Содержание

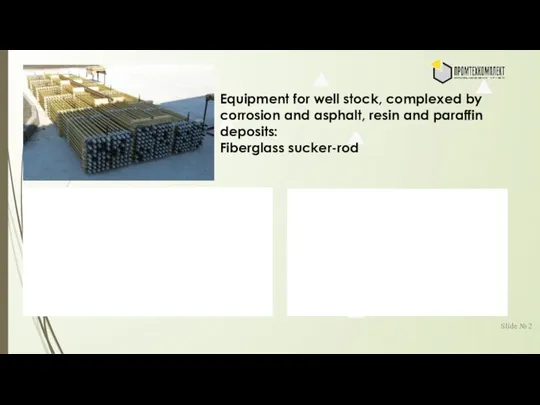

- 2. Slide № Equipment for well stock, complexed by corrosion and asphalt, resin and paraffin deposits: Fiberglass

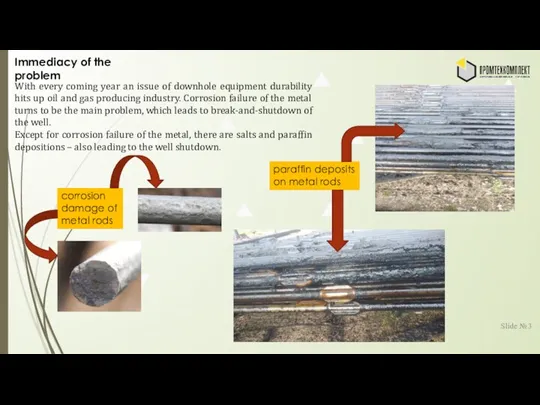

- 3. Slide № With every coming year an issue of downhole equipment durability hits up oil and

- 4. Slide № Main recommended indication for Mud-pump stations: High corrosion activity of produced liquid, average OT

- 5. Fiberglass rods before starting work Fiberglass rods after extraction from the well We note the absence

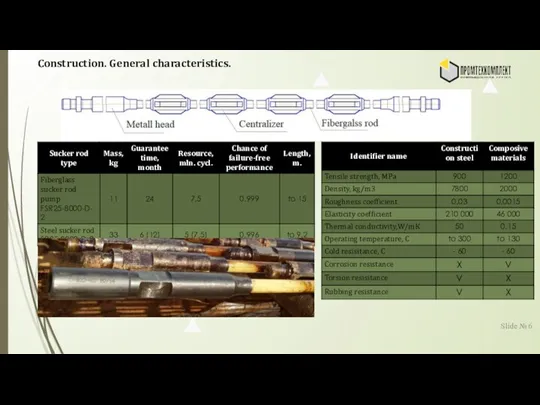

- 6. Slide № Construction. General characteristics.

- 7. Fiberglass pumping rods are manufactured using a unique technology of joining metal and fiberglass. The production

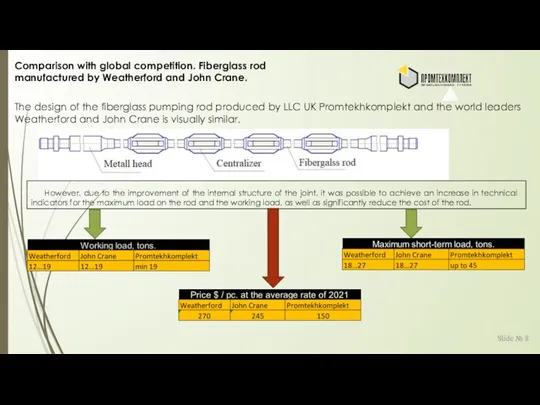

- 8. Comparison with global competition. Fiberglass rod manufactured by Weatherford and John Crane. The design of the

