Содержание

- 2. The only way to win significantly higher profits is through new capacity – but it is

- 3. JAP Definition of Capacity Capacity is the limiting capability of a productive unit to produce within

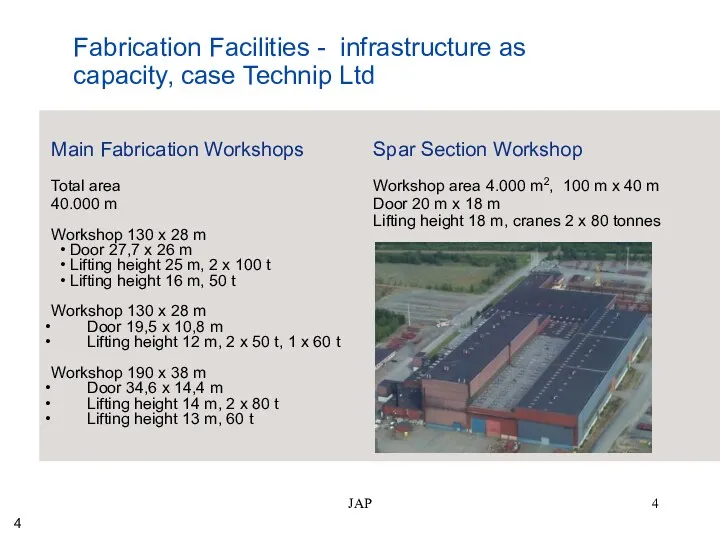

- 4. JAP Main Fabrication Workshops Total area 40.000 m Workshop 130 x 28 m Door 27,7 x

- 5. JAP Measures of capacity Work shop – machine hours, labor (work) hours / day / week

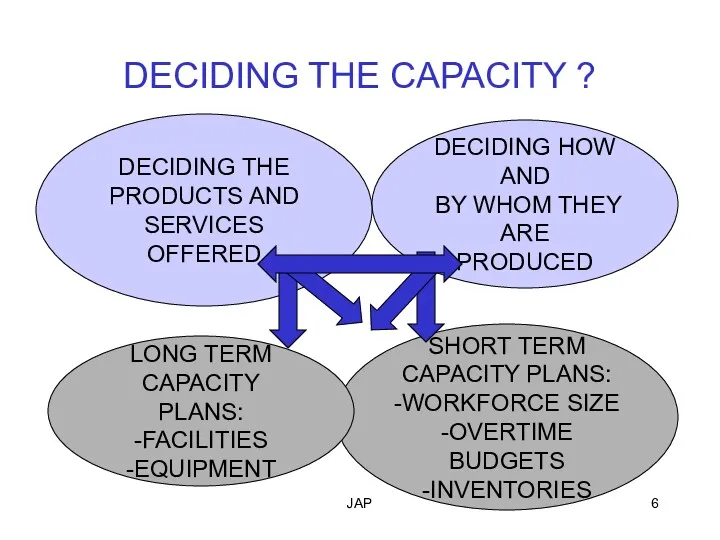

- 6. JAP SHORT TERM CAPACITY PLANS: -WORKFORCE SIZE -OVERTIME BUDGETS -INVENTORIES LONG TERM CAPACITY PLANS: -FACILITIES -EQUIPMENT

