Содержание

- 2. Life of field The life of an oil or gas field can be sub-divided into the

- 3. Exploration well Exploration wells are drilled for data collection in new regions Information is mainly represented

- 4. Exploration phase The length of the exploration phase will depend on the success or otherwise of

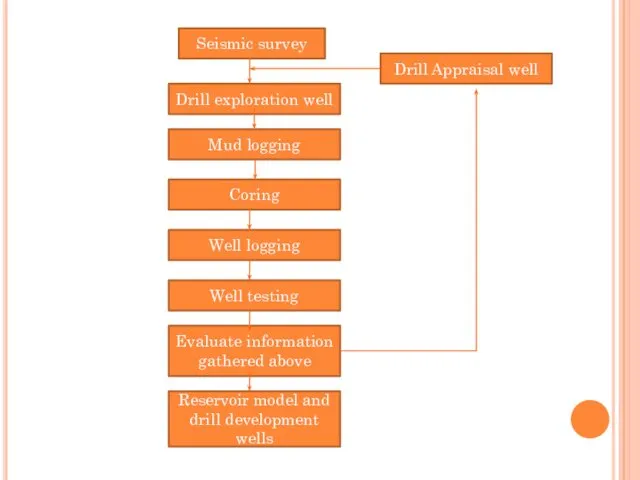

- 5. Seismic survey Drill exploration well Mud logging Coring Well logging Well testing Evaluate information gathered above

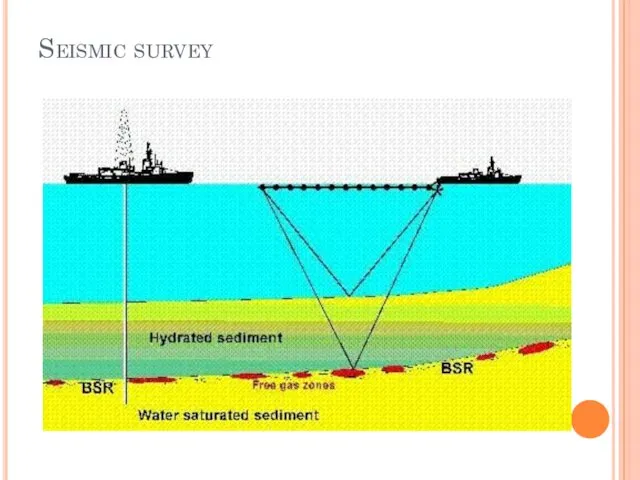

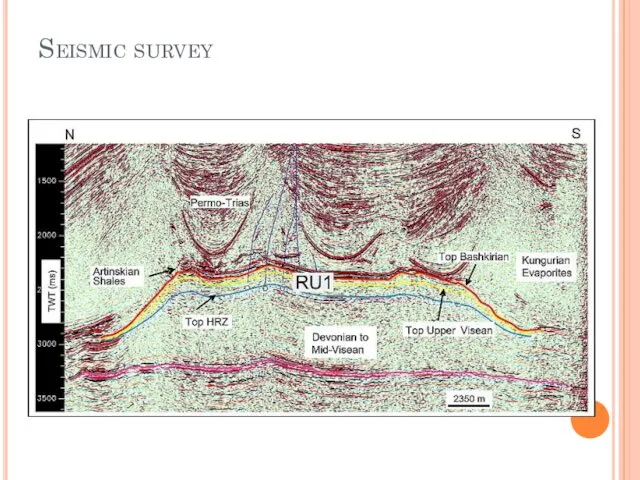

- 6. Seismic survey

- 7. Seismic survey

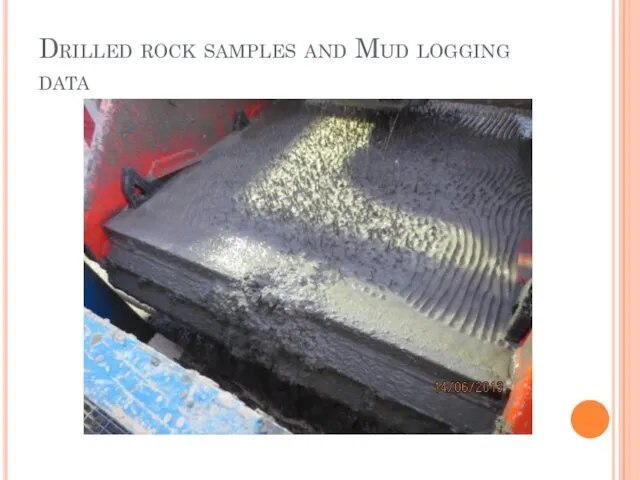

- 8. Drilled rock samples and Mud logging data

- 9. Drilled rock samples and Mud logging data

- 10. Core/core barrel Essentially three different types of coring methods are used to recover formation samples from