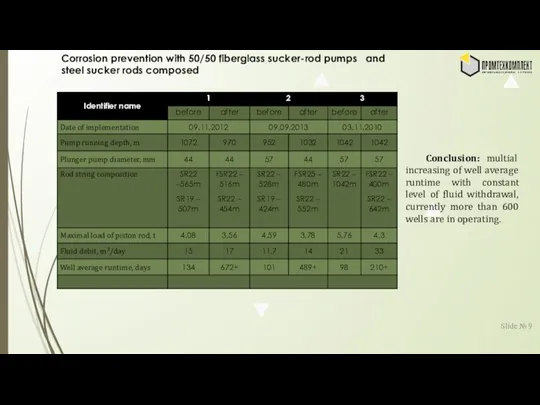

- 9. Slide № Corrosion prevention with 50/50 fiberglass sucker-rod pumps and steel sucker rods composed Conclusion: multial

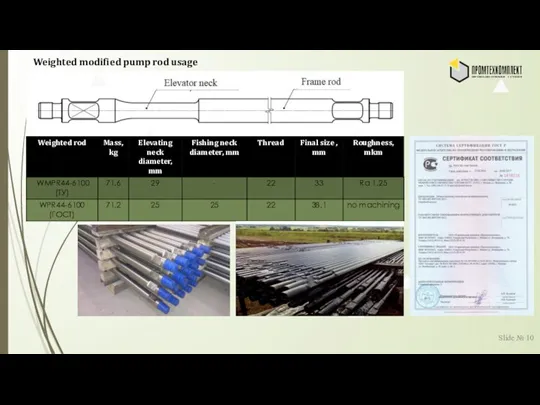

- 10. Slide № Weighted modified pump rod usage

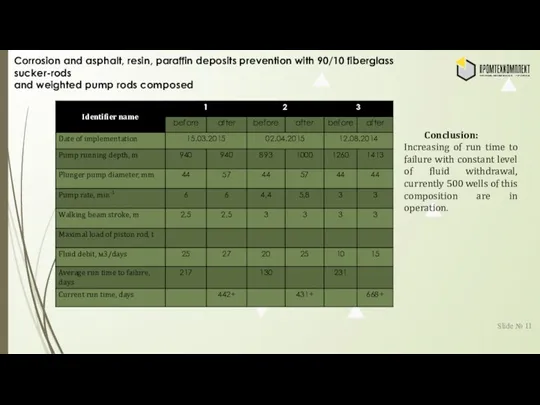

- 11. Slide № Conclusion: Increasing of run time to failure with constant level of fluid withdrawal, currently

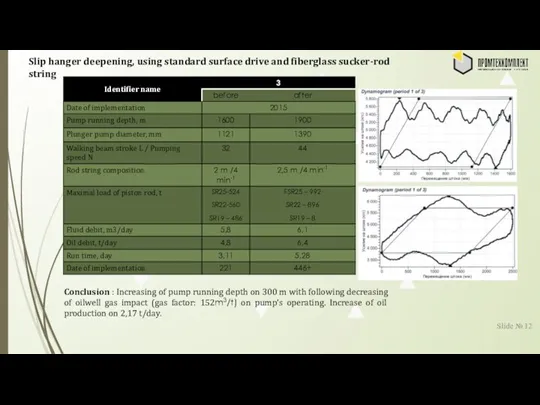

- 12. Slide № Conclusion : Increasing of pump running depth on 300 m with following decreasing of

- 13. Slide № Efficiency of mud-pump station applying is proved on well stock, complicated by high aggressivity

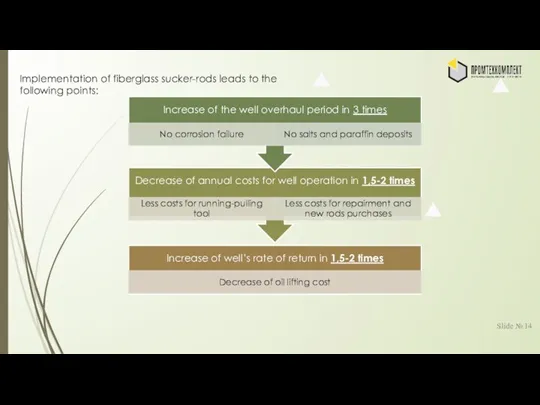

- 14. Slide № Implementation of fiberglass sucker-rods leads to the following points:

