МЭМС и НЭМС: датчики ускорения и поворота, наноприводы, оптические и электронные системы презентация

Содержание

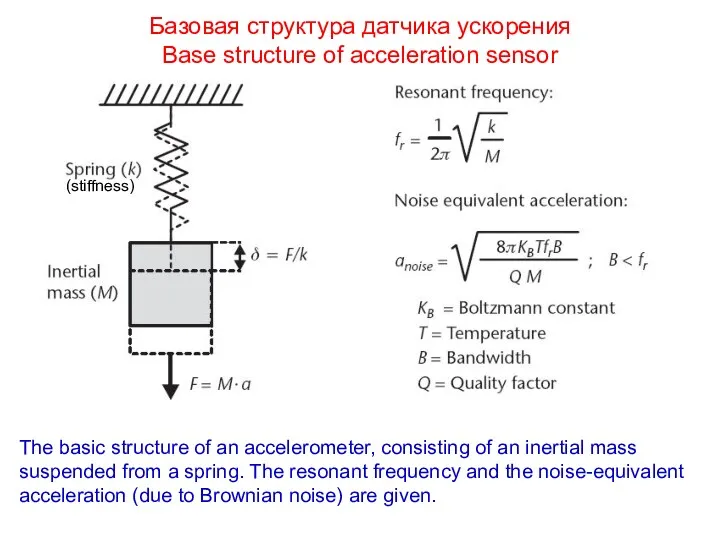

- 2. Базовая структура датчика ускорения Base structure of acceleration sensor The basic structure of an accelerometer, consisting

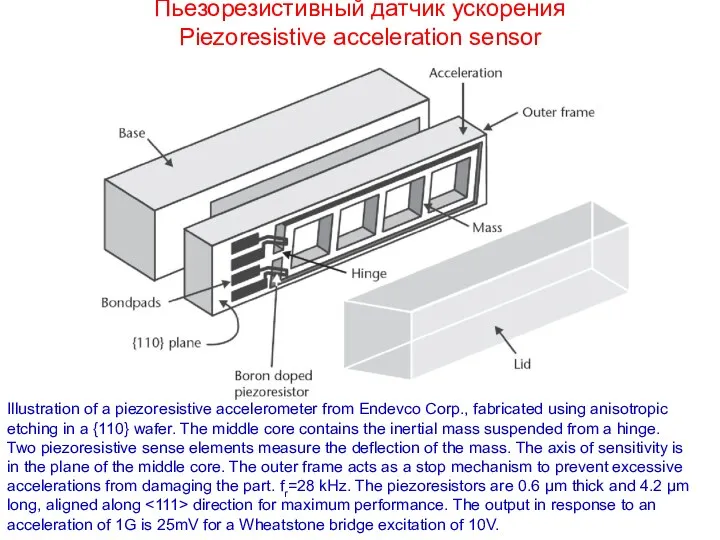

- 3. Пьезорезистивный датчик ускорения Piezoresistive acceleration sensor Illustration of a piezoresistive accelerometer from Endevco Corp., fabricated using

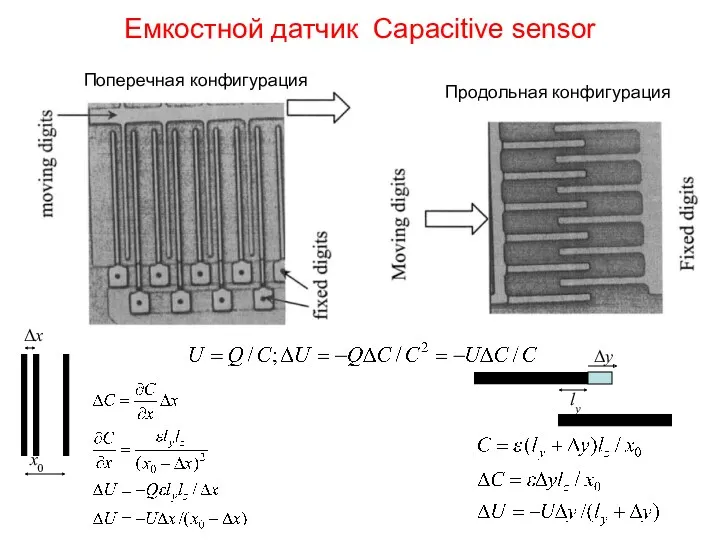

- 4. Емкостной датчик Capacitive sensor Поперечная конфигурация Продольная конфигурация x0 Δx Δy ly

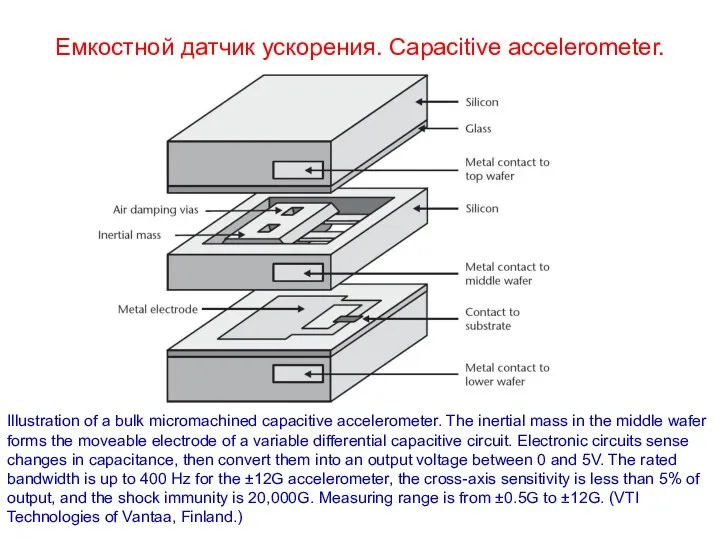

- 5. Емкостной датчик ускорения. Capacitive accelerometer. Illustration of a bulk micromachined capacitive accelerometer. The inertial mass in

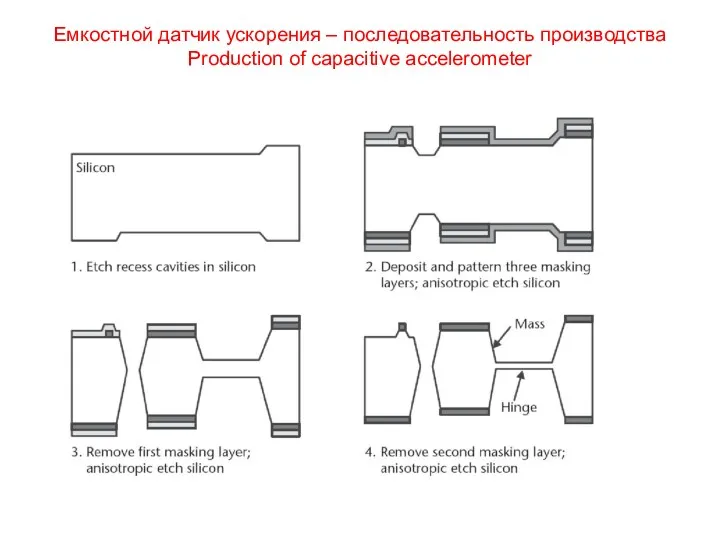

- 6. Емкостной датчик ускорения – последовательность производства Production of capacitive accelerometer

