Содержание

- 2. Замещение пассивных электронных элементов Replacement of passive electronic components

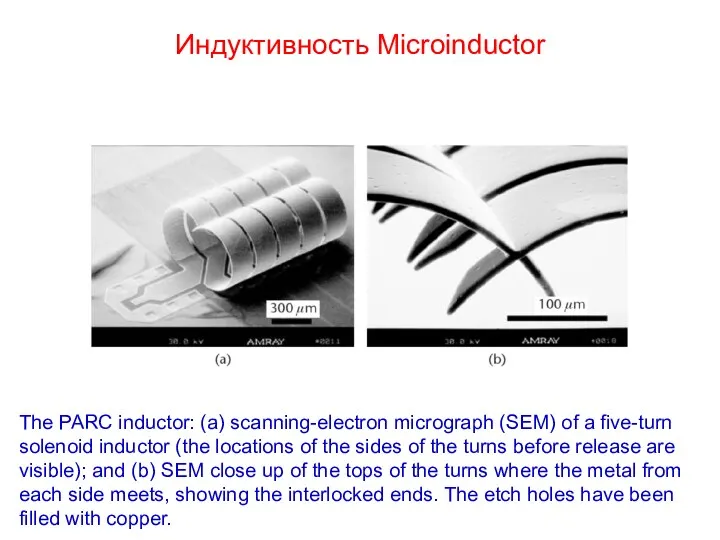

- 3. Индуктивность Microinductor The PARC inductor: (a) scanning-electron micrograph (SEM) of a five-turn solenoid inductor (the locations

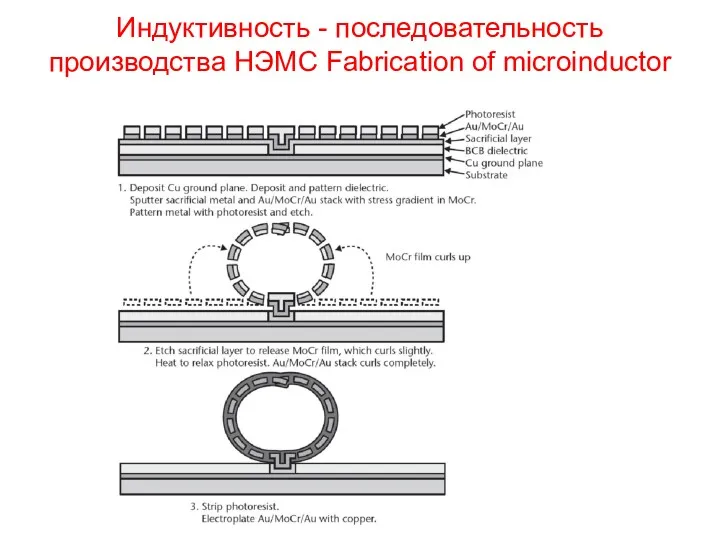

- 4. Индуктивность - последовательность производства НЭМС Fabrication of microinductor

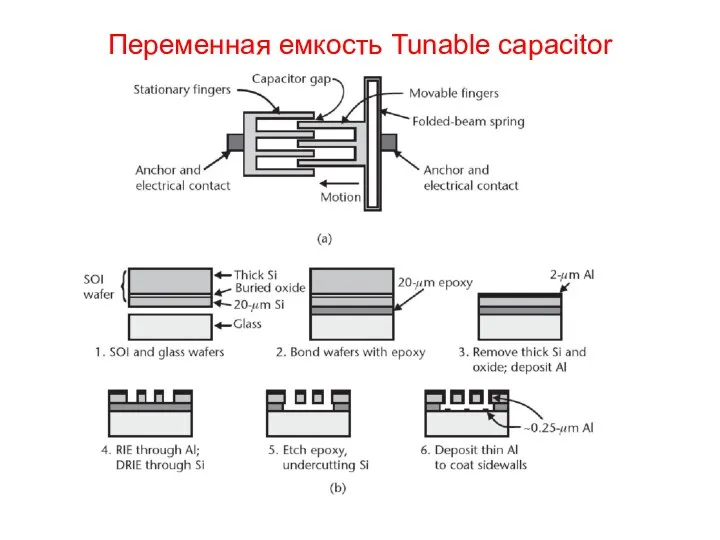

- 5. Переменная емкость Tunable capacitor

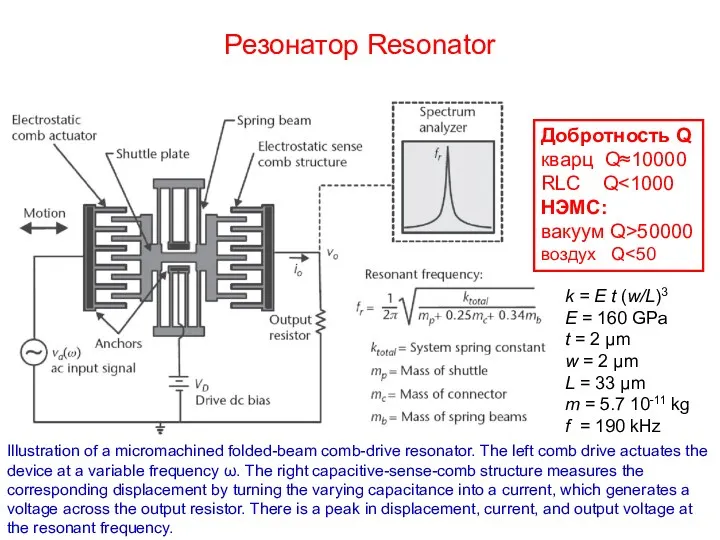

- 6. Резонатор Resonator Illustration of a micromachined folded-beam comb-drive resonator. The left comb drive actuates the device

