The adsorbents nanoporous structures regeneration for industrial dryers by microwave energy презентация

Содержание

- 2. 1 The main researches must be dedicated to a wider exploration of the means for reducing

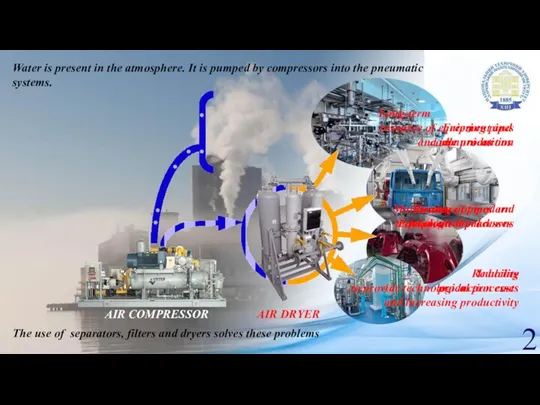

- 3. Rusting of pipes and Equipment breakdowns Inability to provide technological processes Long-term resource of equipment and

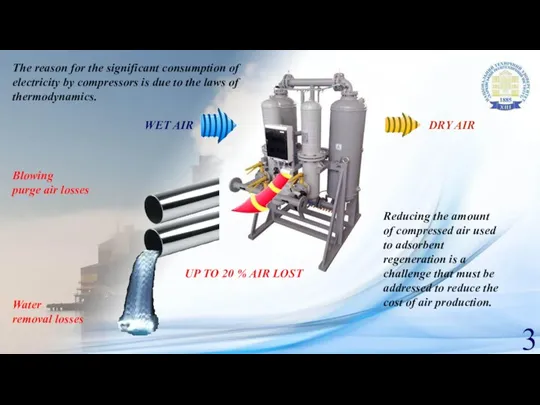

- 4. 3 The reason for the significant consumption of electricity by compressors is due to the laws

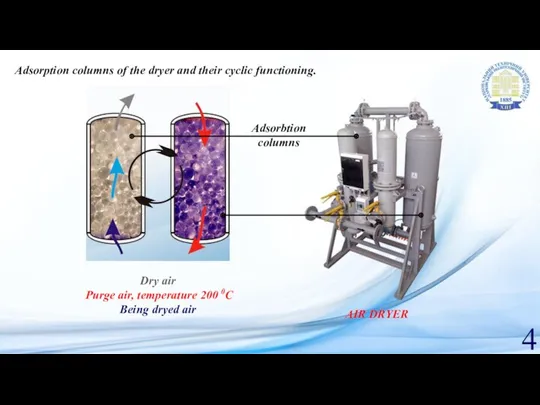

- 5. 4 Adsorption columns of the dryer and their cyclic functioning. Being dryed air Purge air, temperature

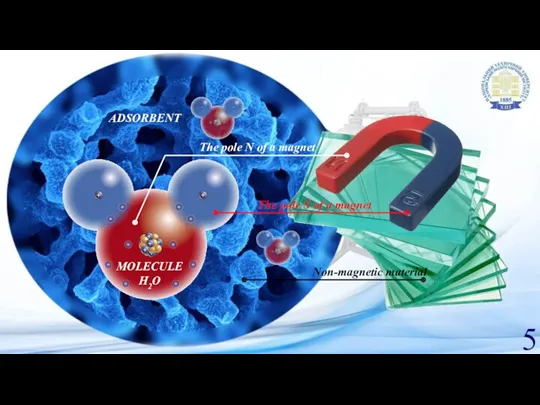

- 6. 5 The pole N of a magnet Non-magnetic material MOLECULE H2O ADSORBENT The pole S of