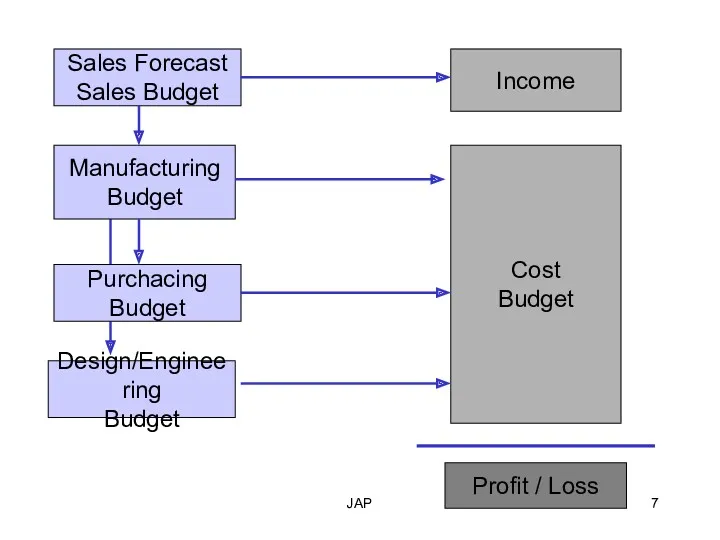

- 7. JAP Sales Forecast Sales Budget Income Manufacturing Budget Purchacing Budget Design/Engineering Budget Cost Budget Profit /

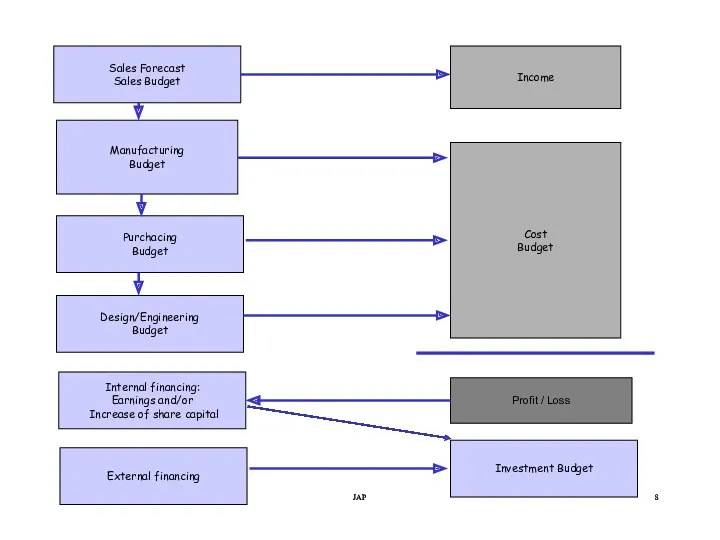

- 8. JAP JAP Sales Forecast Sales Budget Income Manufacturing Budget Purchacing Budget Design/Engineering Budget Cost Budget Profit

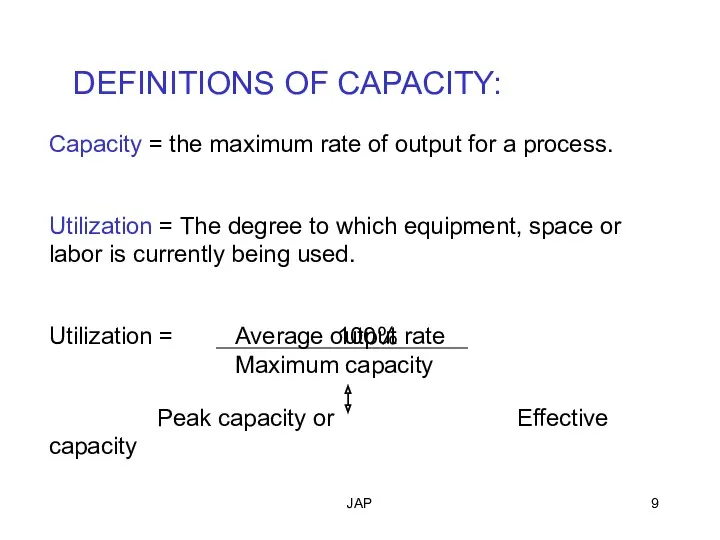

- 9. JAP DEFINITIONS OF CAPACITY: Capacity = the maximum rate of output for a process. Utilization =

- 10. JAP Peak capacity = the maximum output that a process or facility can achieve under ideal

- 11. JAP Problem 2.1. Peak and Effective Capacity If operated around the clock under ideal conditions, the

