- Главная

- Без категории

- Technology Development. Braking Systems for Shaft Hoisting

Содержание

- 2. 3 inhouse Engineering Disciplines for Key “OEM Product Applications“ … USP: System-Integration 100% inhouse by SIEMAG

- 3. 1970 1980 1990 2000 2010 not controlled, residual pressure with constant braking force Single Channel I

- 4. SIEMAG TECBERG is in the position of offering 2 solutions as options as state of the

- 5. SIEMAG TECBERG‘s Engineering Services are a matter of course: 1. keeping international compliance to statutory mining

- 7. Скачать презентацию

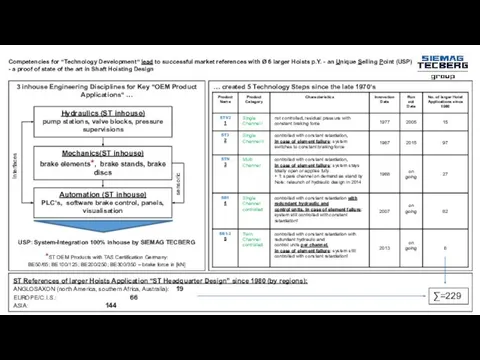

3 inhouse Engineering Disciplines for Key “OEM Product Applications“ …

USP:

3 inhouse Engineering Disciplines for Key “OEM Product Applications“ …

USP:

*ST OEM Products with TAS Certification Germany:

BE50/65; BE100/125; BE200/250; BE300/350 – brake force in [kN]

ST References of larger Hoists Application “ST Headquarter Design” since 1980 (by regions):

ANGLOSAXON (north America, southern Africa, Australia): 19

EUROPE/C.I.S.: 66

ASIA: 144

Competencies for “Technology Development“ lead to successful market references with Ø 6 larger Hoists p.Y. - an Unique Selling Point (USP)

- a proof of state of the art in Shaft Hoisting Design

… created 5 Technology Steps since the late 1970‘s

Hydraulics (ST inhouse)

pump stations, valve blocks, pressure supervisions

Mechanics(ST inhouse)

brake elements*, brake stands, brake discs

Automation (ST inhouse)

PLC‘s, software brake control, panels, visualisation

Interfaces

sensoric

∑=229

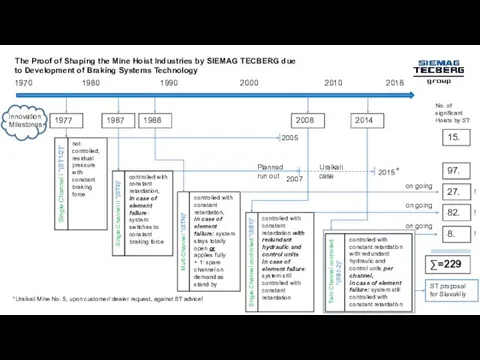

1970

1980

1990

2000

2010

not controlled, residual pressure with constant braking force

Single Channel I

1970

1980

1990

2000

2010

not controlled, residual pressure with constant braking force

Single Channel I

2018

Innovation

Milestones:

1977

1987

controlled with constant retardation,

in case of element failure: system switches to constant braking force

Single Channel II “(ST3)“

controlled with constant retardation,

in case of element failure: system stays totally open or

applies fully

+ 1: spare channel on demand as stand by

Multi Channel “(STN)“

1988

2008

controlled with constant retardation with redundant hydraulic and

control units

in case of element failure: system still controlled with constant retardation

Single Channel controlled “(SB1)“

2014

No. of significant Hoists by ST:

15.

97.

82.

27.

8.

2005

2015*

on going

on going

on going

The Proof of Shaping the Mine Hoist Industries by SIEMAG TECBERG due

to Development of Braking Systems Technology

∑=229

2007

Uralkali

case

Planned

run out

controlled with constant retardation with redundant hydraulic and

control units per channel,

in case of element failure: system still controlled with constant retardation

Twin Channel controlled “(SB1-2)“

*Uralkali Mine No. 5, upon customer/ dealer request, against ST advice!

ST proposal for Slavakliy

!

!

!

