Содержание

- 2. Mobile laser technological complex (MLTC) Solutions for elimination of emergency oil and oil-product spills in various

- 3. 1. Mobile laser technological complex

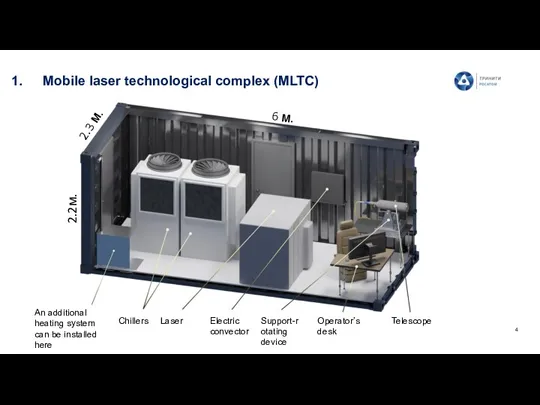

- 4. Mobile laser technological complex (MLTC) 2.2м. 2.3 м. 6 м. An additional heating system can be

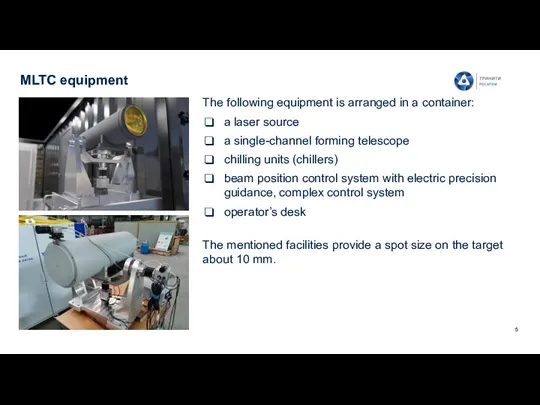

- 5. MLTC equipment The following equipment is arranged in a container: a laser source a single-channel forming

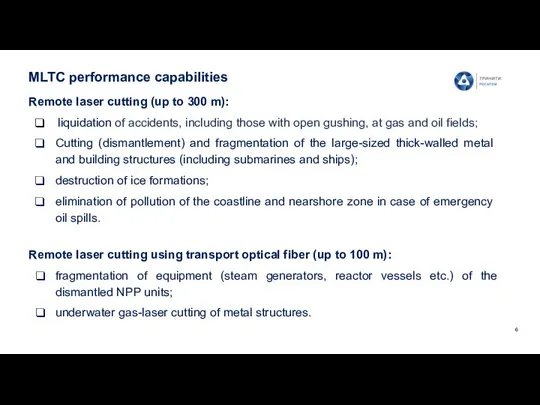

- 6. MLTC performance capabilities Remote laser cutting using transport optical fiber (up to 100 m): fragmentation of

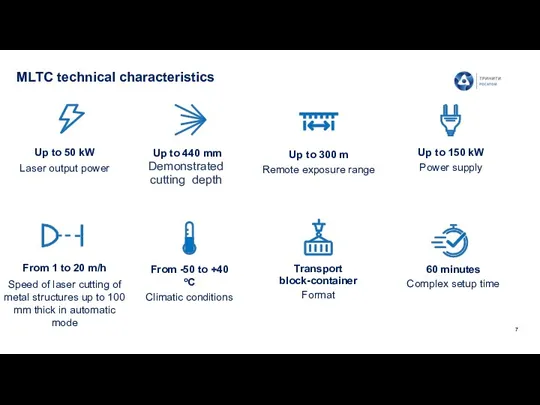

- 7. MLTC technical characteristics Up to 50 kW Laser output power Up to 150 kW Power supply

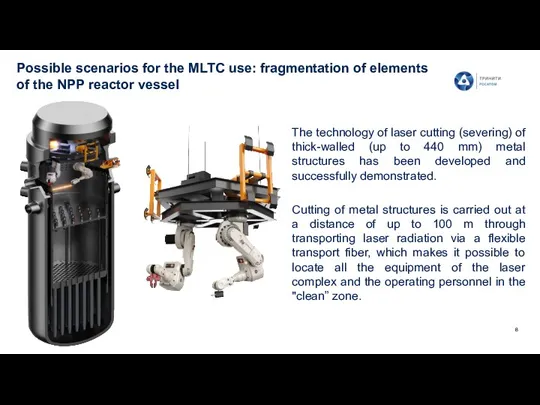

- 8. Possible scenarios for the MLTC use: fragmentation of elements of the NPP reactor vessel The technology