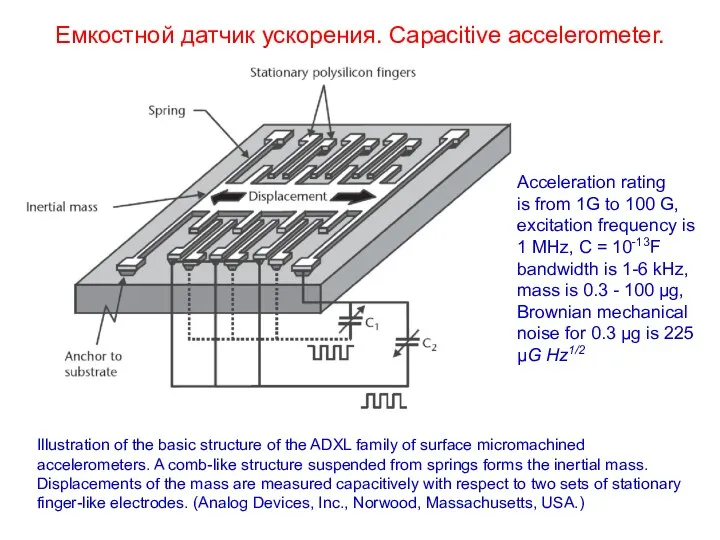

- 7. Емкостной датчик ускорения. Capacitive accelerometer. Illustration of the basic structure of the ADXL family of surface

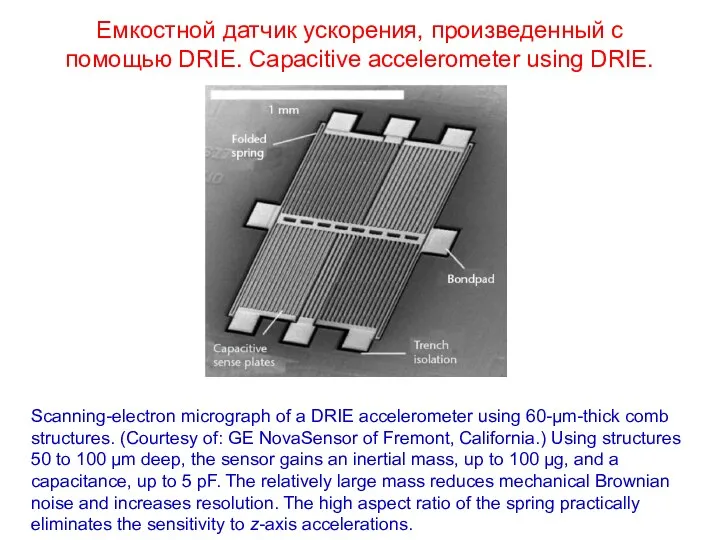

- 8. Емкостной датчик ускорения, произведенный с помощью DRIE. Capacitive accelerometer using DRIE. Scanning-electron micrograph of a DRIE

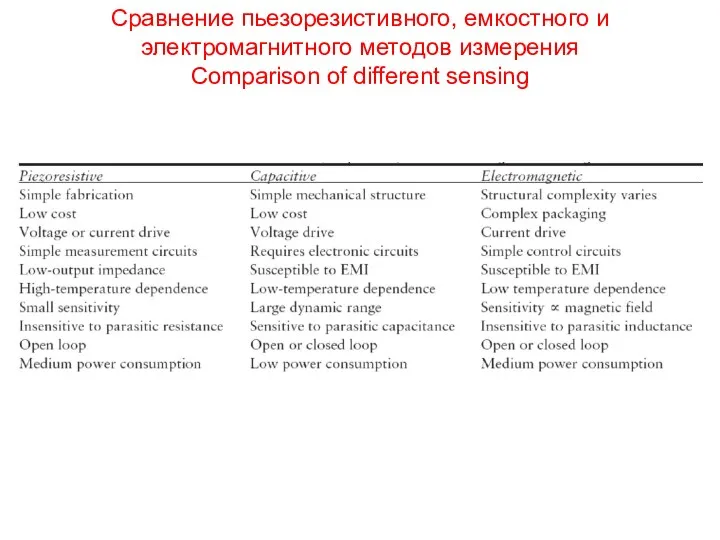

- 9. Сравнение пьезорезистивного, емкостного и электромагнитного методов измерения Comparison of different sensing

- 10. Элементы НЭМС NEMS elements Пассивные Passive Датчики Sensors Приводы (актуаторы) Actuators

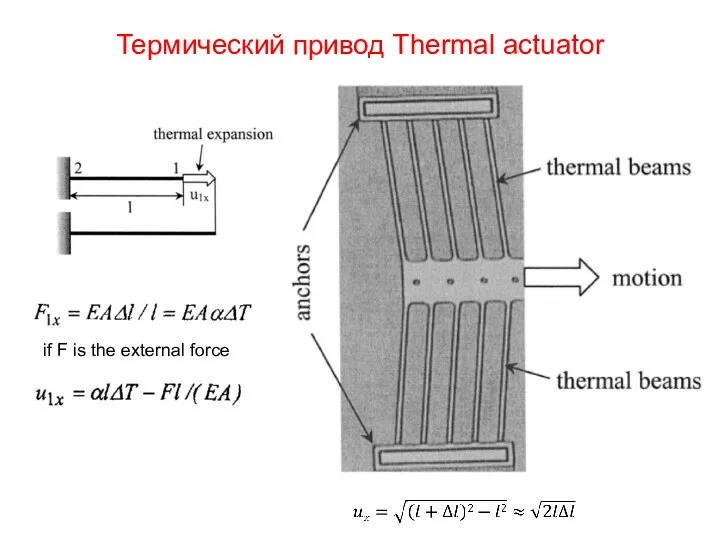

- 11. Термический привод Thermal actuator if F is the external force

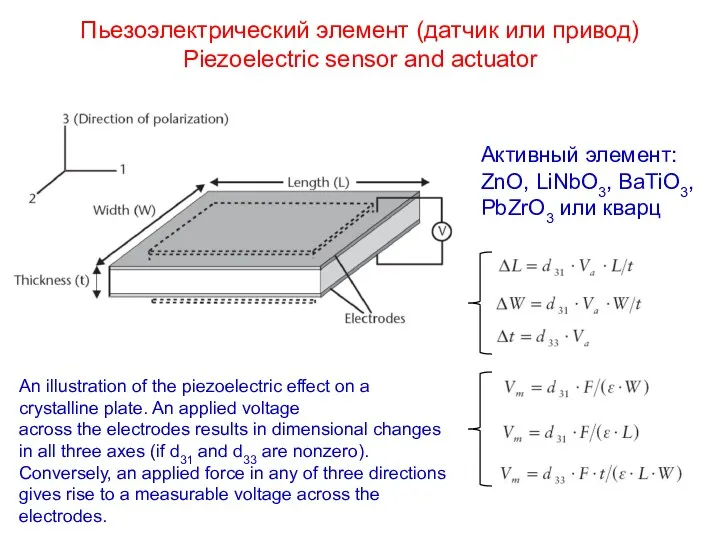

- 12. Пьезоэлектрический элемент (датчик или привод) Piezoelectric sensor and actuator An illustration of the piezoelectric effect on

