Содержание

- 2. The Robot selection The fixture Structure The Air cylinder The machine information 01 02 03 04

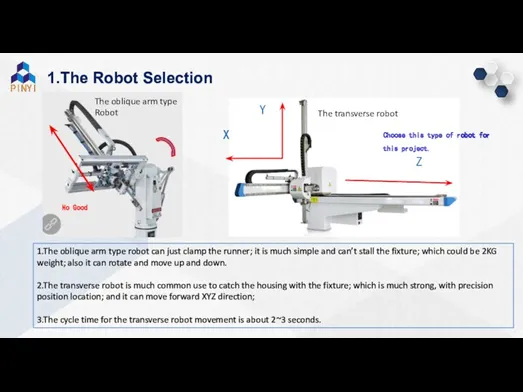

- 3. 1.The Robot Selection 1.The oblique arm type robot can just clamp the runner; it is much

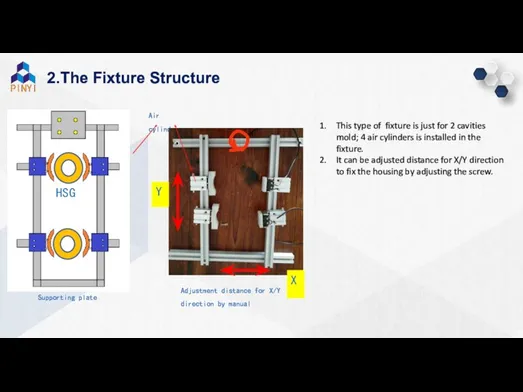

- 4. 2.The Fixture Structure HSG Air cylinder Supporting plate This type of fixture is just for 2

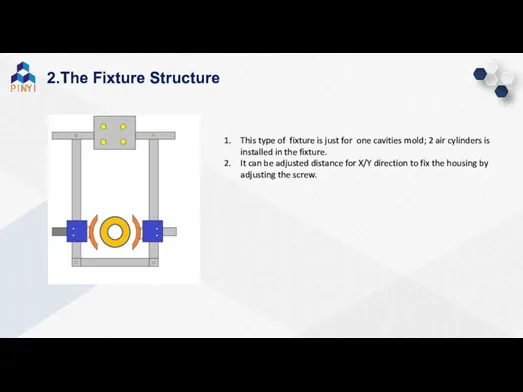

- 5. 2.The Fixture Structure This type of fixture is just for one cavities mold; 2 air cylinders

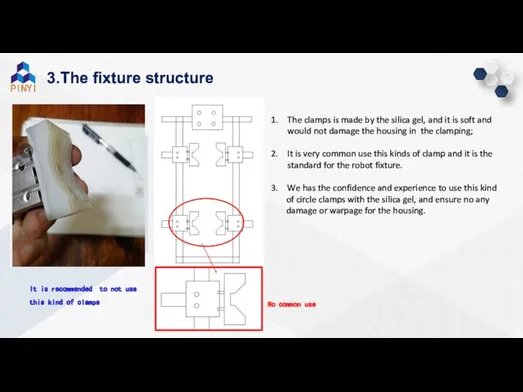

- 6. 3.The fixture structure The clamps is made by the silica gel, and it is soft and

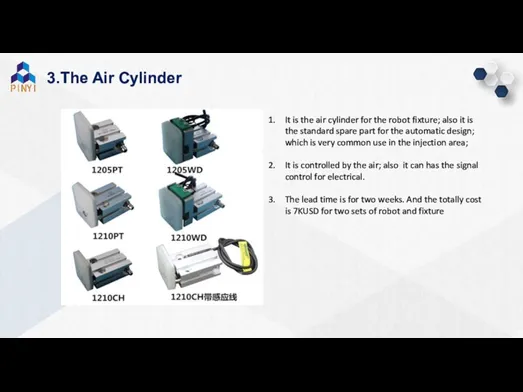

- 7. 3.The Air Cylinder It is the air cylinder for the robot fixture; also it is the