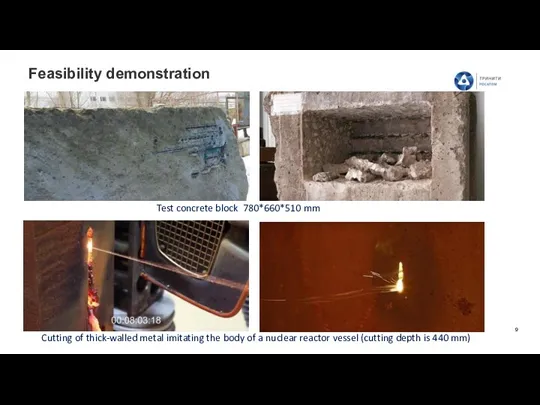

- 9. Feasibility demonstration Test concrete block 780*660*510 mm Cutting of thick-walled metal imitating the body of a

- 10. Examples of laser cutting of structures destroyed in a gas well accident MLTK-20 complex, created in

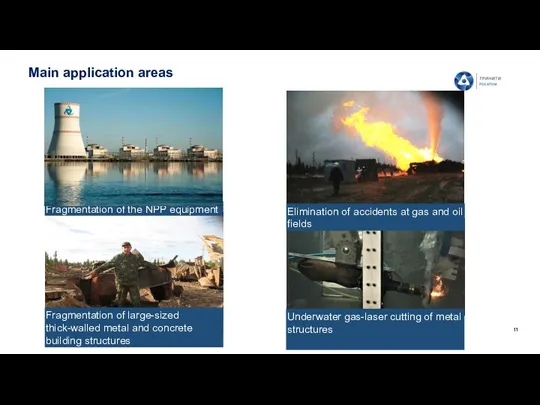

- 11. Main application areas Fragmentation of the NPP equipment Fragmentation of large-sized thick-walled metal and concrete building

- 12. 2. Solutions for elimination of emergency oil and oil-product spills in various conditions, including the Arctic

- 13. Federal law “On Amendments to Article 46 of the Federal Law "On Environmental Protection“” and certain

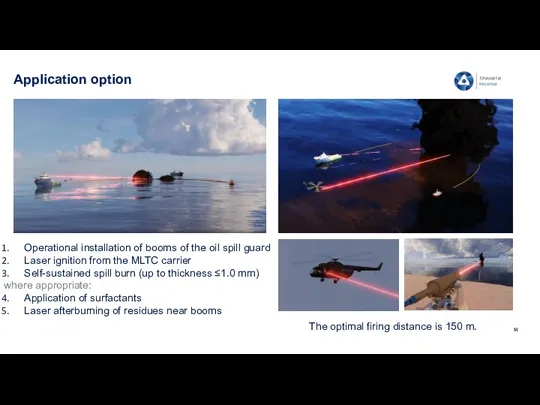

- 14. Application option Operational installation of booms of the oil spill guard Laser ignition from the MLTC

- 15. Equipment outline Laser – 850*800*1100 – 140 kg. Chiller – 400*480*550 – 46 kg. Battery –

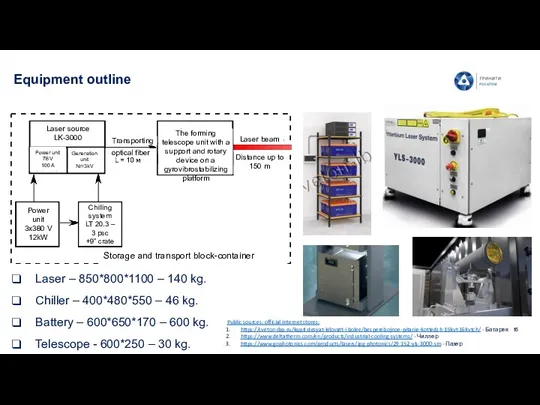

- 16. Approximate cost of developing the complex and providing services Terms: Development of the complex will take

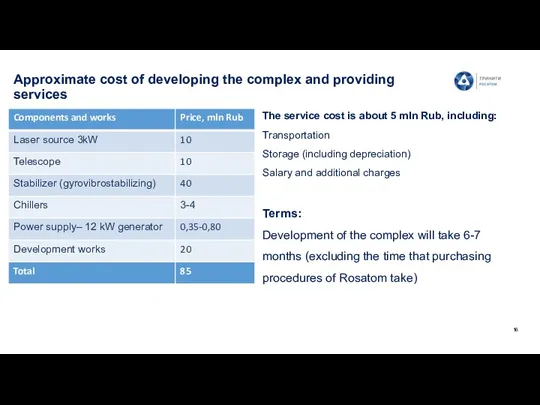

- 17. Successful demonstration of oil spill elimination Resistant oil emulsion on sand Resistant oil emulsion on water

