Basic Elements of Lean Production. Benefits of Lean Production. Implementing Lean Production. Lean Services презентация

Содержание

- 2. Copyright 2006 John Wiley & Sons, Inc. 15- Lecture Outline Basic Elements of Lean Production Benefits

- 3. Copyright 2006 John Wiley & Sons, Inc. 15- Lean Production Doing more with less inventory, fewer

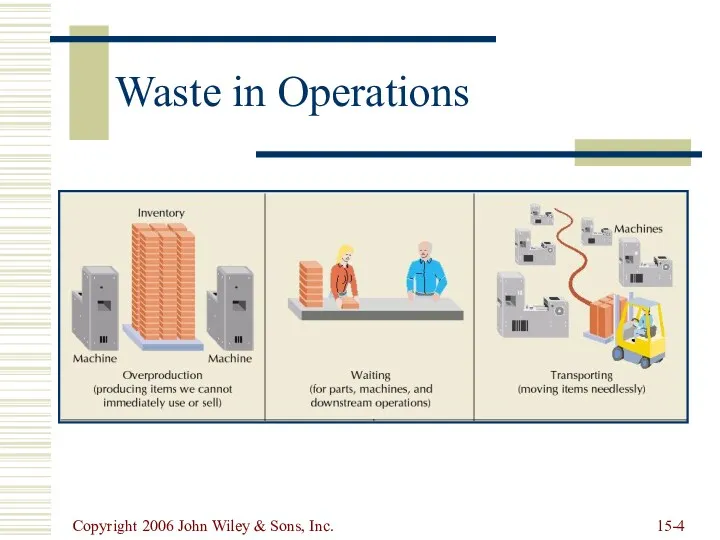

- 4. Copyright 2006 John Wiley & Sons, Inc. 15- Waste in Operations

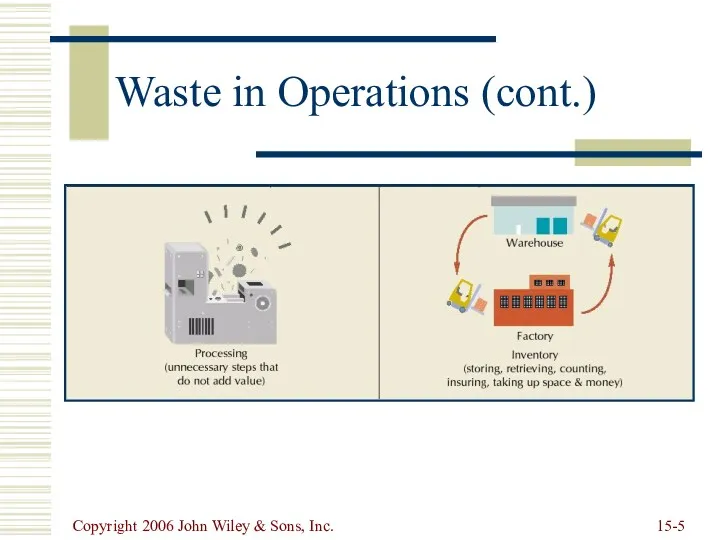

- 5. Copyright 2006 John Wiley & Sons, Inc. 15- Waste in Operations (cont.)

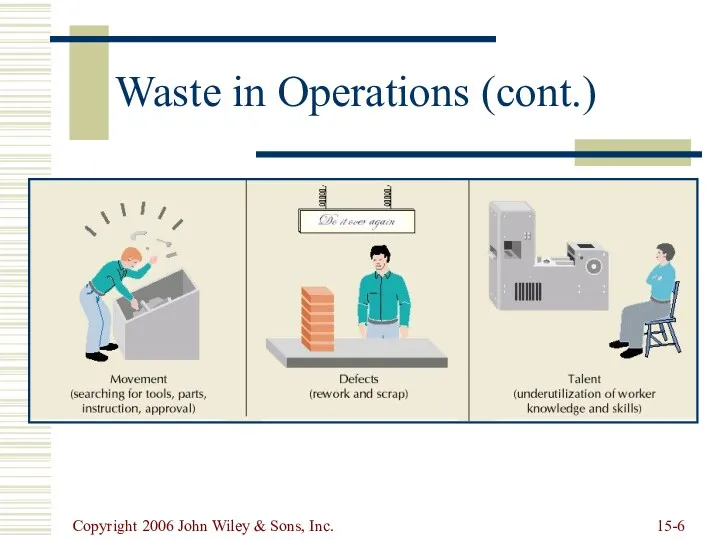

- 6. Copyright 2006 John Wiley & Sons, Inc. 15- Waste in Operations (cont.)