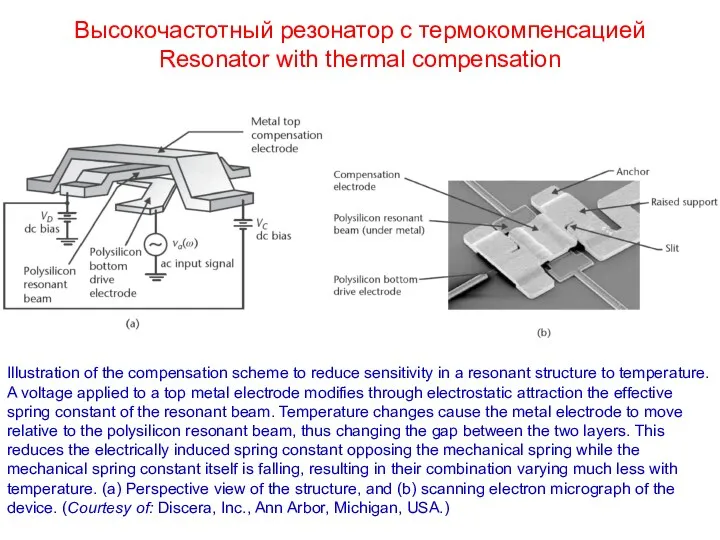

- 7. Высокочастотный резонатор с термокомпенсацией Resonator with thermal compensation Illustration of the compensation scheme to reduce sensitivity

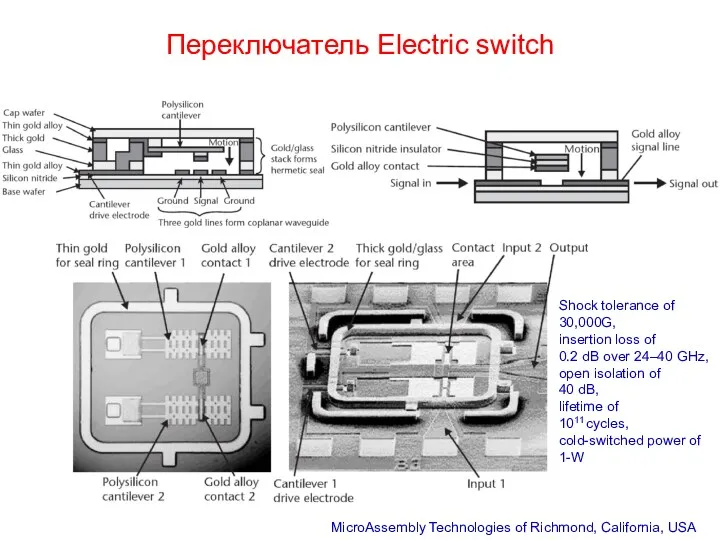

- 8. Переключатель Electric switch MicroAssembly Technologies of Richmond, California, USA Shock tolerance of 30,000G, insertion loss of

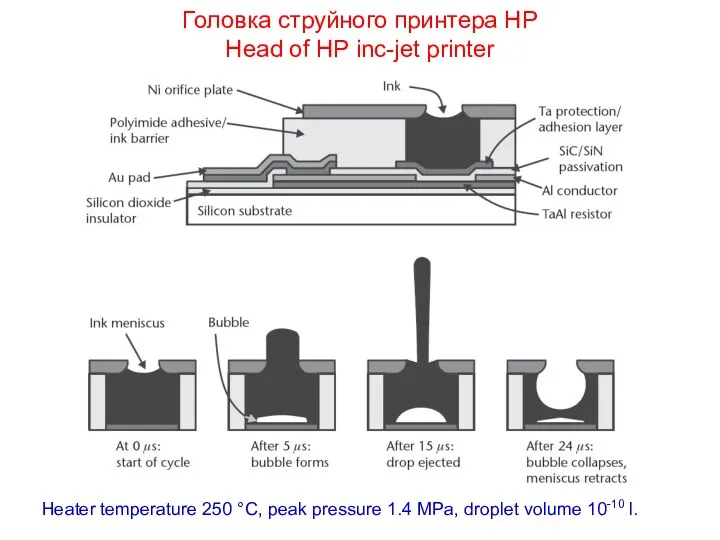

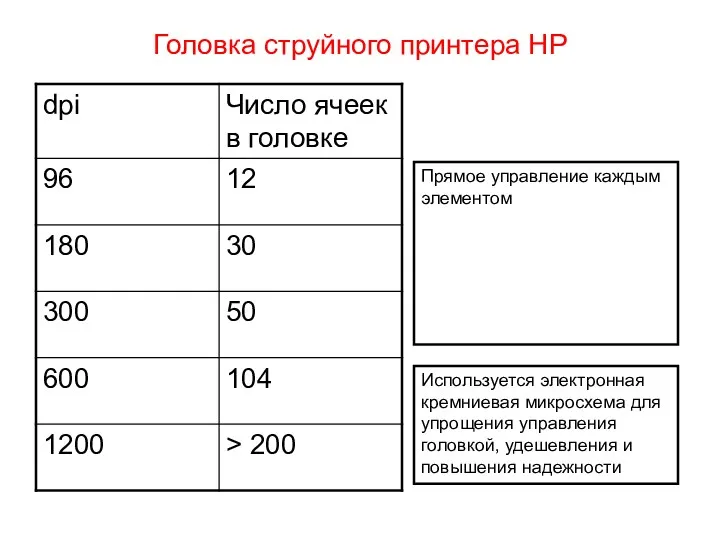

- 9. Головка струйного принтера HP Head of HP inc-jet printer Heater temperature 250 °C, peak pressure 1.4

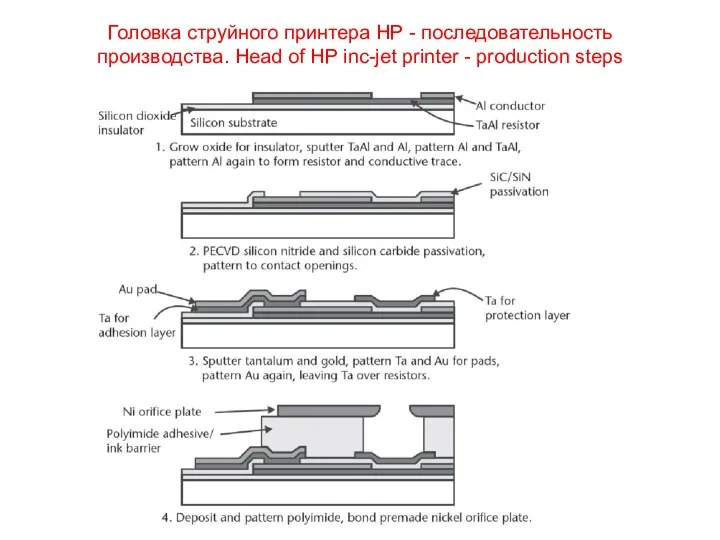

- 10. Головка струйного принтера HP - последовательность производства. Head of HP inc-jet printer - production steps