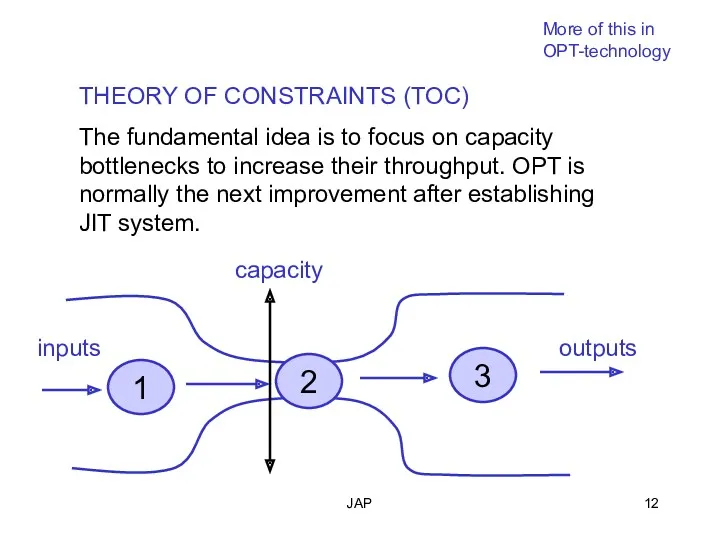

- 12. JAP THEORY OF CONSTRAINTS (TOC) The fundamental idea is to focus on capacity bottlenecks to increase

- 13. JAP Application of TOC involves the following steps: identify the system Bottlenecks (observe the possible floating

- 14. JAP TOC AND OPTIMIZED PRODUCTION TECHNOLOGY (OPT) Main idea is to maximize the utilization of bottleneck

- 15. JAP ECONOMIES OF SCALE – a concept that states that the average unit cost of a

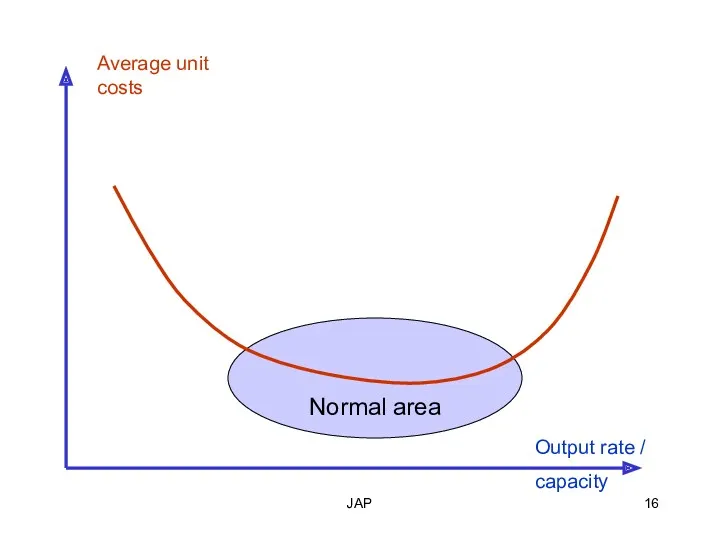

- 16. JAP Normal area Output rate / capacity Average unit costs

- 17. JAP CAPACITY CUSHION – the amount of reserve capacity that a firm maintains to handle sudden

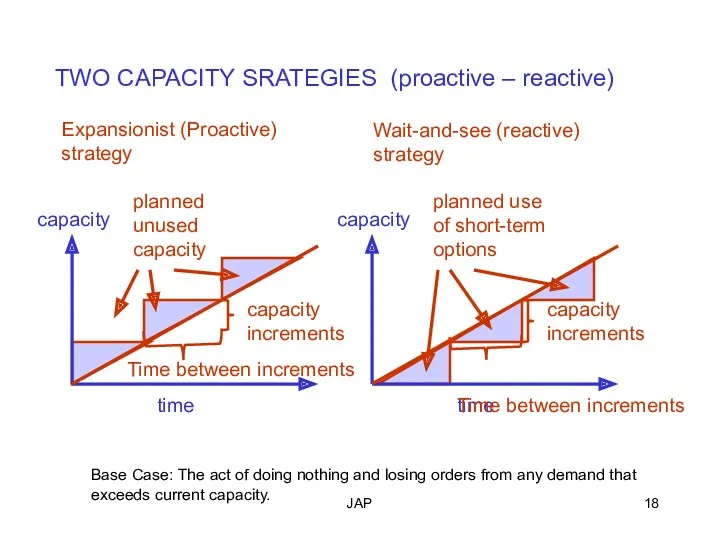

- 18. JAP TWO CAPACITY SRATEGIES (proactive – reactive) time capacity planned unused capacity Time between increments capacity

