Содержание

- 2. Inventory Number: 002764 1st Edition ANSYS Release: 12.0 Published Date: April 30, 2009 Registered Trademarks: ANSYS®

- 3. Agenda Why / what is Rotordynamics Equations for rotating structures Rotating and stationary reference frame Elements

- 4. High speed machinery such as Turbine Engine Rotors, Computer Disk Drives, etc. Very small rotor-stator clearances

- 5. Rotordynamics features Pre-processing: Appropriate element formulation for all geometries Gyroscopic moments generated by rotating parts Bearings

- 6. Rotordynamics features Post-processing Campbell diagrams Mode animation Orbit plots Transient plots and animations User’s guide Advanced

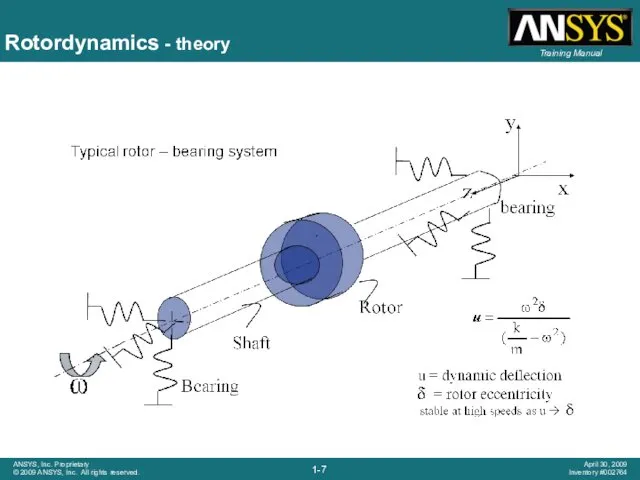

- 7. Rotordynamics - theory

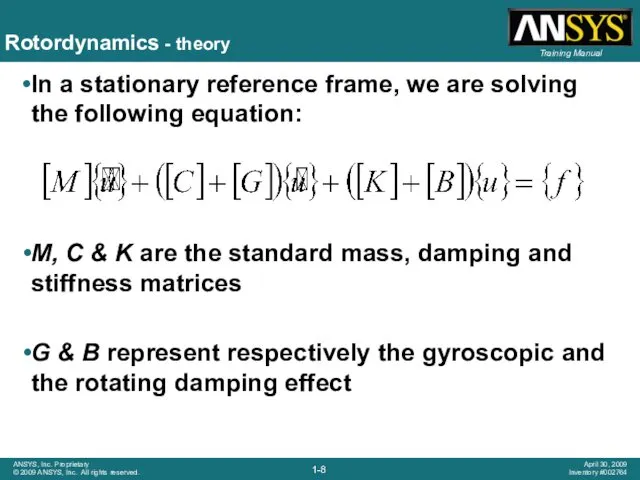

- 8. Rotordynamics - theory In a stationary reference frame, we are solving the following equation: M, C

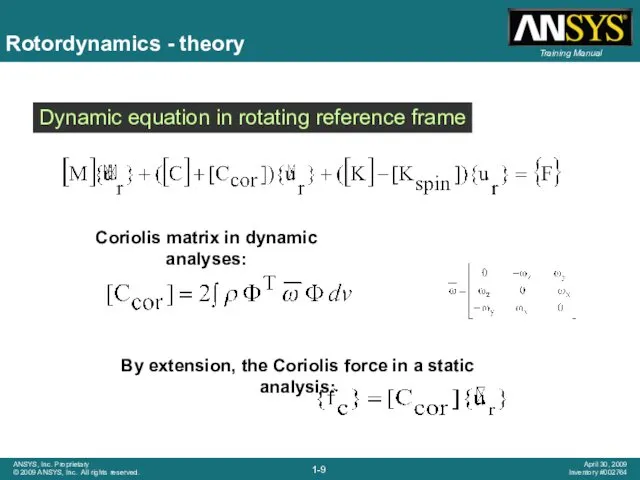

- 9. Coriolis matrix in dynamic analyses: Rotordynamics - theory Dynamic equation in rotating reference frame

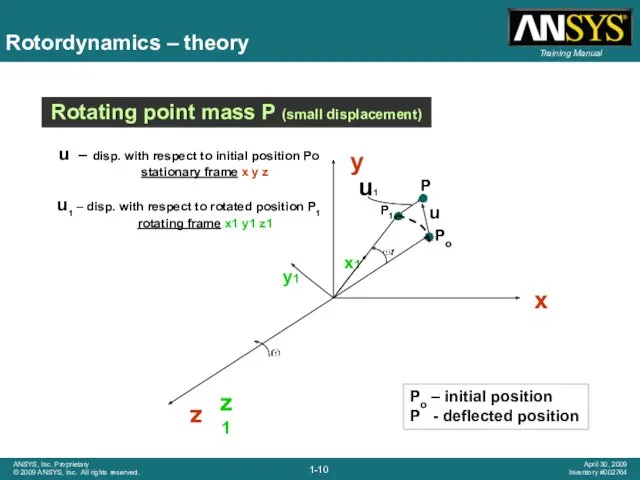

- 10. Rotordynamics – theory

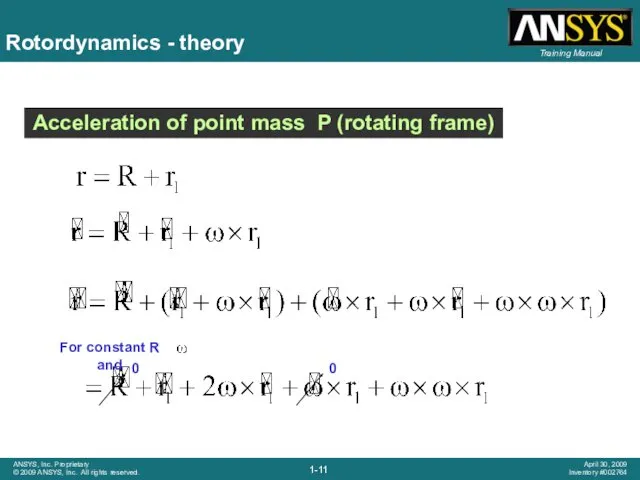

- 11. Rotordynamics - theory

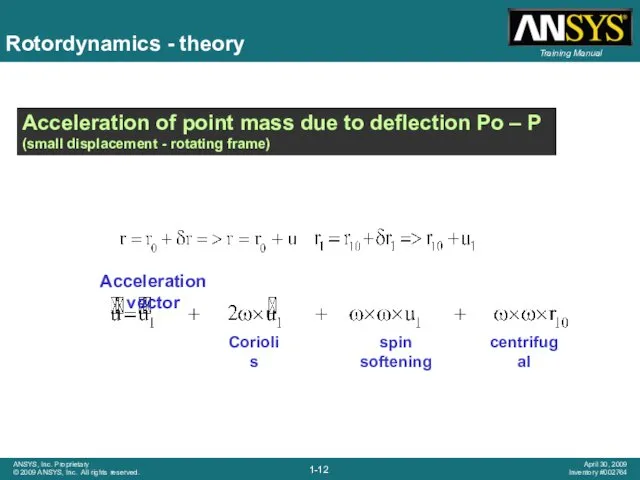

- 12. Rotordynamics - theory Acceleration of point mass due to deflection Po – P (small displacement -

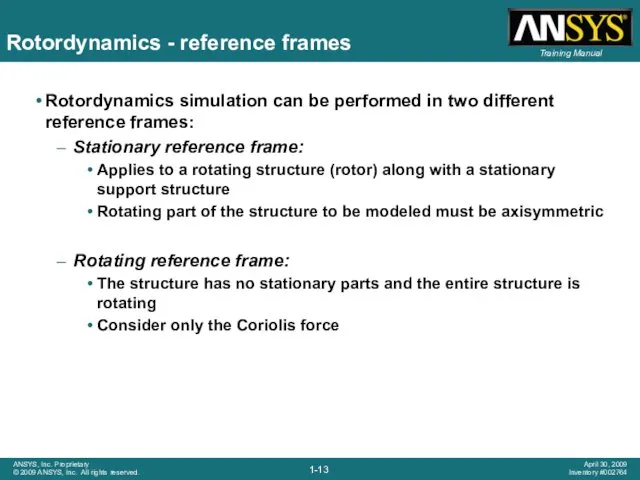

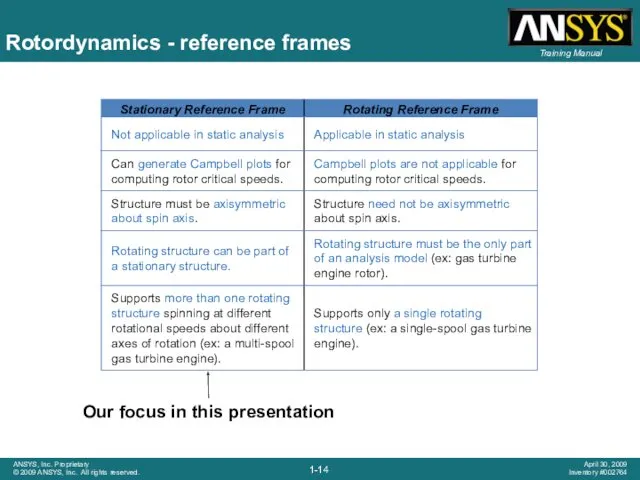

- 13. Rotordynamics - reference frames Rotordynamics simulation can be performed in two different reference frames: Stationary reference

- 14. Our focus in this presentation Rotordynamics - reference frames

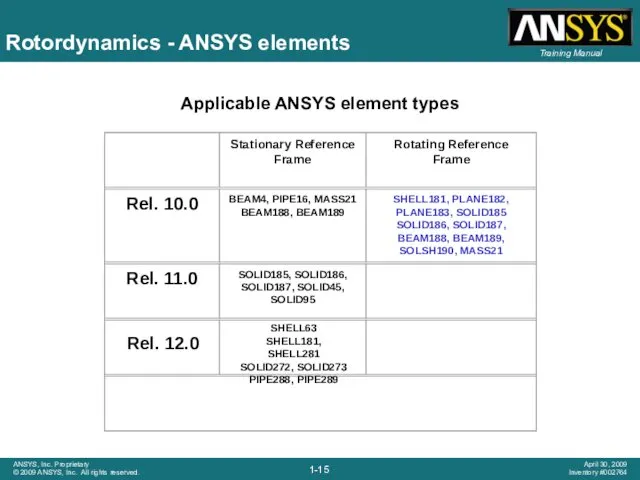

- 15. Applicable ANSYS element types Rotordynamics - ANSYS elements

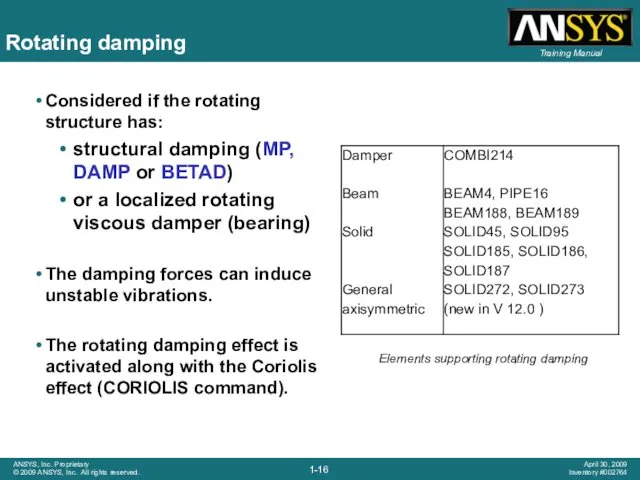

- 16. Rotating damping Considered if the rotating structure has: structural damping (MP, DAMP or BETAD) or a