- 11. Головка струйного принтера HP Используется электронная кремниевая микросхема для упрощения управления головкой, удешевления и повышения надежности

- 12. .Регуляторы потоков. Microvalves • Electronic flow regulation of refrigerant for increased energy savings; • Electronically programmable

- 13. Нормально-открытый регулятор потока Normally open microvalve Illustration of a normally open valve from Redwood Microsystems, Ca.

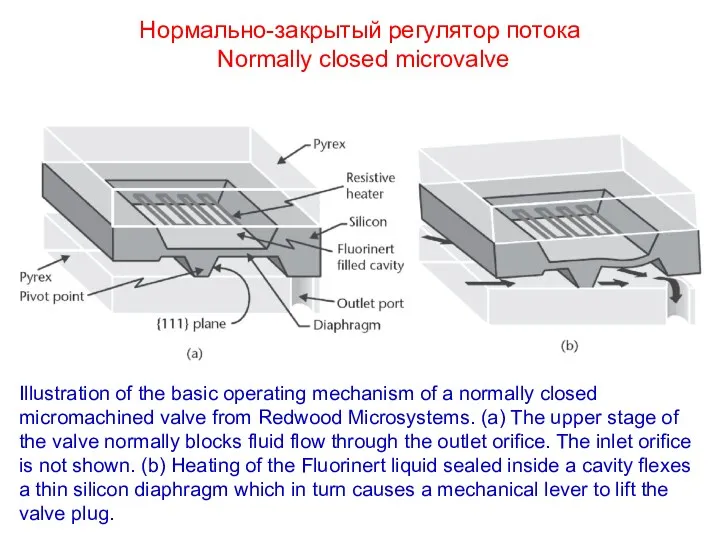

- 14. Нормально-закрытый регулятор потока Normally closed microvalve Illustration of the basic operating mechanism of a normally closed

- 15. Ограничения регулятора потока с термо-пневматическим приводом Утечка тепла Leak of heat Скорость переключения Switching time Предельное

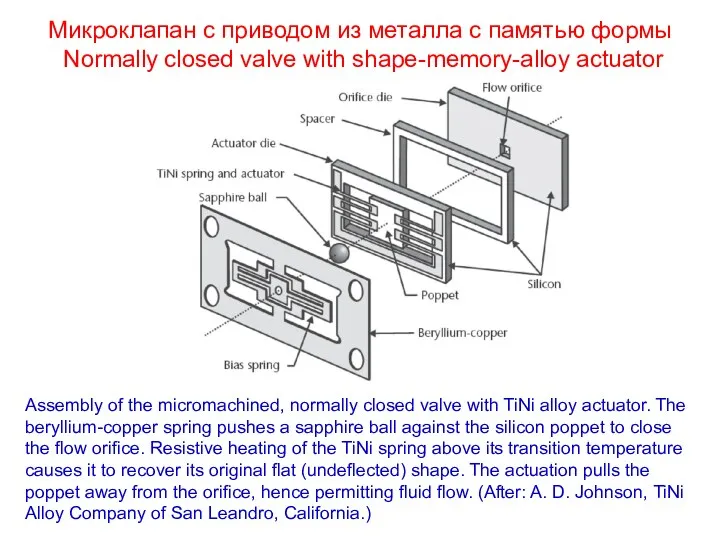

- 16. Микроклапан с приводом из металла с памятью формы Normally closed valve with shape-memory-alloy actuator Assembly of

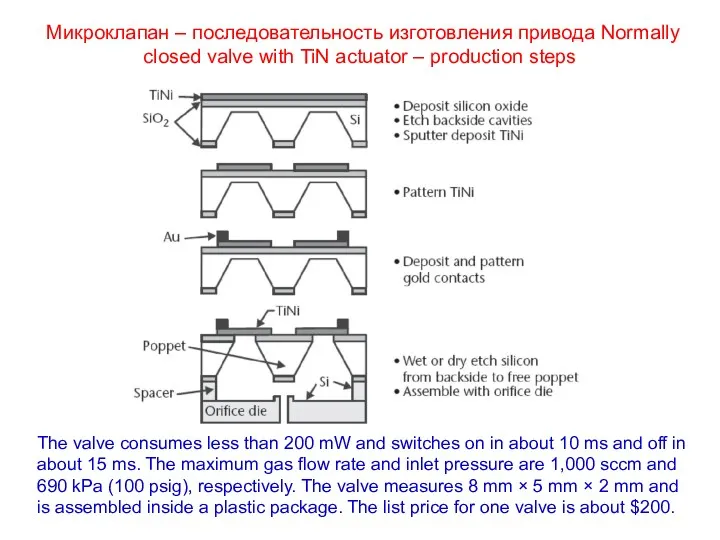

- 17. Микроклапан – последовательность изготовления привода Normally closed valve with TiN actuator – production steps The valve

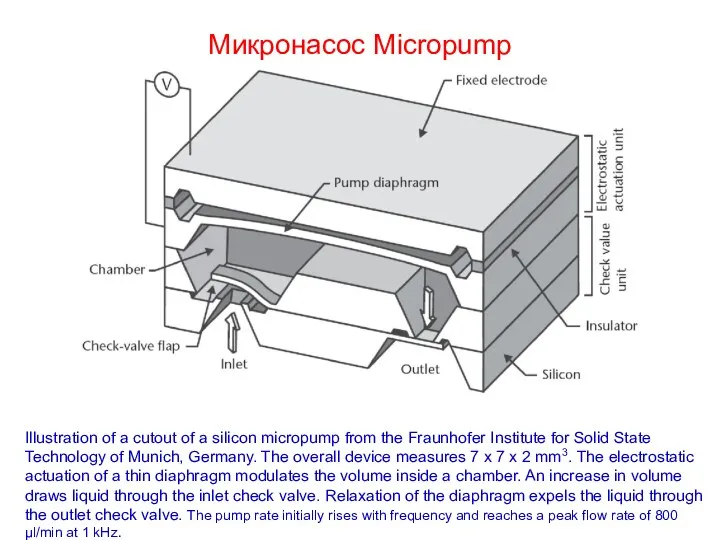

- 18. Микронасос Micropump Illustration of a cutout of a silicon micropump from the Fraunhofer Institute for Solid