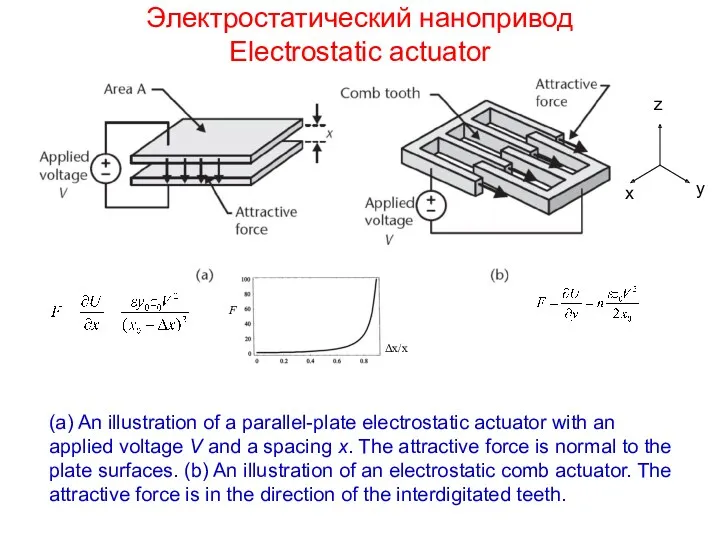

- 13. Электростатический нанопривод Electrostatic actuator (a) An illustration of a parallel-plate electrostatic actuator with an applied voltage

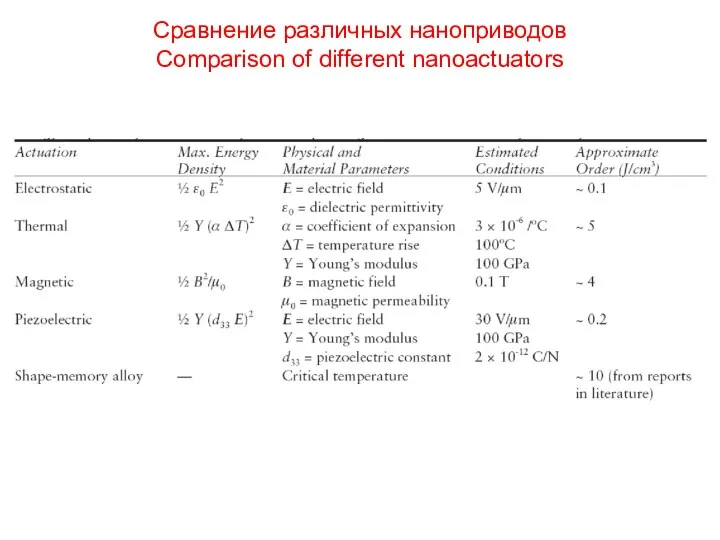

- 14. Сравнение различных наноприводов Comparison of different nanoactuators

- 15. Гироскопы и датчики поворота Gyroscopes and tilt sensors

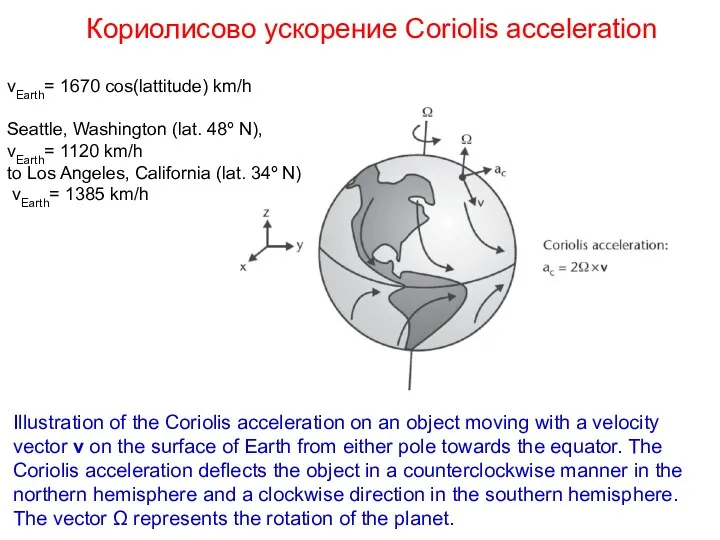

- 16. Кориолисово ускорение Coriolis acceleration Illustration of the Coriolis acceleration on an object moving with a velocity

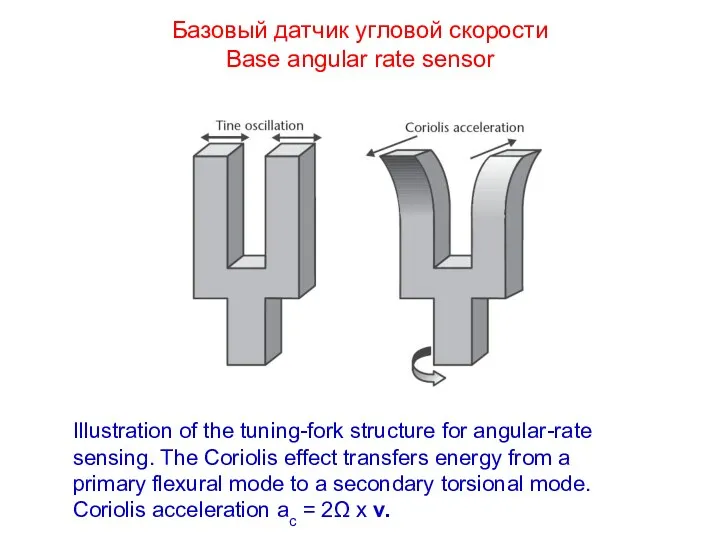

- 17. Базовый датчик угловой скорости Base angular rate sensor Illustration of the tuning-fork structure for angular-rate sensing.

