Содержание

- 2. Preview

- 3. Introduction Pasta is popular because it… Is nutritious Is convenient to buy and prepare Has a

- 4. Inputs: Ingredients Semolina made from durum wheat Water Salt

- 5. Inputs: Ingredients Optional: Eggs Spinach, tomato puree, chilli, mushrooms for flavour Substitutes: Rice, corn, spelt, kamut

- 6. Selection of Semolina Semolina preferential to other flours for its Particle size High protein content of

- 7. Combining ingredients Three steps involve Mixing Processing Extruding

- 8. Combining ingredients: Pre-mixing Ingredients flows into mixer is regulated by a volumetric or gravimetric doser 0.180mm

- 9. Combining ingredients: Mixing Bubbles are removed by a conventional dual shaft mixer to prevent a weak

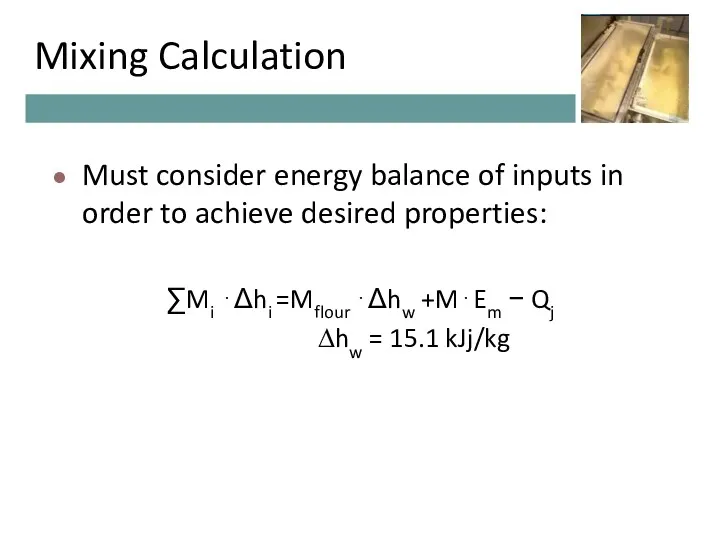

- 10. Mixing Calculation Must consider energy balance of inputs in order to achieve desired properties: ∑Mi ⋅Δhi

- 11. Combining ingredients: Extrusion Gluten matrix develops, assuming dough was sufficiently hydrated

- 12. Extrusion An extruder ____ the dough. Convey Compacts Kneads Relaxes Extrudes

- 13. Extrusion Hydrated semolina mixture drops directly onto the extrusion screw Screw brings mixture to extrusion barrel,

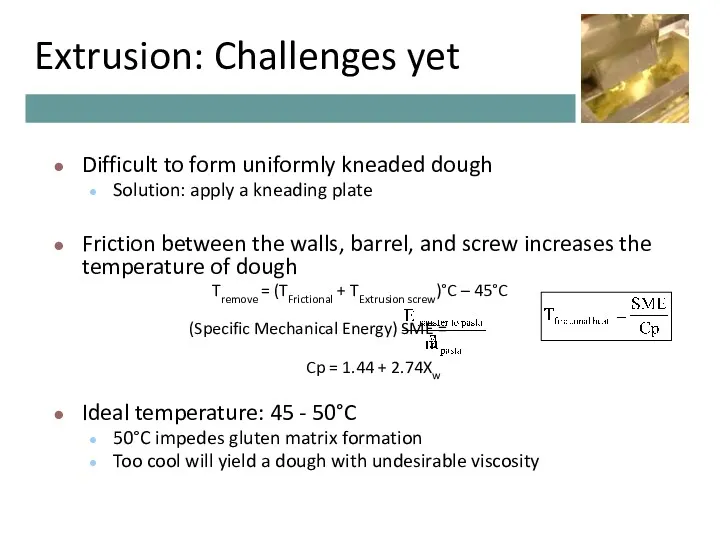

- 14. Extrusion: Challenges yet Difficult to form uniformly kneaded dough Solution: apply a kneading plate Friction between

- 15. Extrusion Long pasta, like spaghetti are allowed a brief rest before entering the die in the

- 16. Extrusion Die is used with an insert to shape pasta Shape of insert determines shape of

- 17. Extrusion Long pastas are left to stand on a spreader which cuts them into uniform lengths

- 18. Drying Purpose: to reduce moisture content to 12% to extend shelf life Limits bacterial growth To

- 19. Drying Four factors involved: Humidity Temperature Time exposure to heat Air flow Air flow and time

