Содержание

- 2. Catalogue 1、Introduction of working principle 2、Introduction of main circuit(parts different from MMA) 3、Introduction of control circuit(parts

- 3. 1、Introduction of working principle

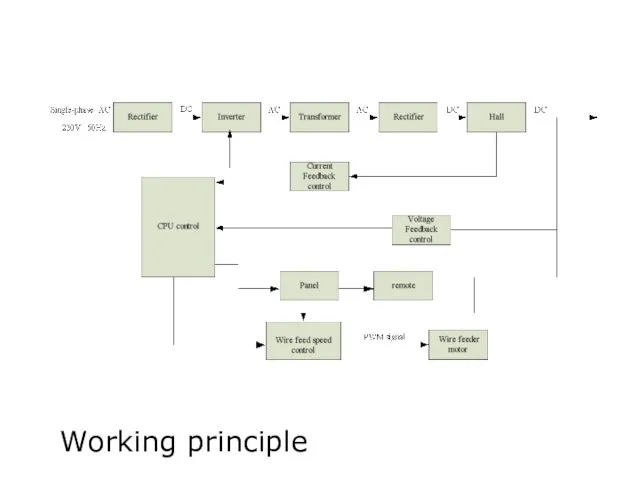

- 4. Working principle

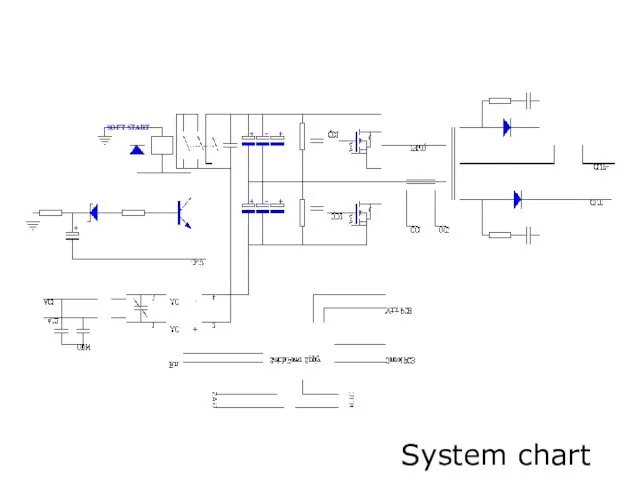

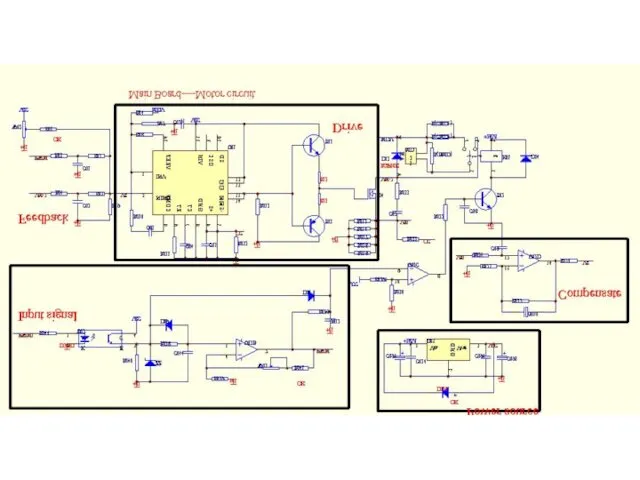

- 5. System chart SOFT START

- 9. 2、Introduction of main circuit(parts different from MMA)