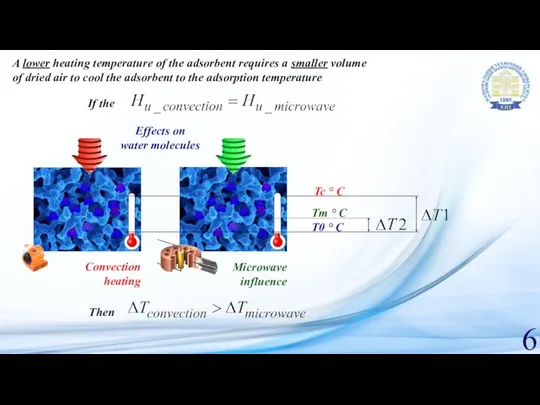

- 7. 6 Convection heating Microwave influence Effects on water molecules Tc ° C T0 ° C Tm

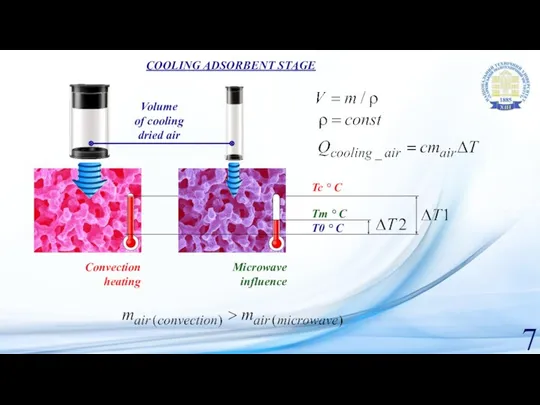

- 8. 7 Convection heating Microwave influence Volume of cooling dried air Tc ° C T0 ° C

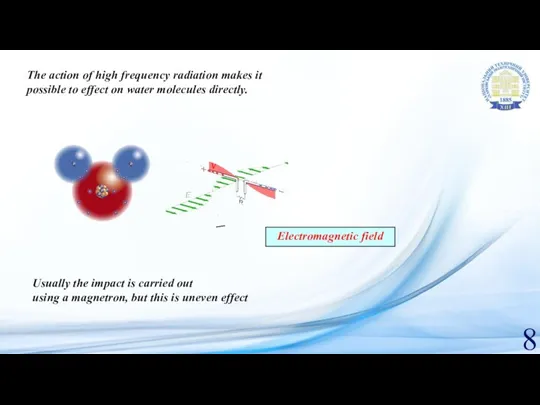

- 9. 8 The action of high frequency radiation makes it possible to effect on water molecules directly.

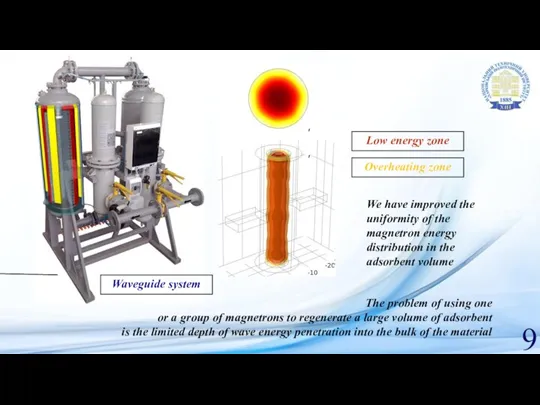

- 10. 9 We have improved the uniformity of the magnetron energy distribution in the adsorbent volume The

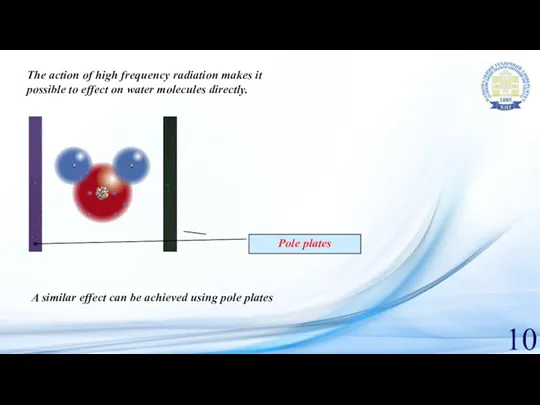

- 11. 10 The action of high frequency radiation makes it possible to effect on water molecules directly.

