Содержание

- 2. Content and Structure Content: Definitions and Principles – why implement QAQC? Types of QAQC: Drilling Survey

- 3. Definitions and Principles – why implement QAQC? QAQC is an often underestimated/overlooked step that is CRITICAL

- 4. Take Away Statement Data Quality: Examples of Common Issues “Data Quality Issues will influence Mineral Resource

- 5. Definitions and Principles – why implement QAQC? “Poor Data in, Poor Estimates Out……put politely” Data Quality:

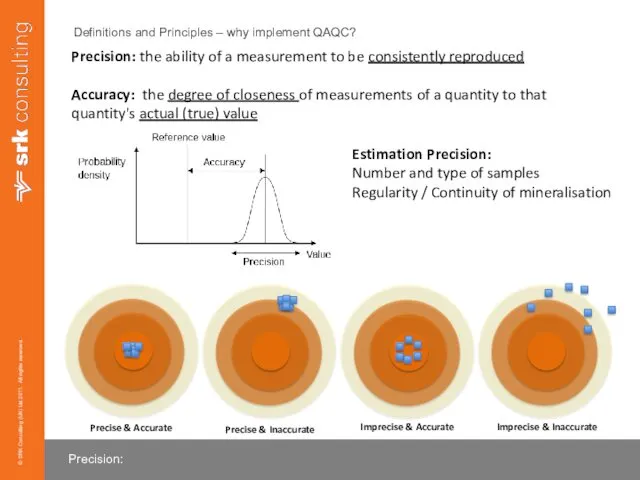

- 6. Definitions and Principles – why implement QAQC? Precision: Precision: the ability of a measurement to be

- 7. Drilling Things to look out for Sample recovery: Is a representative sample being recovered? Does the

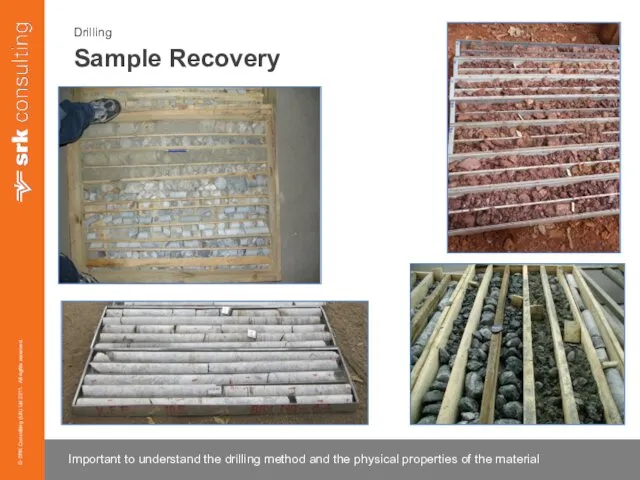

- 8. Drilling Sample Recovery Important to understand the drilling method and the physical properties of the material

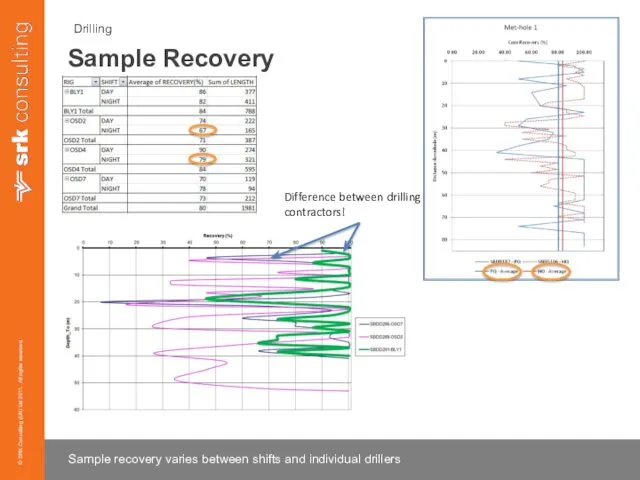

- 9. Drilling Sample recovery varies between shifts and individual drillers Sample Recovery Difference between drilling contractors!