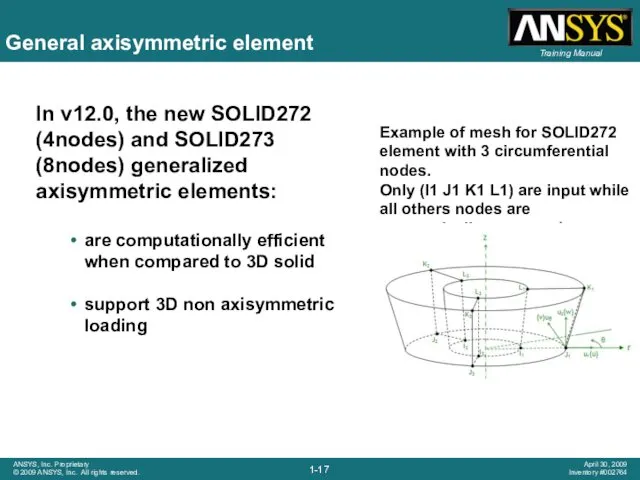

- 17. General axisymmetric element In v12.0, the new SOLID272 (4nodes) and SOLID273 (8nodes) generalized axisymmetric elements: are

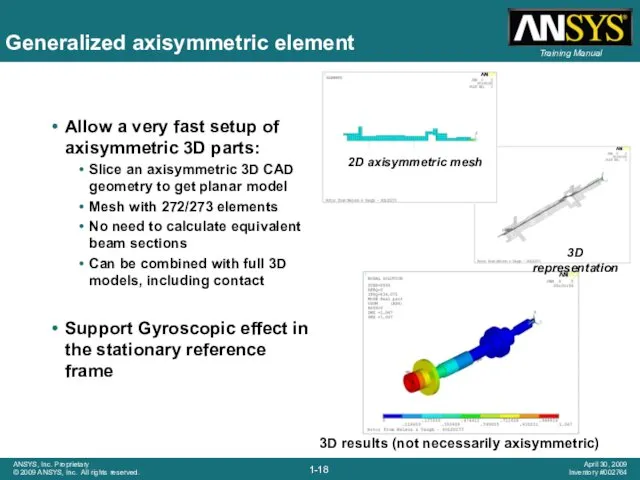

- 18. Generalized axisymmetric element Allow a very fast setup of axisymmetric 3D parts: Slice an axisymmetric 3D

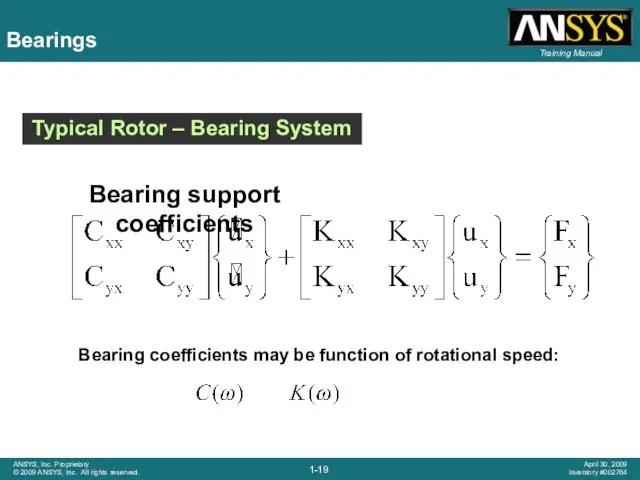

- 19. Bearing coefficients may be function of rotational speed: Typical Rotor – Bearing System Bearings

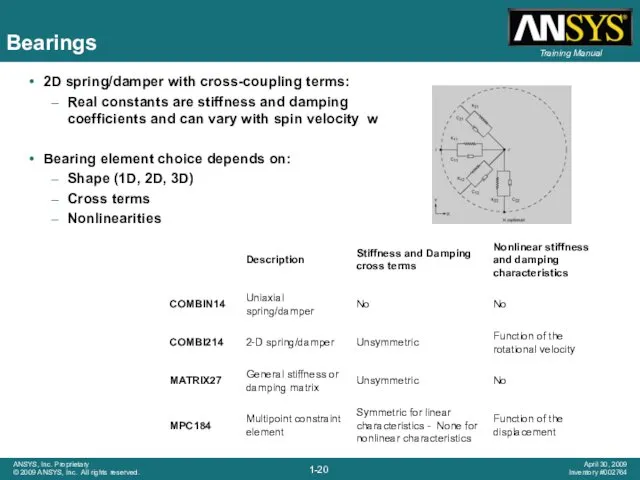

- 20. Bearings 2D spring/damper with cross-coupling terms: Real constants are stiffness and damping coefficients and can vary

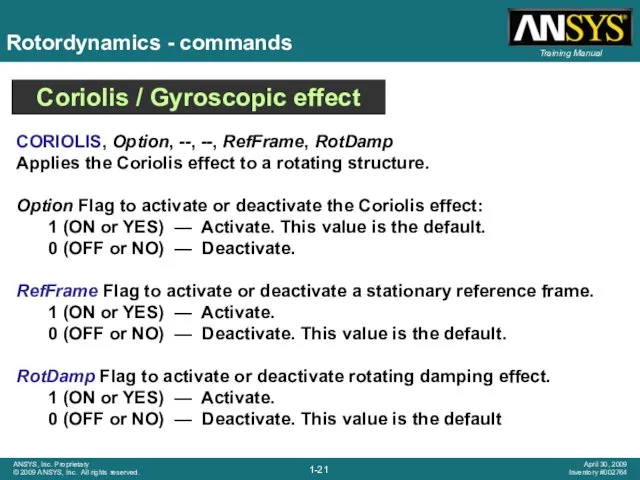

- 21. Rotordynamics - commands Coriolis / Gyroscopic effect CORIOLIS, Option, --, --, RefFrame, RotDamp Applies the Coriolis

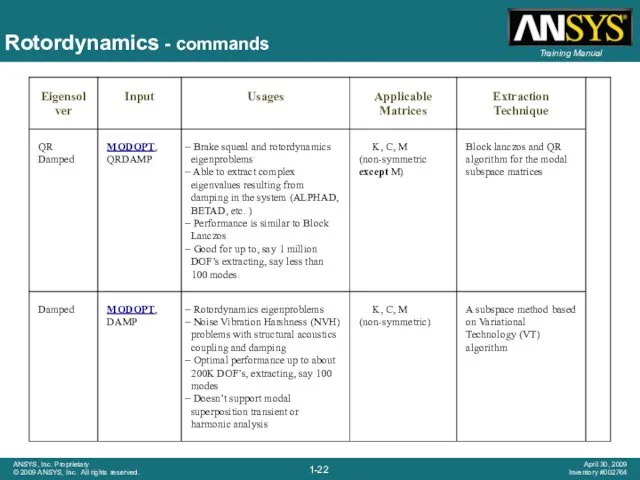

- 22. Rotordynamics - commands

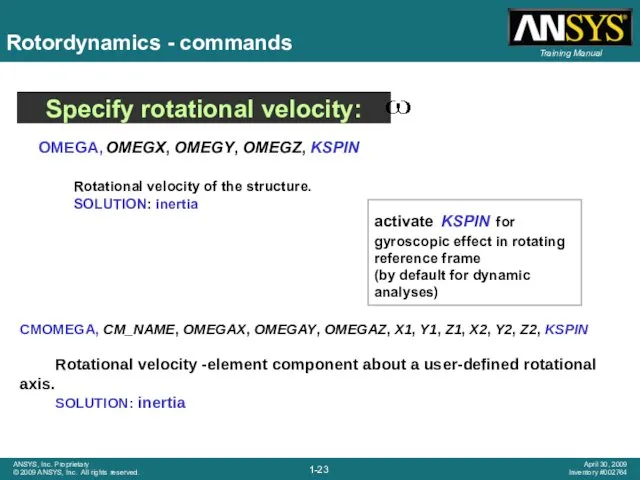

- 23. OMEGA, OMEGX, OMEGY, OMEGZ, KSPIN Rotational velocity of the structure. SOLUTION: inertia CMOMEGA, CM_NAME, OMEGAX, OMEGAY,

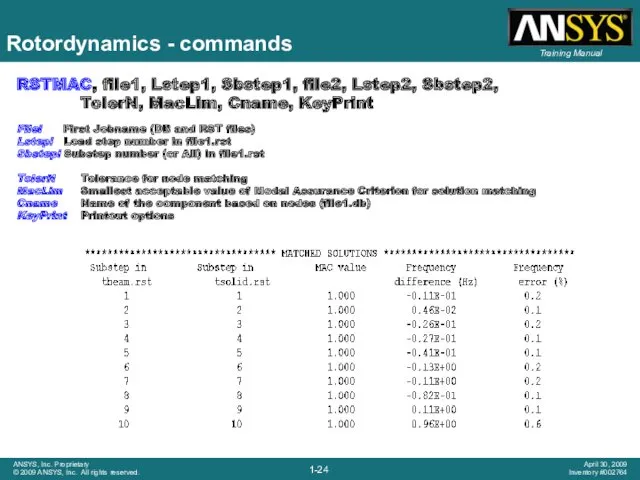

- 24. RSTMAC, file1, Lstep1, Sbstep1, file2, Lstep2, Sbstep2, TolerN, MacLim, Cname, KeyPrint Filei First Jobname (DB and

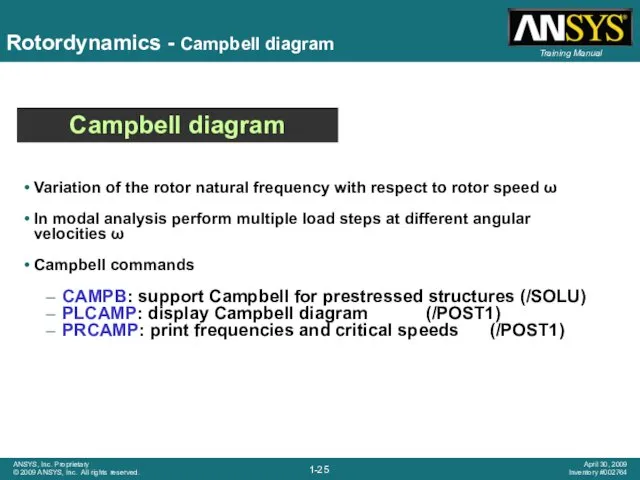

- 25. Rotordynamics - Campbell diagram Variation of the rotor natural frequency with respect to rotor speed ω

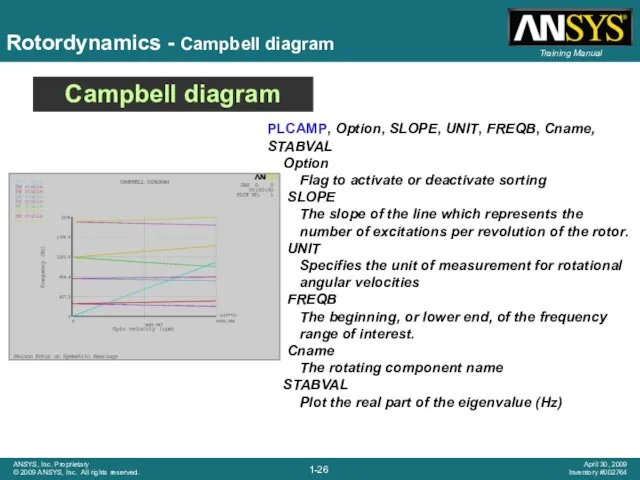

- 26. Rotordynamics - Campbell diagram Campbell diagram PLCAMP, Option, SLOPE, UNIT, FREQB, Cname, STABVAL Option Flag to