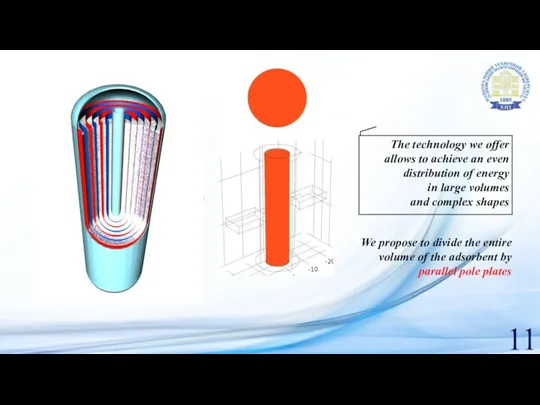

- 12. 11 We propose to divide the entire volume of the adsorbent by parallel pole plates The

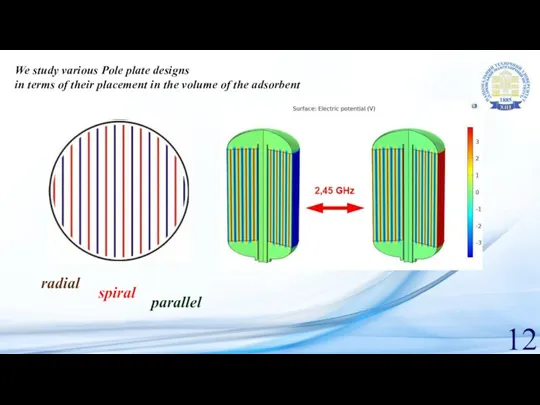

- 13. 12 We study various Pole plate designs in terms of their placement in the volume of

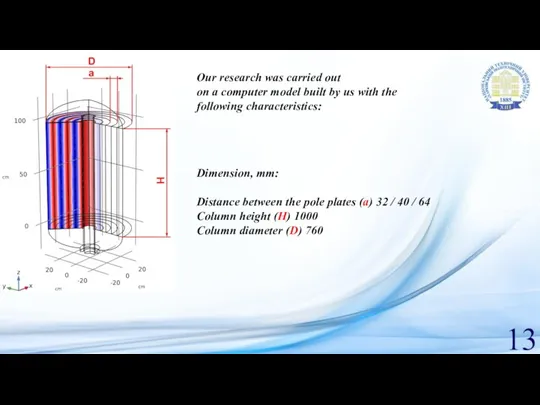

- 14. 13 Dimension, mm: Distance between the pole plates (a) 32 / 40 / 64 Column height

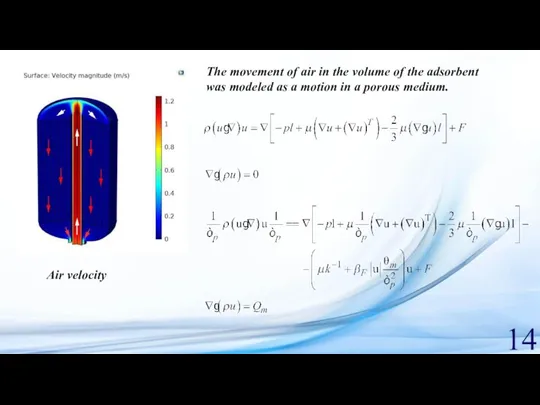

- 15. 14 The movement of air in the volume of the adsorbent was modeled as a motion

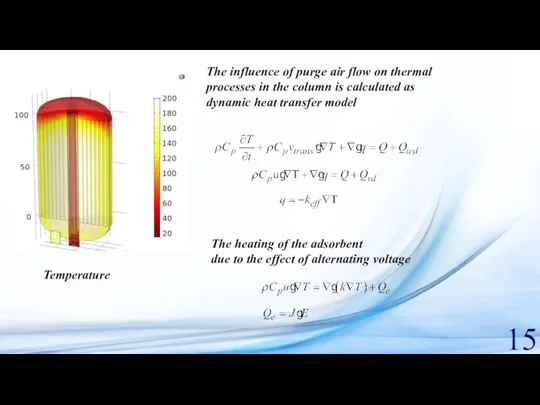

- 16. 15 The influence of purge air flow on thermal processes in the column is calculated as