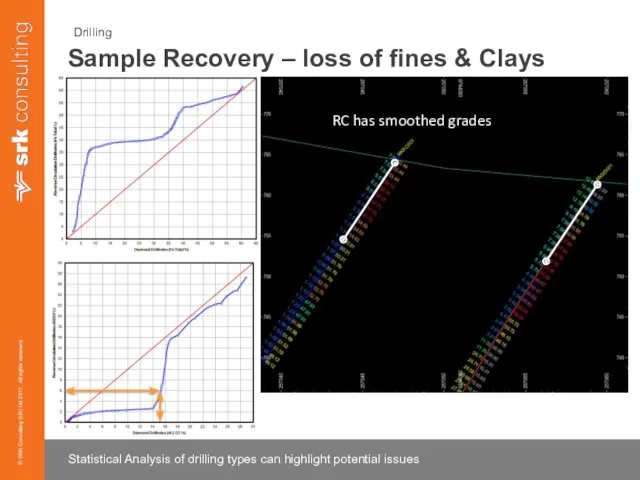

- 10. Drilling Statistical Analysis of drilling types can highlight potential issues Sample Recovery – loss of fines

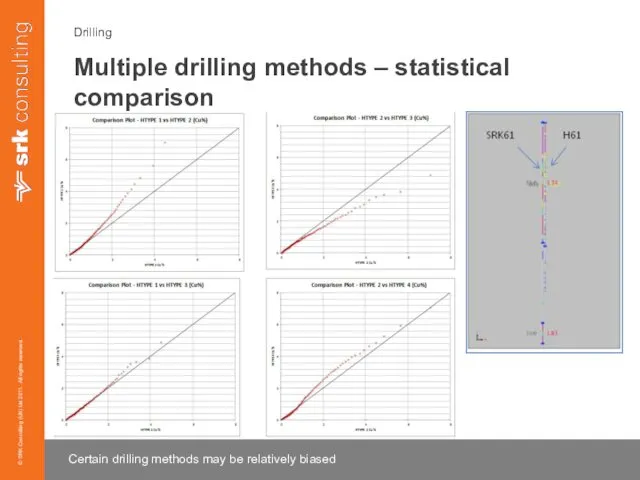

- 11. Drilling Multiple drilling methods – statistical comparison Certain drilling methods may be relatively biased

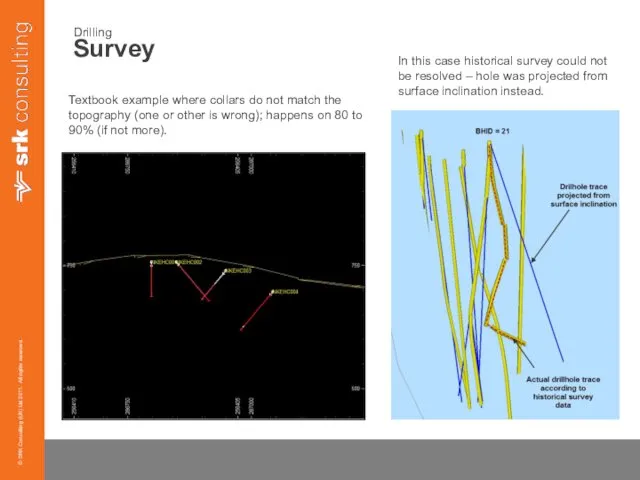

- 12. Drilling Survey Textbook example where collars do not match the topography (one or other is wrong);

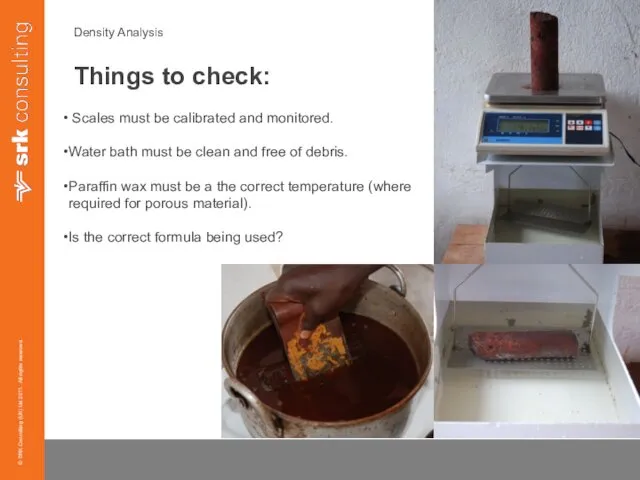

- 13. Density Analysis Things to check: Scales must be calibrated and monitored. Water bath must be clean

- 14. Laboratory QAQC The aim of a good QAQC program: Practices and procedures used in the sampling

- 15. Laboratory QAQC Sampling, Assaying, Rice and Risk 50,000 grains in 1 kg of rice. 1g/t Au