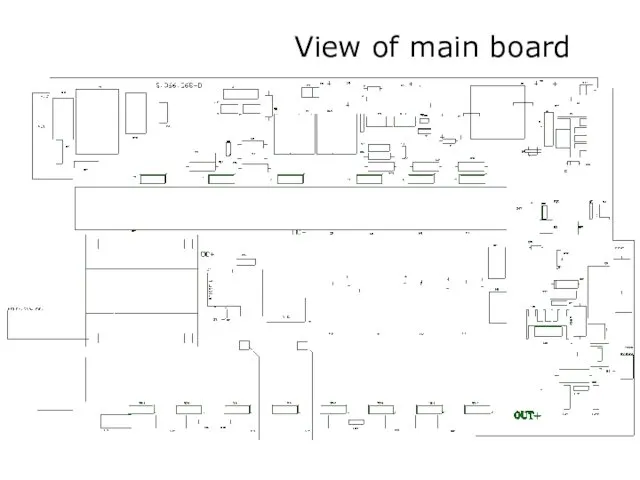

- 11. View of main board

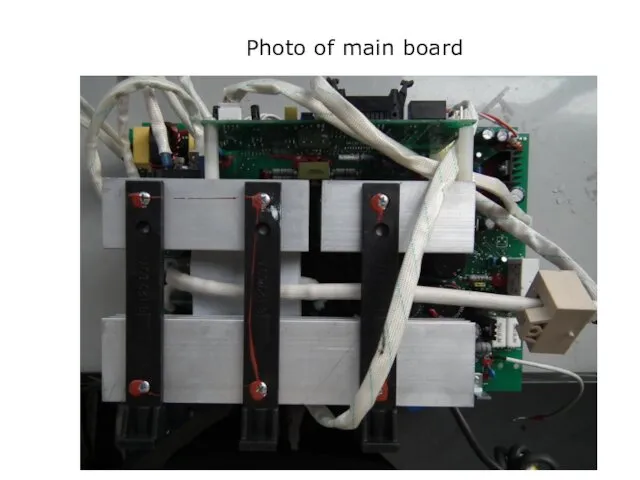

- 12. Photo of main board

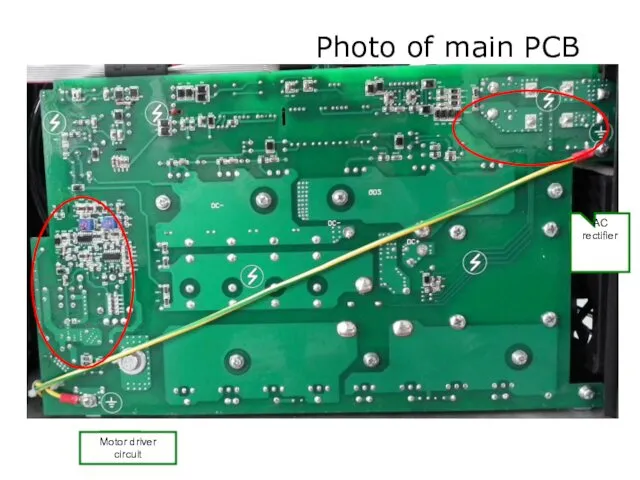

- 13. Photo of main PCB AC rectifier Motor driver circuit

- 14. 3、Introduction of control circuit(parts different from MMA)