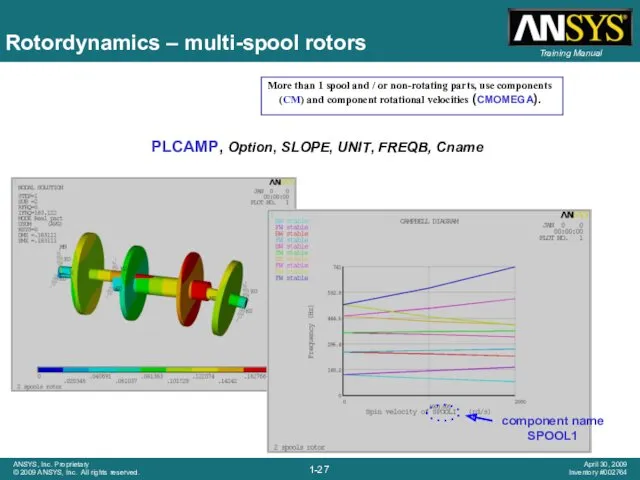

- 27. Rotordynamics – multi-spool rotors More than 1 spool and / or non-rotating parts, use components (CM)

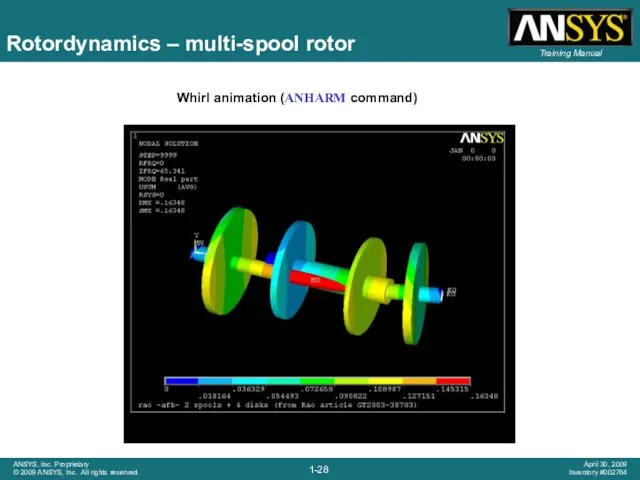

- 28. Rotordynamics – multi-spool rotor Whirl animation (ANHARM command)

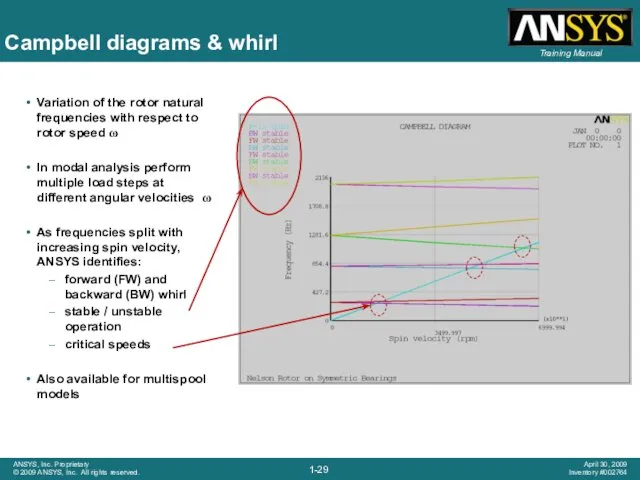

- 29. Campbell diagrams & whirl Variation of the rotor natural frequencies with respect to rotor speed ω

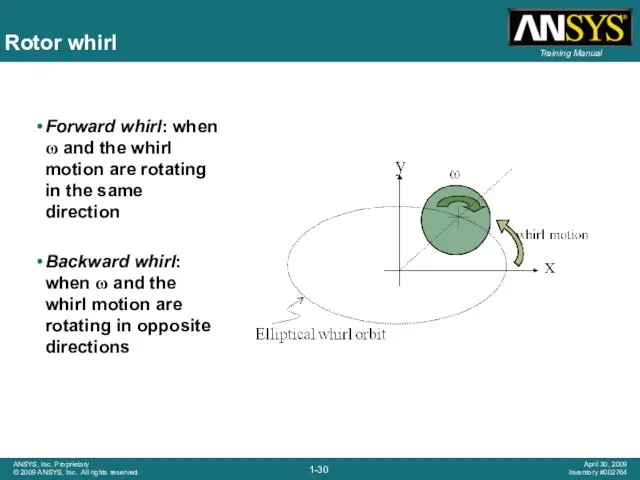

- 30. Rotor whirl Forward whirl: when ω and the whirl motion are rotating in the same direction

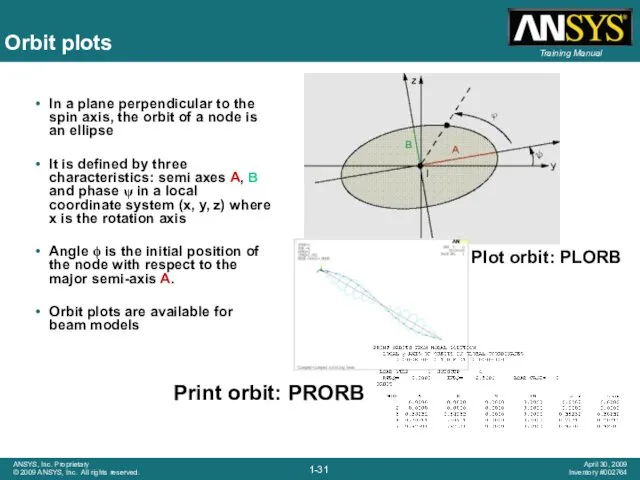

- 31. Orbit plots In a plane perpendicular to the spin axis, the orbit of a node is

- 32. Rotordynamics – forced response Possible excitations caused by rotation velocity ω are: Unbalance (ω) Coupling misalignment

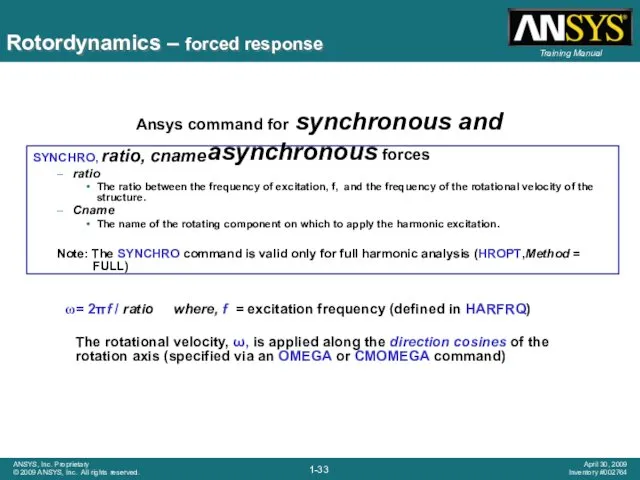

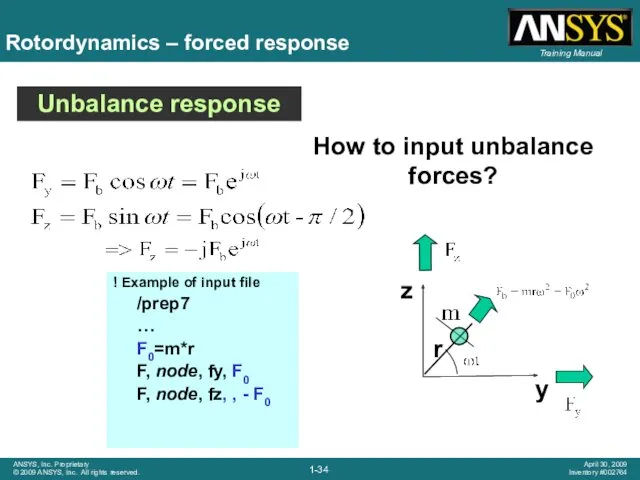

- 33. SYNCHRO, ratio, cname ratio The ratio between the frequency of excitation, f, and the frequency of

- 34. ! Example of input file /prep7 … F0=m*r F, node, fy, F0 F, node, fz, ,

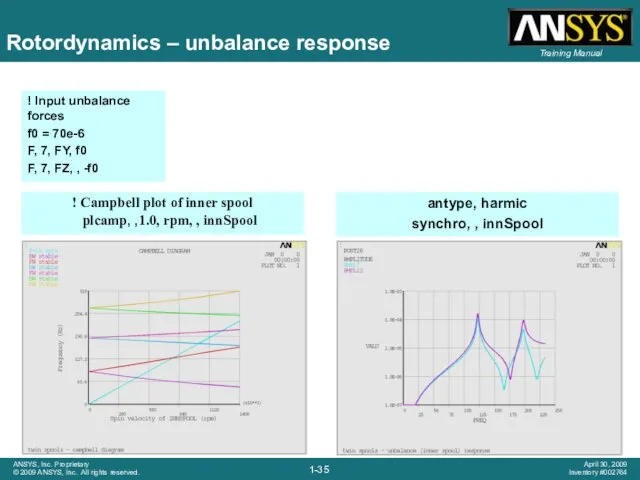

- 35. ! Campbell plot of inner spool plcamp, ,1.0, rpm, , innSpool ! Input unbalance forces f0

- 36. Stability Self-excited vibrations in a rotating structure cause an increase of the vibration amplitude over time

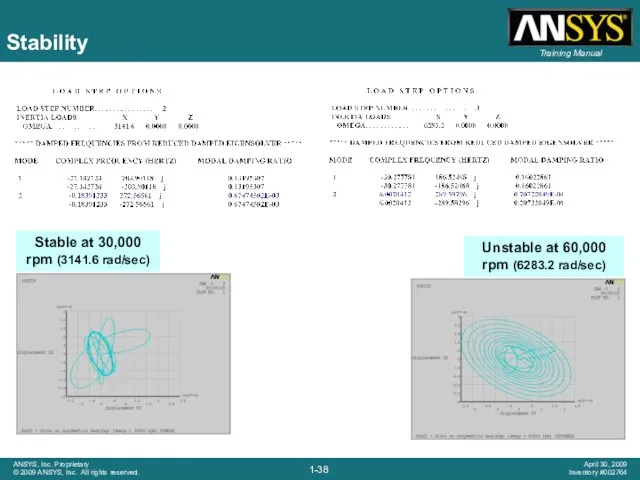

- 37. Stability

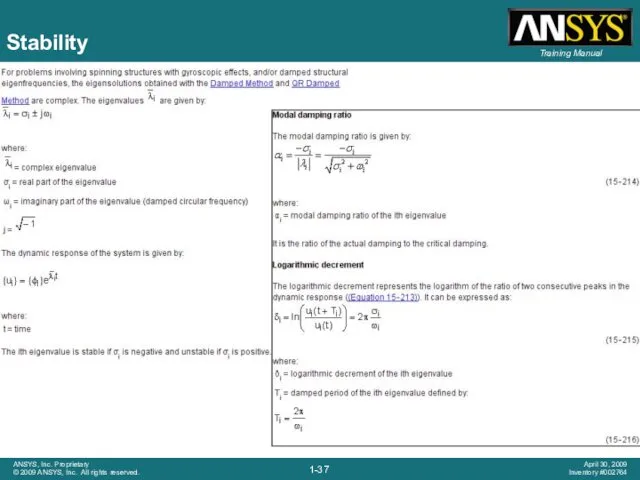

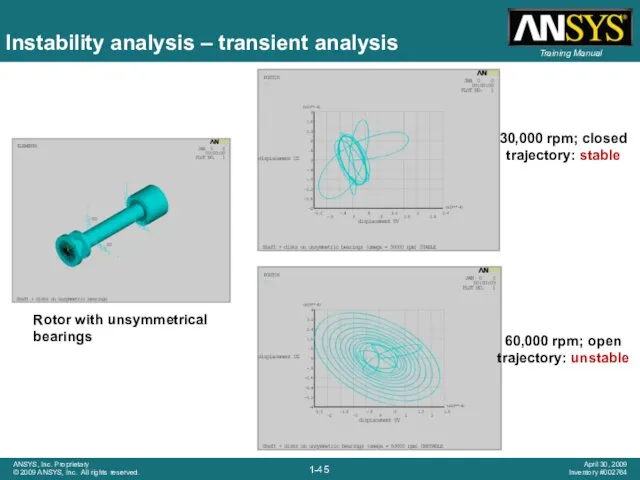

- 38. Stability Stable at 30,000 rpm (3141.6 rad/sec) Unstable at 60,000 rpm (6283.2 rad/sec)