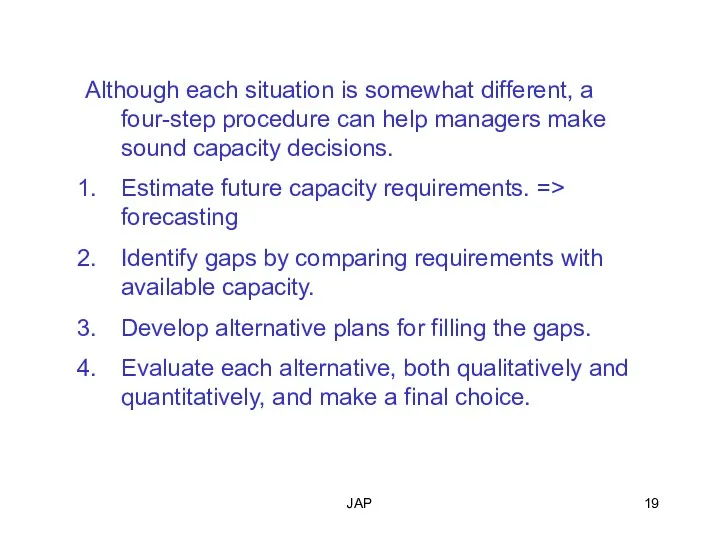

- 19. JAP Although each situation is somewhat different, a four-step procedure can help managers make sound capacity

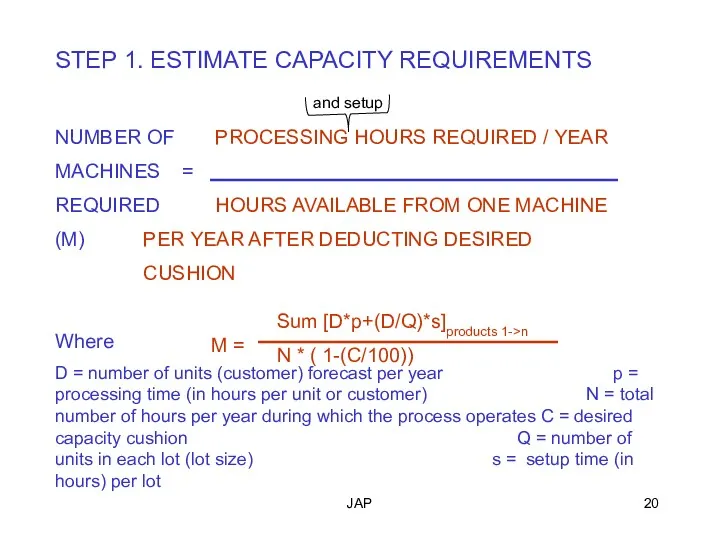

- 20. JAP STEP 1. ESTIMATE CAPACITY REQUIREMENTS NUMBER OF PROCESSING HOURS REQUIRED / YEAR MACHINES = REQUIRED

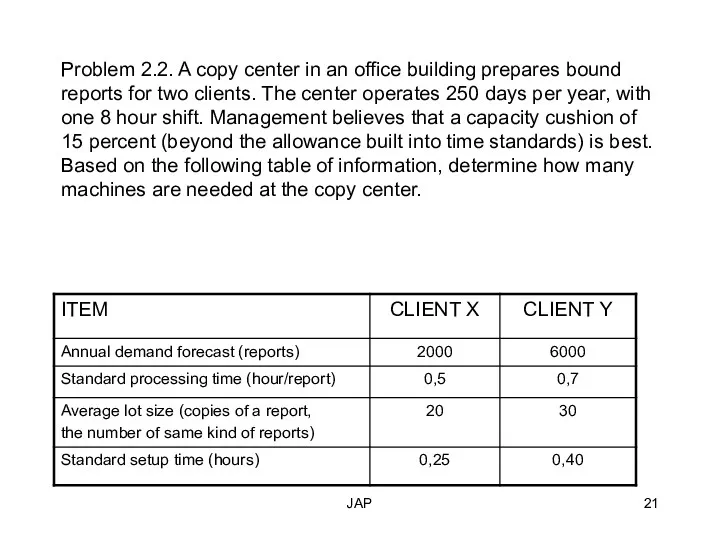

- 21. JAP Problem 2.2. A copy center in an office building prepares bound reports for two clients.