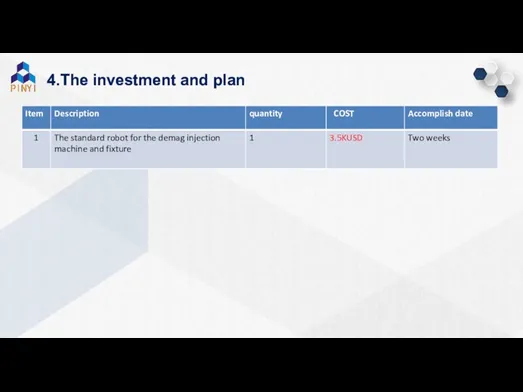

- 8. 4.The investment and plan

- 9. 5.The machine information Waiting for customer prompt advice and suggest for the project improvement; Reminds: Customer

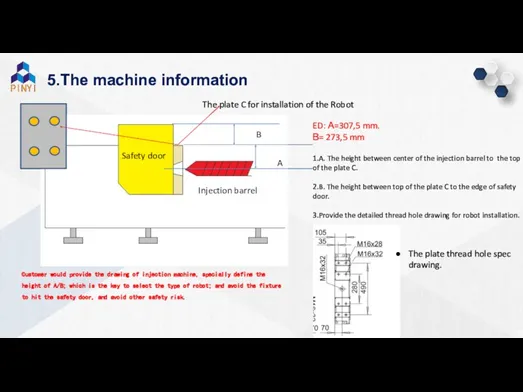

- 10. 5.The machine information Safety door Injection barrel B A The plate C for installation of the

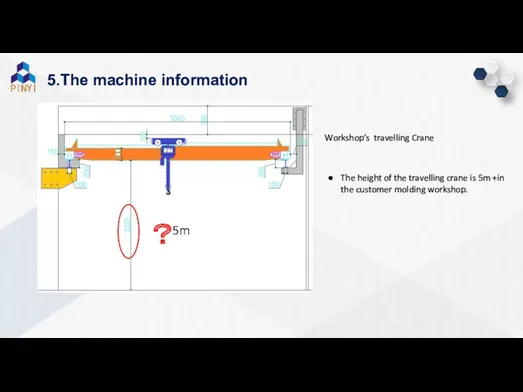

- 11. 5.The machine information Workshop’s travelling Crane The height of the travelling crane is 5m +in the

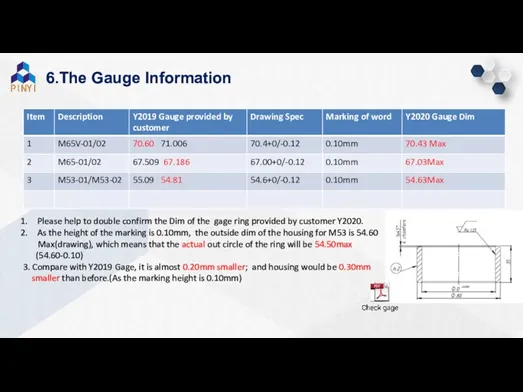

- 12. 6.The Gauge Information Please help to double confirm the Dim of the gage ring provided by

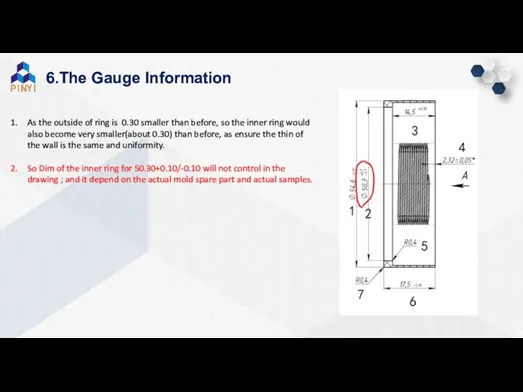

- 13. 6.The Gauge Information As the outside of ring is 0.30 smaller than before, so the inner