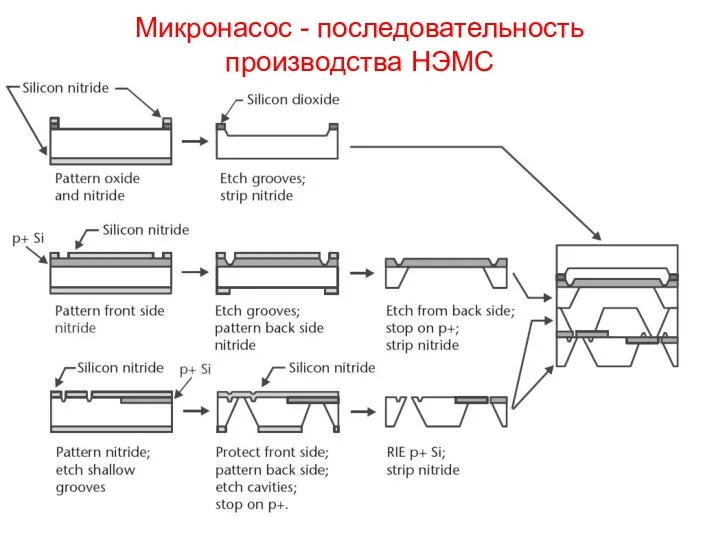

- 19. Микронасос - последовательность производства НЭМС

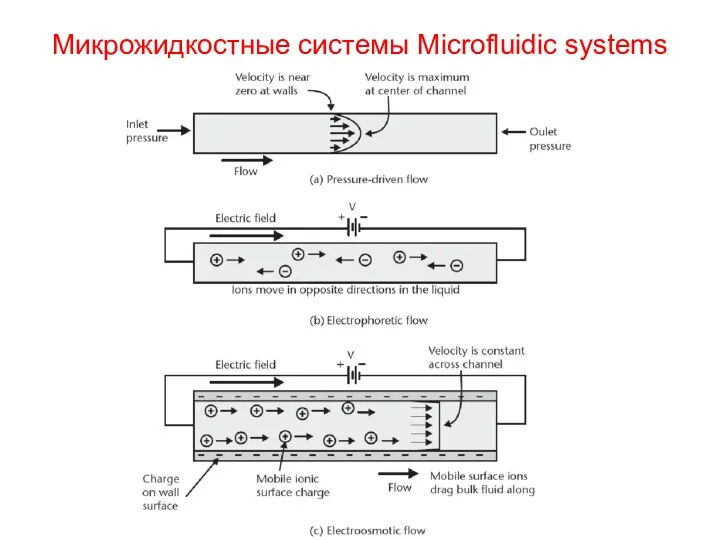

- 20. Микрожидкостные системы Microfluidic systems

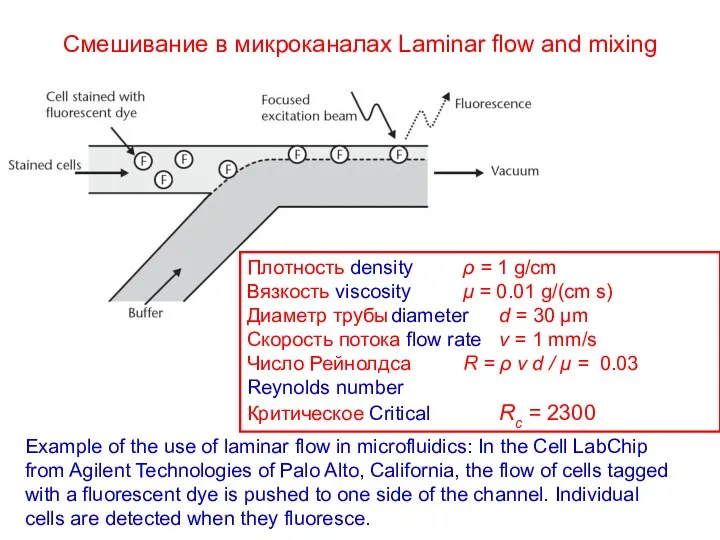

- 21. Смешивание в микроканалах Laminar flow and mixing Example of the use of laminar flow in microfluidics:

