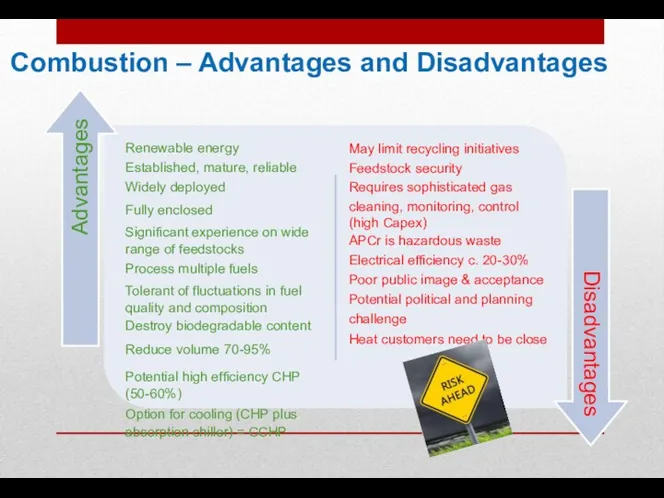

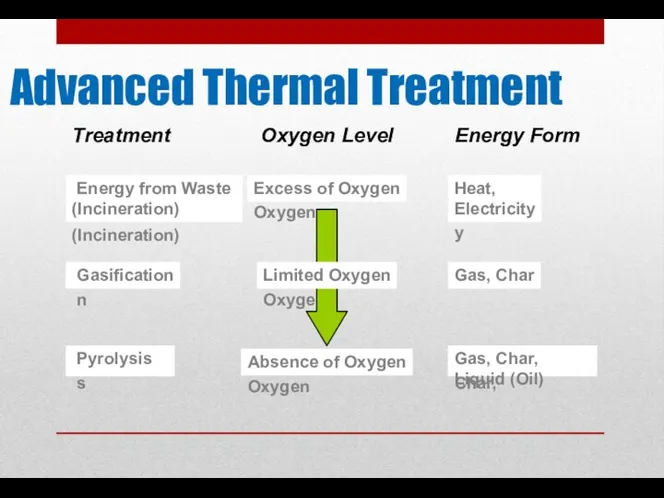

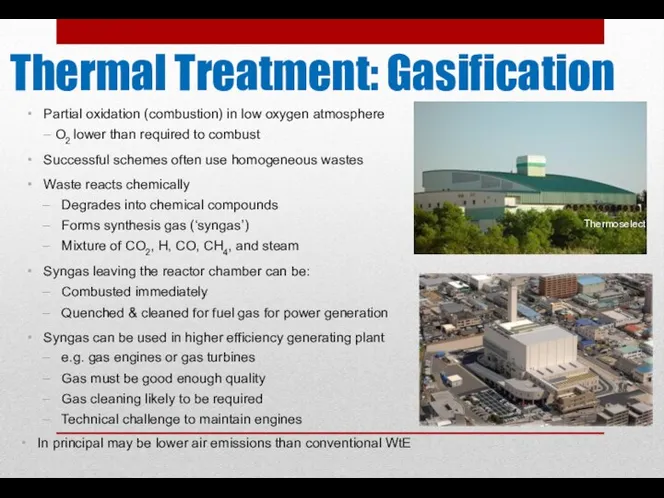

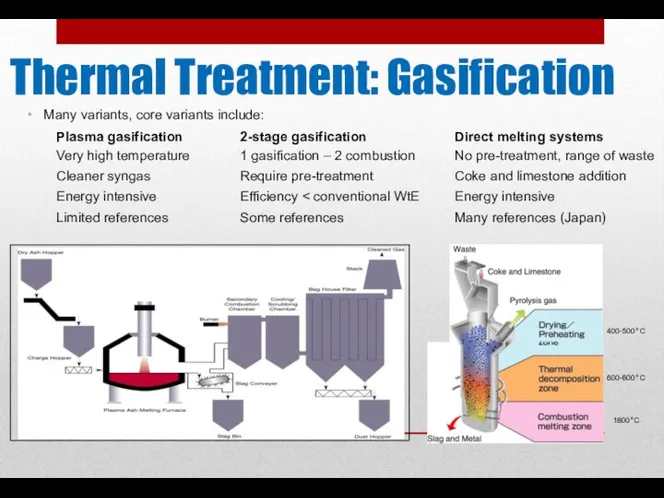

Combustion (incineration) – burning waste to recover energy

Combustion in a furnace

at high temperatures (European Directive 850°C for at least 2 seconds)