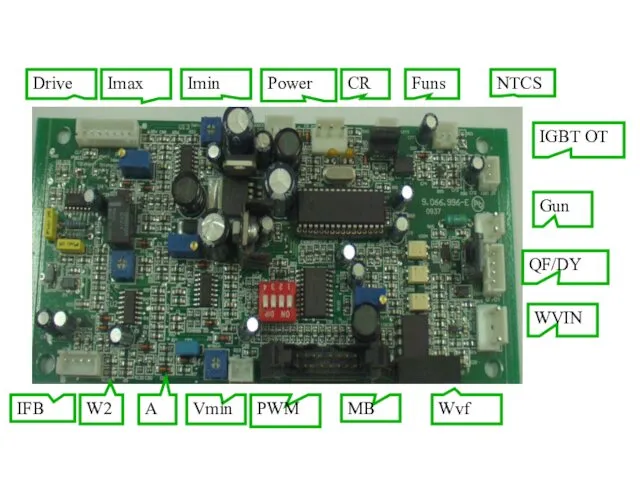

- 17. WVIN IGBT OT Gun QF/DY Drive Power CR NTCS Funs IFB PWM MB Imax Imin W2

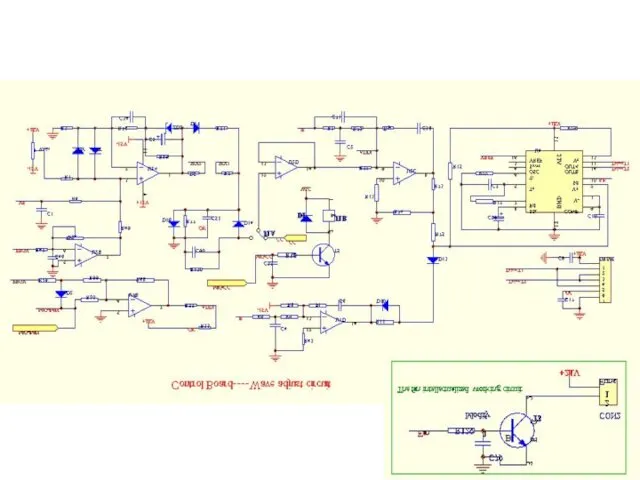

- 18. DRIVE--Connected with main board to provide drive signal for discrete IGBT. Pin 1---- +15V;Pin 2~5---- Drive

- 19. IGBT OT--Connected with the IGBT NTC to provide over-temperature signal for MCU. WVIN--Connected with the output

- 20. Imax—used to adjust maximum welding current (MMA). Imin—used to adjust minimum welding current (MMA). A—used to

