? Current base case 3 ½” tbg, cemented in

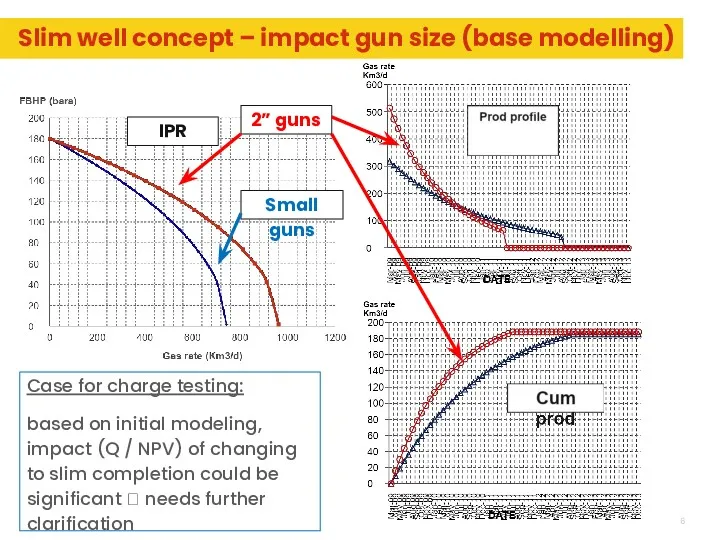

- 6. Slim well concept – impact gun size (base modelling) 2” guns Small guns IPR Case for

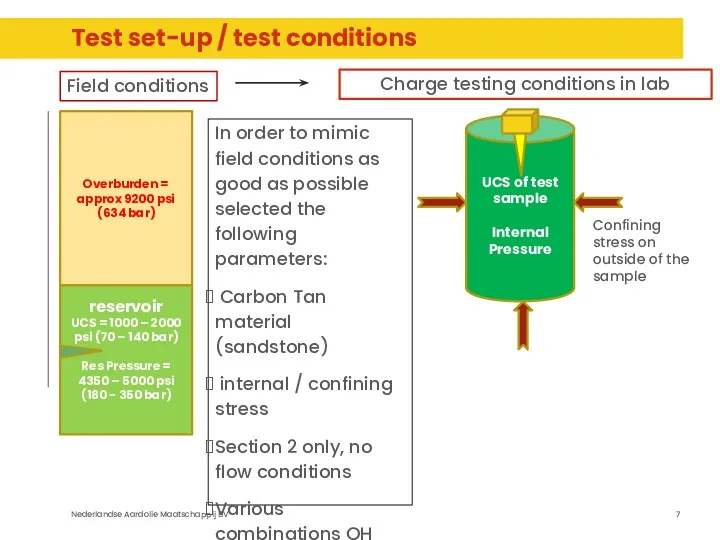

- 7. Charge testing conditions in lab reservoir UCS = 1000 – 2000 psi (70 – 140 bar)

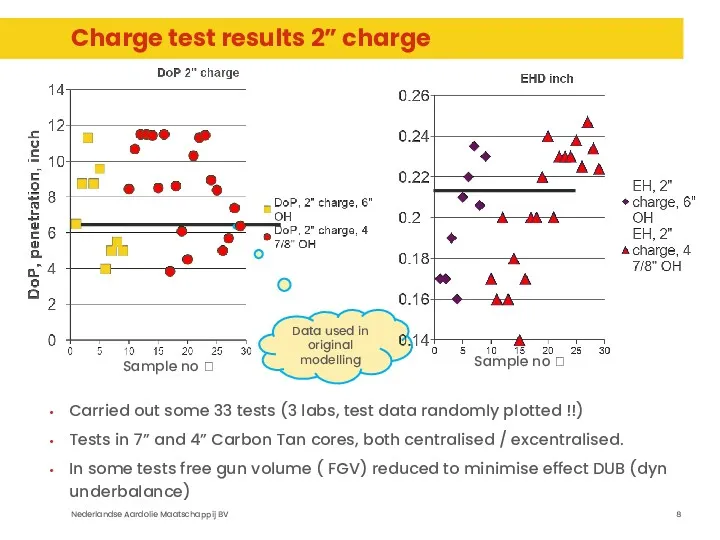

- 8. Charge test results 2” charge Carried out some 33 tests (3 labs, test data randomly plotted

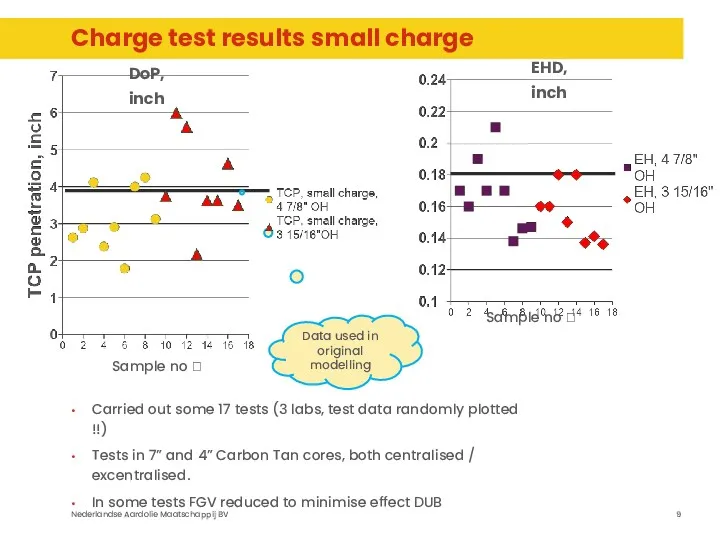

- 9. Charge test results small charge Carried out some 17 tests (3 labs, test data randomly plotted