- 20. Drying: Air flow Direct contact between air and the pasta enables the most efficient method of

- 21. Drying: Humidity Wet hot air (40-70% w/w) Prevent product from cracking at high temperatures

- 22. Drying: Exposure Time High temperatures requires shorter exposure time Rapid drying may form cracks in the

- 23. Drying: Temperature Needs to be regulated because Too high: damage product and destroy nutrients Too low:

- 24. Drying: Temperature Regulations Short pastas are regulated by: Being on a shaking pre-dryer to decrease time

- 25. Use of Ultra High Temperature Application of Ultra-High Temperature May cause non-enzymatic browning May result in

- 26. Improper cooling? Damage the packaging Contaminated product Brittle product

- 27. Nutritional and Sensory Quality Nutritious Carbohydrates Protein Vitamin B Iron Folic acid Not fattening itself

- 28. Nutritional and Sensory Quality Ideal food for diabetics, especially whole grain products Slow digestion Maintains steady

- 29. Nutritional and Sensory Quality Yellowness of pasta determine by Adding eggs Adding β-carotene (most times) β-carotene

- 30. Nutritional and Sensory Quality Cooking should not exceed >50°C Damage gluten matrix Loss of lysine, vitamins,

- 31. Summary Mixing, extruding, and drying are required in pasta processing Extrusion process forms gluten network Useful

- 32. Summary Drying creates a moisture gradient Reduces required drying energy, temperature, and time Drying requires attention

- 34. Скачать презентацию

Основные понятия информационных технологий

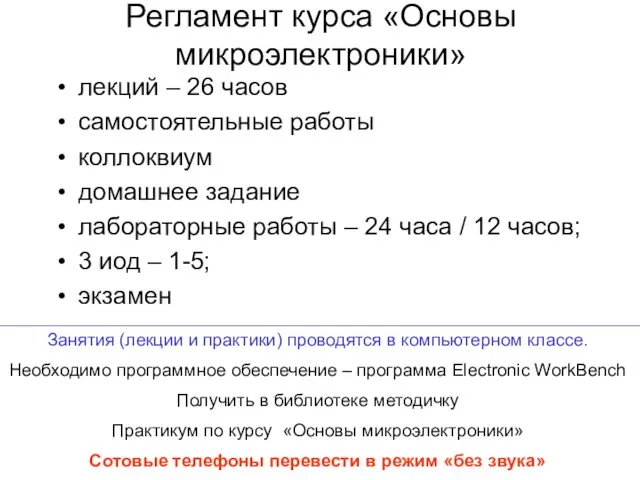

Основные понятия информационных технологий Основы микроэлектроники

Основы микроэлектроники Дикие животные

Дикие животные Писатели нашего района

Писатели нашего района Частица НЕ в пословицах, поговорках и загадках

Частица НЕ в пословицах, поговорках и загадках Проектирование автомобильных дорог

Проектирование автомобильных дорог Оценка теневой активности компаний строительной отрасли (на примере города Челябинска)

Оценка теневой активности компаний строительной отрасли (на примере города Челябинска) Храм бессребреников Космы и Дамиана в д. Долоцкое Устюженского района

Храм бессребреников Космы и Дамиана в д. Долоцкое Устюженского района Тематическая викторина. Растениеводство в фольклоре. Загадки.

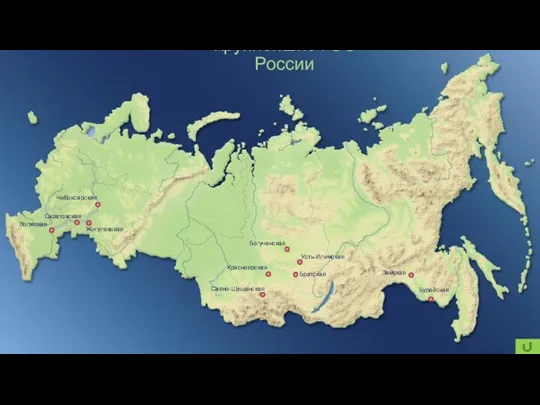

Тематическая викторина. Растениеводство в фольклоре. Загадки. Крупнейшие ГЭС России