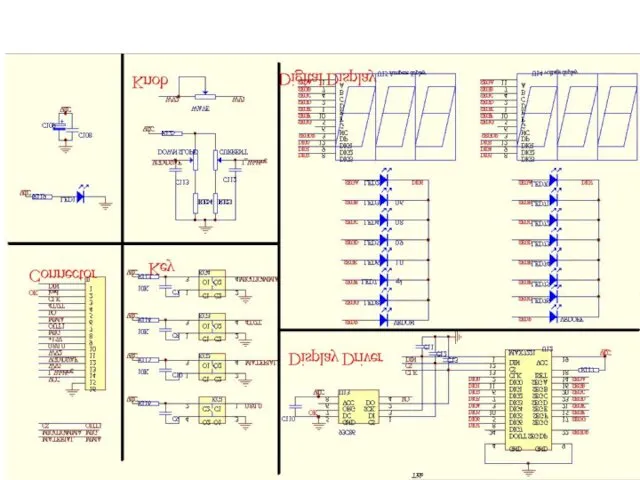

- 21. 4、Introduction of panel circuit

- 22. Electrical drawing of panel board

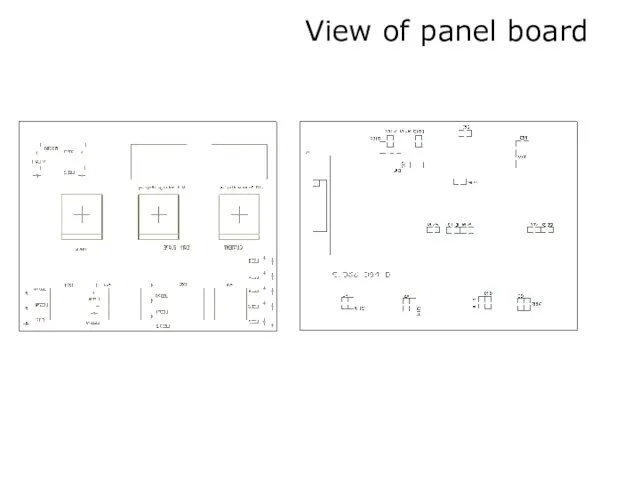

- 23. View of panel board

- 24. Photo of panel board

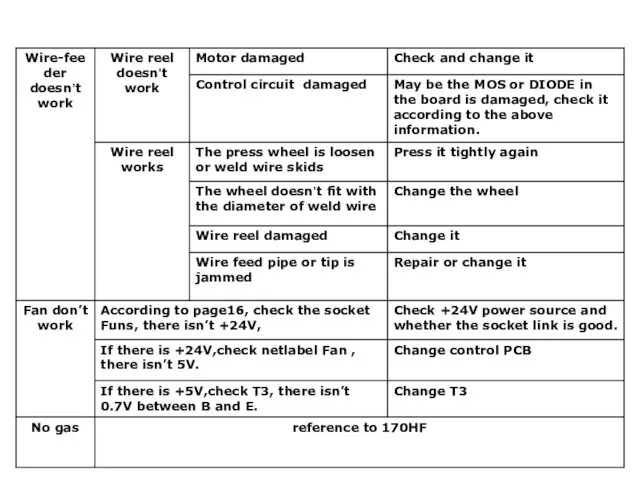

- 25. 5、Troubleshooting Series A: Troubles about panel display Series B: Troubles about power system

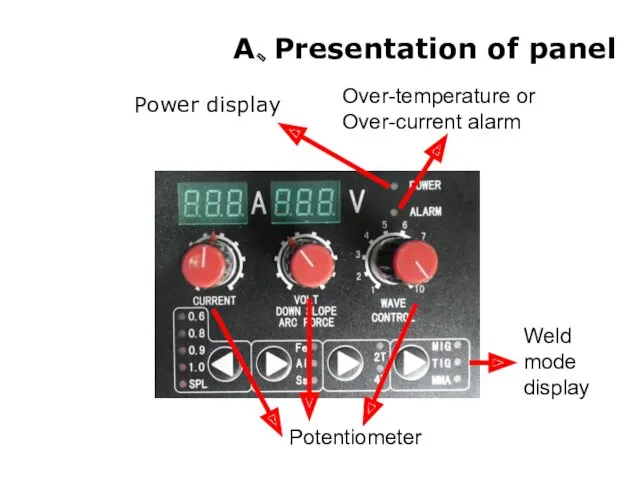

- 26. A、Presentation of panel Power display Over-temperature or Over-current alarm Potentiometer Weld mode display

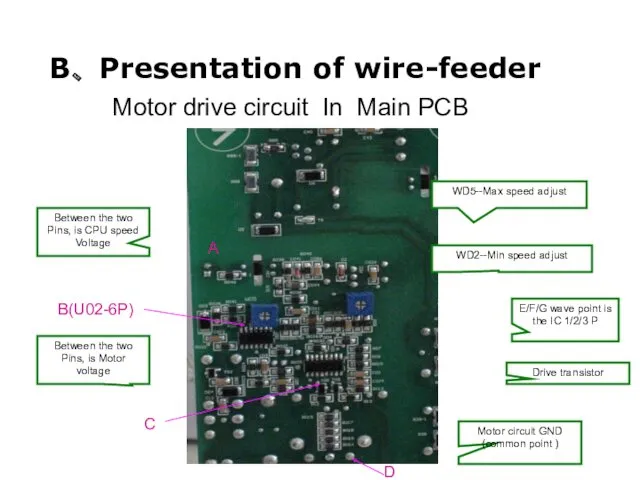

- 27. Motor drive circuit In Main PCB WD5--Max speed adjust WD2--Min speed adjust Between the two Pins,