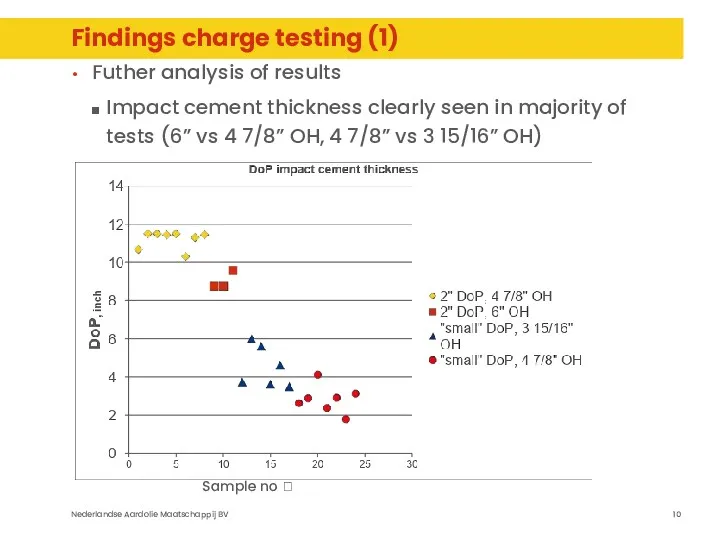

- 10. Findings charge testing (1) Futher analysis of results Impact cement thickness clearly seen in majority of

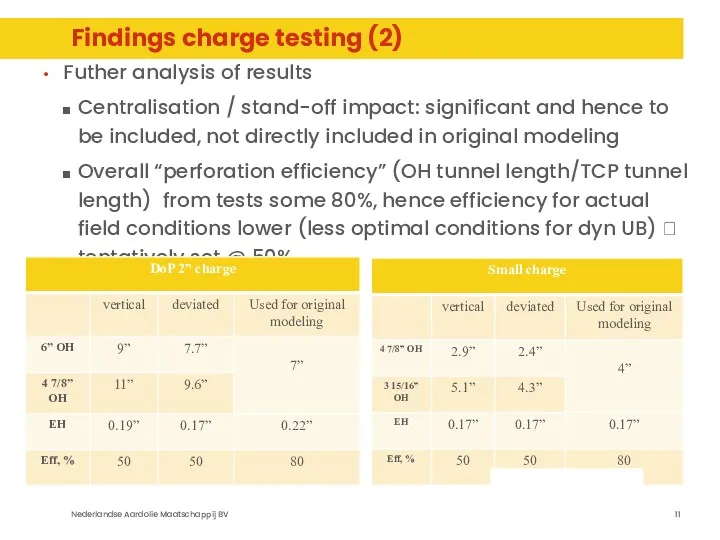

- 11. Findings charge testing (2) Futher analysis of results Centralisation / stand-off impact: significant and hence to

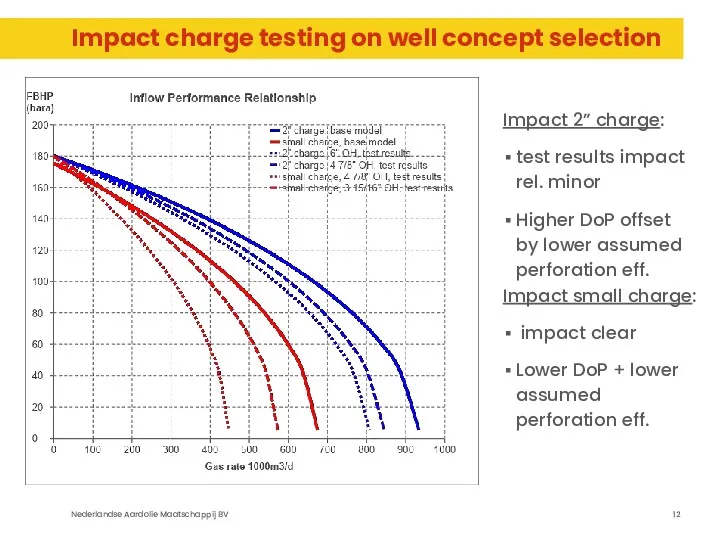

- 12. Impact charge testing on well concept selection Impact 2” charge: test results impact rel. minor Higher