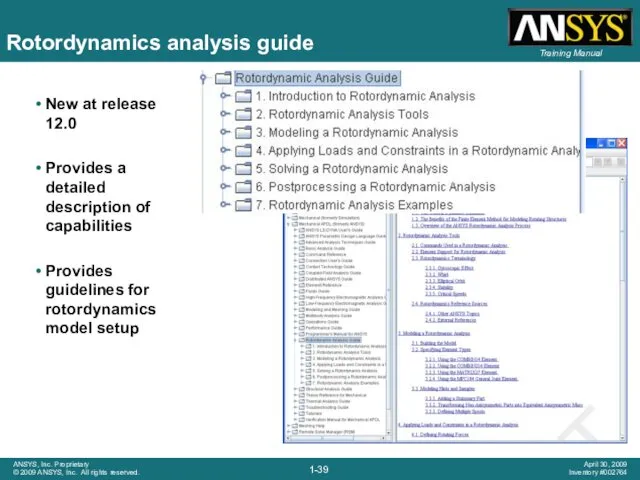

- 39. Rotordynamics analysis guide New at release 12.0 Provides a detailed description of capabilities Provides guidelines for

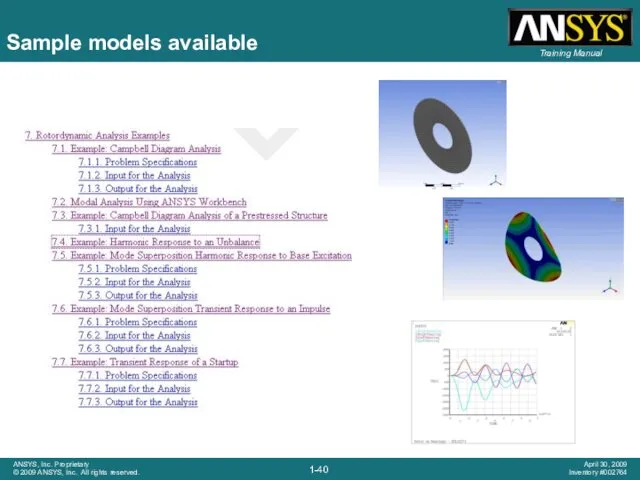

- 40. Sample models available

- 41. Some examples

- 42. Validation examples

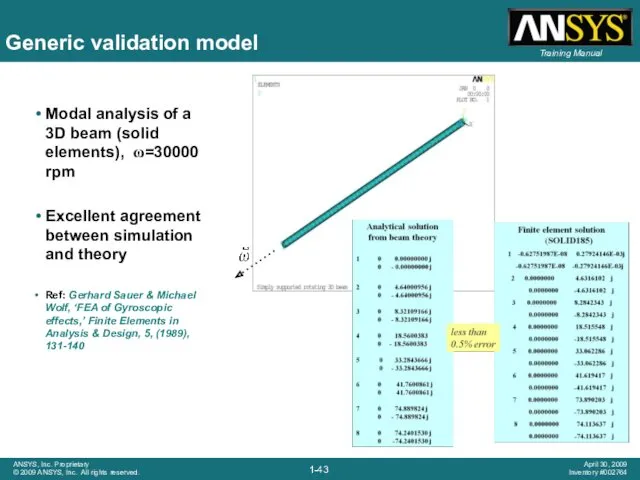

- 43. Generic validation model Modal analysis of a 3D beam (solid elements), ω=30000 rpm Excellent agreement between

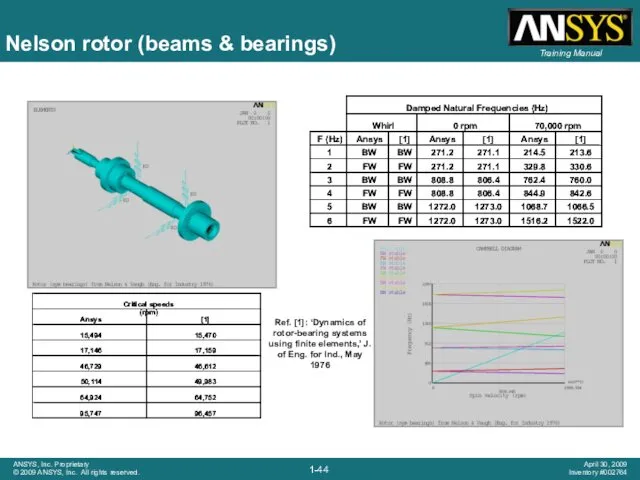

- 44. Nelson rotor (beams & bearings)

- 45. Instability analysis – transient analysis 30,000 rpm; closed trajectory: stable 60,000 rpm; open trajectory: unstable Rotor

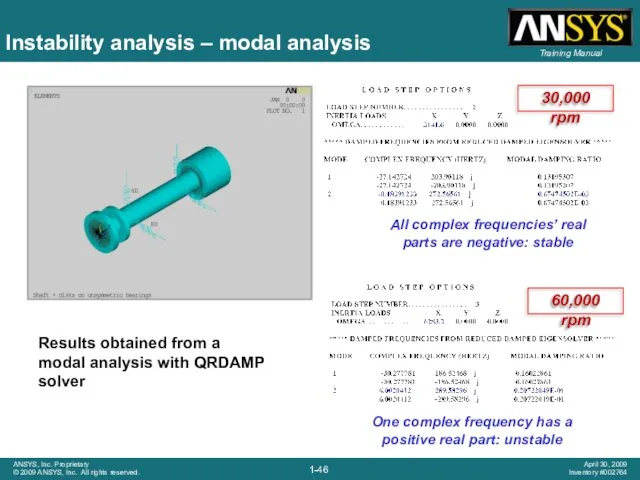

- 46. Instability analysis – modal analysis All complex frequencies’ real parts are negative: stable One complex frequency

- 47. Effect of rotating damping

- 48. Rotating damping example Comparison of the dynamics of a simple model with and without rotating damping

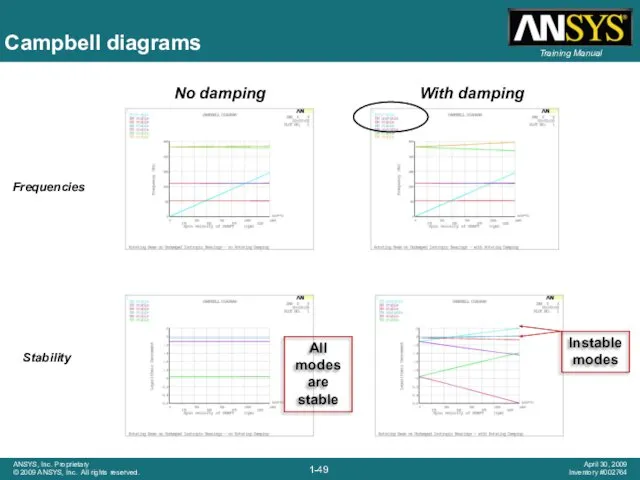

- 49. Campbell diagrams Frequencies Stability

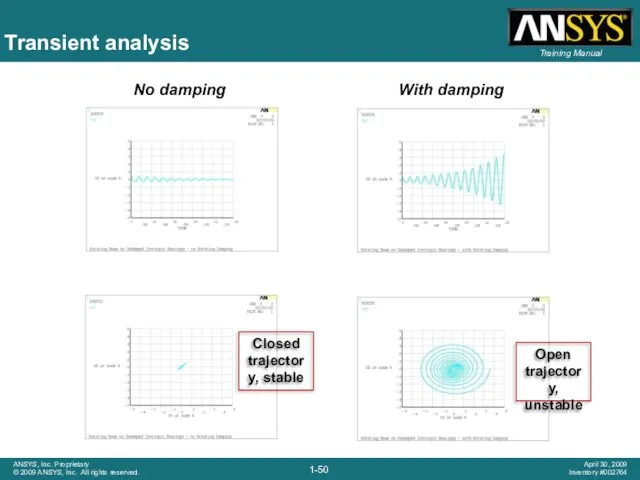

- 50. Transient analysis No damping With damping Closed trajectory, stable Open trajectory, unstable

- 51. Rotordynamics with ANSYS Workbench

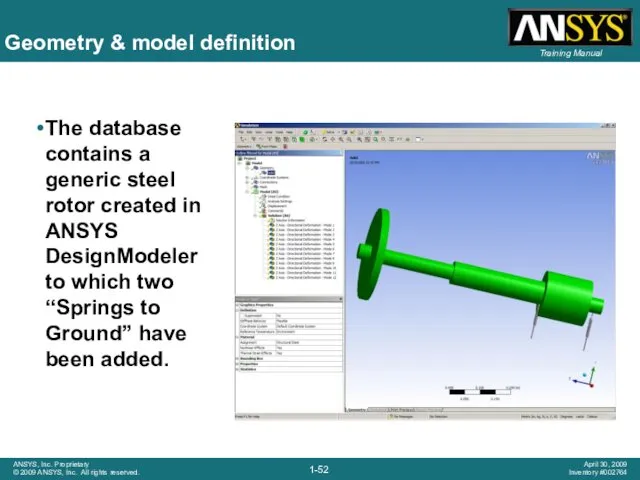

- 52. Geometry & model definition The database contains a generic steel rotor created in ANSYS DesignModeler to

- 53. Bearing definition The standard Simulation springs are changed to bearing elements utilizing the parameter, _sid to

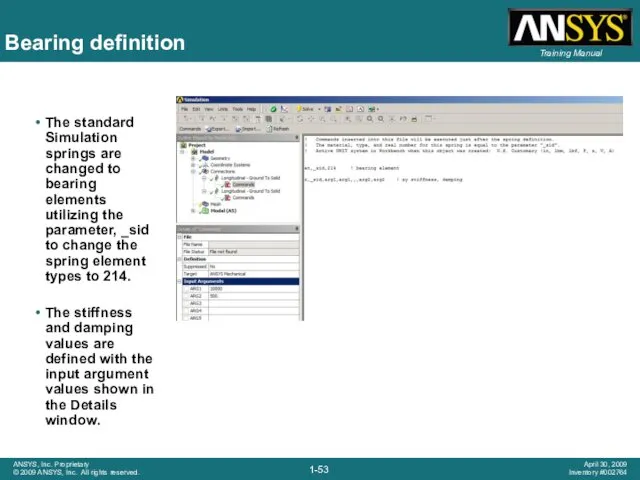

- 54. Solution settings for modal analysis A commands object inserted into the analysis branch switches the default