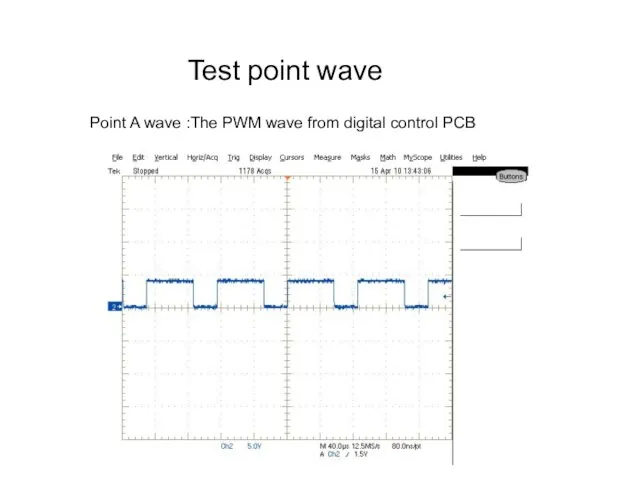

- 28. Test point wave Point A wave :The PWM wave from digital control PCB

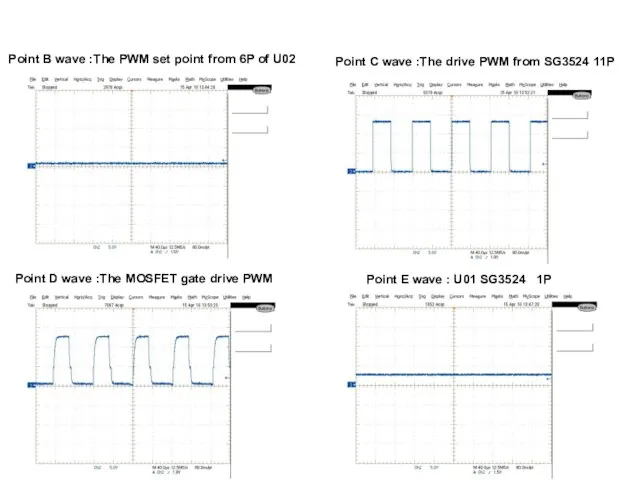

- 29. Point B wave :The PWM set point from 6P of U02 Point C wave :The drive

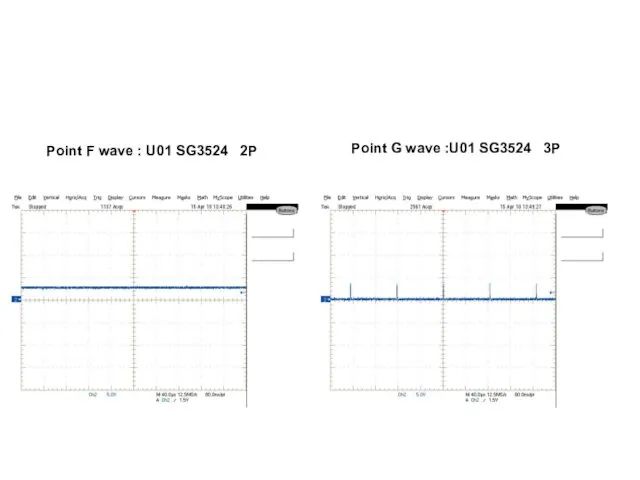

- 30. Point F wave : U01 SG3524 2P Point G wave :U01 SG3524 3P

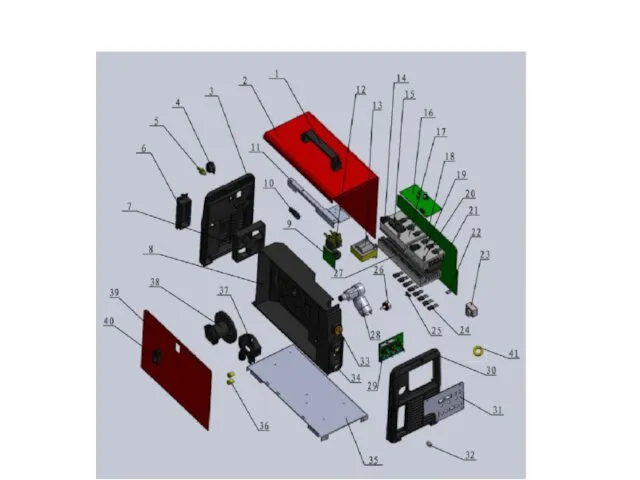

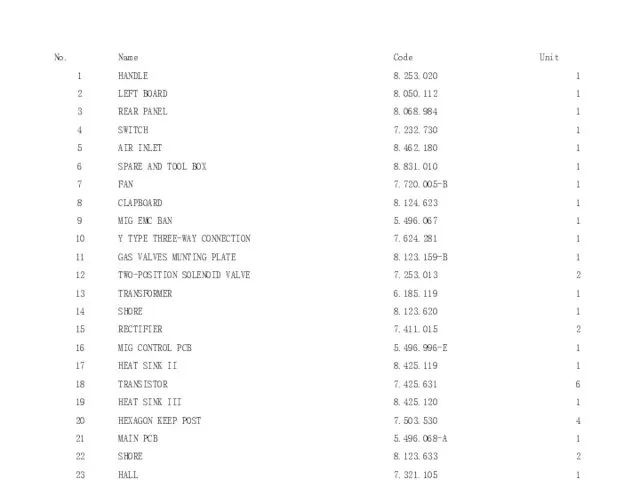

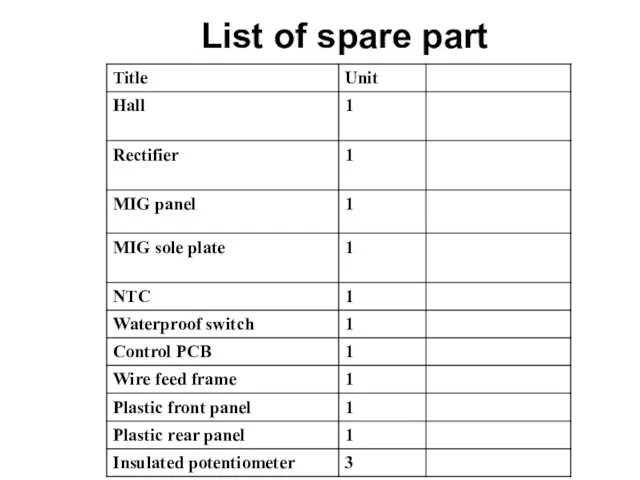

- 32. List of spare part

- 34. Скачать презентацию

Конспект образовательной деятельности по экологии в средней группе с использованием ИКТ на тему: Берегите лес

Конспект образовательной деятельности по экологии в средней группе с использованием ИКТ на тему: Берегите лес Основные характеристики центрального процессора

Основные характеристики центрального процессора методическое пособие

методическое пособие Теоретические основы органической химии

Теоретические основы органической химии немного обо мне

немного обо мне Автоматизация звука Ч в словах, предложениях.

Автоматизация звука Ч в словах, предложениях. Презентация Панорама классного часа.

Презентация Панорама классного часа. Перинатальная патология центральной нервной системы

Перинатальная патология центральной нервной системы Синегнойная палочка (Pseudomonas aeruginosa)