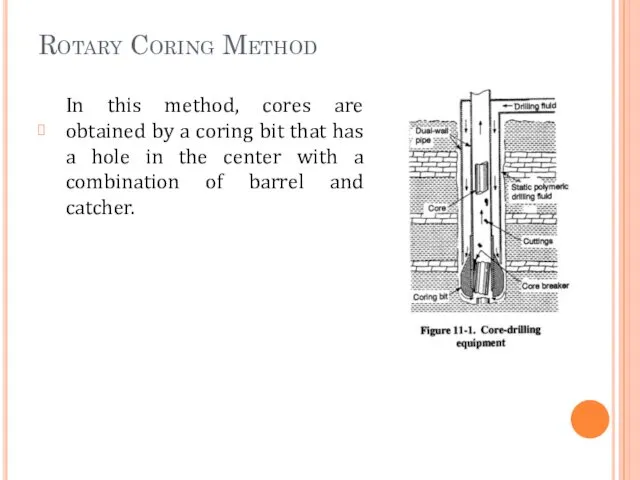

- 11. Rotary Coring Method In this method, cores are obtained by a coring bit that has a

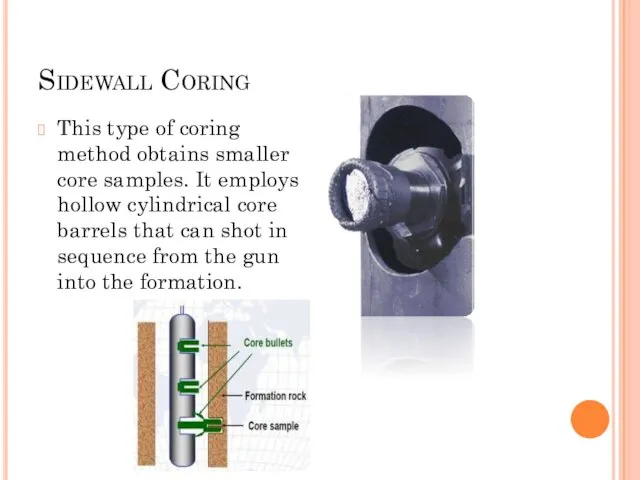

- 12. Sidewall Coring This type of coring method obtains smaller core samples. It employs hollow cylindrical core

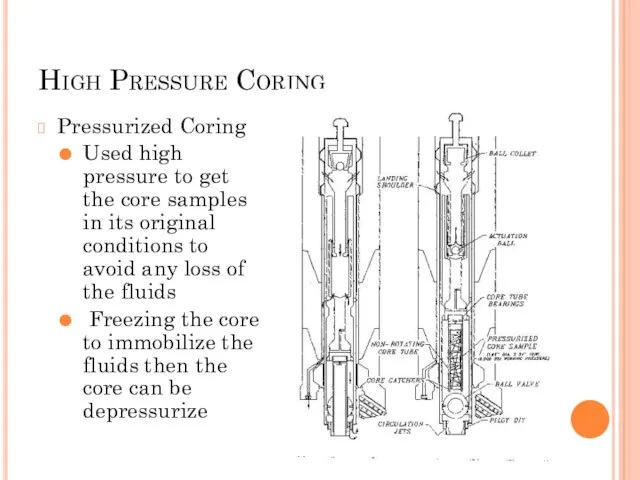

- 13. High Pressure Coring Pressurized Coring Used high pressure to get the core samples in its original