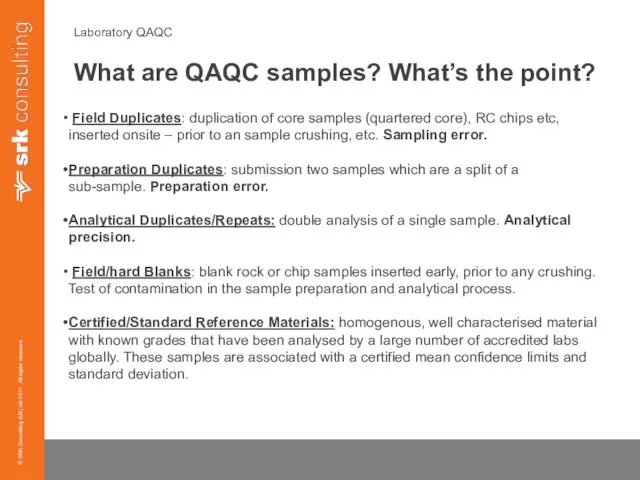

- 16. Laboratory QAQC What are QAQC samples? What’s the point? Field Duplicates: duplication of core samples (quartered

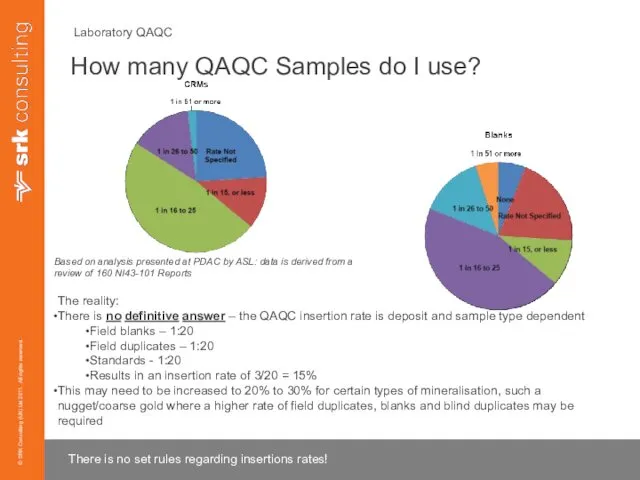

- 17. Laboratory QAQC How many QAQC Samples do I use? There is no set rules regarding insertions

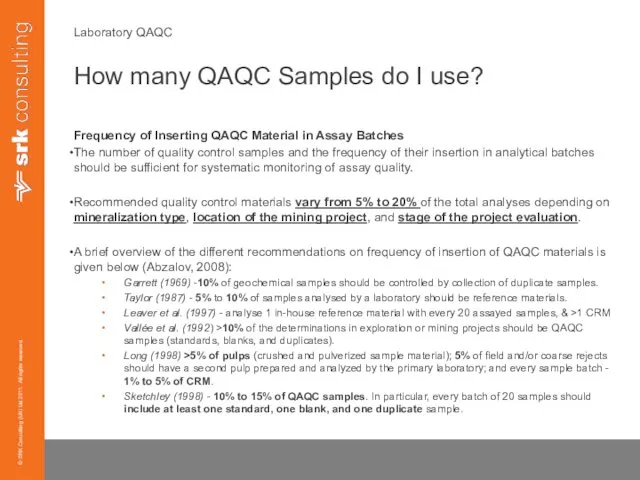

- 18. Laboratory QAQC How many QAQC Samples do I use? Frequency of Inserting QAQC Material in Assay

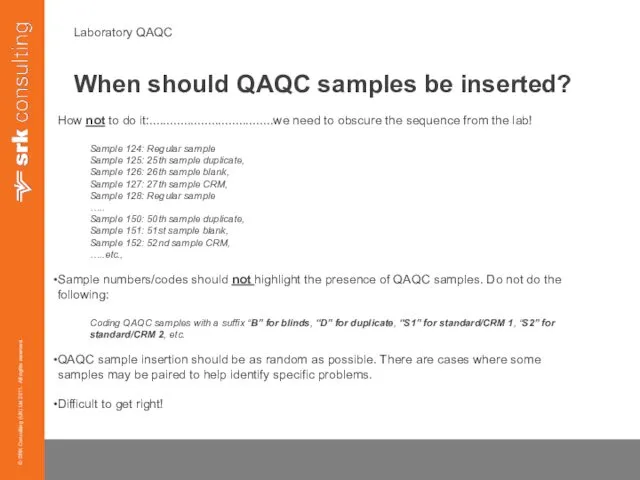

- 19. Laboratory QAQC When should QAQC samples be inserted? How not to do it:....................................we need to obscure