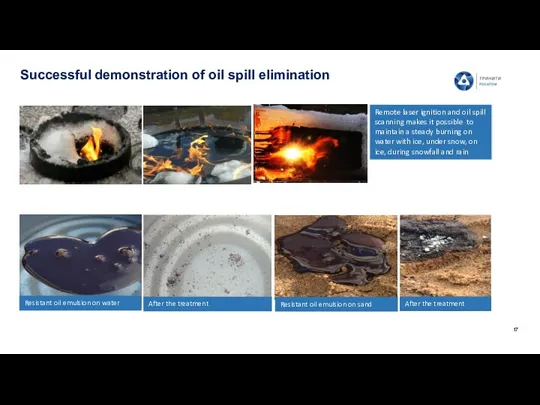

- 18. Advantages of laser oil spill elimination Safety for personnel, due to remote exposure (in the case

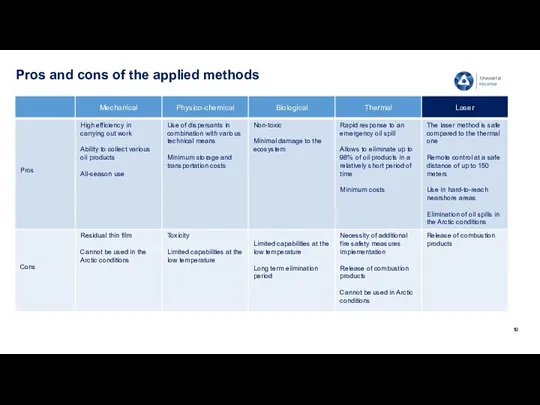

- 19. Pros and cons of the applied methods

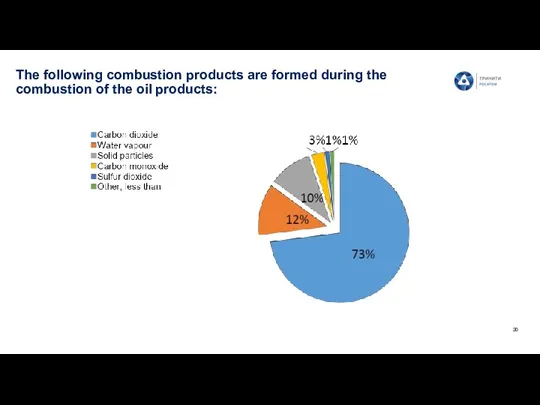

- 20. The following combustion products are formed during the combustion of the oil products:

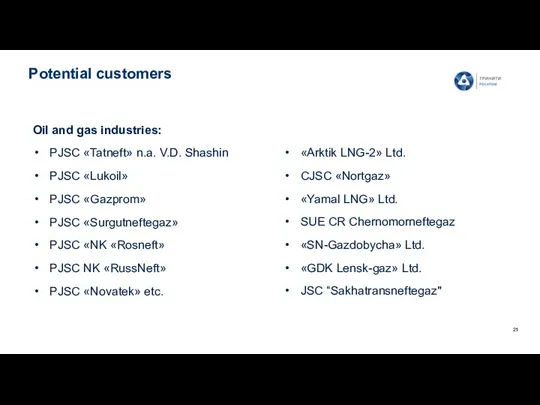

- 21. Potential customers Oil and gas industries: PJSC «Tatneft» n.a. V.D. Shashin PJSC «Lukoil» PJSC «Gazprom» PJSC

- 22. 3. Mobile laser technological complex for underwater cutting

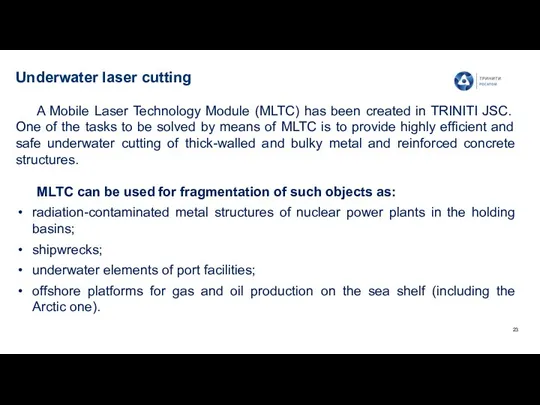

- 23. Underwater laser cutting A Mobile Laser Technology Module (MLTC) has been created in TRINITI JSC. One

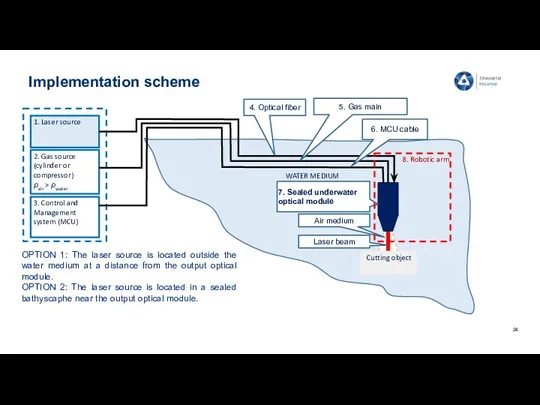

- 24. Implementation scheme 1. Laser source 2. Gas source (cylinder or compressor) ρair > ρwater 3. Control