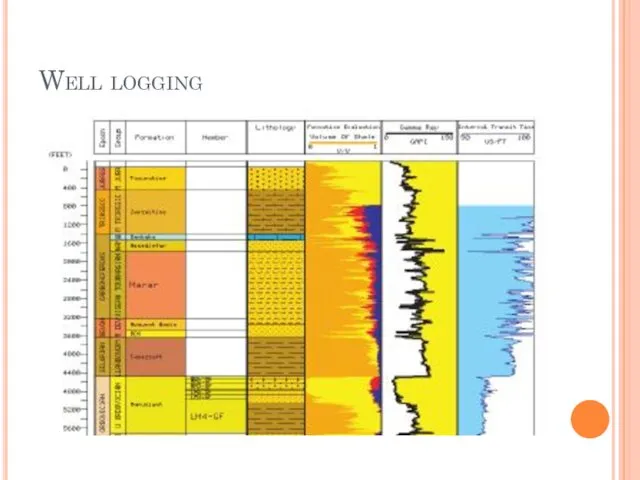

- 14. Well logging

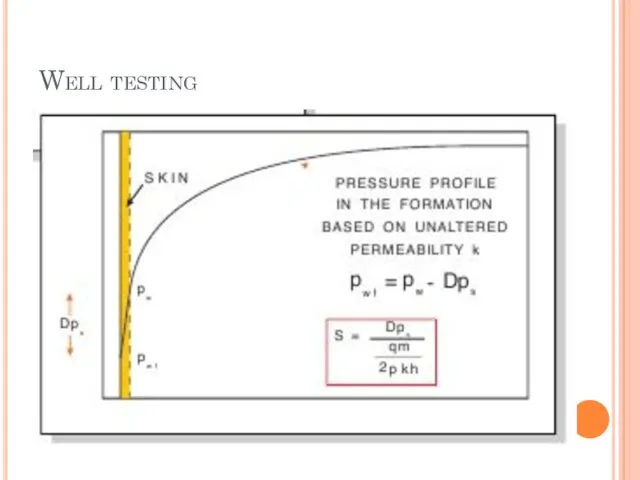

- 15. Well testing

- 16. Appraisal well If an economically attractive discovery is made on the prospect then the company enters

- 17. Company announcement example SAGW-1 Discovery well: 27m net pay (21m oil / 6m gas) in Triassic

- 18. Company announcement example SAGW-4 appraisal well logged 20 meters of gas condensate and oil pay with

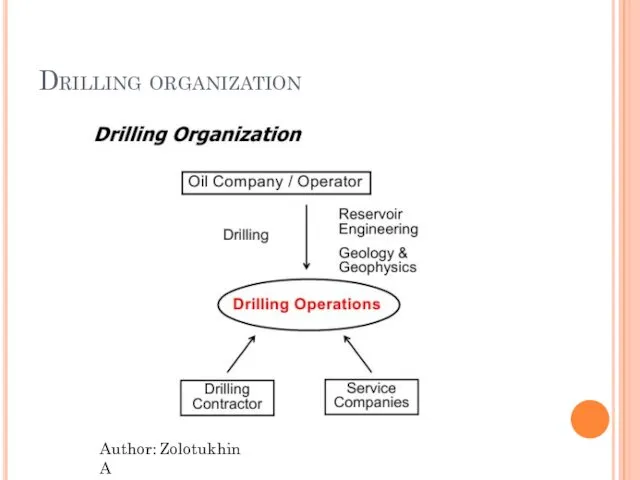

- 19. Drilling organization Author: Zolotukhin A

- 20. Operator The oil company who manages the drilling and/or production operations is known as the operator.

- 21. Drilling Contractor There are many different management strategies for drilling a well but in virtually all

- 22. The toolpusher The drilling contractor will employ a toolpusher to be in overall charge of the

- 23. Drilling Proposal The proposal for drilling the well is prepared by the geologists and reservoir engineers

- 24. Drilling program The drilling program is prepared by the Drilling Engineer and contains the following: •

- 25. THE DRILLING PROCESS

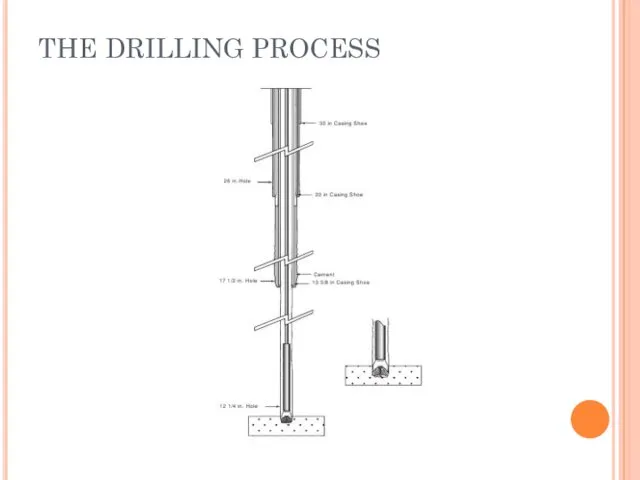

- 26. Типы профилей скважин Относительно точки входа в заданный горизонт профиль скважины бывает: Вертикальным. Зенитный угол меньше