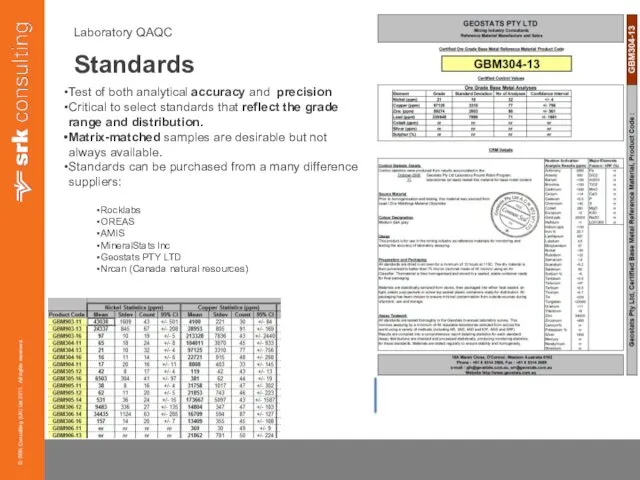

- 20. Laboratory QAQC Standards Test of both analytical accuracy and precision Critical to select standards that reflect

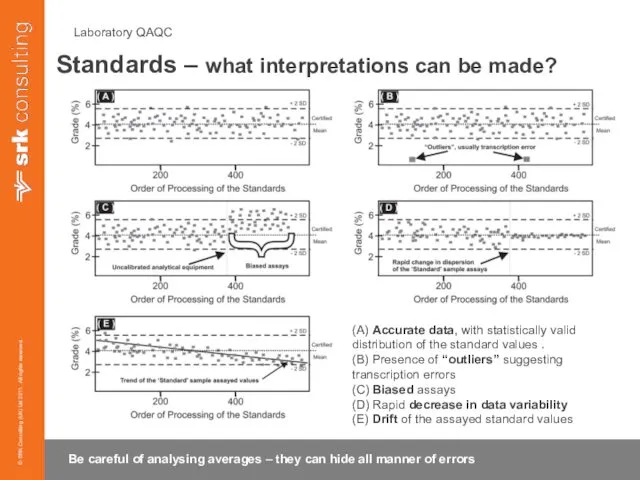

- 21. Laboratory QAQC Be careful of analysing averages – they can hide all manner of errors (A)

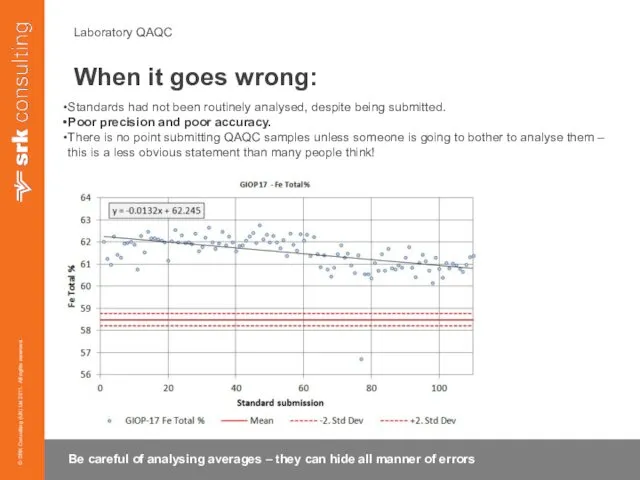

- 22. Laboratory QAQC When it goes wrong: Be careful of analysing averages – they can hide all

- 23. Laboratory QAQC Observation of improvements

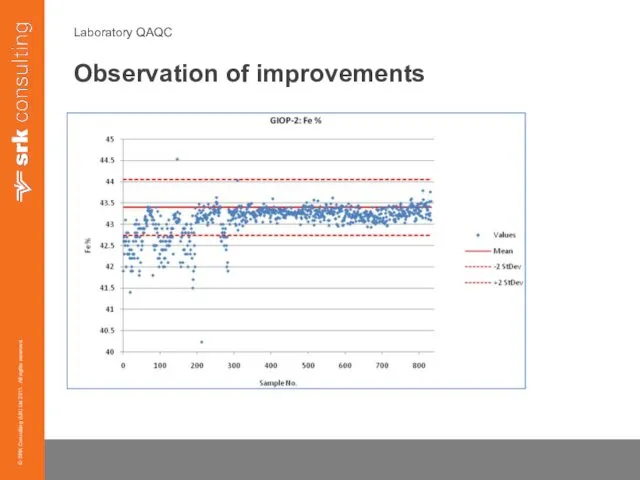

- 24. Laboratory QAQC Duplicates Bias at an onsite lab (iron ore XRF). Not detected for several weeks