- 25. Technology comparison

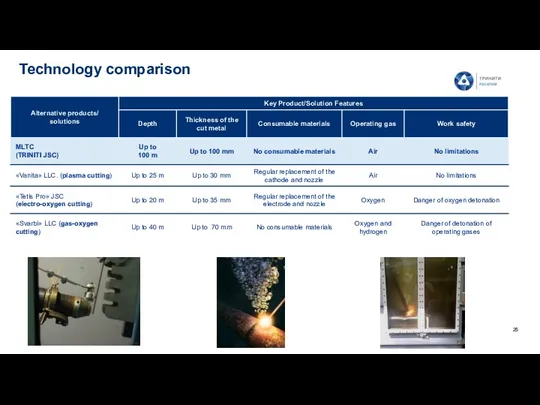

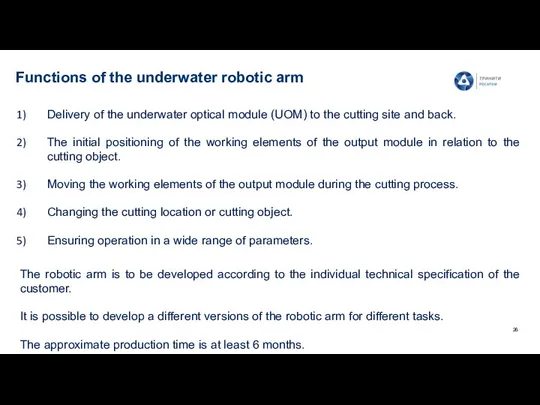

- 26. Functions of the underwater robotic arm The robotic arm is to be developed according to the

- 28. Скачать презентацию

Работа под управлением ОС Windows

Работа под управлением ОС Windows Многоэтажные промышленные здания

Многоэтажные промышленные здания f-6a699244

f-6a699244 Трансформаторы. Устройство трансформаторов

Трансформаторы. Устройство трансформаторов Внеурочная деятельность 4 класс. Презентация Умелые руки (мини-коробка) Диск

Внеурочная деятельность 4 класс. Презентация Умелые руки (мини-коробка) Диск Разноцветный маркетинг

Разноцветный маркетинг Метапредметная игра Самый умный

Метапредметная игра Самый умный Лабораторная работа: изучение элементов бурильной колонны

Лабораторная работа: изучение элементов бурильной колонны Визуально-оптический метод контроля

Визуально-оптический метод контроля Ультразвук и инфразвук. (9 класс)

Ультразвук и инфразвук. (9 класс) Бурение скважин. (Тема 1.4)

Бурение скважин. (Тема 1.4) 9 мая - День победы!

9 мая - День победы! Умножение дробей. 6 класс

Умножение дробей. 6 класс Симбиотикалық емес аэробты және анаэробты азотофиксаторлар

Симбиотикалық емес аэробты және анаэробты азотофиксаторлар Викторина. Фотографии

Викторина. Фотографии Презентация к уроку Химические свойства металлов

Презентация к уроку Химические свойства металлов Реализация образовательной области Физическая культура в соответствии с ФГТ ( итоги года)

Реализация образовательной области Физическая культура в соответствии с ФГТ ( итоги года) Трубопроводный транспорт нефти и газа

Трубопроводный транспорт нефти и газа Развитие речи на уроках русского языка в рамках реализации ФГОС

Развитие речи на уроках русского языка в рамках реализации ФГОС Отчеты главы города Нефтеюганска о результатах своей деятельности и результатах деятельности администрации города

Отчеты главы города Нефтеюганска о результатах своей деятельности и результатах деятельности администрации города Конкурс переводчиков

Конкурс переводчиков Решение уравнений. 7 класс

Решение уравнений. 7 класс Знаменитости умершие от употребления наркотиков-1

Знаменитости умершие от употребления наркотиков-1 Портфолио музыкального руководителя.

Портфолио музыкального руководителя. Презентация к родительскому собранию Как здорово, что есть семья

Презентация к родительскому собранию Как здорово, что есть семья презентация к статье Организация внеурочной деятельности в начальной школе.

презентация к статье Организация внеурочной деятельности в начальной школе. Комплексные меры борьбы с сорняками в посевах полевых культур. (Лекция 6)

Комплексные меры борьбы с сорняками в посевах полевых культур. (Лекция 6) Теория колебаний

Теория колебаний