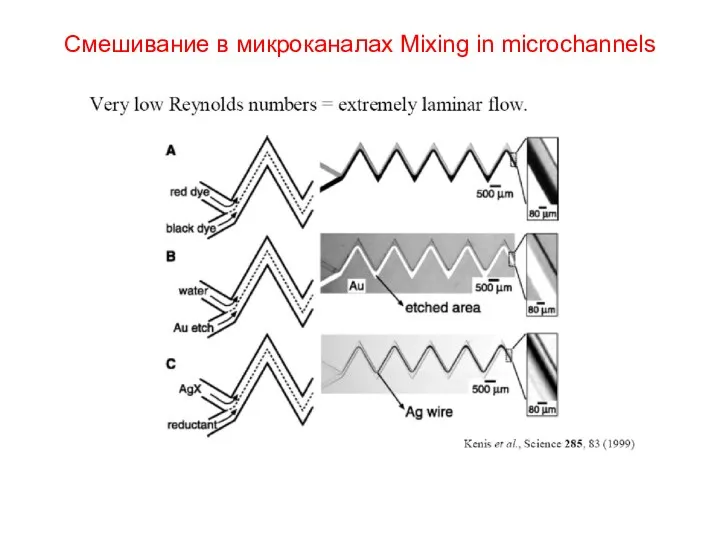

- 22. Смешивание в микроканалах Mixing in microchannels

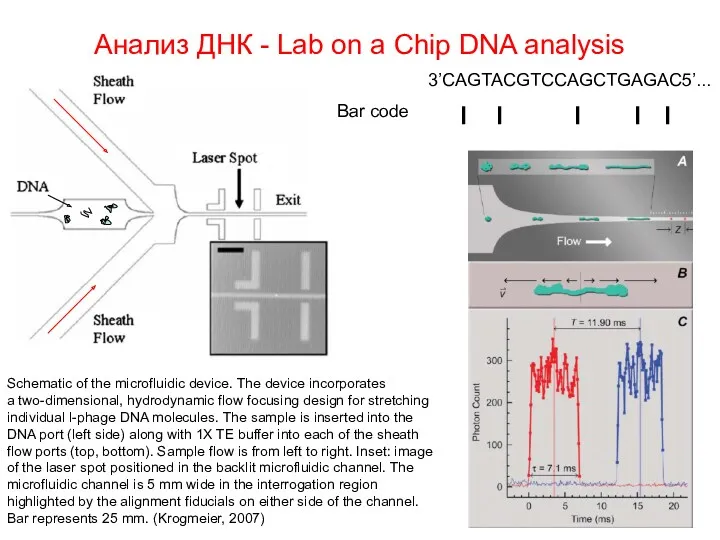

- 23. Анализ ДНК - Lab on a Chip DNA analysis Schematic of the microfluidic device. The device

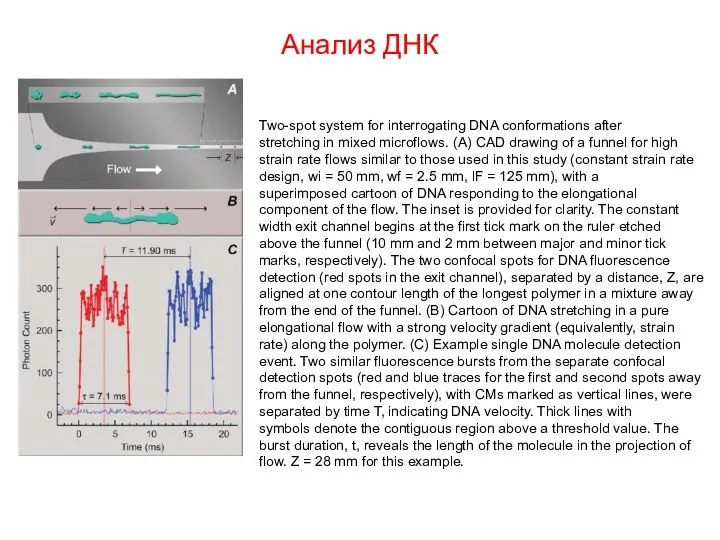

- 24. Анализ ДНК Two-spot system for interrogating DNA conformations after stretching in mixed microflows. (A) CAD drawing

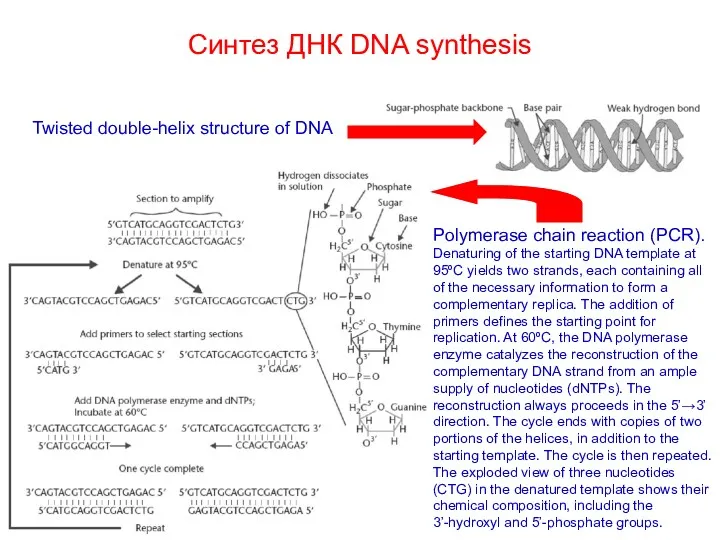

- 25. Синтез ДНК DNA synthesis Twisted double-helix structure of DNA Polymerase chain reaction (PCR). Denaturing of the

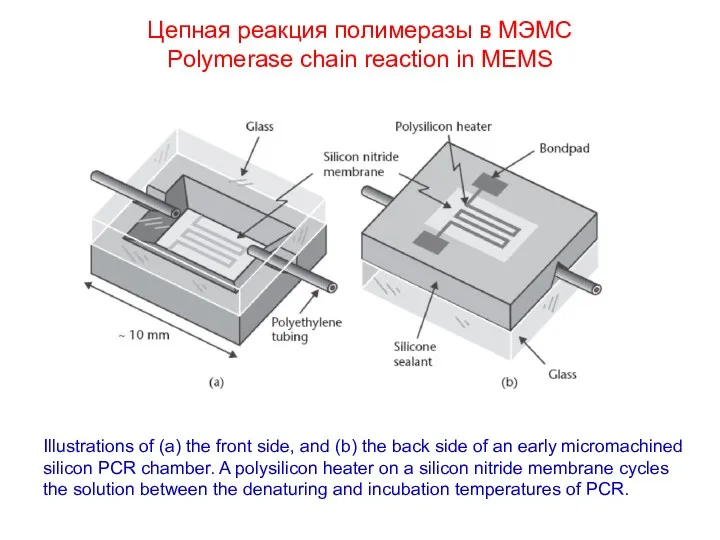

- 26. Цепная реакция полимеразы в МЭМС Polymerase chain reaction in MEMS Illustrations of (a) the front side,