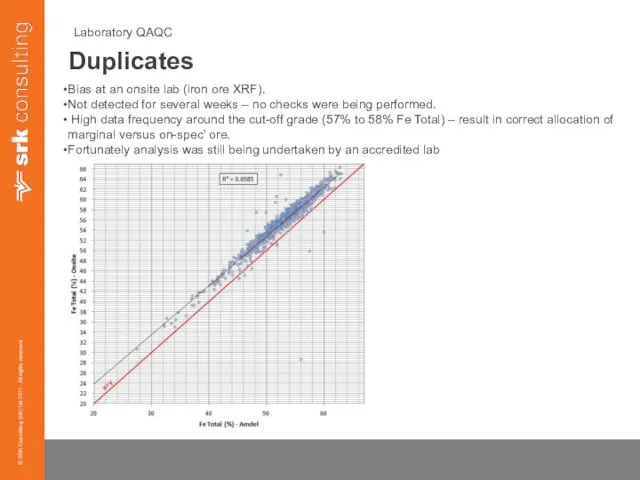

- 25. Laboratory QAQC Duplicates Analysis Transcription errors?

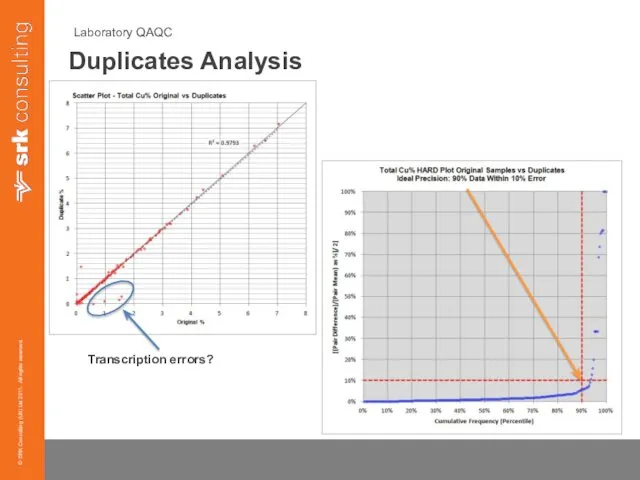

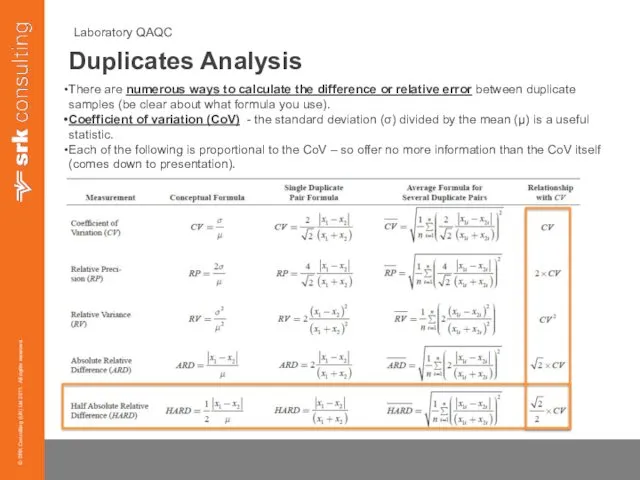

- 26. Laboratory QAQC Duplicates Analysis There are numerous ways to calculate the difference or relative error between

- 27. Laboratory QAQC Blanks Sourcing blanks can be difficult for some projects – matching the colour with