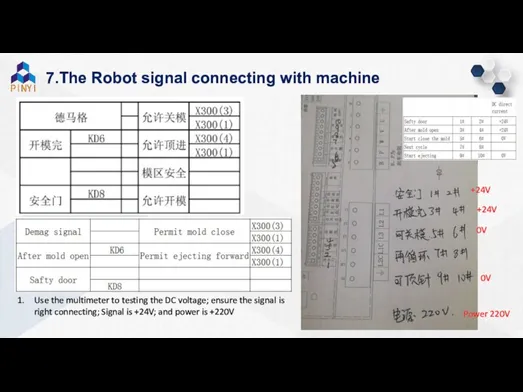

- 14. 7.The Robot signal connecting with machine +24V +24V 0V 0V Power 220V Use the multimeter to

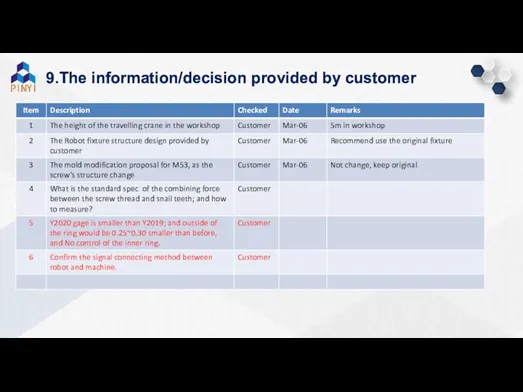

- 15. 9.The information/decision provided by customer

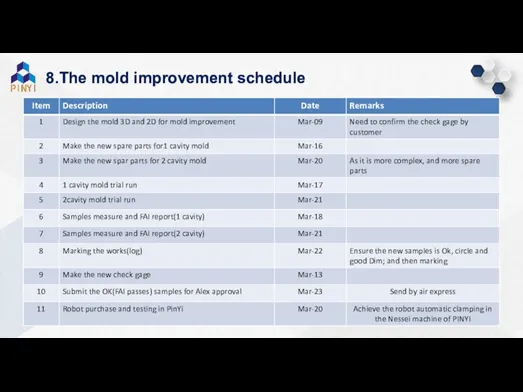

- 16. 8.The mold improvement schedule

- 18. Скачать презентацию

Поздравляю с Новым годом

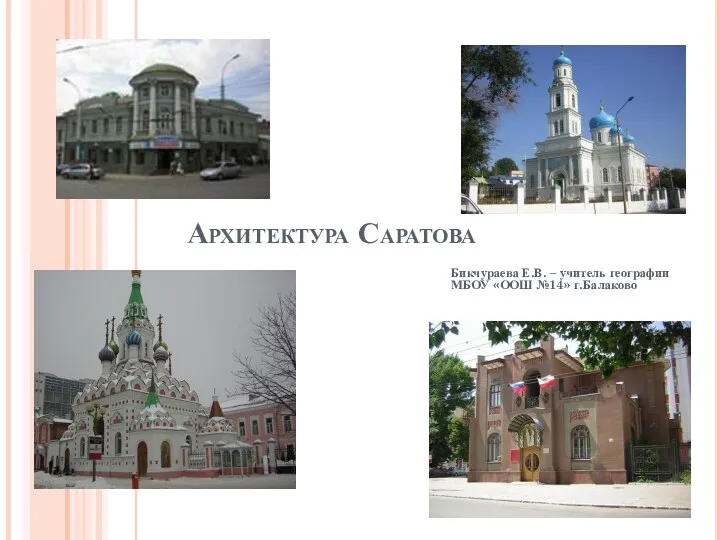

Поздравляю с Новым годом Архитектура Саратова

Архитектура Саратова Поле, його властивості

Поле, його властивості Здоровый образ жизни, мы против расизма

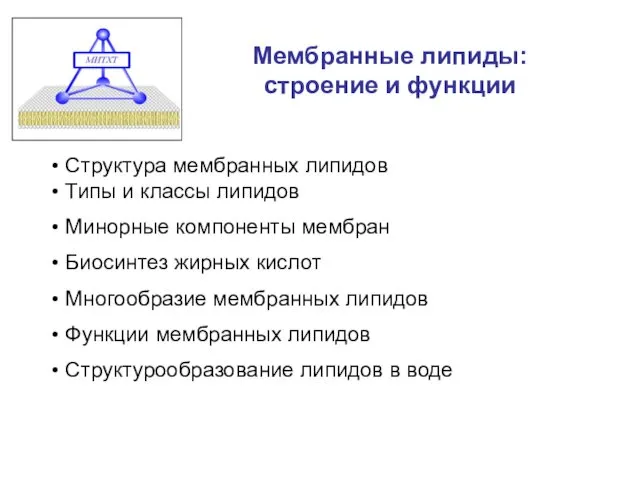

Здоровый образ жизни, мы против расизма Мембранные липиды: строение и функции

Мембранные липиды: строение и функции Биологические особенности и технология выращивания огурца в открытом грунте

Биологические особенности и технология выращивания огурца в открытом грунте Презентация к уроку

Презентация к уроку Приёмники оптического излучения

Приёмники оптического излучения Презентация к уроку Поэты Ставрополья о родном крае и о природе родного края

Презентация к уроку Поэты Ставрополья о родном крае и о природе родного края Презентация С.Т.Аксаков - певец родной природы

Презентация С.Т.Аксаков - певец родной природы Ответственность в хозяйственном праве

Ответственность в хозяйственном праве Классный час Моя малая Родина