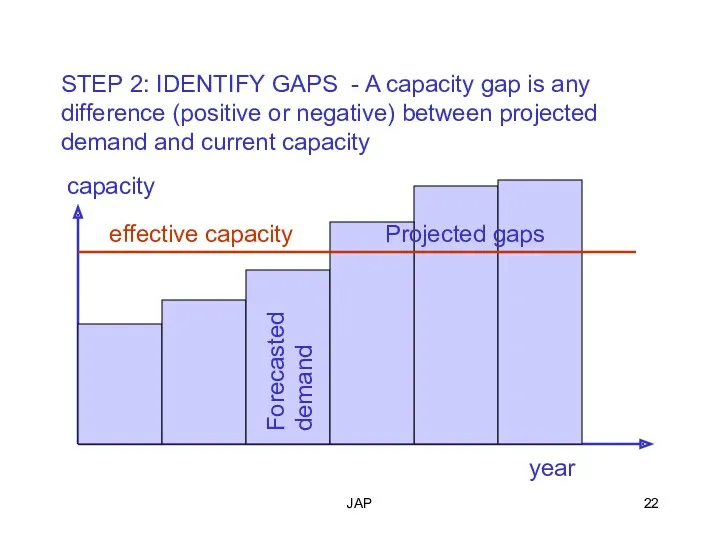

- 22. JAP STEP 2: IDENTIFY GAPS - A capacity gap is any difference (positive or negative) between

- 23. JAP STEP 3 – DEVELOP ALTERNATIVES – to cope with projected gaps. “Base case” - do

- 24. JAP Problem of capacity: part X requires grinding (work phases A and B). How many machines

- 25. JAP Problem 2.3. Grandmother’s Chicken Restaurant is experiencing a boom in business. Although the kitchen is

- 26. JAP Problem 2.4. Evaluating the alternatives: One alternative for Grandmothers kitchen is to expand both the

- 27. JAP TOOLS FOR CAPACITY PLANNING: WAITING LINE MODELS - Because arrival time to a work center

- 28. JAP Management is redesigning the customer service process at helpdesk. Accommodating four customers is important. Customers

- 29. JAP Problem 2.5. Finding break even quantity A machine job is considering to start with a

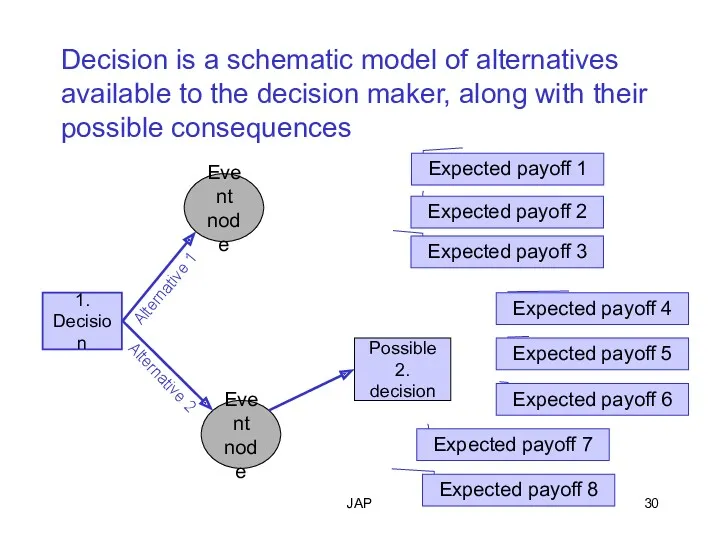

- 30. JAP Decision is a schematic model of alternatives available to the decision maker, along with their