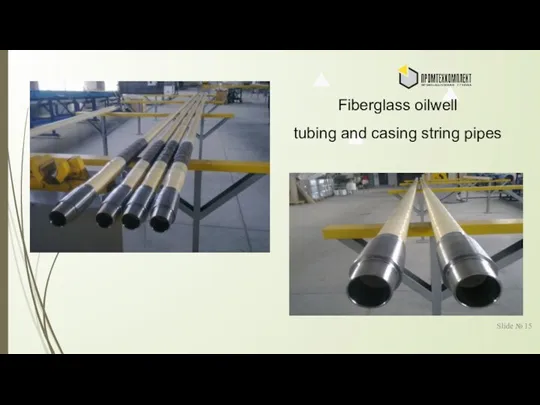

- 15. Slide № Fiberglass oilwell tubing and casing string pipes

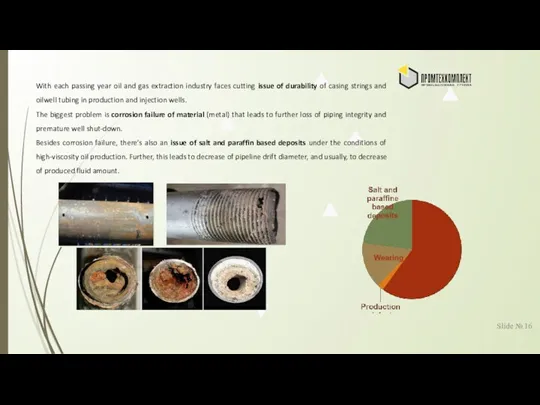

- 16. Slide № With each passing year oil and gas extraction industry faces cutting issue of durability

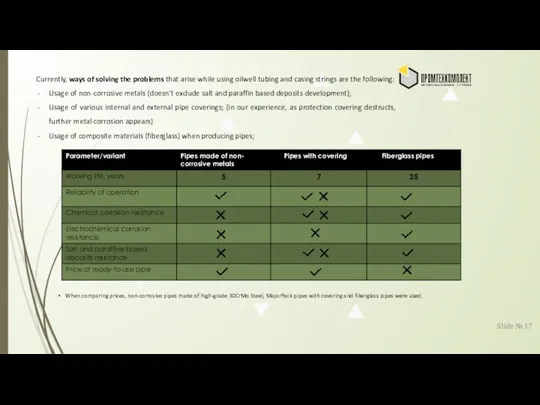

- 17. Slide № Currently, ways of solving the problems that arise while using oilwell tubing and casing

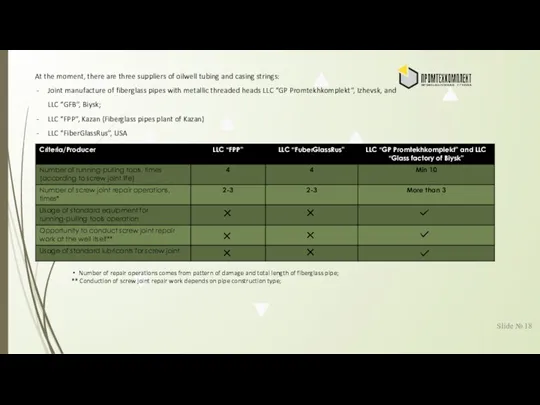

- 18. Slide № At the moment, there are three suppliers of oilwell tubing and casing strings: Joint

