< >

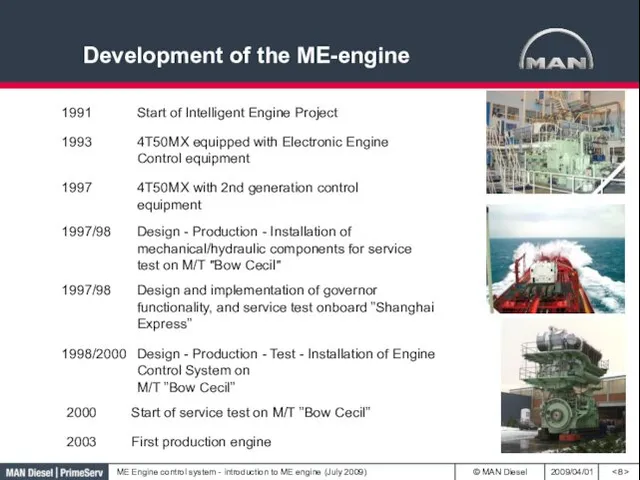

1991 Start of Intelligent Engine Project

1993 4T50MX equipped with Electronic Engine Control

equipment

1997 4T50MX with 2nd generation control equipment

2003 First production engine

1998/2000 Design - Production - Test - Installation of Engine Control System on

M/T ”Bow Cecil”

1997/98 Design - Production - Installation of mechanical/hydraulic components for service test on M/T "Bow Cecil"

2000 Start of service test on M/T ”Bow Cecil”

1997/98 Design and implementation of governor functionality, and service test onboard ”Shanghai Express”

Development of the ME-engine

20190716_proekt_dvazhdy_dva_chetyre

20190716_proekt_dvazhdy_dva_chetyre Библиографический калейдоскоп

Библиографический калейдоскоп Проза и стихи – братья или враги?

Проза и стихи – братья или враги? Презентация мастер-класса к занятию по теме Новогодняя сказка

Презентация мастер-класса к занятию по теме Новогодняя сказка Презентация : Организация работы по воспитанию у детей сознательной дисциплины и культуры поведения.

Презентация : Организация работы по воспитанию у детей сознательной дисциплины и культуры поведения. Словарные слова (1-2 класс)

Словарные слова (1-2 класс) Хроническая сердечная недостаточность

Хроническая сердечная недостаточность Портфолио тьютора - Базуновой Н.А. ГБОУ ГСГ СП-10. Москва.

Портфолио тьютора - Базуновой Н.А. ГБОУ ГСГ СП-10. Москва. Оценочная деятельность

Оценочная деятельность Мир природы в стихах и сказках

Мир природы в стихах и сказках Проектная и исследовательская деятельность в начальной школе

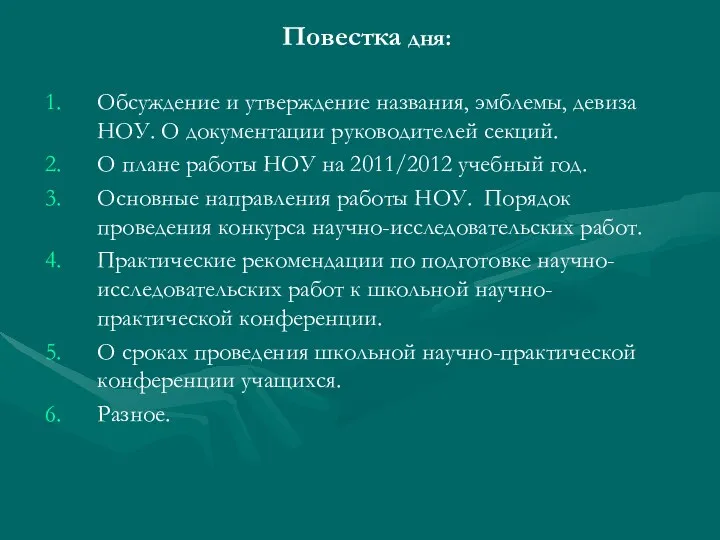

Проектная и исследовательская деятельность в начальной школе Заседание №1 клуба Поиск (НОУ)

Заседание №1 клуба Поиск (НОУ) Буклет Нашим дедушкам и бабушкам посвящается…

Буклет Нашим дедушкам и бабушкам посвящается… Торжественная линенйка, посвященная инаугурации президента школы

Торжественная линенйка, посвященная инаугурации президента школы Почерк и характер

Почерк и характер Презентация Формирование валеологической культуры дошкольников

Презентация Формирование валеологической культуры дошкольников Здоровьесберегающие технологии на занятиях по иностранному языку

Здоровьесберегающие технологии на занятиях по иностранному языку Презентация Сенсорное воспитание детей старшего дошкольного возраста

Презентация Сенсорное воспитание детей старшего дошкольного возраста Биржа как инструмент рынка

Биржа как инструмент рынка Программирование как этап решения задач на компьютере. Начала программирования

Программирование как этап решения задач на компьютере. Начала программирования Геотермалдық энергиясы

Геотермалдық энергиясы Кто курит табак, тот сам себе враг

Кто курит табак, тот сам себе враг Города на старых водных торговых путях

Города на старых водных торговых путях Кто имя дал славное городу. История названия нашего города - Прокопьевск

Кто имя дал славное городу. История названия нашего города - Прокопьевск Упрощение логических выражений

Упрощение логических выражений Віруси

Віруси Сибирская металлургическая база

Сибирская металлургическая база Профилактика виктимного поведения у обучающихся группы риска

Профилактика виктимного поведения у обучающихся группы риска