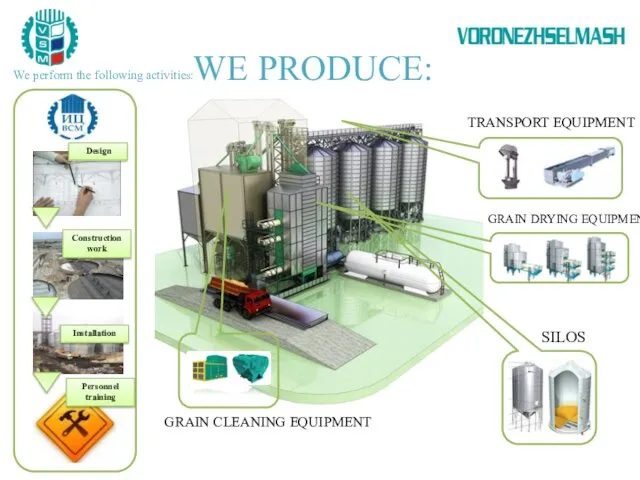

RANGE OF PRODUCTS

Voronezhselmash - the only plant in Russia which produces

full range of elevator equipment

Grain-cleaning machines

Dryers

Transport equipment for elevators

Stationary Equipment

The new family of high-performance Optic Sorters 20 types, capacity from 20 to 300 t. / H.

The new Trier family (from 5 to 20 t. / hr)

Self-mobile machinery

Louver-type series SVM

Mine type series SVSH

The dryers used energy saving and automatic control

Bucket Elevators - Industrial elevator HB-50 (50 m / h), LV-100 (100 t / h), LV-175 (175 t / h). Farmers elevator CDD-25 (25 t / h), UXO-50 (50 t / h).

Drag Conveyers Series KSV - KSV-50 (50 t / h), KSV-100 (100t / h)

SILO

Optic Sorters

Capacity 5, 10, 15, 20 t. / hr.

Seed Lines

Hangars

Православие о божьем суде

Православие о божьем суде Становление эстетики как науки. Движение за обновление искусств и ремесел

Становление эстетики как науки. Движение за обновление искусств и ремесел презентация Конструирование технологической карты урока в соответствии с требованиями ФГОС

презентация Конструирование технологической карты урока в соответствии с требованиями ФГОС Театр Дель Арте

Театр Дель Арте Столетняя война. Англия и Франция

Столетняя война. Англия и Франция Установки для дуговой сварки неплавящимся электродом. Тема 3-1

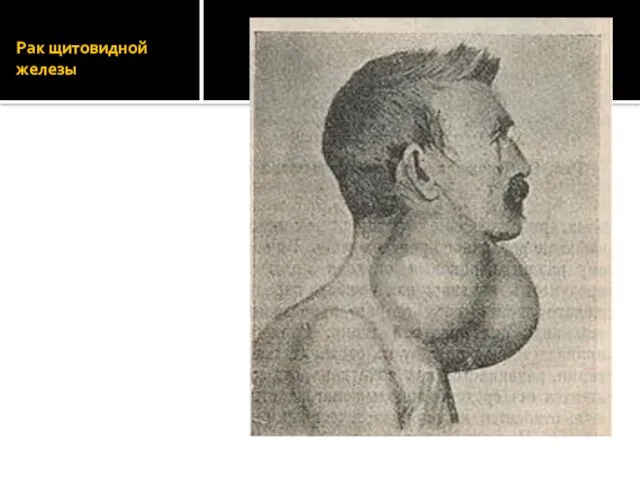

Установки для дуговой сварки неплавящимся электродом. Тема 3-1 Рак щитовидной железы

Рак щитовидной железы Great English writers

Great English writers Достижения КГАСУ в области изучения эпоксидных смол

Достижения КГАСУ в области изучения эпоксидных смол Перспектива интерьера. Построить перспективу полуоткрытых дверей на фронтальной и боковой стенах

Перспектива интерьера. Построить перспективу полуоткрытых дверей на фронтальной и боковой стенах Районыбыз һәм Бирдебәк авылы тарихын өйрәнү

Районыбыз һәм Бирдебәк авылы тарихын өйрәнү Внеурочная деятельность Народные игры

Внеурочная деятельность Народные игры Архитектура компьютера. Технические средства реализации информационных процессов

Архитектура компьютера. Технические средства реализации информационных процессов Механізм попередження дискримінації деяких категорій осіб

Механізм попередження дискримінації деяких категорій осіб Влияние различных фракций гумуса на рост и развитие Avena Sativa L

Влияние различных фракций гумуса на рост и развитие Avena Sativa L Проект Я в кругу друзей

Проект Я в кругу друзей В человеке всё должно быть прекрасно...