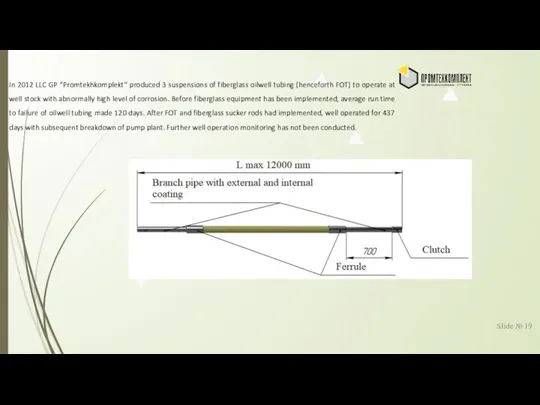

- 19. Slide № In 2012 LLC GP “Promtekhkomplekt” produced 3 suspensions of fiberglass oilwell tubing (henceforth FOT)

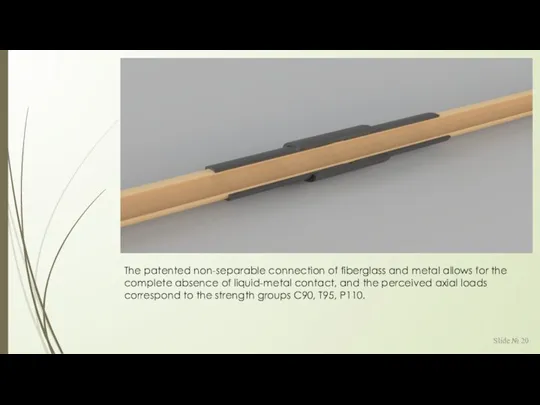

- 20. Slide № The patented non-separable connection of fiberglass and metal allows for the complete absence of

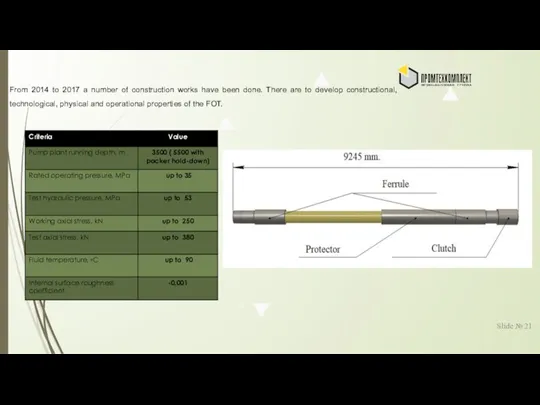

- 21. Slide № From 2014 to 2017 a number of construction works have been done. There are

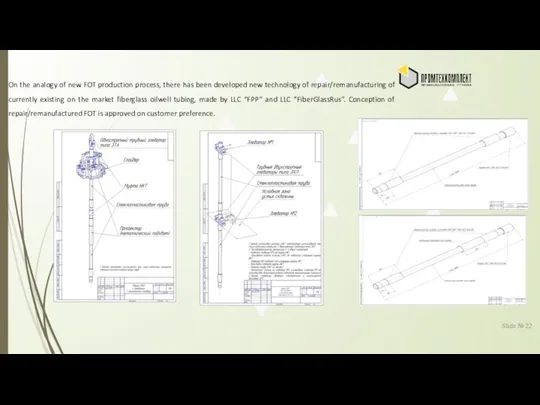

- 22. Slide № On the analogy of new FOT production process, there has been developed new technology

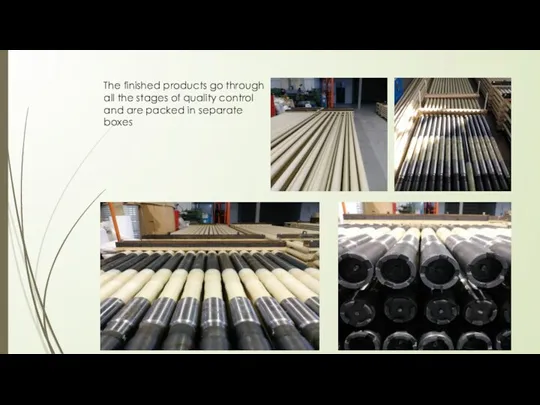

- 23. The finished products go through all the stages of quality control and are packed in separate