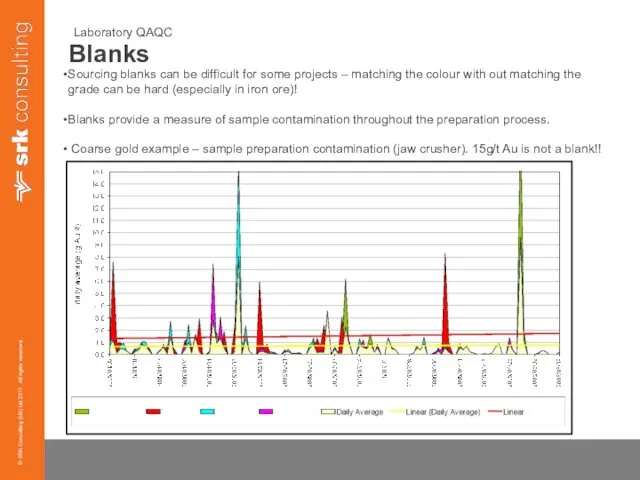

- 28. Laboratory QAQC Blanks The problem: crushing and pulverising equipment was not adequately clean between samples. Gold

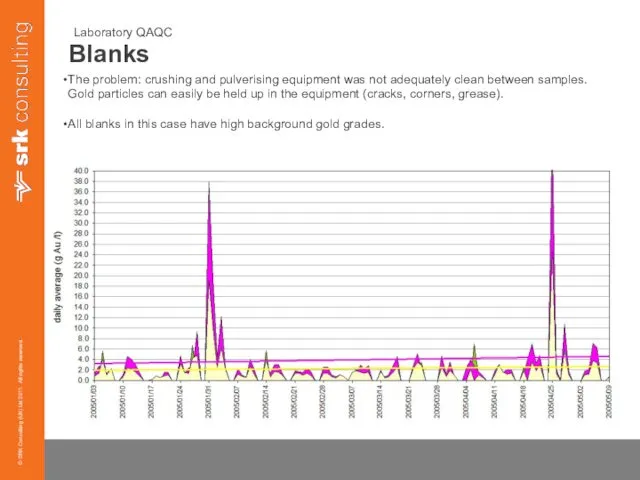

- 29. Laboratory QAQC Decisions Points

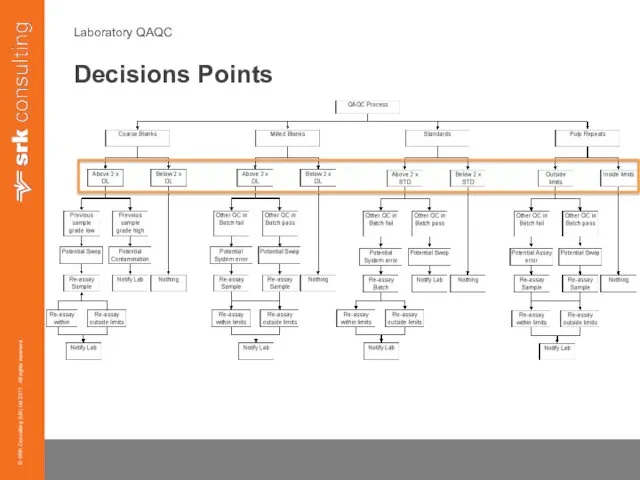

- 30. SRK Coal QAQC Coal QAQC: Data Collection – common problems: Geophysical logs and Lithologically and Structural

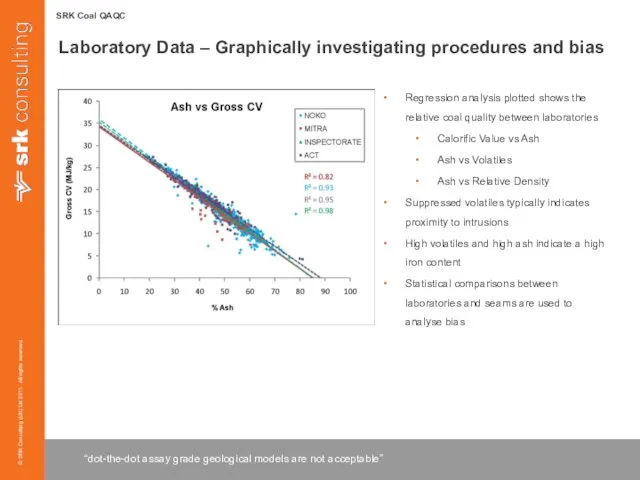

- 31. Take Away Statement “dot-the-dot assay grade geological models are not acceptable” © SRK Consulting (UK) Ltd