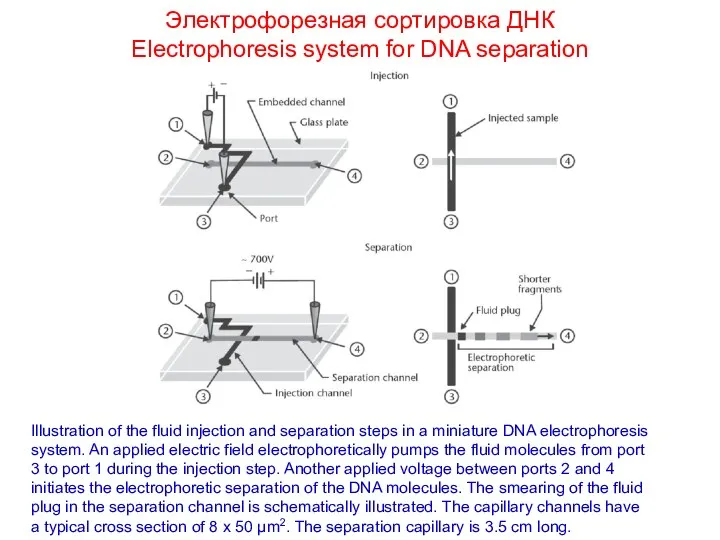

- 27. Электрофорезная сортировка ДНК Electrophoresis system for DNA separation Illustration of the fluid injection and separation steps

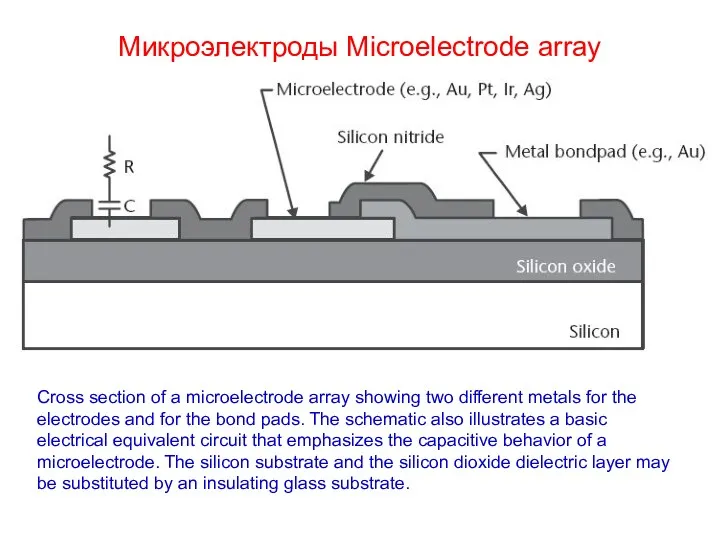

- 28. Микроэлектроды Microelectrode array Cross section of a microelectrode array showing two different metals for the electrodes

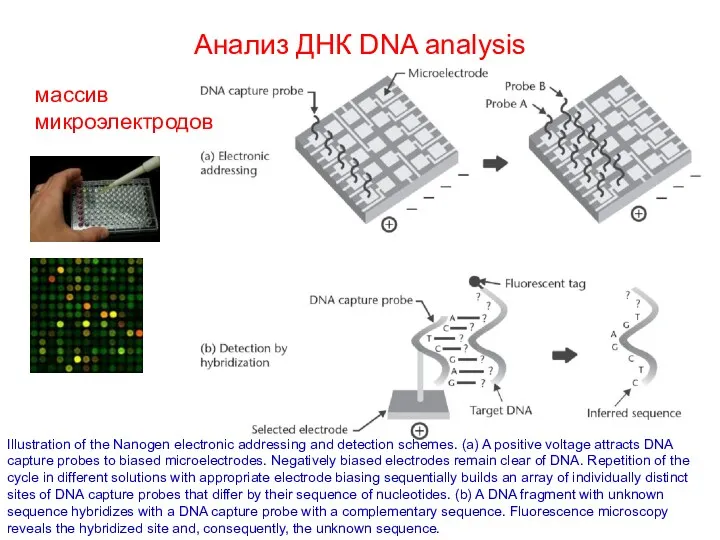

- 29. Анализ ДНК DNA analysis Illustration of the Nanogen electronic addressing and detection schemes. (a) A positive

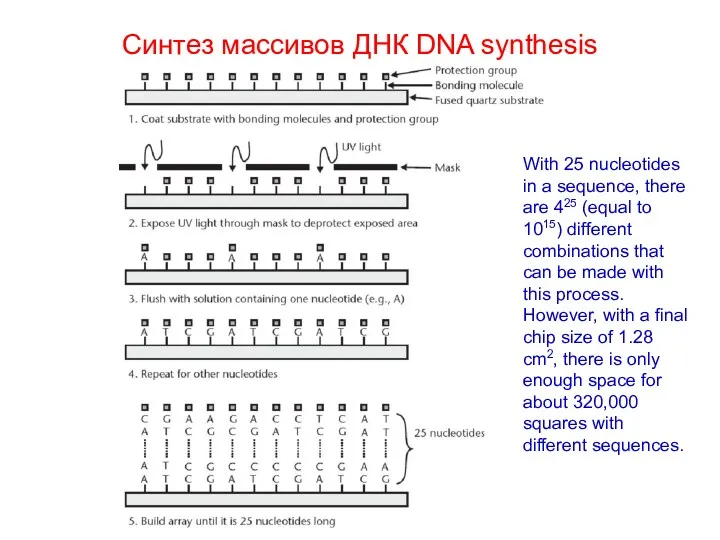

- 30. Синтез массивов ДНК DNA synthesis With 25 nucleotides in a sequence, there are 425 (equal to