Energy in waste converted to heat (hot gases) Gases pass to a boiler (option integrated furnace-boiler)

Heat transferred into hot water to produce superheated steam

Steam generates electricity via a turbine

Heat recovered in CHP (Combined Heat and Power) mode

Outputs

Bottom ash – commonly recovered (metals & aggregate)

Air pollution control residues – landfilled (hazardous)

Co-combustion (power plant) as secondary fuel

Economic and carbon savings Incineration Directive compliance

Thermal Treatment: Combustion

Вежливость

Вежливость Психічний розвиток дитини від народження до вступу у школу

Психічний розвиток дитини від народження до вступу у школу Совершенствование государственной политики развития оборонно-промышленного комплекса

Совершенствование государственной политики развития оборонно-промышленного комплекса ПРЕЗЕНТАЦИЯ Тюрин АА

ПРЕЗЕНТАЦИЯ Тюрин АА Безопасность в быту. Правила для детей

Безопасность в быту. Правила для детей Презентация по географии на тему:География как наука

Презентация по географии на тему:География как наука Подбор смешных фото

Подбор смешных фото Детская площадка г. Уржум

Детская площадка г. Уржум Встроенные функции в Excel

Встроенные функции в Excel Основы государственной культурной политики Российской Федерации

Основы государственной культурной политики Российской Федерации Перпендикулярность прямой и плоскости

Перпендикулярность прямой и плоскости Архитектура параллельных вычислительных систем. Часть 1. История и проблематика. Основы параллельного программирования

Архитектура параллельных вычислительных систем. Часть 1. История и проблематика. Основы параллельного программирования Факторинговые операции коммерческих банков

Факторинговые операции коммерческих банков своя игра Новогодний переполох

своя игра Новогодний переполох Моделирование и проектирование строительных технологий

Моделирование и проектирование строительных технологий Презентация по технологии Малахитовая шкатулка 4 класс

Презентация по технологии Малахитовая шкатулка 4 класс Личность и психологические установки

Личность и психологические установки Шаблон (фон) презентации. 23 февраля. Часть 2

Шаблон (фон) презентации. 23 февраля. Часть 2 Презентация Проектная деятельность в детском саду

Презентация Проектная деятельность в детском саду Виды штукатурки

Виды штукатурки Добро и зло. Понятие греха, раскаяния и воздаяния

Добро и зло. Понятие греха, раскаяния и воздаяния Перинатальная патология нервной системы. Детский церебральный паралич

Перинатальная патология нервной системы. Детский церебральный паралич схематичное изображение правил занятий с детьми в песочнице

схематичное изображение правил занятий с детьми в песочнице Сестринское обследование - первый этап сестринского ухода

Сестринское обследование - первый этап сестринского ухода Классный час по ПДД В нашем чудном городке знаем дорожные знаки все!

Классный час по ПДД В нашем чудном городке знаем дорожные знаки все! Инженерлік – геодезиялық тірек тораптары

Инженерлік – геодезиялық тірек тораптары презентация к интегрированной организованной деятельности Знакомство с миром театра Диск

презентация к интегрированной организованной деятельности Знакомство с миром театра Диск Медицинадағы жасушалық технология. Репродуктивті технологиялар (экстракорпоралдық ұрықтандыру(ЭКҰ). Клеткаларды клондау

Медицинадағы жасушалық технология. Репродуктивті технологиялар (экстракорпоралдық ұрықтандыру(ЭКҰ). Клеткаларды клондау