- 32. QAQC Databases

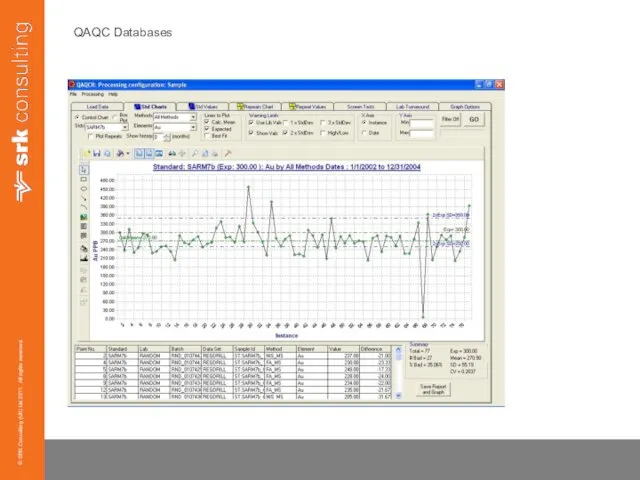

- 33. Auditing Laboratories and Preparation Facilities – What to Look out for! Are samples stored and delivered

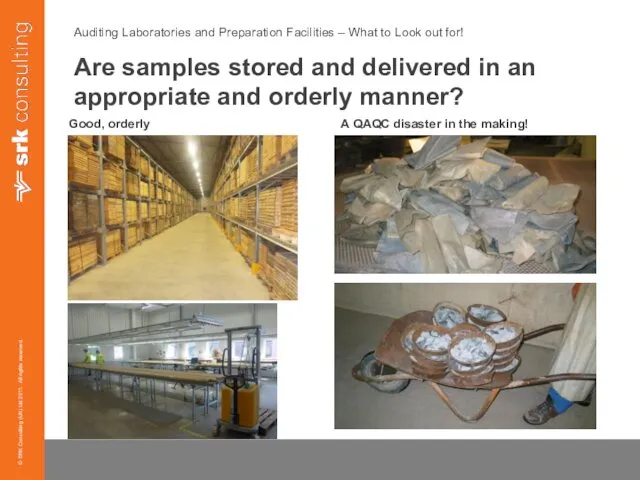

- 34. Auditing Laboratories and Preparation Facilities – What to Look out for! Are samples identifiable, labelled, etc?

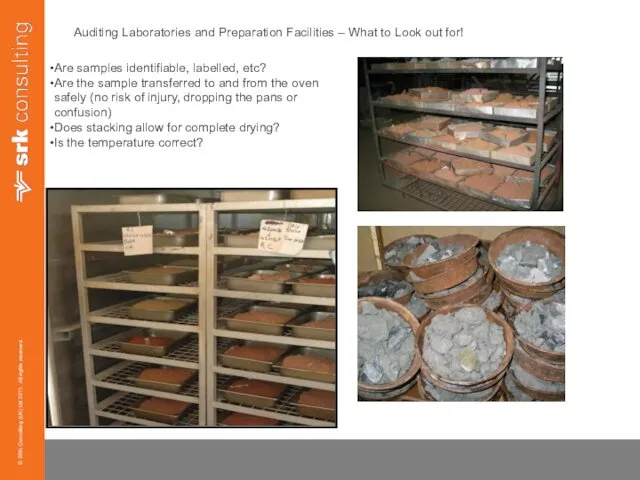

- 35. Auditing Laboratories and Preparation Facilities – What to Look out for! The Good, Bad and the

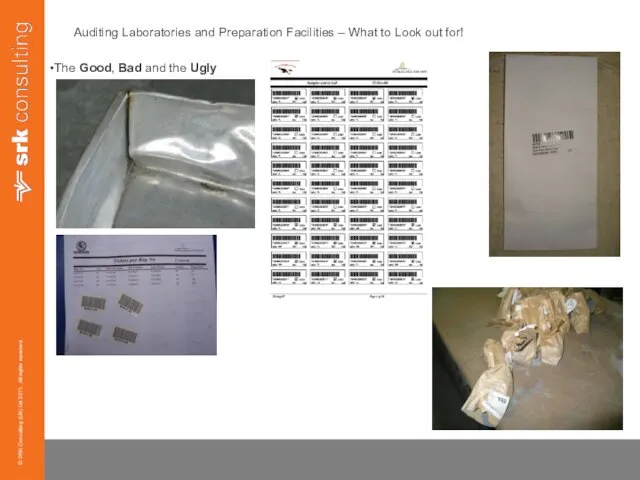

- 36. Auditing Laboratories and Preparation Facilities – What to Look out for! Crushing and Pulverising Blanks should