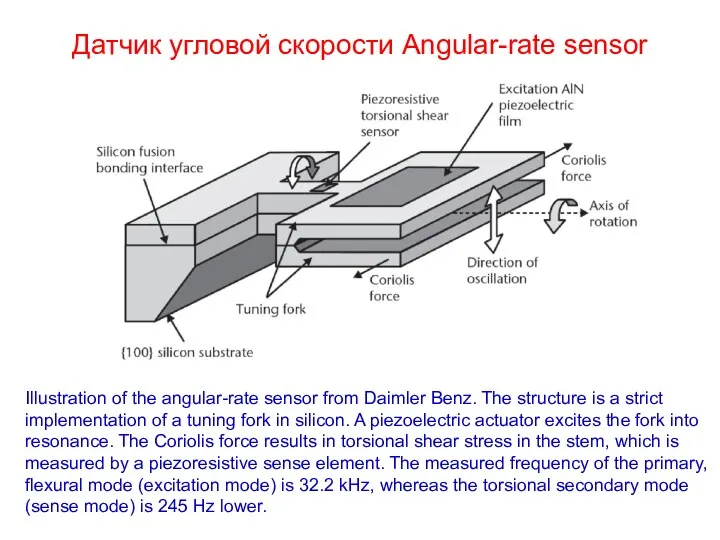

- 18. Датчик угловой скорости Angular-rate sensor Illustration of the angular-rate sensor from Daimler Benz. The structure is

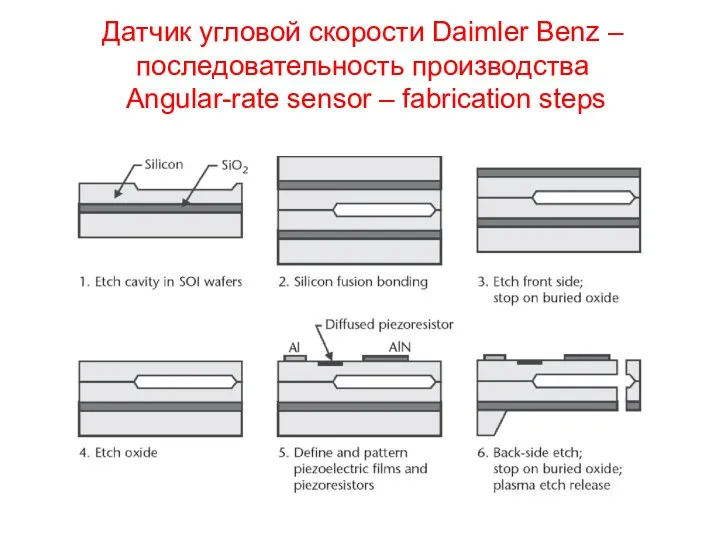

- 19. Датчик угловой скорости Daimler Benz – последовательность производства Angular-rate sensor – fabrication steps

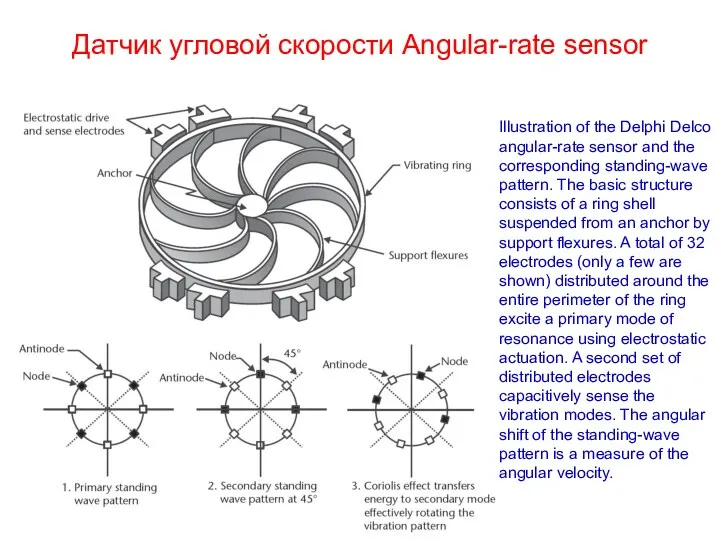

- 20. Датчик угловой скорости Angular-rate sensor Illustration of the Delphi Delco angular-rate sensor and the corresponding standing-wave

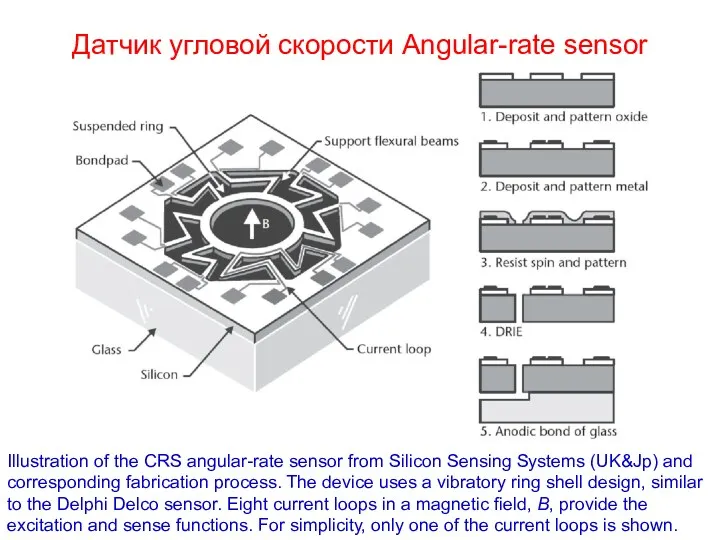

- 21. Датчик угловой скорости Angular-rate sensor Illustration of the CRS angular-rate sensor from Silicon Sensing Systems (UK&Jp)

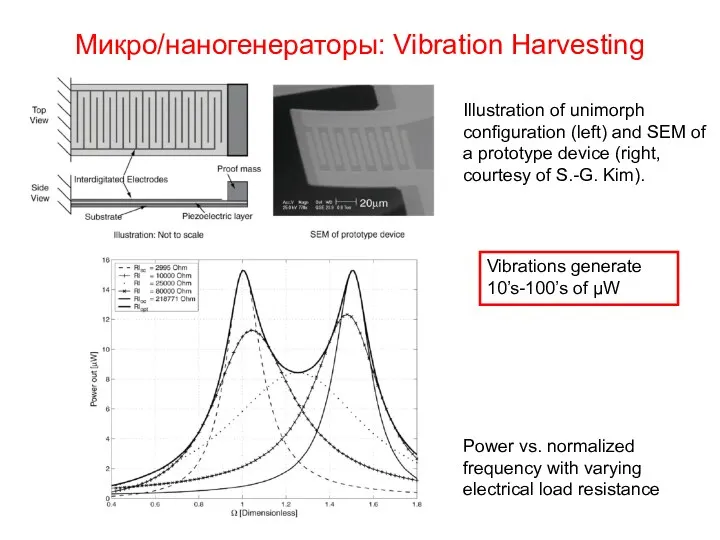

- 22. Микро/наногенераторы: Vibration Harvesting Power vs. normalized frequency with varying electrical load resistance Illustration of unimorph configuration