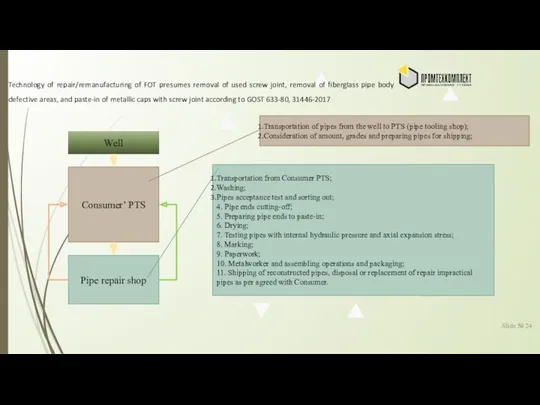

- 24. Slide № Technology of repair/remanufacturing of FOT presumes removal of used screw joint, removal of fiberglass

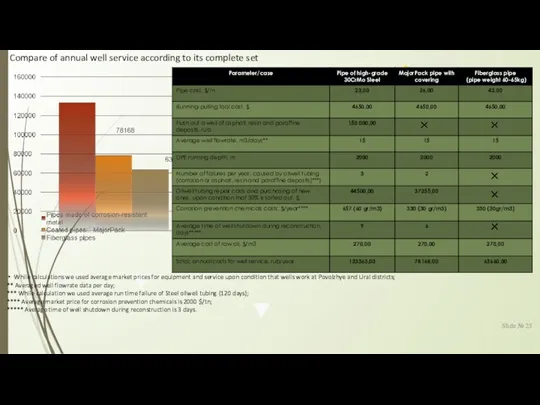

- 25. Slide № While calculations we used average market prices for equipment and service upon condition that

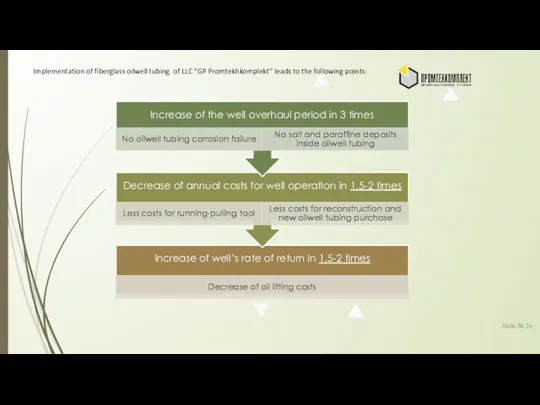

- 26. Slide № Implementation of fiberglass oilwell tubing of LLC “GP Promtekhkomplekt” leads to the following points:

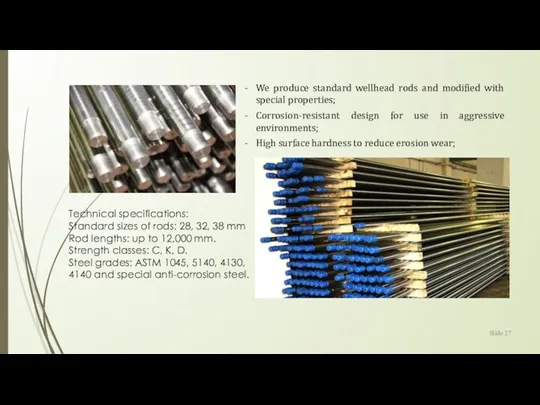

- 27. Slide 27 We produce standard wellhead rods and modified with special properties; Corrosion-resistant design for use

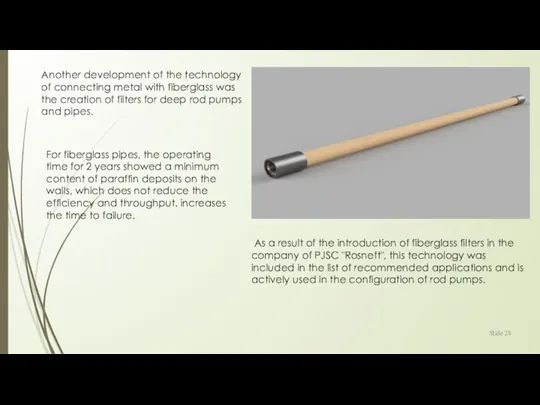

- 28. Slide 28 Another development of the technology of connecting metal with fiberglass was the creation of