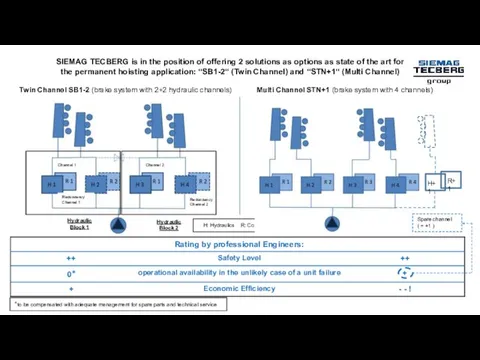

SIEMAG TECBERG is in the position of offering 2 solutions

SIEMAG TECBERG is in the position of offering 2 solutions

the permanent hoisting application: “SB1-2“ (Twin Channel) and “STN+1“ (Multi Channel)

H: Hydraulics R: Control Circuit

Twin Channel SB1-2 (brake system with 2+2 hydraulic channels)

Multi Channel STN+1 (brake system with 4 channels)

Channel 2

Channel 1

Redundancy Channel 1

Redundancy Channel 2

Hydraulic Block 1

Hydraulic Block 2

*to be compensated with adequate management for spare parts and technical service

SIEMAG TECBERG‘s Engineering Services are a matter of course:

1. keeping international

SIEMAG TECBERG‘s Engineering Services are a matter of course:

1. keeping international

2. providing certified and field references for brakes with constant braking force, constant retardation

and Safety Integrity Level [SIL 2 & 3] special applications

3. providing compliance for all risk analysis scenarios through robust designs and peer reviews

4. providing compliance in international safety standards and features with brake control philosophy for Man Riding Hoists

5. providing a dedicated fully comprehensive diagnostic system to support service personnel in the maintenance of the brake control operation

Мнемотехника

Мнемотехника Фотоальбом. В память о любимой мамочке

Фотоальбом. В память о любимой мамочке Приобретенные пороки сердца

Приобретенные пороки сердца Конфликтные картинки

Конфликтные картинки Альтернативные источники энергии

Альтернативные источники энергии Биологическая очистка сточных вод

Биологическая очистка сточных вод Скважина, ее элементы и конструкции. Классификация скважин

Скважина, ее элементы и конструкции. Классификация скважин Семья. Традиции. Обычаи. Семейные ценности

Семья. Традиции. Обычаи. Семейные ценности : Лекарственные растения.

: Лекарственные растения. Анализ ситуации на рынке энергоресурсов

Анализ ситуации на рынке энергоресурсов Презентация ко дню матери Милая мама

Презентация ко дню матери Милая мама формирование вокально-хоровых навыков у дошкольников

формирование вокально-хоровых навыков у дошкольников Контроль технического состояния скважин. Лекция № 6

Контроль технического состояния скважин. Лекция № 6 Сенсорное развитие детей раннего возраста

Сенсорное развитие детей раннего возраста Карбонильные соединения - альдегиды

Карбонильные соединения - альдегиды Основы организации строительства и реконструкции железных дорог

Основы организации строительства и реконструкции железных дорог Картофель. Продукты из картофеля

Картофель. Продукты из картофеля Применение смазочно-охлаждающих жидкостей (СОЖ)

Применение смазочно-охлаждающих жидкостей (СОЖ) Технология формирования иноязычных грамматических навыков

Технология формирования иноязычных грамматических навыков Суицидальное поведение детей и подростков: определение, виды, причины, выявление

Суицидальное поведение детей и подростков: определение, виды, причины, выявление Современные методы инженерной защиты от оползней

Современные методы инженерной защиты от оползней Презентация Правила пожарной безопасности в лесу

Презентация Правила пожарной безопасности в лесу Предвыборная программа Шаровой Полины

Предвыборная программа Шаровой Полины Узор в полосе для косынки треугольной формы. 2 класс специальной коррекционной школы

Узор в полосе для косынки треугольной формы. 2 класс специальной коррекционной школы План -конспект урока по химии в 9 классе Ионные уравнения с презентацией

План -конспект урока по химии в 9 классе Ионные уравнения с презентацией Как вывести предприятие из финансового кризиса

Как вывести предприятие из финансового кризиса МЕТОДИЧЕСКИЙ ДОКЛАД и презентация на тему: Нетрадиционные методы обучения или о таинстве простых

МЕТОДИЧЕСКИЙ ДОКЛАД и презентация на тему: Нетрадиционные методы обучения или о таинстве простых Let’s make some pancakes

Let’s make some pancakes