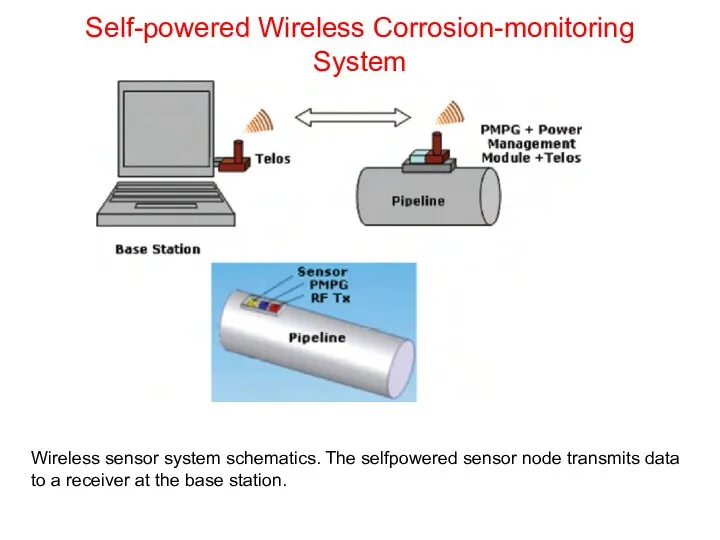

- 23. Self-powered Wireless Corrosion-monitoring System Wireless sensor system schematics. The selfpowered sensor node transmits data to a

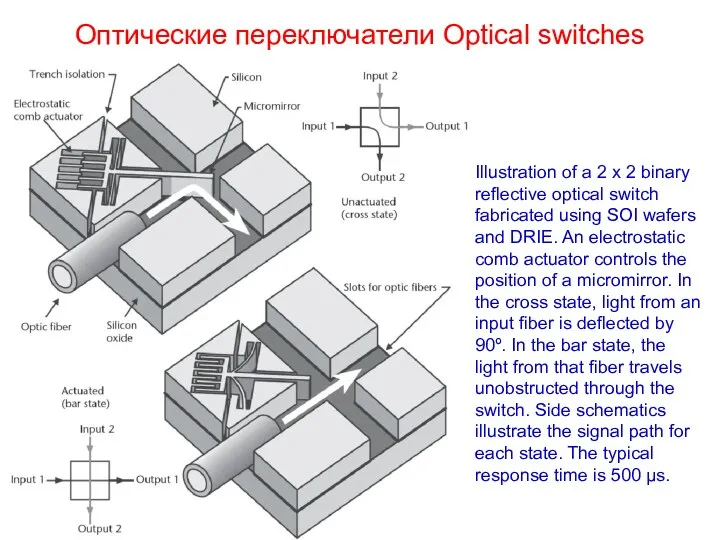

- 24. Оптические переключатели Optical switches Illustration of a 2 x 2 binary reflective optical switch fabricated using

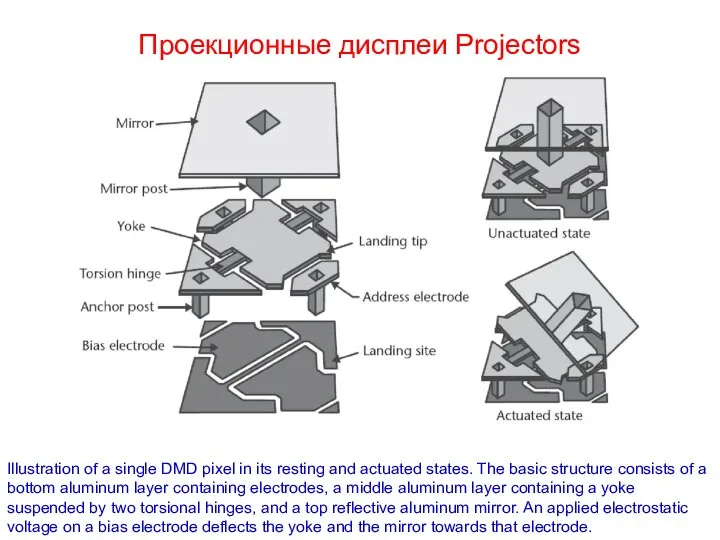

- 25. Проекционные дисплеи Projectors Illustration of a single DMD pixel in its resting and actuated states. The

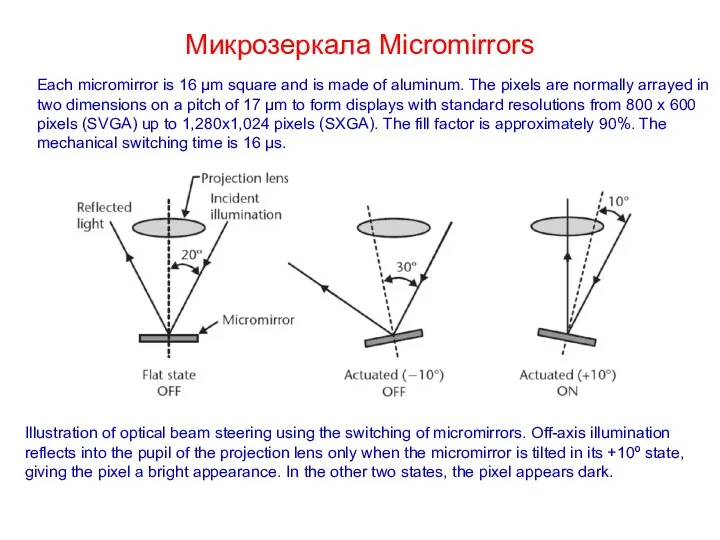

- 26. Микрозеркалa Micromirrors Illustration of optical beam steering using the switching of micromirrors. Off-axis illumination reflects into

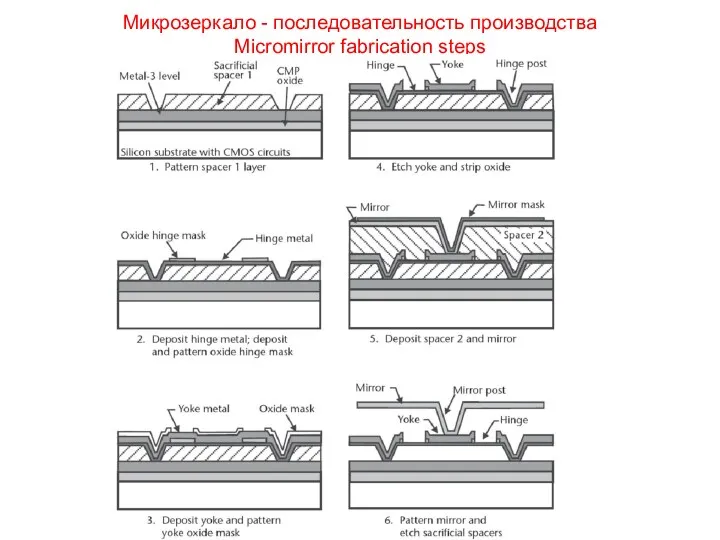

- 27. Микрозеркало - последовательность производства Micromirror fabrication steps