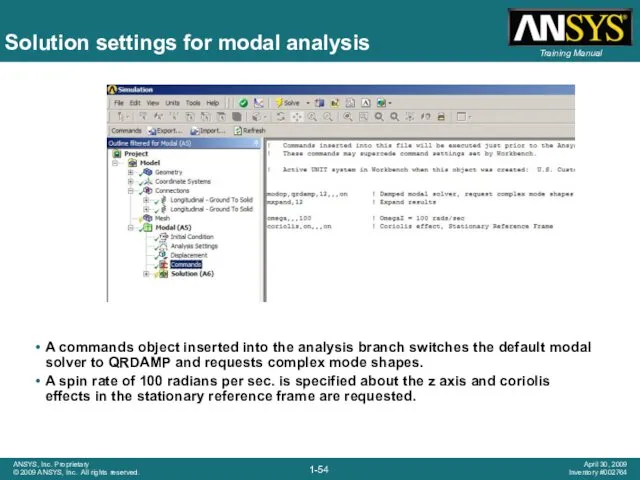

- 55. Solution information While the solution is running, the solution output can be monitored. The output shown

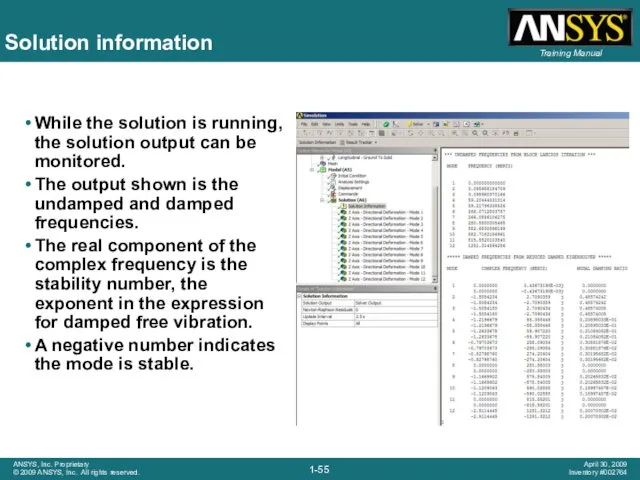

- 56. Modal results Complex modal results are shown in the tabular view of the results. Complex eigenshapes

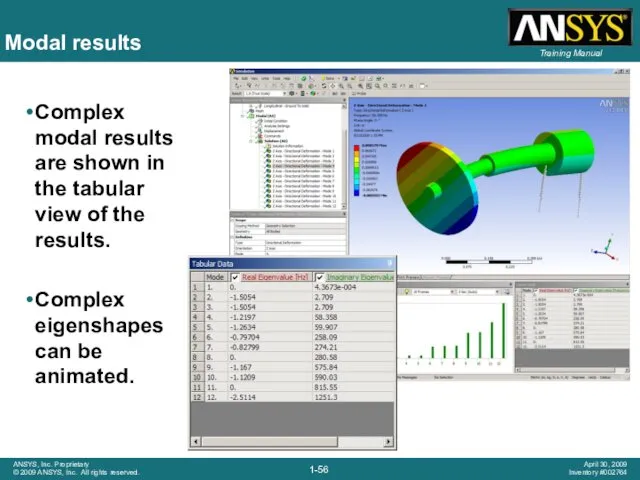

- 57. Animated modal shape

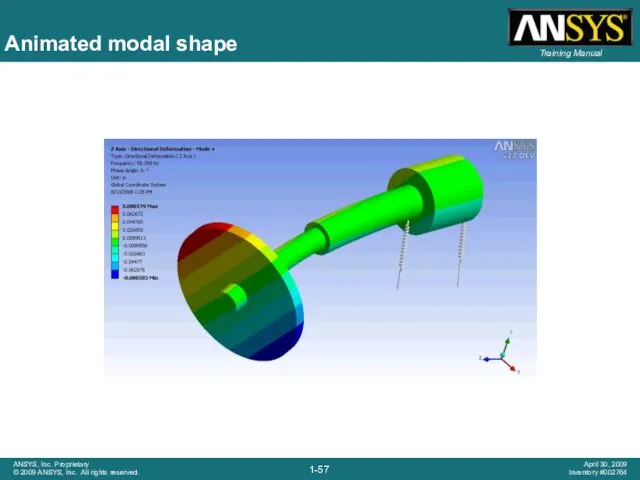

- 58. Compressor model Solid model & casing simulation

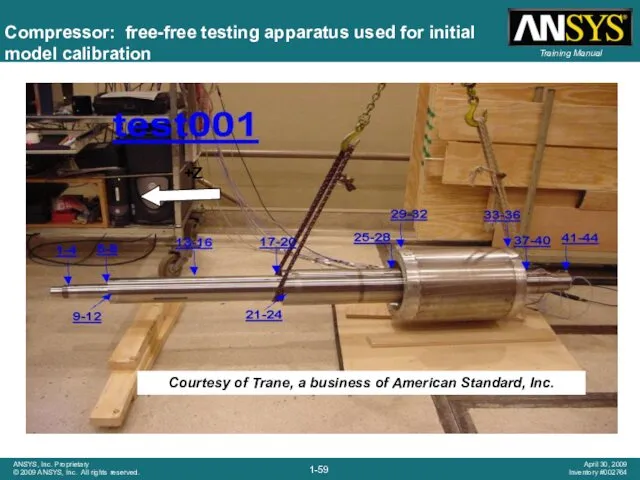

- 59. Compressor: free-free testing apparatus used for initial model calibration +Z Courtesy of Trane, a business of

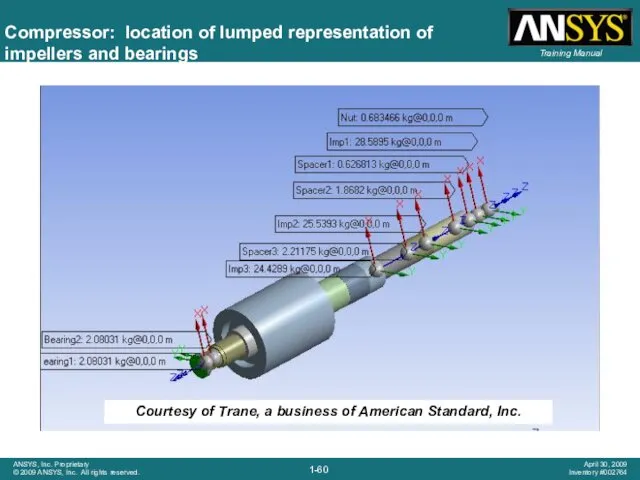

- 60. Compressor: location of lumped representation of impellers and bearings Courtesy of Trane, a business of American

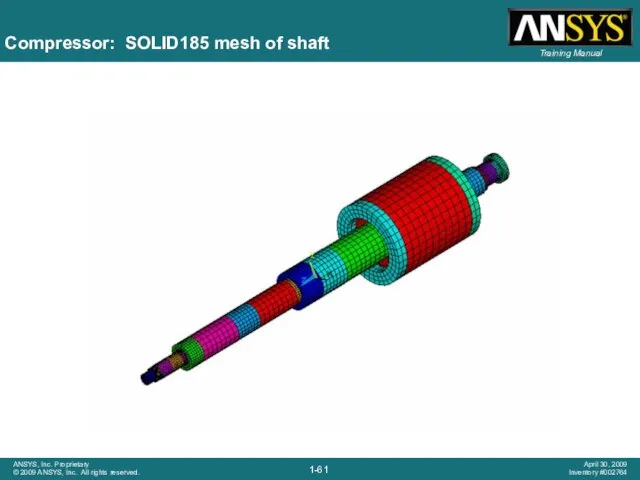

- 61. Compressor: SOLID185 mesh of shaft Very stiff symmetric contact between axial segments

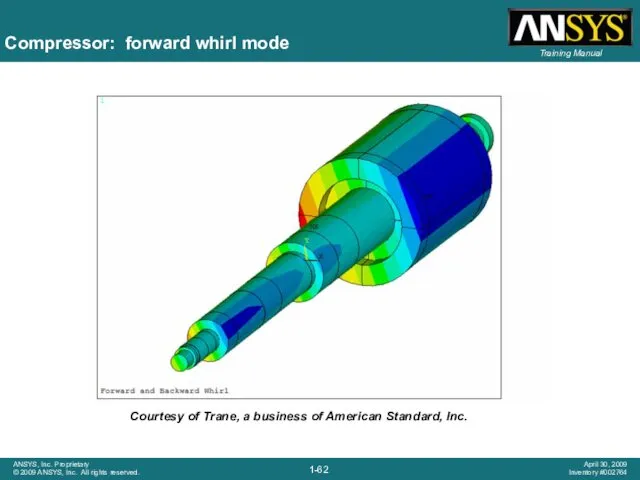

- 62. Compressor: forward whirl mode Courtesy of Trane, a business of American Standard, Inc.

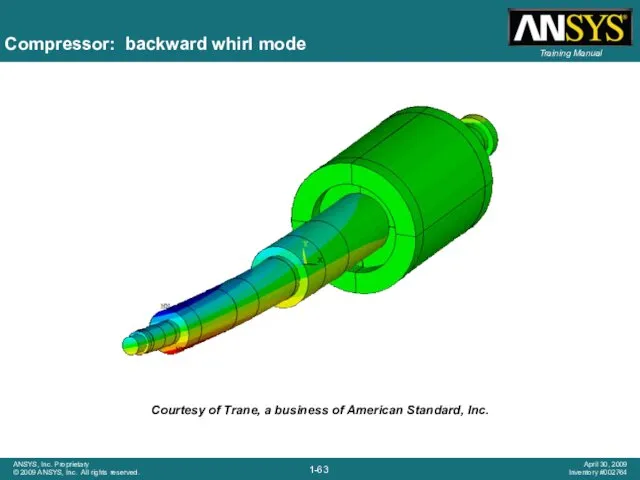

- 63. Compressor: backward whirl mode Courtesy of Trane, a business of American Standard, Inc.