В человеке всё должно быть прекрасно... Портфолио Семёновой Алины, учащейся 2 а класса

Портфолио Семёновой Алины, учащейся 2 а класса Мозжилкина Д.А. ИБМ4 11-А (5)

Мозжилкина Д.А. ИБМ4 11-А (5) Who’s who? appearance (внешность)

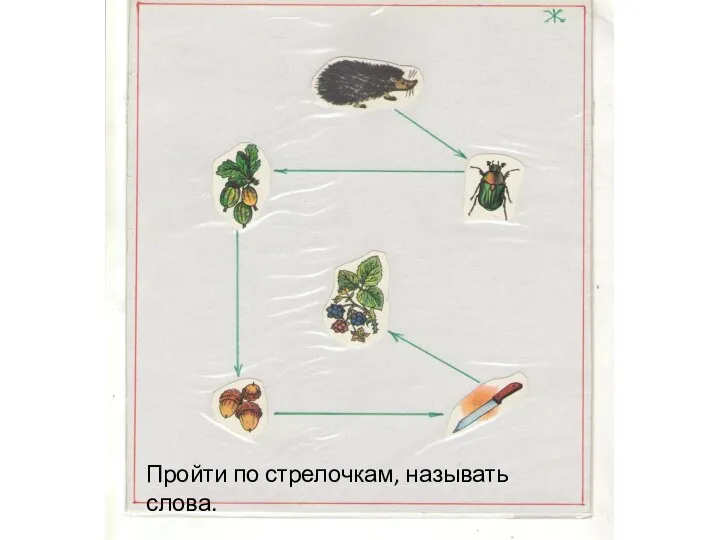

Who’s who? appearance (внешность) Занимательные задания для автоматизации звука Ж.

Занимательные задания для автоматизации звука Ж. Звезда Элема Климова. 85 лет со дня рождения выдающегося режиссера

Звезда Элема Климова. 85 лет со дня рождения выдающегося режиссера Основы маршрутизации

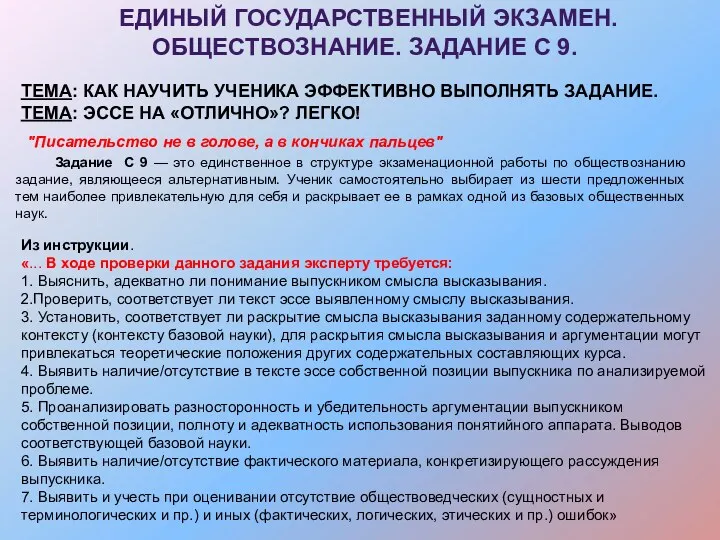

Основы маршрутизации для подготовки к ЕГЭ по обществознанию

для подготовки к ЕГЭ по обществознанию Презентация для родителей Готовность ребенка к школе

Презентация для родителей Готовность ребенка к школе Видеокарты и их характеристики

Видеокарты и их характеристики Уход за глазами. Промывание глаз

Уход за глазами. Промывание глаз Классный час Люби и знай свой край. Чимеевский Свято-Казанский монастырь

Классный час Люби и знай свой край. Чимеевский Свято-Казанский монастырь