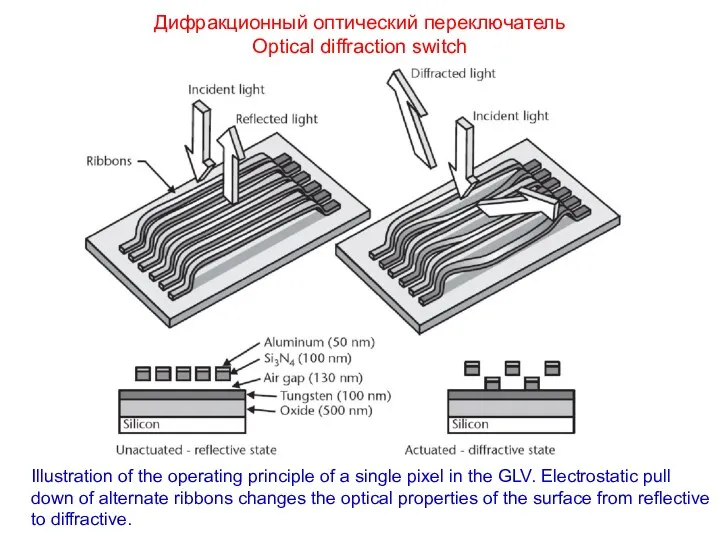

- 28. Дифракционный оптический переключатель Optical diffraction switch Illustration of the operating principle of a single pixel in

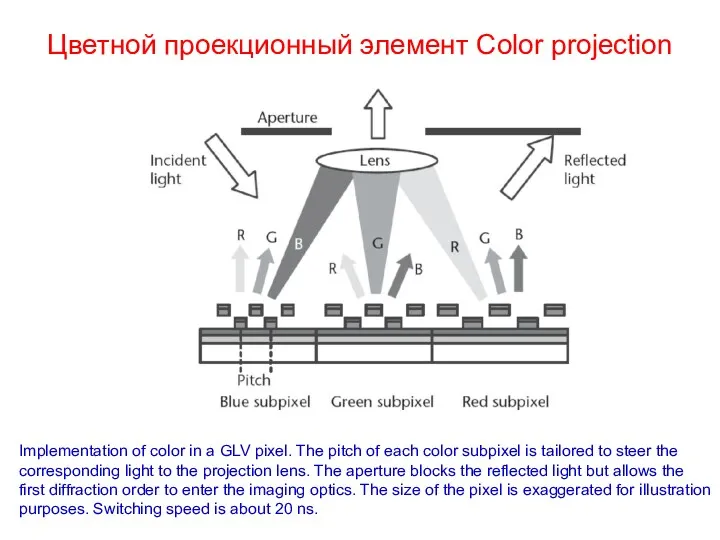

- 29. Цветной проекционный элемент Color projection Implementation of color in a GLV pixel. The pitch of each

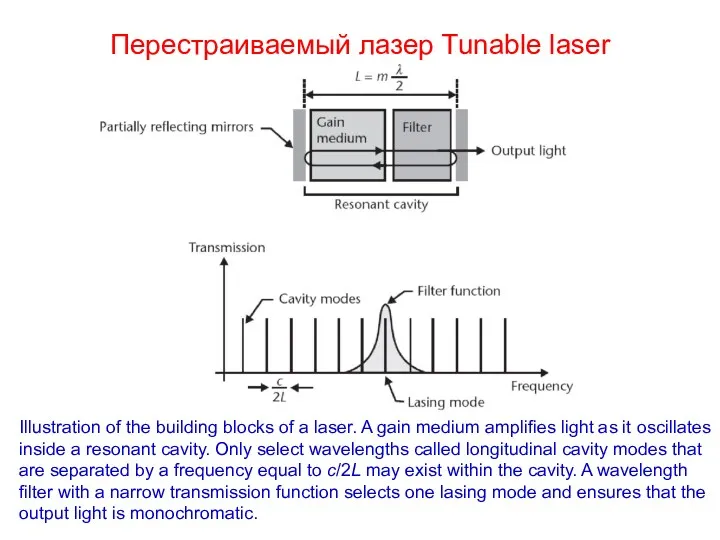

- 30. Перестраиваемый лазер Tunable laser Illustration of the building blocks of a laser. A gain medium amplifies

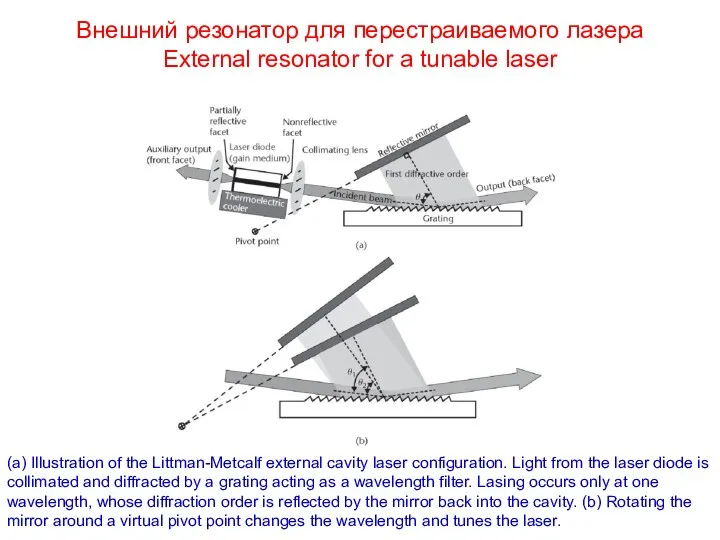

- 31. Внешний резонатор для перестраиваемого лазера External resonator for a tunable laser (a) Illustration of the Littman-Metcalf

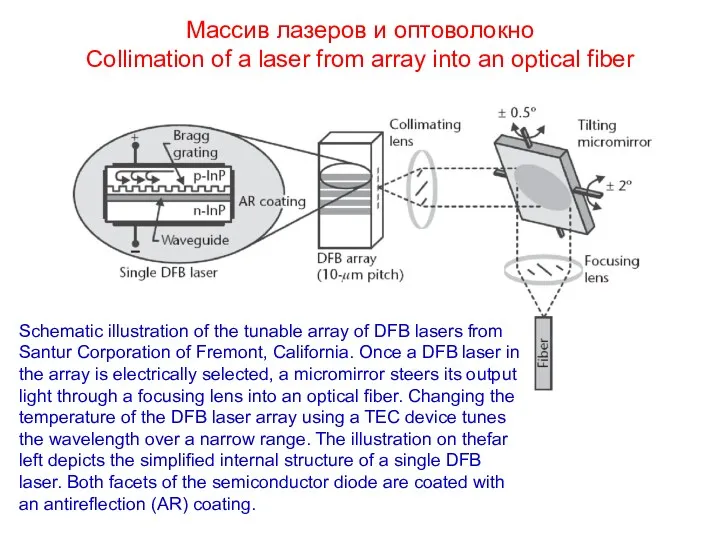

- 32. Массив лазеров и оптоволокно Collimation of a laser from array into an optical fiber Schematic illustration