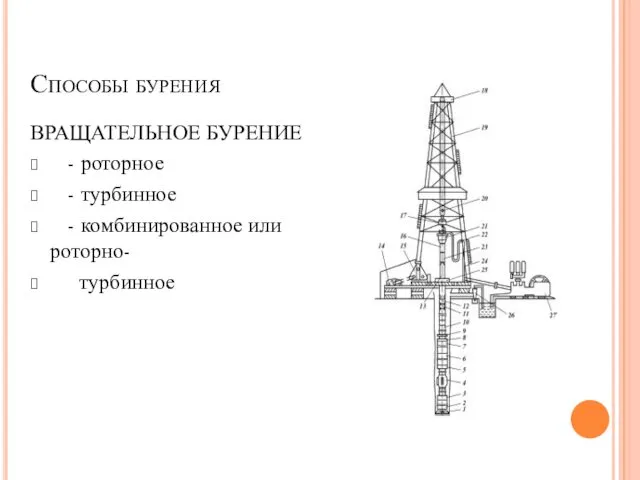

- 27. Способы бурения ВРАЩАТЕЛЬНОЕ БУРЕНИЕ - роторное - турбинное - комбинированное или роторно- турбинное

- 28. Методы бурения Роторно-турбинный. Наиболее распространенный в настоящее время. Позволяет управлять траекторией ствола скважины без подъема КНБК

- 31. Скачать презентацию

Ветка дуба

Ветка дуба Материалы для оформления в художественно-оформительских и отделочных работах: металл, стекло, дерево

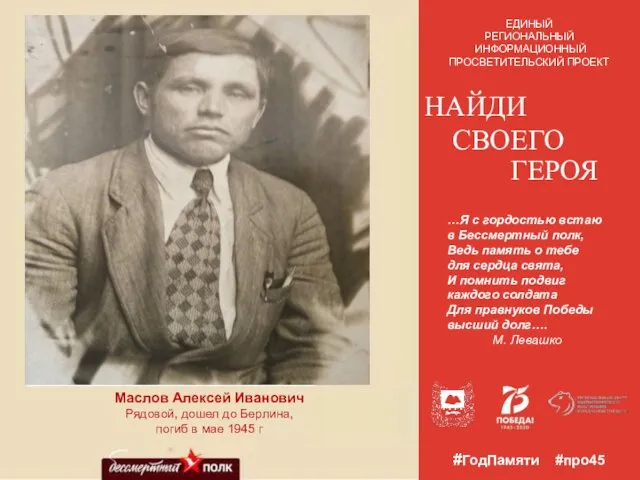

Материалы для оформления в художественно-оформительских и отделочных работах: металл, стекло, дерево Найди своего героя

Найди своего героя Основы метрологии. Виды измерений, их классификация. Принцип измерений

Основы метрологии. Виды измерений, их классификация. Принцип измерений Новогодняя Снежинка-пушинка. Мастер-класс

Новогодняя Снежинка-пушинка. Мастер-класс Чай та чайні напої

Чай та чайні напої Методы развития стрессоустойчивости у дошкольников

Методы развития стрессоустойчивости у дошкольников Аннотация основной образовательной программы дошкольного образования ДОУ для родителей.

Аннотация основной образовательной программы дошкольного образования ДОУ для родителей. Состав буровой установки

Состав буровой установки Теория поэтапного формирования умственных действий П.Я. Гальперина

Теория поэтапного формирования умственных действий П.Я. Гальперина Родительское собрание: Как воспитать уверенность ребёнка в себе

Родительское собрание: Как воспитать уверенность ребёнка в себе Использование ИКТ на уроках географии

Использование ИКТ на уроках географии Открытая разработка Томь-Усинского каменноугольного месторождения

Открытая разработка Томь-Усинского каменноугольного месторождения Грозовые разряды

Грозовые разряды История пожарной охраны

История пожарной охраны Центрально - симметричные фигуры

Центрально - симметричные фигуры Новинки автопрома 2016-2018 гг

Новинки автопрома 2016-2018 гг Осенние ноты в вокальной и инструментальной музыке

Осенние ноты в вокальной и инструментальной музыке Презентация занятия Как сохранить здоровье?

Презентация занятия Как сохранить здоровье? Музыкальная композиция

Музыкальная композиция Роль дошкольного образовательного учреждения в повышении педагогической культуры семьи (методическое пособие для воспитателей ДОУ)

Роль дошкольного образовательного учреждения в повышении педагогической культуры семьи (методическое пособие для воспитателей ДОУ) Mechanisms and Simple Machines. Industrial equipment

Mechanisms and Simple Machines. Industrial equipment Проект Создаём портрет слова ябеда

Проект Создаём портрет слова ябеда Пищевые добавки их влияние на организм человека

Пищевые добавки их влияние на организм человека Возрастные особенности детей 1.5 - 2 лет

Возрастные особенности детей 1.5 - 2 лет Награды Великой Отечественной войны

Награды Великой Отечественной войны как подготовить ребенка к школе

как подготовить ребенка к школе Психология личности

Психология личности