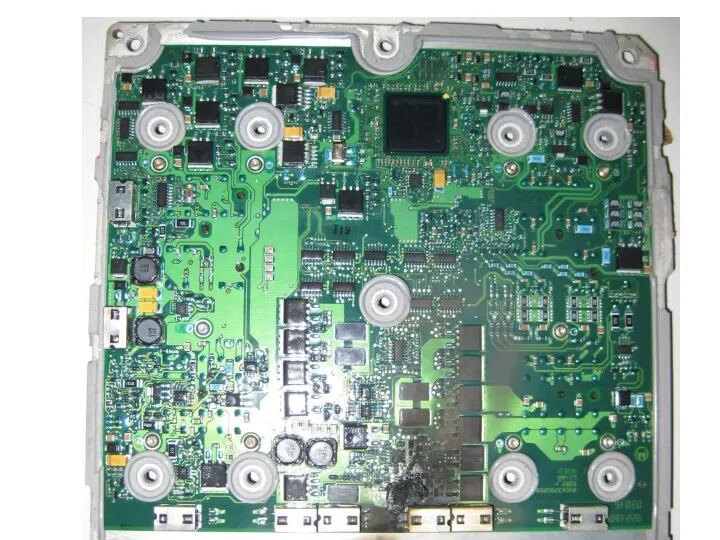

Крупнейшие ГЭС России EMS mulfunction

EMS mulfunction Топливная система тепловоза

Топливная система тепловоза Рекомендации от составителей КИМ по обществознанию

Рекомендации от составителей КИМ по обществознанию Аҳоли орасида соғлом турмуш-тарзини шакллантиришнинг замонавий йўналишлари мавзусида врачларнинг малакасини ошириш цикли

Аҳоли орасида соғлом турмуш-тарзини шакллантиришнинг замонавий йўналишлари мавзусида врачларнинг малакасини ошириш цикли Развитие художественно-эстетических умений на уроках декоративного рисования

Развитие художественно-эстетических умений на уроках декоративного рисования Презентация педагогического проекта Формирование элементарных математических представлений как средство развития мыслительной деятельности у дошкольников с задержкой психического развития

Презентация педагогического проекта Формирование элементарных математических представлений как средство развития мыслительной деятельности у дошкольников с задержкой психического развития Австралия - маленький материк с большим сердцем

Австралия - маленький материк с большим сердцем Презентация для детей Домашние животные

Презентация для детей Домашние животные Социальный контракт

Социальный контракт Дифференциальная диагностика сыпи у детей

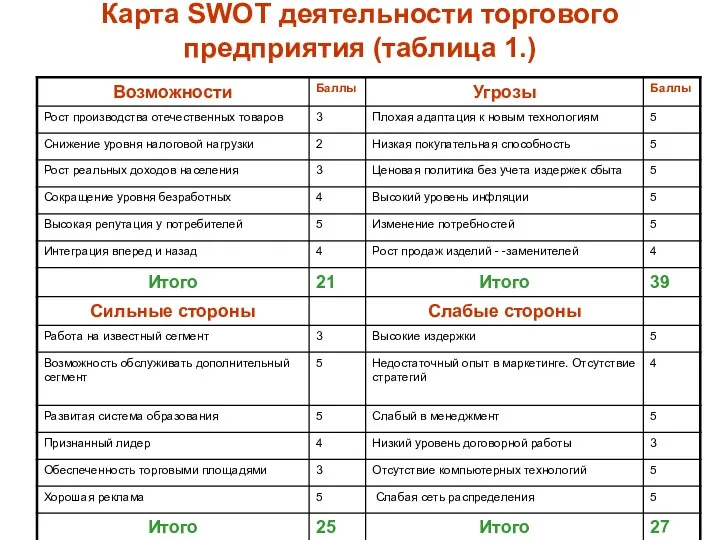

Дифференциальная диагностика сыпи у детей Карта SWOT деятельности торгового предприятия

Карта SWOT деятельности торгового предприятия Сценарий интеллектуального конкурса для старших дошкольников Я шагаю по Москве

Сценарий интеллектуального конкурса для старших дошкольников Я шагаю по Москве Открытое занятие по внеурочной деятельности Умелые ручки

Открытое занятие по внеурочной деятельности Умелые ручки Информационно-технологическое обеспечение государственной (итоговой) аттестации обучающихся, освоивших образовательные программы основного общего образования.

Информационно-технологическое обеспечение государственной (итоговой) аттестации обучающихся, освоивших образовательные программы основного общего образования. Создание предметно – развивающей среды в ДОУ в соответствии с ФГОС

Создание предметно – развивающей среды в ДОУ в соответствии с ФГОС Співвідношення типів даних та елементів для введення даних, зчитування даних з елементів введення

Співвідношення типів даних та елементів для введення даних, зчитування даних з елементів введення Пример презентации Наладчик

Пример презентации Наладчик О дарах Святого Духа

О дарах Святого Духа