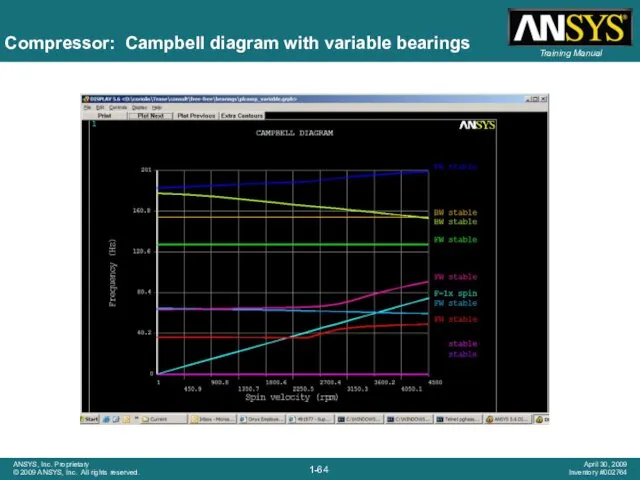

- 64. Compressor: Campbell diagram with variable bearings

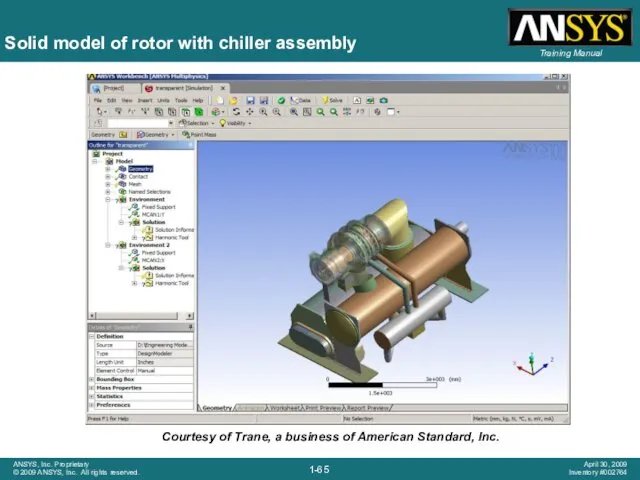

- 65. Solid model of rotor with chiller assembly Courtesy of Trane, a business of American Standard, Inc.

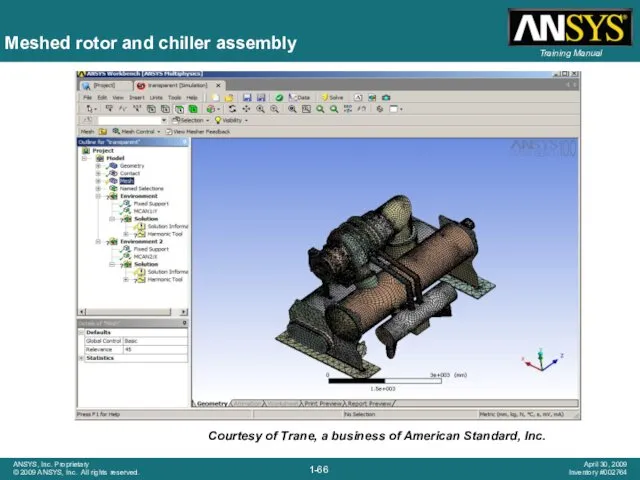

- 66. Meshed rotor and chiller assembly Courtesy of Trane, a business of American Standard, Inc.

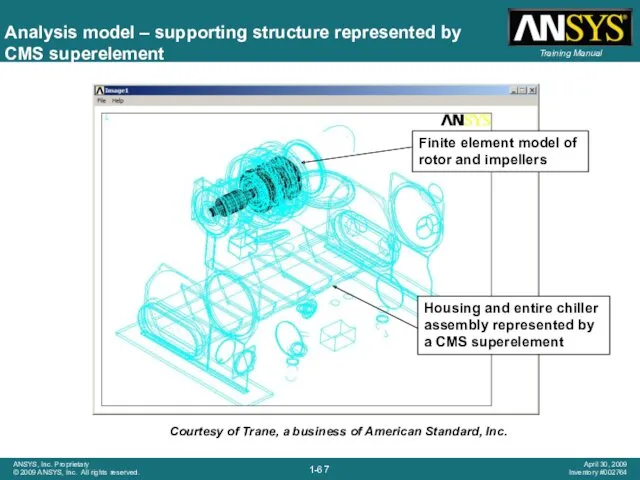

- 67. Analysis model – supporting structure represented by CMS superelement Courtesy of Trane, a business of American

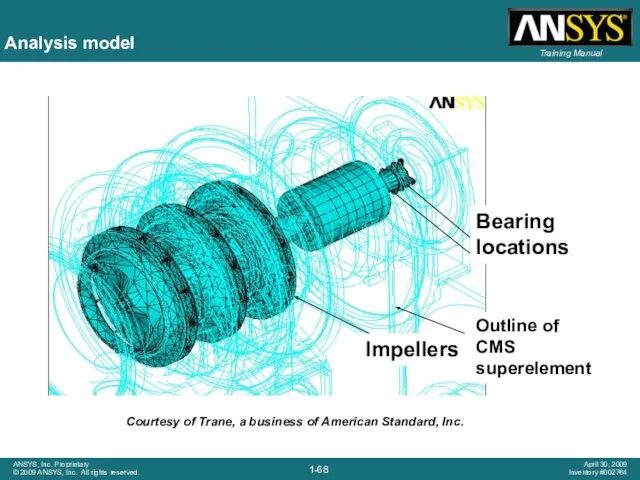

- 68. Analysis model Courtesy of Trane, a business of American Standard, Inc.

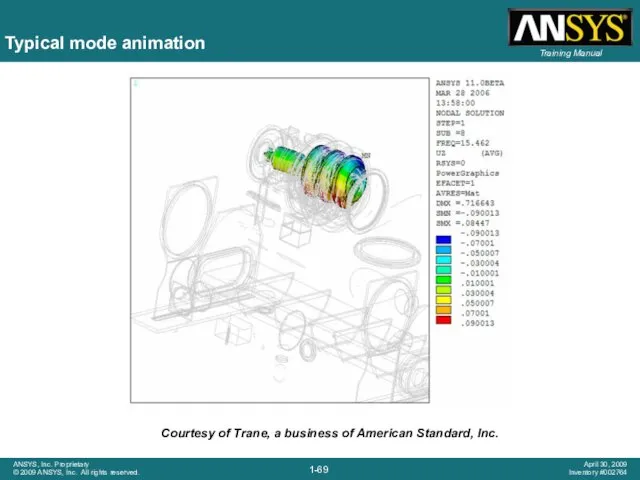

- 69. Typical mode animation Courtesy of Trane, a business of American Standard, Inc.

- 70. Blower shaft model Transient startup & effect of prestress

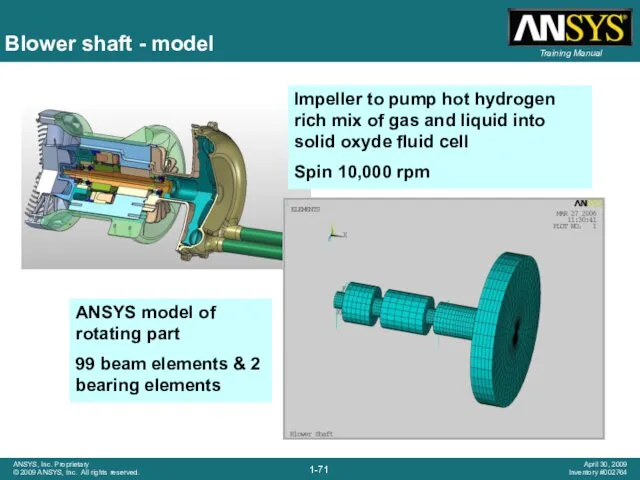

- 71. Blower shaft - model Impeller to pump hot hydrogen rich mix of gas and liquid into

- 72. Blower shaft - modal analysis Frequencies and corresponding mode shapes orbits

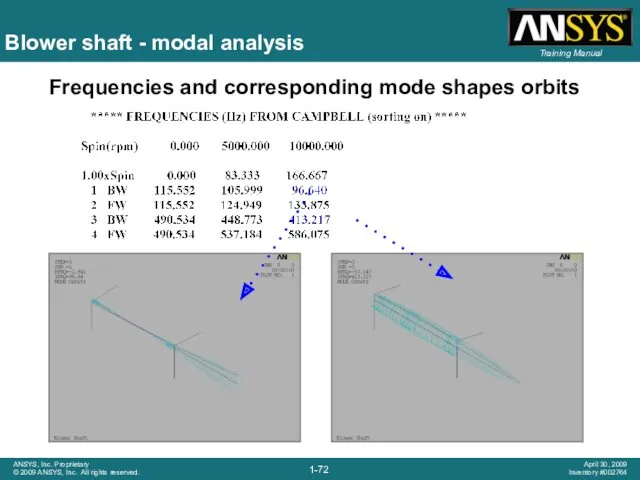

- 73. Blower shaft – modal analysis Frequencies Stability

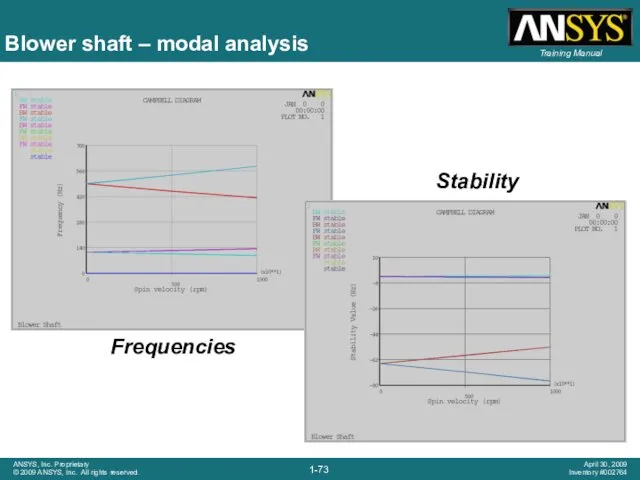

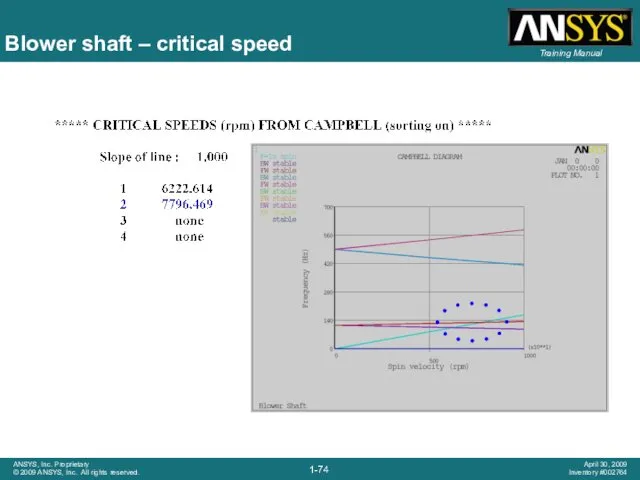

- 74. Blower shaft – critical speed

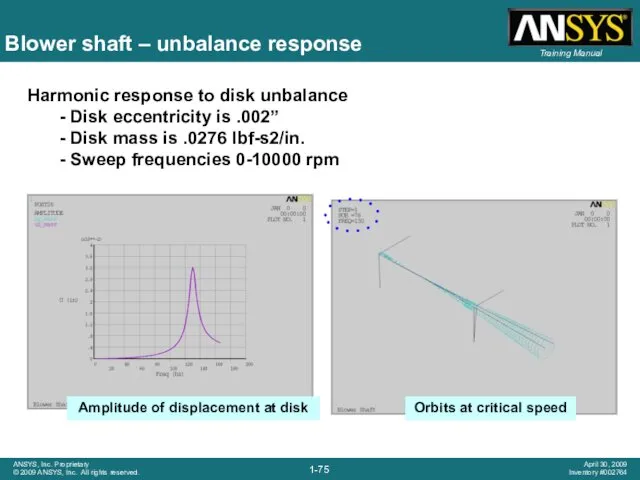

- 75. Blower shaft – unbalance response Harmonic response to disk unbalance - Disk eccentricity is .002” -