- 30. Скачать презентацию

Напутствие выпускникам

Напутствие выпускникам Континент Антарктида

Континент Антарктида Догмат воплощения

Догмат воплощения Методы поверхностного упрочнения

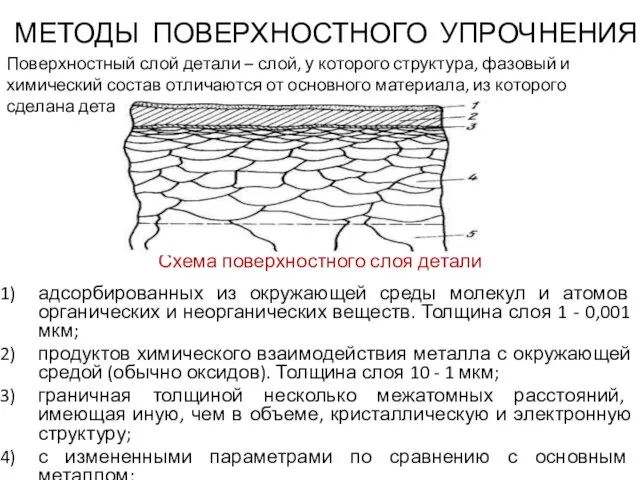

Методы поверхностного упрочнения X-PLEX для окрашивания волос

X-PLEX для окрашивания волос Предметно - развивающая среда ориентированная на ребенка.

Предметно - развивающая среда ориентированная на ребенка. Arduino - это инструмент для проектирования электронных устройств (электронный конструктор)

Arduino - это инструмент для проектирования электронных устройств (электронный конструктор) История развития бухгалтерского дела в России и за рубежом

История развития бухгалтерского дела в России и за рубежом Виды керамической плитки

Виды керамической плитки Презентация по теме Приобщение детей к народному творчеству как средство экологического воспитания

Презентация по теме Приобщение детей к народному творчеству как средство экологического воспитания Разработка стратегии развития отрасли жилищное строительство

Разработка стратегии развития отрасли жилищное строительство Сервис будущего

Сервис будущего Древнеславянские, древнебританские страшилки

Древнеславянские, древнебританские страшилки Ваш ребёнок - будущий пятиклассник

Ваш ребёнок - будущий пятиклассник Гимнастика для глаз

Гимнастика для глаз Выступление из опыта работы по теме: Сказкотерапия как инновационная технология духовно-нравственного воспитания дошкольников

Выступление из опыта работы по теме: Сказкотерапия как инновационная технология духовно-нравственного воспитания дошкольников Мои выступления

Мои выступления Презентация к празднику Прощай, 1 класс

Презентация к празднику Прощай, 1 класс из опыта работы

из опыта работы Блокада Ленинграда

Блокада Ленинграда Психологические характеристики младших школьников с разным социометрическим статусом

Психологические характеристики младших школьников с разным социометрическим статусом Обобщающий урок по теме Африка

Обобщающий урок по теме Африка Социальные акции: тематика акций, участники акций, правила поведения

Социальные акции: тематика акций, участники акций, правила поведения Михаил Васильевич Ломоносов.

Михаил Васильевич Ломоносов. Творчість митців італійського Відродження

Творчість митців італійського Відродження Разработка программы моделирования канала передачи потоковых данных оптико-электронных средств

Разработка программы моделирования канала передачи потоковых данных оптико-электронных средств Презентация Периодическая система химических элементов

Презентация Периодическая система химических элементов Управление каналами распределения

Управление каналами распределения