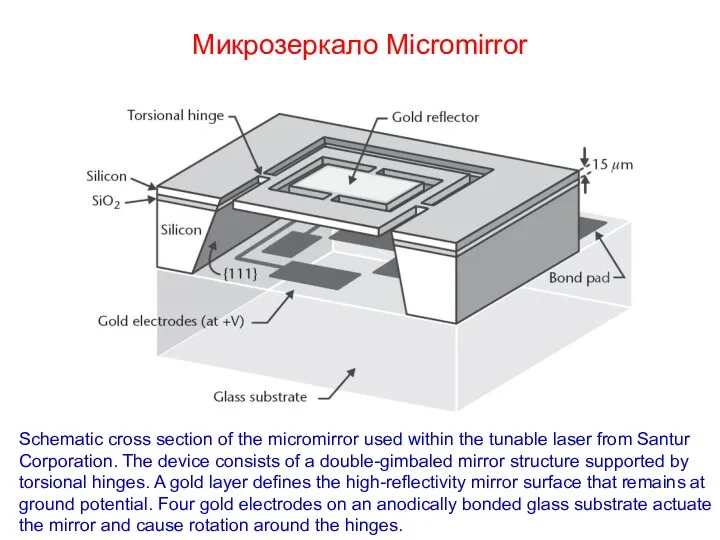

- 33. Микрозеркало Micromirror Schematic cross section of the micromirror used within the tunable laser from Santur Corporation.

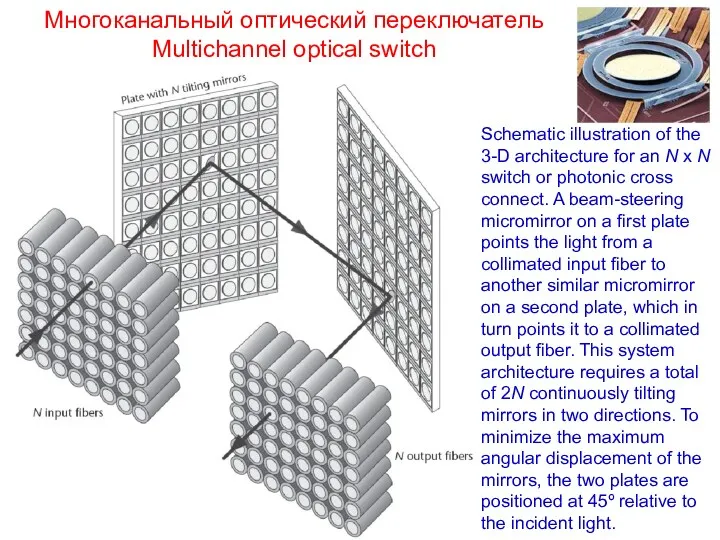

- 34. Многоканальный оптический переключатель Multichannel optical switch Schematic illustration of the 3-D architecture for an N x

- 35. Замещение пассивных электронных элементов Replacement of passive electronic components

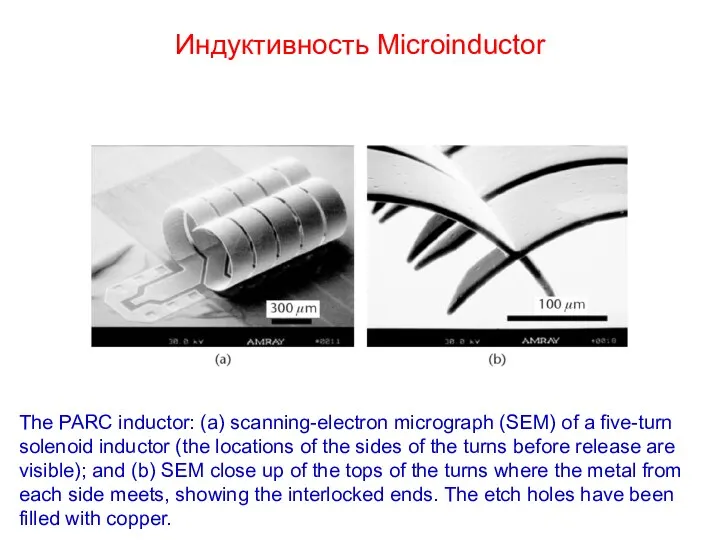

- 36. Индуктивность Microinductor The PARC inductor: (a) scanning-electron micrograph (SEM) of a five-turn solenoid inductor (the locations

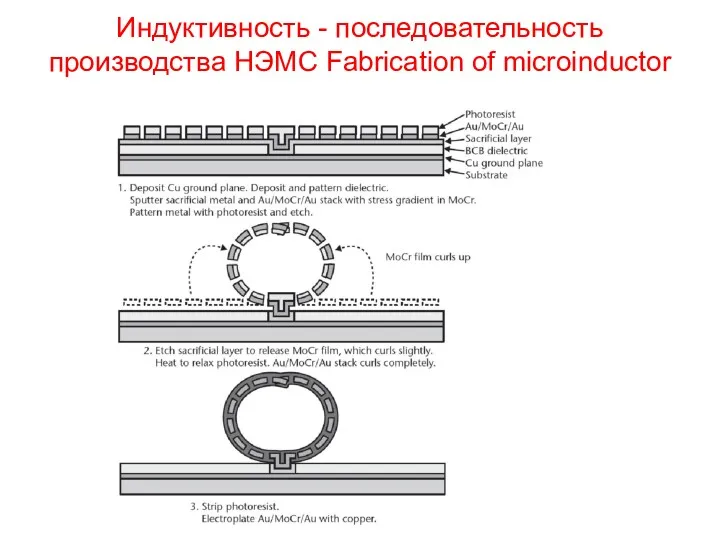

- 37. Индуктивность - последовательность производства НЭМС Fabrication of microinductor