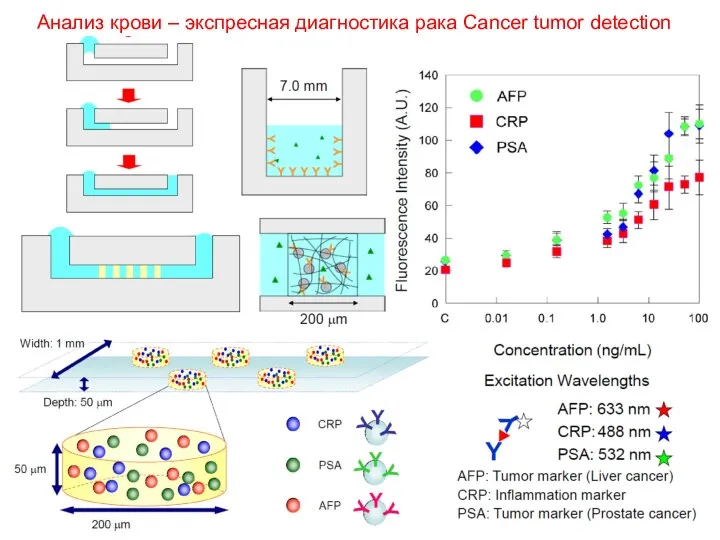

- 31. Анализ крови – экспресная диагностика рака Cancer tumor detection

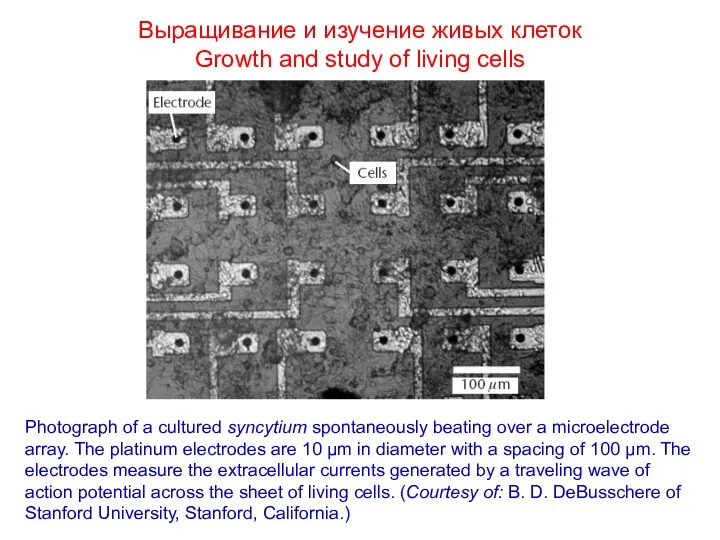

- 32. Выращивание и изучение живых клеток Growth and study of living cells Photograph of a cultured syncytium

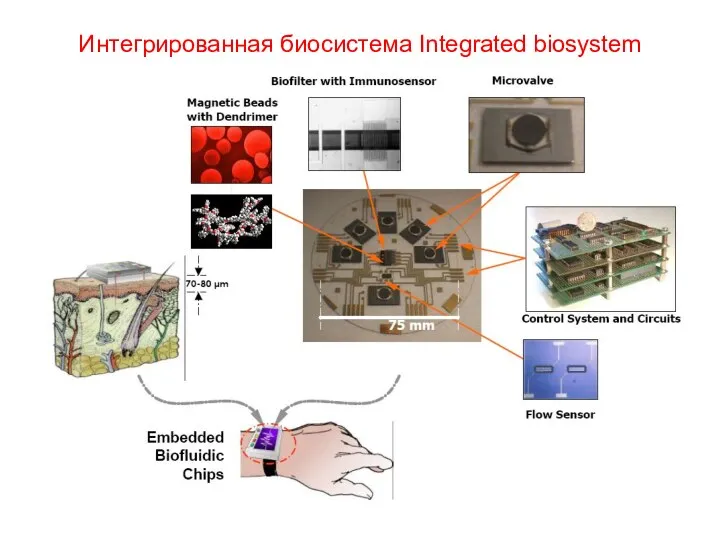

- 33. Интегрированная биосистема Integrated biosystem

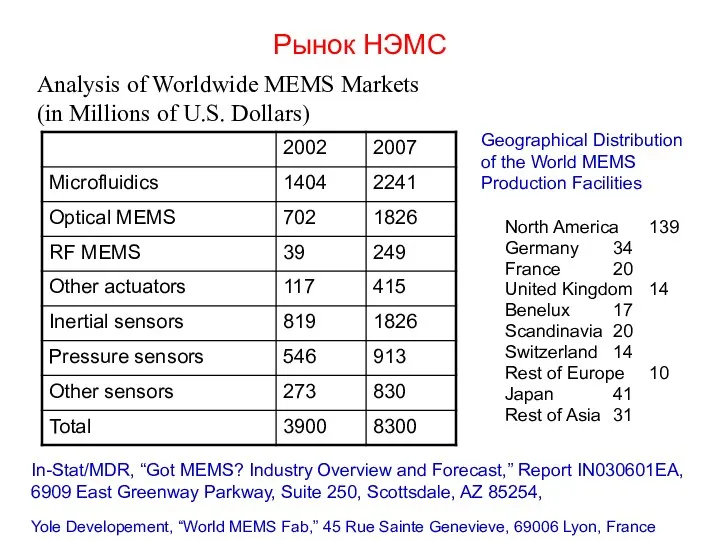

- 34. Рынок НЭМС Analysis of Worldwide MEMS Markets (in Millions of U.S. Dollars) In-Stat/MDR, “Got MEMS? Industry

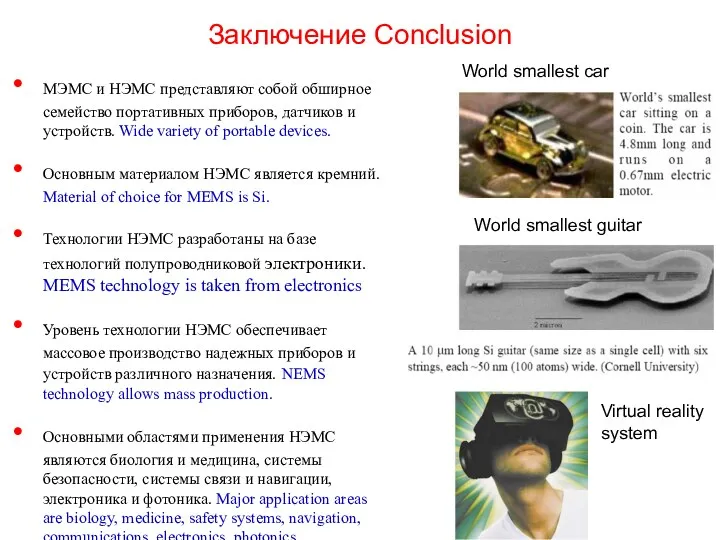

- 35. МЭМС и НЭМС представляют собой обширное семейство портативных приборов, датчиков и устройств. Wide variety of portable