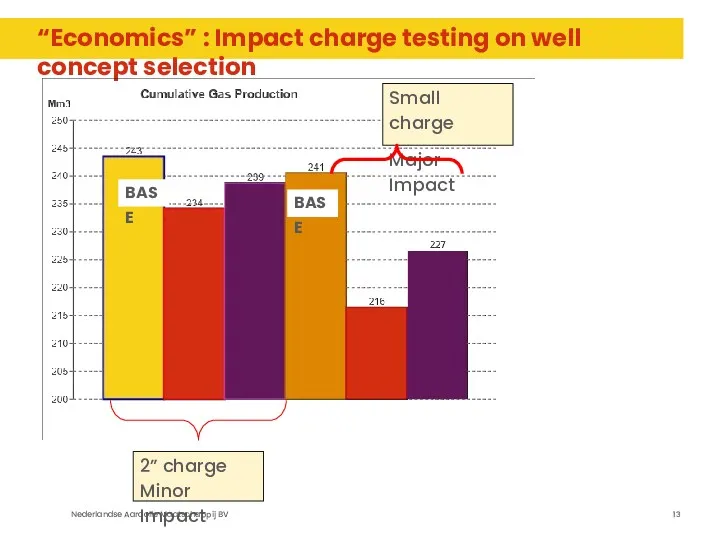

- 13. “Economics” : Impact charge testing on well concept selection BASE BASE 2” charge Minor Impact Small

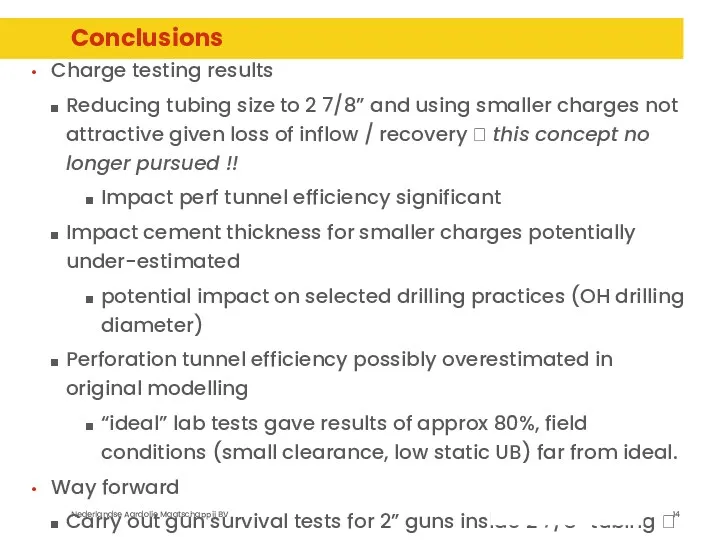

- 14. Conclusions Charge testing results Reducing tubing size to 2 7/8” and using smaller charges not attractive

- 16. Скачать презентацию

презентация к уроку обж Экстремальные ситуации для человека в природной среде

презентация к уроку обж Экстремальные ситуации для человека в природной среде Валютный курс и валютная политика. Тема 7

Валютный курс и валютная политика. Тема 7 Презентация к уроку о русской выхухоли Русская выхухоль

Презентация к уроку о русской выхухоли Русская выхухоль Что же такое Космос?

Что же такое Космос? Опроные конспекты к ЕГЭ по русскому (с тренировочными заданиями)

Опроные конспекты к ЕГЭ по русскому (с тренировочными заданиями) Cочетанные и множественные повреждения

Cочетанные и множественные повреждения Правила чтения Священного Корана

Правила чтения Священного Корана Ультразвуковое исследование тазобедренного сустава у взрослых и детей старшего возраста

Ультразвуковое исследование тазобедренного сустава у взрослых и детей старшего возраста T-link Web-based translation service

T-link Web-based translation service О проекте герба Кемеровской области - Кузбасса

О проекте герба Кемеровской области - Кузбасса Работа с датчиками

Работа с датчиками Базовые понятия абдоминальной хирургии

Базовые понятия абдоминальной хирургии Взаимодействие общества и природы

Взаимодействие общества и природы Обувь

Обувь Эволюция серии Fallout

Эволюция серии Fallout Северный морской путь

Северный морской путь 10 законов дружбы

10 законов дружбы Значение пальчиковых игр для развития речи дошкольника

Значение пальчиковых игр для развития речи дошкольника Саул. Царственные задатки и непослушание, гордость, зависть

Саул. Царственные задатки и непослушание, гордость, зависть Необычное путешествие. Конкурс-игра

Необычное путешествие. Конкурс-игра Урок-презентация. Работа с различными материалами. Рождественский венок

Урок-презентация. Работа с различными материалами. Рождественский венок IPhone

IPhone Презентация Ганутель

Презентация Ганутель Красота – это открытое рекомендательное письмо, завоёвывающее сердца. Кожа

Красота – это открытое рекомендательное письмо, завоёвывающее сердца. Кожа Презентация Первые весенние цветы

Презентация Первые весенние цветы Правапіс е, ё – я ў простых словах

Правапіс е, ё – я ў простых словах Предпосылки возникновения дарвинизма. (Лекция 3)

Предпосылки возникновения дарвинизма. (Лекция 3) Контрольная закупка молока коровьего

Контрольная закупка молока коровьего