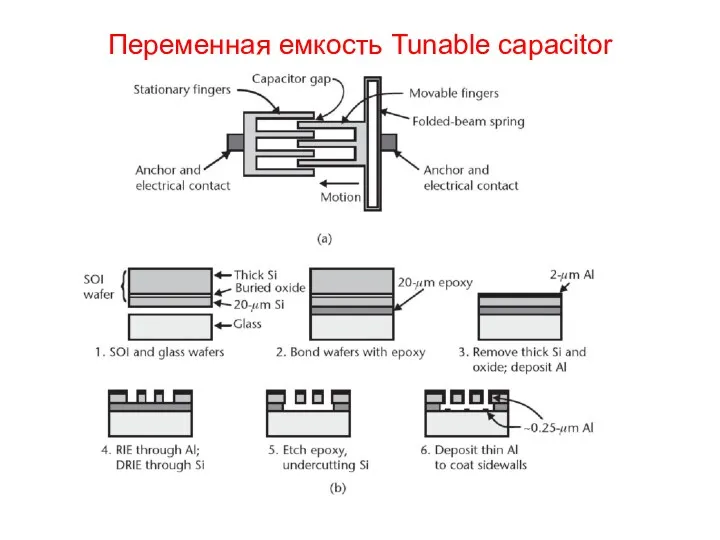

- 38. Переменная емкость Tunable capacitor

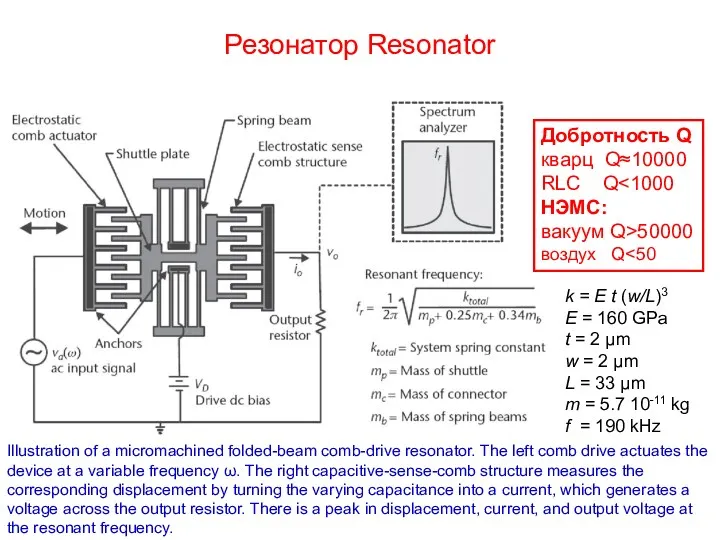

- 39. Резонатор Resonator Illustration of a micromachined folded-beam comb-drive resonator. The left comb drive actuates the device

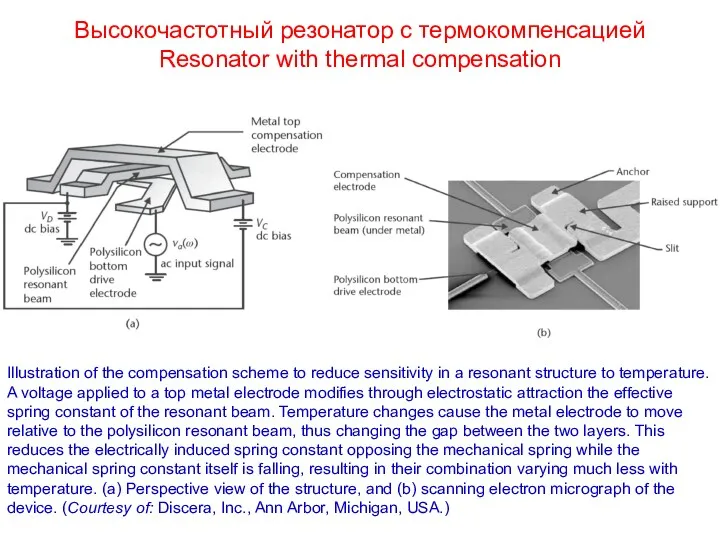

- 40. Высокочастотный резонатор с термокомпенсацией Resonator with thermal compensation Illustration of the compensation scheme to reduce sensitivity

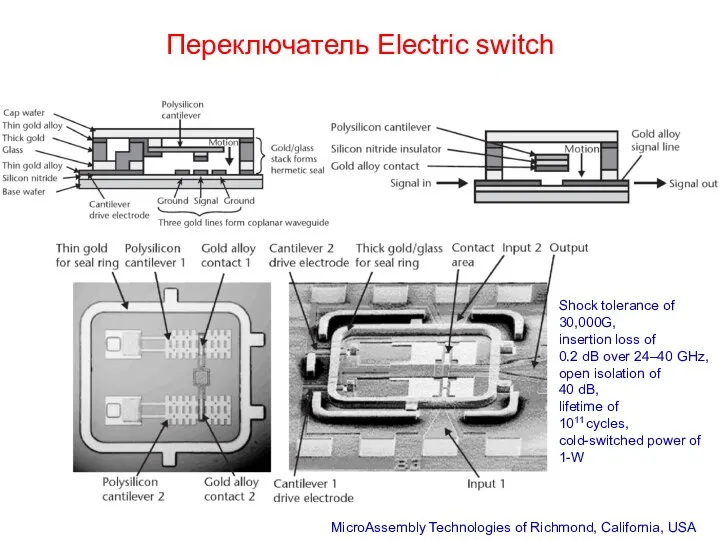

- 41. Переключатель Electric switch MicroAssembly Technologies of Richmond, California, USA Shock tolerance of 30,000G, insertion loss of

- 42. To be continued

- 44. Скачать презентацию

Гидравлика

Гидравлика урок-игра по физике по теме Плотность

урок-игра по физике по теме Плотность Анализ технического паспорта асинхронного электродвигателя

Анализ технического паспорта асинхронного электродвигателя Мегаконструкції. Найбільший в світі екскаватор

Мегаконструкції. Найбільший в світі екскаватор Современные автомобили и двигатели

Современные автомобили и двигатели Внедрение ФГОС общего образования второго поколения по физике

Внедрение ФГОС общего образования второго поколения по физике Технология мини-исследования на уроках физики

Технология мини-исследования на уроках физики спектры

спектры Bbs wheels range 1999 ilustrated catalog

Bbs wheels range 1999 ilustrated catalog Законам механики подчиняются движения всех окружающих нас тел

Законам механики подчиняются движения всех окружающих нас тел Конкурс учителей Есть идея!

Конкурс учителей Есть идея! Олимпийские игры и физика

Олимпийские игры и физика Памятка по неисправностям автосцепного устройства при техническом обслуживании

Памятка по неисправностям автосцепного устройства при техническом обслуживании Урок физики в 10 классе Газовые законы

Урок физики в 10 классе Газовые законы Звуковые волны

Звуковые волны Элементарные частицы. Микромир

Элементарные частицы. Микромир Идеальный газ. Основное уравнение МКТ идеального газа

Идеальный газ. Основное уравнение МКТ идеального газа Нормирование точности поверхностей деталей машин по взаимному расположению, обозначения их на чертежах

Нормирование точности поверхностей деталей машин по взаимному расположению, обозначения их на чертежах презентация по теме Сила трения.

презентация по теме Сила трения. Стискання газів. Рівняння Менделєєва-Клапейрона

Стискання газів. Рівняння Менделєєва-Клапейрона Axles and shafts

Axles and shafts дополнение к уроку физики Испарение

дополнение к уроку физики Испарение Изобретени радио А.С. Поповым

Изобретени радио А.С. Поповым Гармонические колебания и их характеристики

Гармонические колебания и их характеристики Цепные передачи

Цепные передачи Mechanism

Mechanism Classical angular momentum and magnetic dipole moment

Classical angular momentum and magnetic dipole moment Кинематика вращательного движения

Кинематика вращательного движения