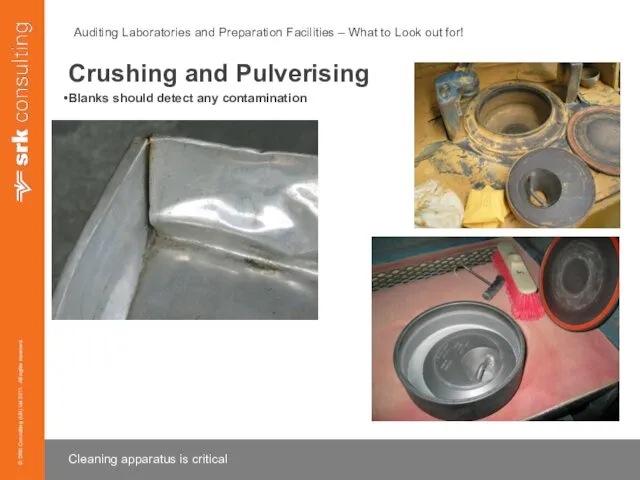

- 37. Auditing Laboratories and Preparation Facilities – What to Look out for! Crushing and Pulverising

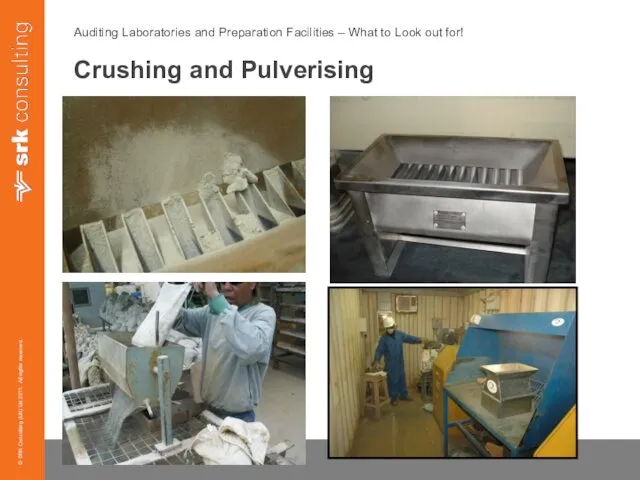

- 39. Скачать презентацию

Технологические методы повышения ресурса и надежности работы деталей машин

Технологические методы повышения ресурса и надежности работы деталей машин Дезинфекция на предприятиях пищевой промышленности

Дезинфекция на предприятиях пищевой промышленности Нормативно-правовые основы обеспечения единства измерения в РФ

Нормативно-правовые основы обеспечения единства измерения в РФ Стиль модерн

Стиль модерн Звездный час по математике

Звездный час по математике Концепция нового товара или услуги

Концепция нового товара или услуги Технология строительного производства. Работы подготовительного периода

Технология строительного производства. Работы подготовительного периода Договор подряда, его сторон, элементы и содержание

Договор подряда, его сторон, элементы и содержание Человек в изменившемся мире: материальная культура и повседневность

Человек в изменившемся мире: материальная культура и повседневность Человек как духовное существо

Человек как духовное существо Географические координаты

Географические координаты Технология интервью

Технология интервью Первая мировая война

Первая мировая война Электронное пособие

Электронное пособие Восстание Степана Разина

Восстание Степана Разина Безопасность на детской площадке

Безопасность на детской площадке Кадры предприятия

Кадры предприятия Философия эпохи Возрождения

Философия эпохи Возрождения Интерфейс связи RS-485

Интерфейс связи RS-485 Работа с бумагой в нетрадиционной технике - квиллинг Букет нарциссов к 8 марта

Работа с бумагой в нетрадиционной технике - квиллинг Букет нарциссов к 8 марта My family

My family Комнатные растения

Комнатные растения Физический и моральный износ промышленных зданий и сооружений. (Лекция 2)

Физический и моральный износ промышленных зданий и сооружений. (Лекция 2) Память о военной славе. Песни, фильмы, стихи, памятники, картины

Память о военной славе. Песни, фильмы, стихи, памятники, картины Презентация Руссая народная кукла. Домашние обрядовые куклы

Презентация Руссая народная кукла. Домашние обрядовые куклы Стили и направления в живописи

Стили и направления в живописи Флагманская программа ассоциация военно-патриотических клубов Красноярского края

Флагманская программа ассоциация военно-патриотических клубов Красноярского края Водоподготовка. Дегазация воды

Водоподготовка. Дегазация воды