Классный час Моя малая Родина Радуга творчества

Радуга творчества Погода и климат

Погода и климат Деталь беттерін металдармен қорытпалармен жабу

Деталь беттерін металдармен қорытпалармен жабу Анализ портфеля акций

Анализ портфеля акций Духовно-нравственное воспитание учащихся

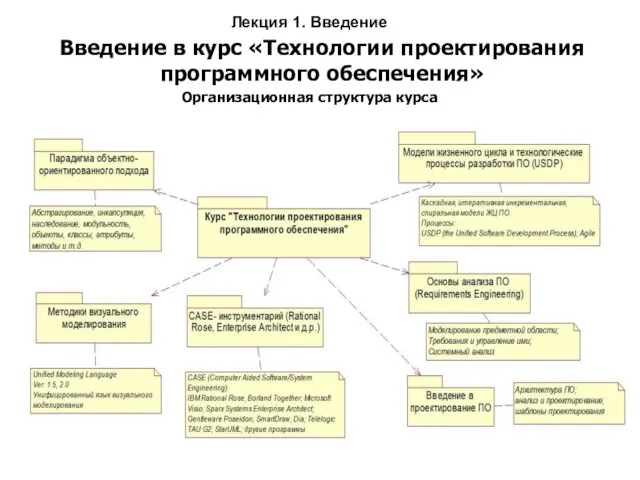

Духовно-нравственное воспитание учащихся Основные элементы базовой нотации языка UML

Основные элементы базовой нотации языка UML Церковь Одигитрии Смоленской (XVII в) - символ Вязьмы

Церковь Одигитрии Смоленской (XVII в) - символ Вязьмы Благоустройство территории района Богородское города Москвы в 2020 г

Благоустройство территории района Богородское города Москвы в 2020 г Наряд для семейного обеда (урок технологии в 6 классе)

Наряд для семейного обеда (урок технологии в 6 классе) Санитарное просвещение и гигиеническое воспитание населения

Санитарное просвещение и гигиеническое воспитание населения Презентация Заповеди Блаженствпо предмету ОПК

Презентация Заповеди Блаженствпо предмету ОПК Воронецкая (2)

Воронецкая (2) Помощь подростку в выборе профессии

Помощь подростку в выборе профессии ПРЕЗЕНТАЦИЯ о животных

ПРЕЗЕНТАЦИЯ о животных Всероссийский образовательный командный турнир Знайки (2-4 классы)

Всероссийский образовательный командный турнир Знайки (2-4 классы) Промывочные агрегаты

Промывочные агрегаты