- 37. Скачать презентацию

Вільне падіння. Прискорення вільного падіння

Вільне падіння. Прискорення вільного падіння Классификация систем автоматического регулирования

Классификация систем автоматического регулирования Снятие, замена приводного ремня ГРМ Chevrolet Lacetti

Снятие, замена приводного ремня ГРМ Chevrolet Lacetti Молекулярно-кинетические свойства коллоидных систем

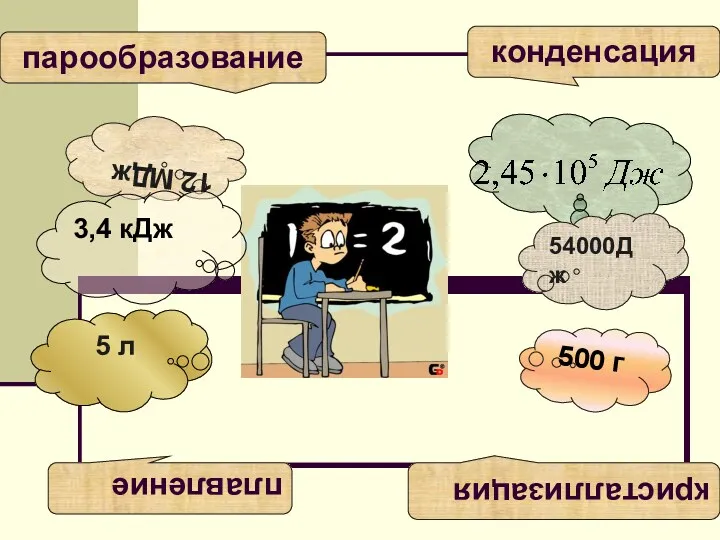

Молекулярно-кинетические свойства коллоидных систем Презентация-игра, 7-8 класс

Презентация-игра, 7-8 класс Элементарные частицы

Элементарные частицы История появления квадрокоптеров

История появления квадрокоптеров Делимость электрического заряда

Делимость электрического заряда Урок по теме Электризация тел 8 класс

Урок по теме Электризация тел 8 класс Радиоактивность. Урок физики 9 класс

Радиоактивность. Урок физики 9 класс Сила тока. Единицы силы тока

Сила тока. Единицы силы тока Газораспределительный механизм

Газораспределительный механизм Спидометр

Спидометр Kernfusion in der sonne

Kernfusion in der sonne Глава 5. Пьезоэлектрический эффект и электрострикция

Глава 5. Пьезоэлектрический эффект и электрострикция Агрегатные состояния вещества. Урок в 7 классе

Агрегатные состояния вещества. Урок в 7 классе Презентация Способы изменения внутренней энергии 8 класс

Презентация Способы изменения внутренней энергии 8 класс Элементы теории атомного ядра

Элементы теории атомного ядра Шпонды және шлицты қосылыстар

Шпонды және шлицты қосылыстар методическая разработка раздела курса физики 7 класса Давление

методическая разработка раздела курса физики 7 класса Давление Урок по теме Расчёт пути и времени движения 7 класс

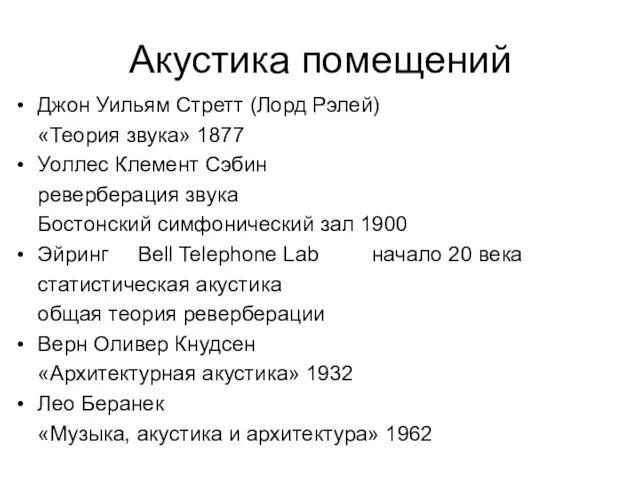

Урок по теме Расчёт пути и времени движения 7 класс Акустика помещений

Акустика помещений Закон всемирного тяготения. Сила тяжести. Невесомость

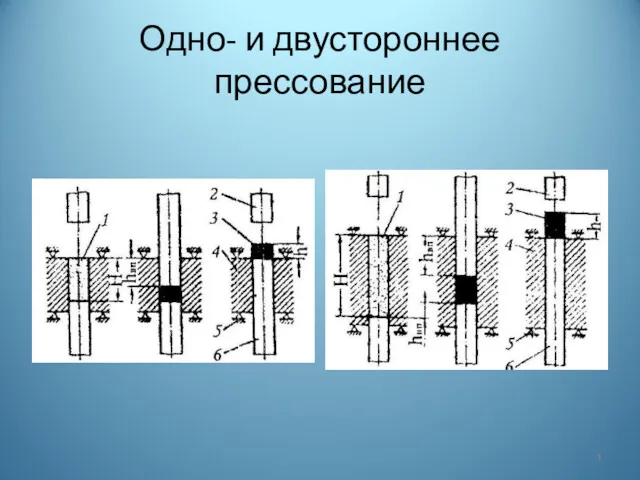

Закон всемирного тяготения. Сила тяжести. Невесомость Одно- и двустороннее прессование деталей

Одно- и двустороннее прессование деталей Количество теплоты. Единицы количества теплоты. Удельная теплоемкость. 8 класс

Количество теплоты. Единицы количества теплоты. Удельная теплоемкость. 8 класс сказка физического содержания Добро и зло

сказка физического содержания Добро и зло Понятие о трехфазных цепях

Понятие о трехфазных цепях Основы генерирования и формирования сигналов. Лекция 2

Основы генерирования и формирования сигналов. Лекция 2