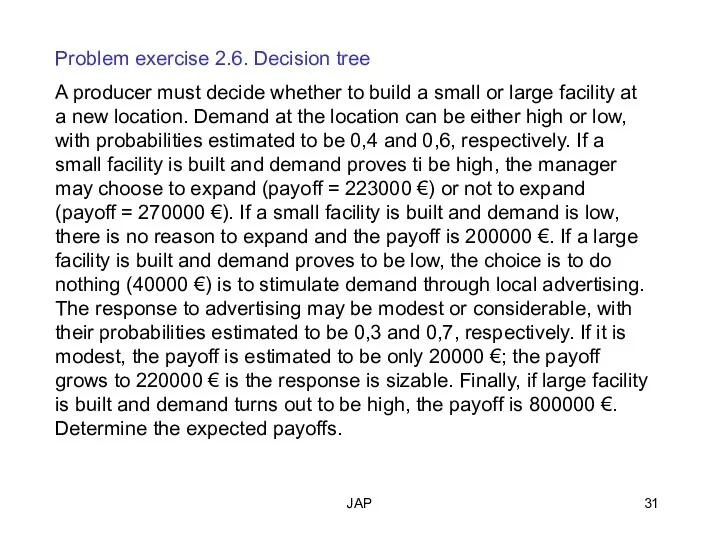

- 31. JAP Problem exercise 2.6. Decision tree A producer must decide whether to build a small or

- 33. Скачать презентацию

Рынок труда и социальная политика регионов

Рынок труда и социальная политика регионов Элементы методики экономического анализа

Элементы методики экономического анализа Міжнародний ринок товарів, послуг та інновацій

Міжнародний ринок товарів, послуг та інновацій Субъекты и объекты международных экономических отношений

Субъекты и объекты международных экономических отношений Институционализм

Институционализм Исследование перехода к хаосу в экономических системах

Исследование перехода к хаосу в экономических системах Дискриминация на рынке труда

Дискриминация на рынке труда Macroeconomic Indicators: What They Are & How to Use Them

Macroeconomic Indicators: What They Are & How to Use Them Основные этапы развития экономической теории

Основные этапы развития экономической теории Экономикалық теорияның пәні және зерттеу әдістері

Экономикалық теорияның пәні және зерттеу әдістері Противоречия размещения производительных сил и регионального развития

Противоречия размещения производительных сил и регионального развития Гравитационная модель и социально-экономическое развитие Курской области и Черноземья

Гравитационная модель и социально-экономическое развитие Курской области и Черноземья Италия. Миграция рабочей силы

Италия. Миграция рабочей силы Безработица: причины и последствия

Безработица: причины и последствия Лекция № 5. Вмешательство государства и общественное благосостояние

Лекция № 5. Вмешательство государства и общественное благосостояние Український ринок M&A: злиття і поглинання українських компаній

Український ринок M&A: злиття і поглинання українських компаній Прямое действие международных договоров системы ВТО (всемирная торговая организация) в России

Прямое действие международных договоров системы ВТО (всемирная торговая организация) в России Макроэкономическое равновесие в открытой экономике

Макроэкономическое равновесие в открытой экономике Анализ экономической деятельности автотранспортных предприятий. Краткий курс МДК

Анализ экономической деятельности автотранспортных предприятий. Краткий курс МДК Введение в микроэкономику

Введение в микроэкономику Анализ эффективности работы исследуемого предприятия

Анализ эффективности работы исследуемого предприятия Управление товарными запасами в фармацевтической организации

Управление товарными запасами в фармацевтической организации Экономические институты и собственность в рыночной экономике

Экономические институты и собственность в рыночной экономике Планування і аналіз трудових показників

Планування і аналіз трудових показників Расчет показателей использования трудовых ресурсов предприятия

Расчет показателей использования трудовых ресурсов предприятия Статистика затрат и промежуточного потребления

Статистика затрат и промежуточного потребления Причины безработицы

Причины безработицы Тема 7. Рынок труда. Заработная плата

Тема 7. Рынок труда. Заработная плата