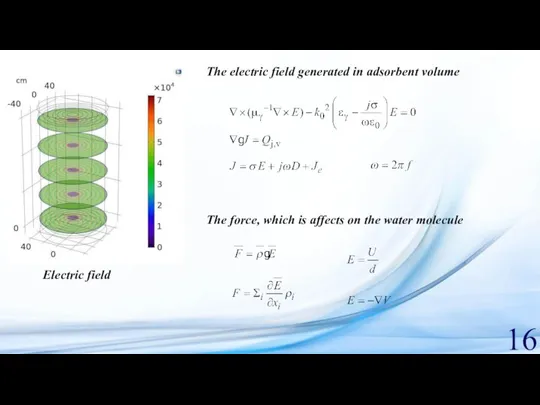

- 17. 16 The force, which is affects on the water molecule The electric field generated in adsorbent

- 18. 17 The dependence of the heating intensity of exposure to microwave frequency [GHz]

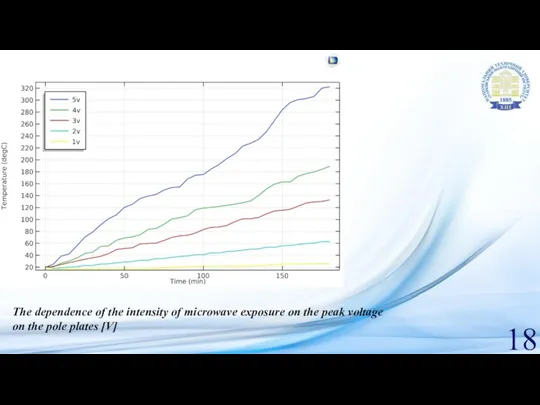

- 19. 18 The dependence of the intensity of microwave exposure on the peak voltage on the pole

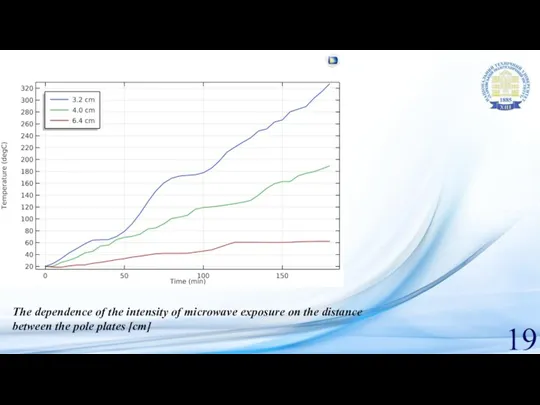

- 20. 19 The dependence of the intensity of microwave exposure on the distance between the pole plates

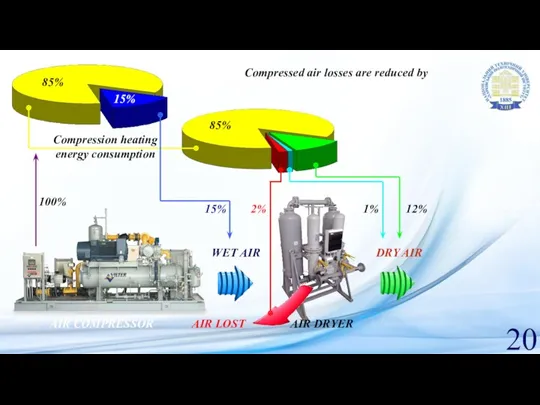

- 21. 20 WET AIR DRY AIR AIR LOST AIR COMPRESSOR AIR DRYER 85% 85% Compression heating energy

- 22. Thank You for Your time and attention! The studied design allows the use of microwave regeneration

- 24. Скачать презентацию

![17 The dependence of the heating intensity of exposure to microwave frequency [GHz]](/_ipx/f_webp&q_80&fit_contain&s_1440x1080/imagesDir/jpg/314736/slide-17.jpg)

Звукоизоляция. Изоляция воздушного шума

Звукоизоляция. Изоляция воздушного шума Послеоперационная когнитивная дисфункция и уровень церебральной перфузии у пациентов с атеросклерозом ВСА

Послеоперационная когнитивная дисфункция и уровень церебральной перфузии у пациентов с атеросклерозом ВСА Русский народный промысел: Вятское кружево

Русский народный промысел: Вятское кружево Атқарушы механизмдер және реттеуші органдар

Атқарушы механизмдер және реттеуші органдар Презентация Использование алгоритмов детьми подготовительной группы в сюжетно-ролевых играх.