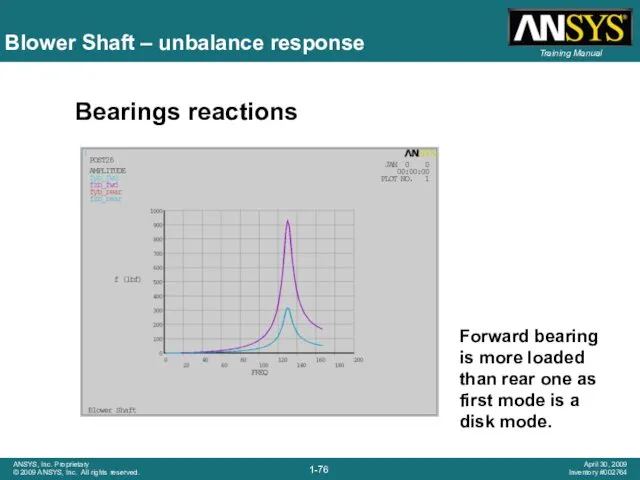

- 76. Blower Shaft – unbalance response Bearings reactions Forward bearing is more loaded than rear one as

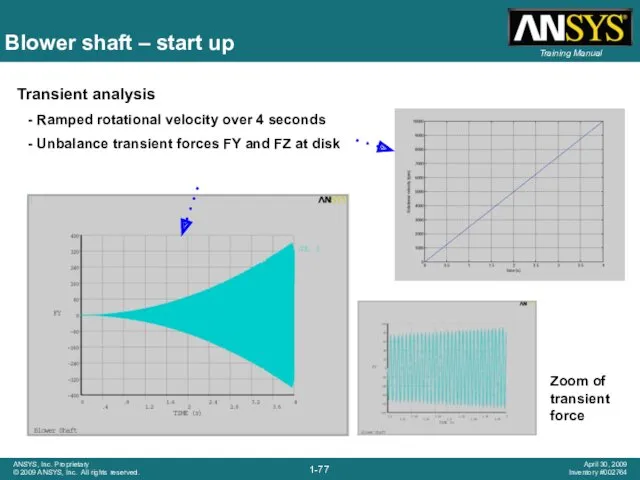

- 77. Blower shaft – start up Transient analysis Ramped rotational velocity over 4 seconds Unbalance transient forces

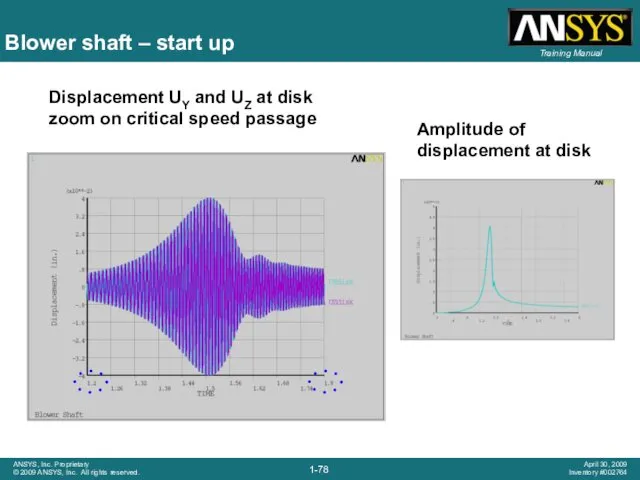

- 78. Blower shaft – start up Displacement UY and UZ at disk zoom on critical speed passage

- 79. Blower shaft – start up Transient orbits 0 to 4 seconds 3 to 4 seconds As

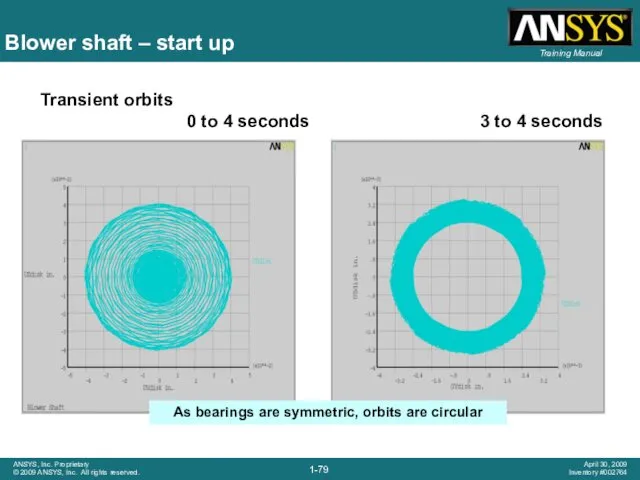

- 80. Blower shaft – prestress Include prestress due to thermal loading: Thermal body load up to 1500

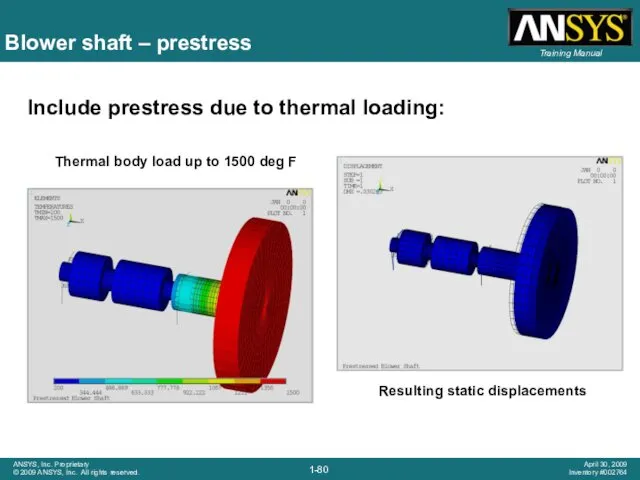

- 81. Blower shaft – Campbell diagram comparison No prestress With thermal prestress

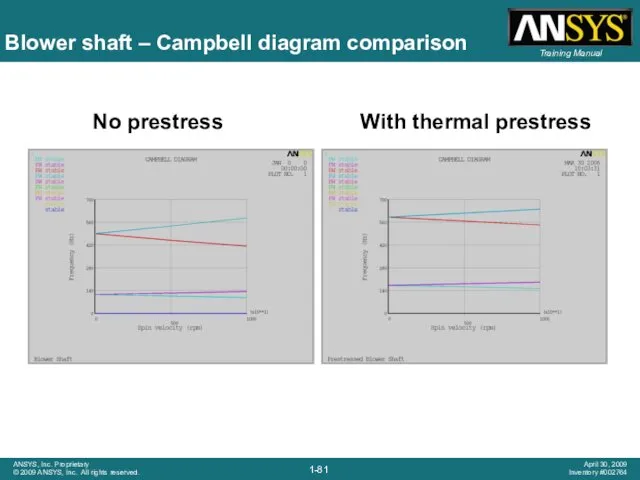

- 82. Demo’s Agenda 3D model Point mass by user Automatic Rigid Body B.C. / Remote displacement Bearing

- 83. Rotordynamics with ANSYS Workbench A workflow example

- 84. Storyboard The geometry is provided in form of a Parasolid file Part of the shaft must

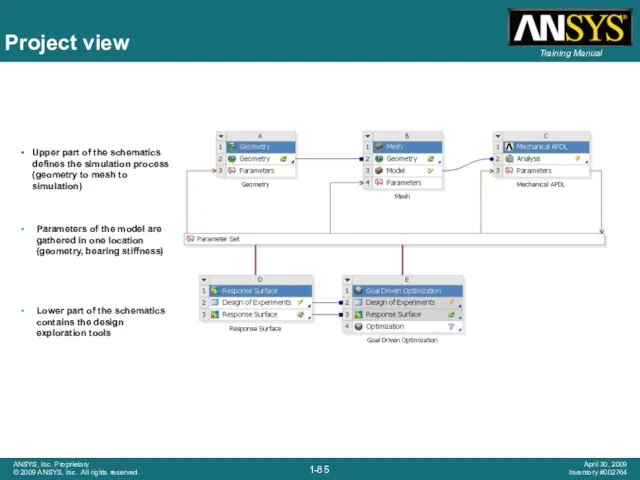

- 85. Project view Upper part of the schematics defines the simulation process (geometry to mesh to simulation)

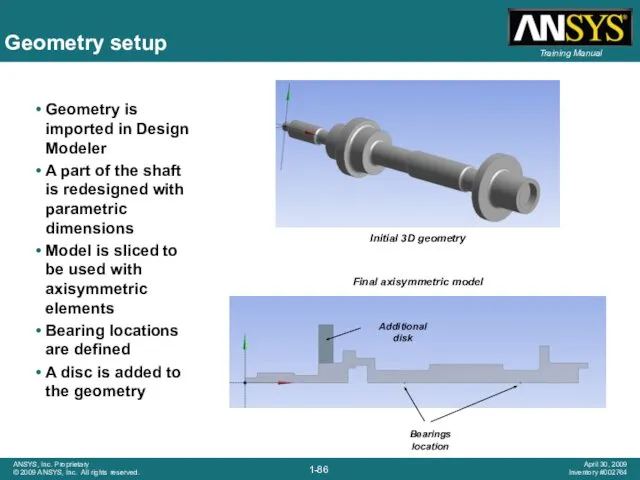

- 86. Geometry setup Geometry is imported in Design Modeler A part of the shaft is redesigned with

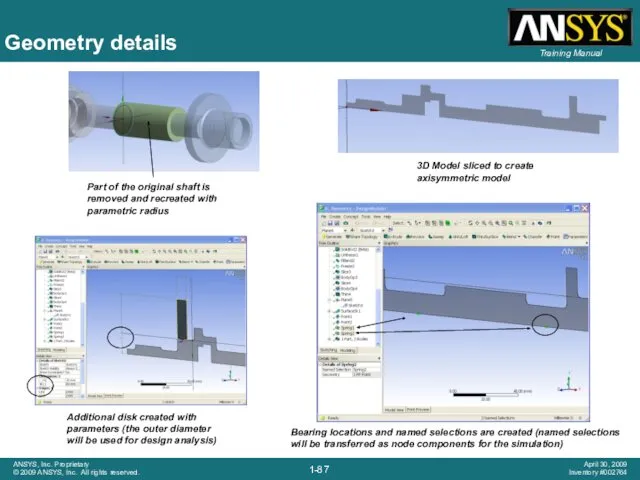

- 87. Geometry details Part of the original shaft is removed and recreated with parametric radius 3D Model

- 88. Mesh The model is meshed using the WB meshing tools

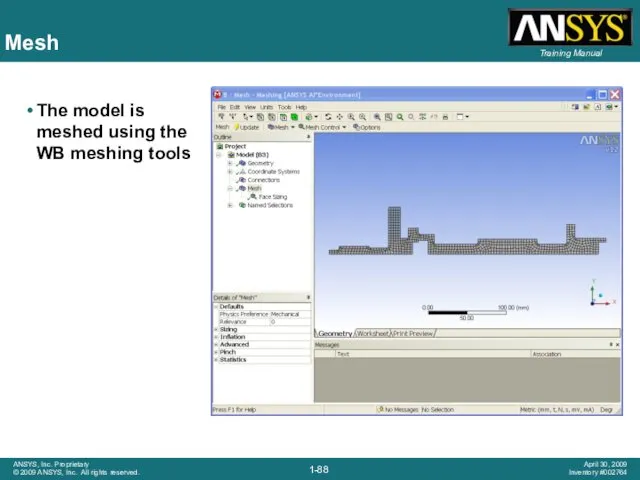

- 89. Simulation Simulation is performed using an APDL script that defines: Element types Bearings Boundary conditions Solutions