Синегнойная палочка (Pseudomonas aeruginosa) Навигационное планирование и подготовка судна к переходу по маршруту

Навигационное планирование и подготовка судна к переходу по маршруту Балалар ертегілері

Балалар ертегілері Моя будущая профессия: Стоматолог

Моя будущая профессия: Стоматолог Представление о семье!!!

Представление о семье!!! Базовые понятия языка Си

Базовые понятия языка Си Знаменитые люди поселка Вырица. Иван Антонович Ефремов

Знаменитые люди поселка Вырица. Иван Антонович Ефремов Презентация 1

Презентация 1 Шероховатость поверхности

Шероховатость поверхности Система финансирования дополнительных занятий

Система финансирования дополнительных занятий Любимый мой Башкортостан

Любимый мой Башкортостан проект Солнышко в технике изонити

проект Солнышко в технике изонити Моя мама учитель. презентация

Моя мама учитель. презентация Физиология нейрона, нервного волокна и синапса

Физиология нейрона, нервного волокна и синапса Кроссворд на тему Отечественная война 1812 года

Кроссворд на тему Отечественная война 1812 года класс. ЛР №5

класс. ЛР №5 Конденсационная установка

Конденсационная установка Презентация Весёлая гимнастика для язычка часть2

Презентация Весёлая гимнастика для язычка часть2 XIX Всемирный фестиваль молодёжи и студентов

XIX Всемирный фестиваль молодёжи и студентов Сегментирование и позиционирование

Сегментирование и позиционирование