Презентация Использование алгоритмов детьми подготовительной группы в сюжетно-ролевых играх. Формування конкурентноздатної команди

Формування конкурентноздатної команди Автоматты қайта қосылу

Автоматты қайта қосылу Презентация Мой логопедический кабинет

Презентация Мой логопедический кабинет Строение клетки. Эндоплазматическая сеть. Комплекс гольджи. Лизосомы. Клеточные включения

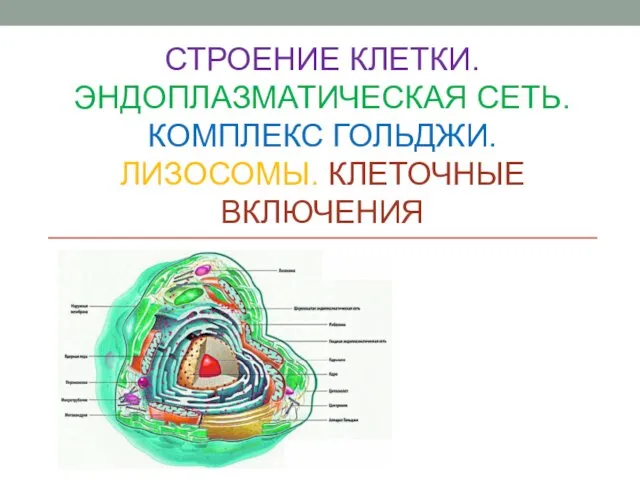

Строение клетки. Эндоплазматическая сеть. Комплекс гольджи. Лизосомы. Клеточные включения Цифровые данные. Цифровая технология. Цифровая революция

Цифровые данные. Цифровая технология. Цифровая революция Іван ІV Грозний

Іван ІV Грозний Рыбы - типичные водные животные.Строение рыб. Приспособление к водному образу жизни

Рыбы - типичные водные животные.Строение рыб. Приспособление к водному образу жизни Презентация к статье Формы взаимодействия педагога с детьми в условиях реализации образовательной программы Югорский трамплин

Презентация к статье Формы взаимодействия педагога с детьми в условиях реализации образовательной программы Югорский трамплин презентация к статье по исследовательской работе

презентация к статье по исследовательской работе Виды предпринимательства

Виды предпринимательства Дороги поэта. К юбилею М.Ю. Лермонтова

Дороги поэта. К юбилею М.Ю. Лермонтова Химиядағы жылдамдық түсінігі. Химиялық реакция жылдамдығына әсер ететін факторлар

Химиядағы жылдамдық түсінігі. Химиялық реакция жылдамдығына әсер ететін факторлар Молодежь против коррупции

Молодежь против коррупции Население РФ. Численность и естественный прирост населения

Население РФ. Численность и естественный прирост населения Презентация к Проектной работе Что мы знаем о яйце

Презентация к Проектной работе Что мы знаем о яйце Урок 20. Общение-основа социального взаимодействия_

Урок 20. Общение-основа социального взаимодействия_ Оптимизация логистических процессов региональных автодилерских предприятий

Оптимизация логистических процессов региональных автодилерских предприятий Интенсивная терапия кровопотери, геморрагического шока, коагулопатий

Интенсивная терапия кровопотери, геморрагического шока, коагулопатий Образование в СССР в 20-х годах

Образование в СССР в 20-х годах Русский народ

Русский народ конспек урока Население России 8 класс

конспек урока Население России 8 класс Формирование мотивационного компонента готовности к обучению в школе через развитие познавательных процессов дошкольников

Формирование мотивационного компонента готовности к обучению в школе через развитие познавательных процессов дошкольников Решение расчетных задач по химии алгебраическим способом.

Решение расчетных задач по химии алгебраическим способом.