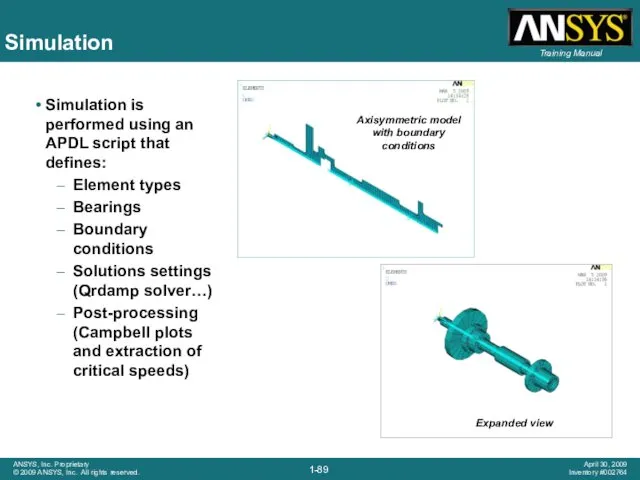

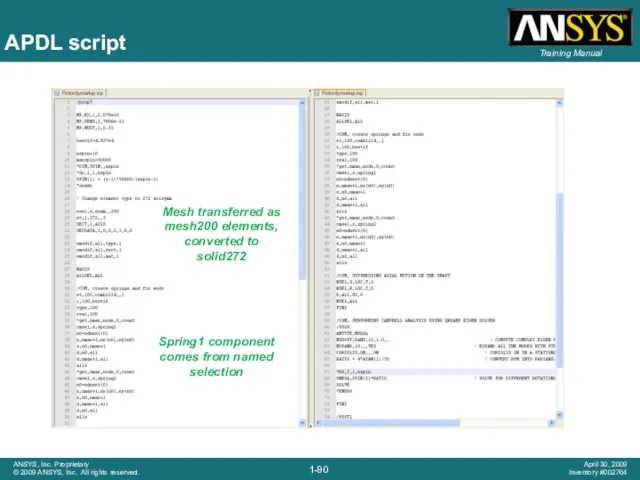

- 90. APDL script Spring1 component comes from named selection Mesh transferred as mesh200 elements, converted to solid272

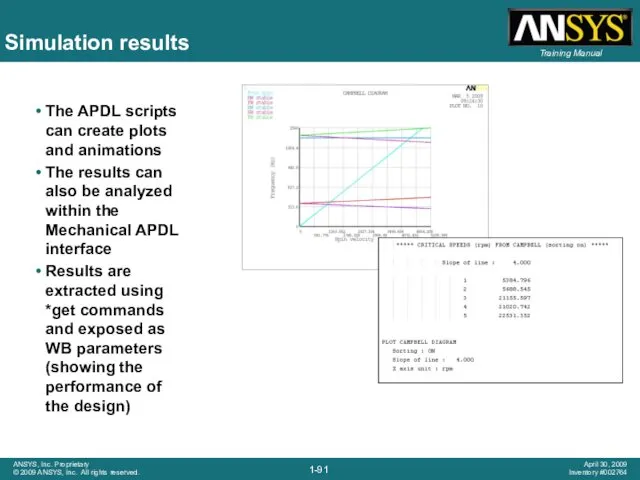

- 91. Simulation results The APDL scripts can create plots and animations The results can also be analyzed

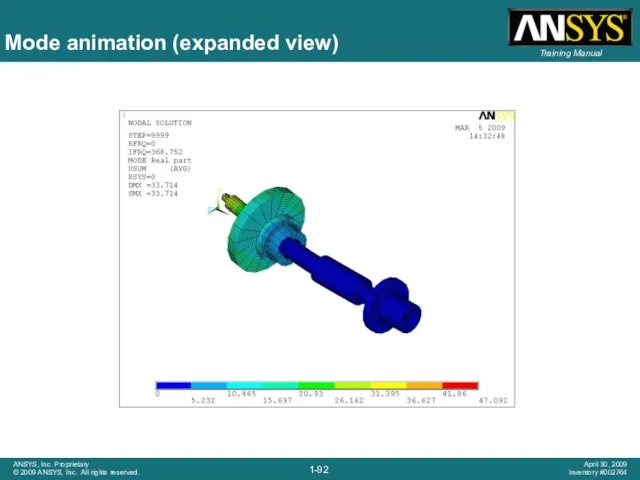

- 92. Mode animation (expanded view)

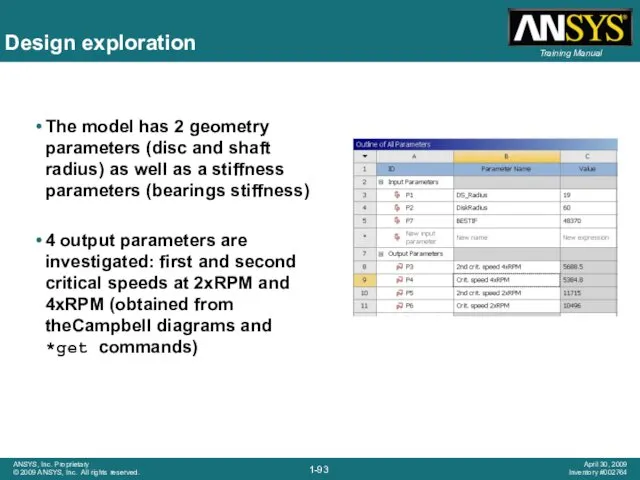

- 93. Design exploration The model has 2 geometry parameters (disc and shaft radius) as well as a

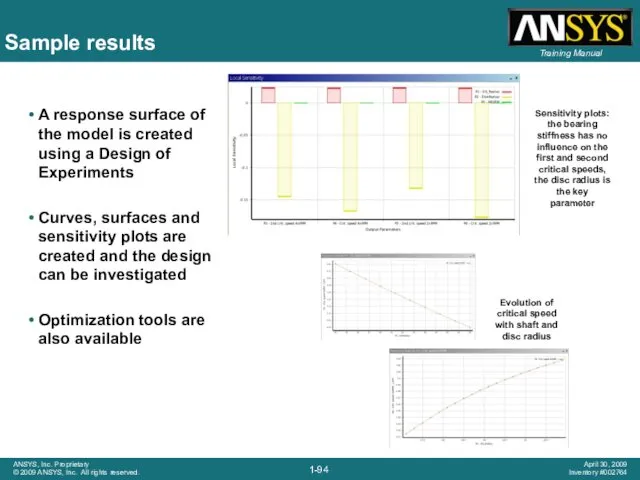

- 94. Sample results A response surface of the model is created using a Design of Experiments Curves,

- 96. Скачать презентацию

Теплові насоси та кондиціонери

Теплові насоси та кондиціонери Дисперсия света

Дисперсия света Сучасна модель атома. Протонно-нейтронна модель ядра атома. Ядерні сили. Ізотопи

Сучасна модель атома. Протонно-нейтронна модель ядра атома. Ядерні сили. Ізотопи Физика. Эволюция взгляда на физическую картину мира

Физика. Эволюция взгляда на физическую картину мира конструктор урока по теме Постоянный ток

конструктор урока по теме Постоянный ток Резание металла и проволоки слесарной ножовкой

Резание металла и проволоки слесарной ножовкой Отражение в горизонтальном зеркале

Отражение в горизонтальном зеркале Принцип суперпозиции сил

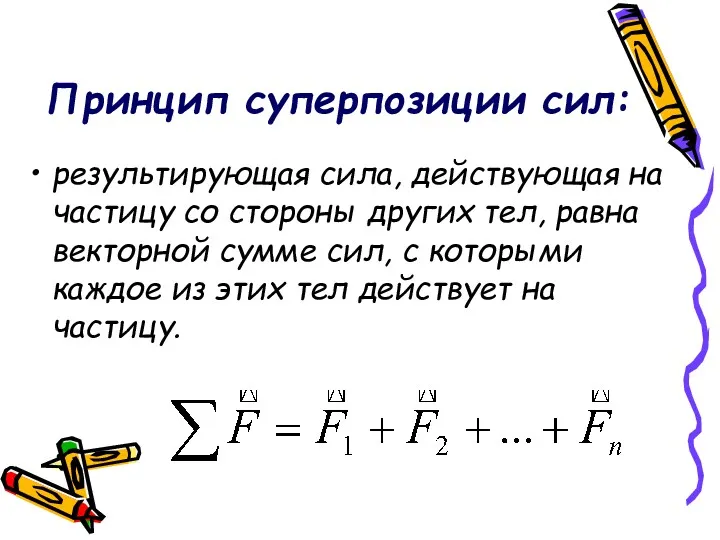

Принцип суперпозиции сил Плотность вещества. 7 класс

Плотность вещества. 7 класс Sm-Nd метод

Sm-Nd метод Основные понятия электросвязи. Информация, сообщение, сигнал

Основные понятия электросвязи. Информация, сообщение, сигнал Свободные колебания простых одномерных осцилляторов

Свободные колебания простых одномерных осцилляторов Електричний струм у різних середовищах

Електричний струм у різних середовищах Шкала электромагнитного излучения

Шкала электромагнитного излучения Кремний. Строение полупроводников

Кремний. Строение полупроводников Yüzey ve kompozi̇syon (9)

Yüzey ve kompozi̇syon (9) Интерактивный урок Эксплуатация и ремонт. Возможные неисправности топливораздаточных колонок и способы их устранения

Интерактивный урок Эксплуатация и ремонт. Возможные неисправности топливораздаточных колонок и способы их устранения Реактивное движение

Реактивное движение Изготовление столярного соединения УС-1

Изготовление столярного соединения УС-1 Законы автоматического регулирования

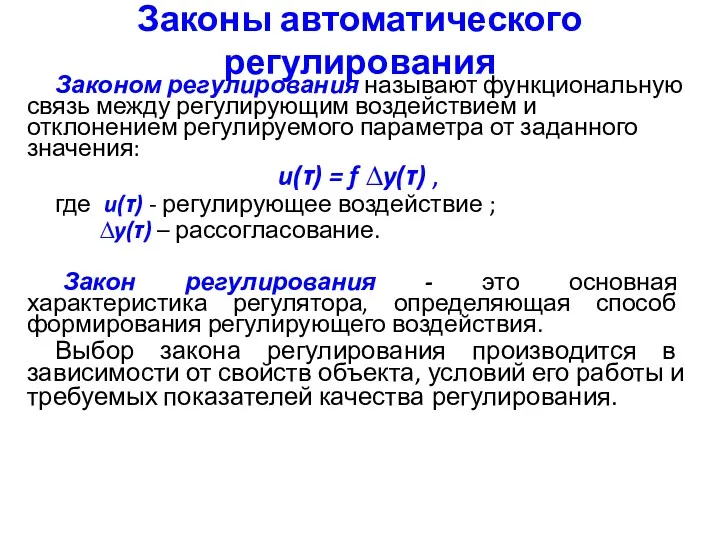

Законы автоматического регулирования Конспект урока по физике в 10 классе на тему Температура

Конспект урока по физике в 10 классе на тему Температура Испарение. Насыщенный и ненасыщенный пар

Испарение. Насыщенный и ненасыщенный пар Вертолет Ми-8МТВ. Несущий винт

Вертолет Ми-8МТВ. Несущий винт Chassis

Chassis Emission spectrum of H

Emission spectrum of H Спектрофотометрия и спектрофлуориметрия

Спектрофотометрия и спектрофлуориметрия Поляризация света. Лекция №3

Поляризация света. Лекция №3 Механические характеристики производственных механизмов и электродвигателей

Механические характеристики производственных механизмов и электродвигателей