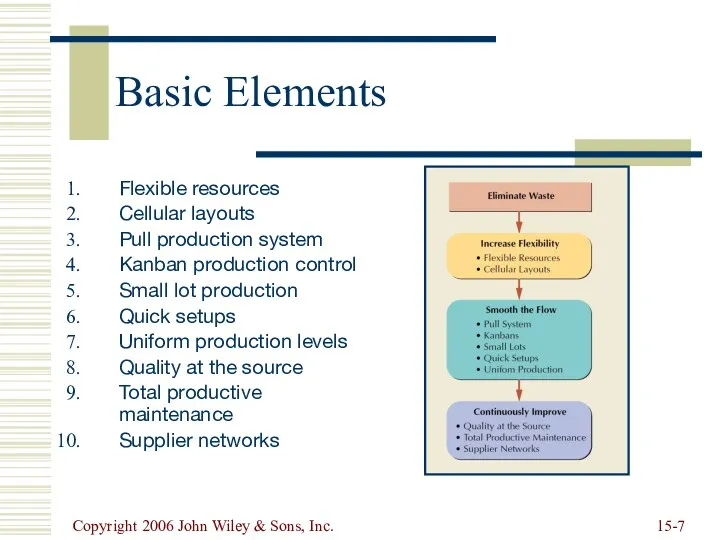

- 7. Copyright 2006 John Wiley & Sons, Inc. 15- Basic Elements Flexible resources Cellular layouts Pull production

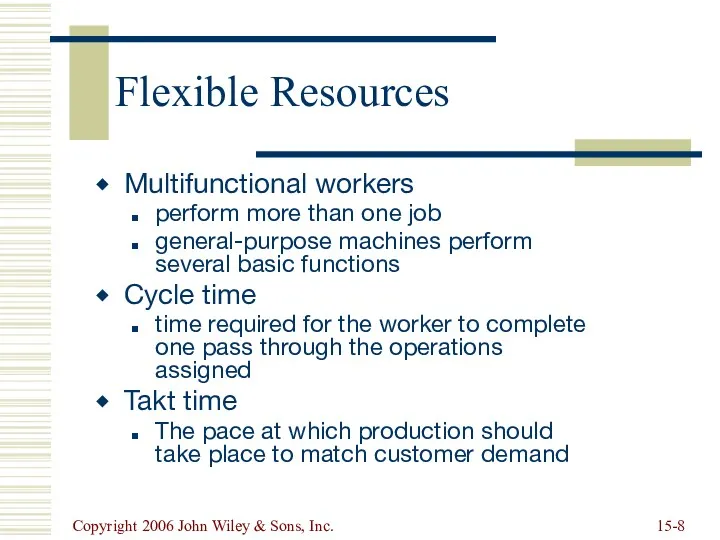

- 8. Copyright 2006 John Wiley & Sons, Inc. 15- Flexible Resources Multifunctional workers perform more than one

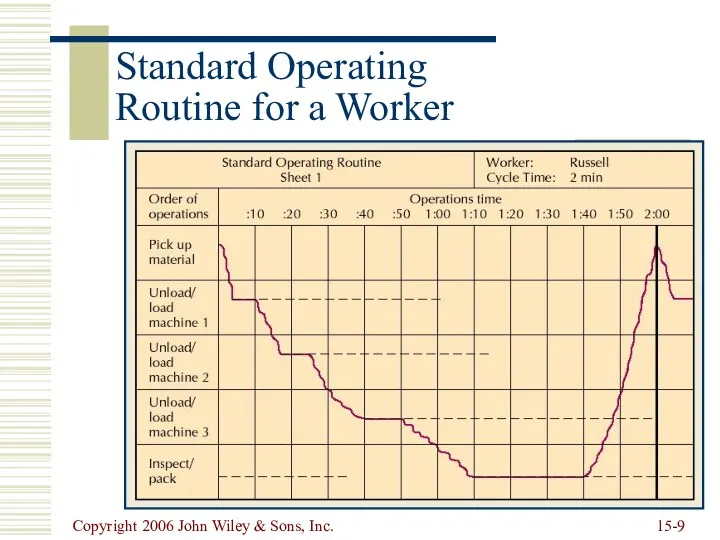

- 9. Copyright 2006 John Wiley & Sons, Inc. 15- Standard Operating Routine for a Worker

- 10. Copyright 2006 John Wiley & Sons, Inc. 15- Cellular Layouts Manufacturing cells comprised of dissimilar machines

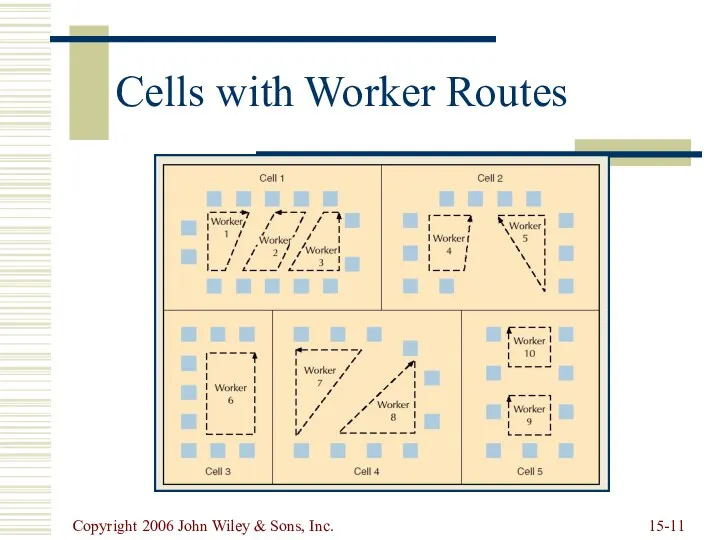

- 11. Copyright 2006 John Wiley & Sons, Inc. 15- Cells with Worker Routes

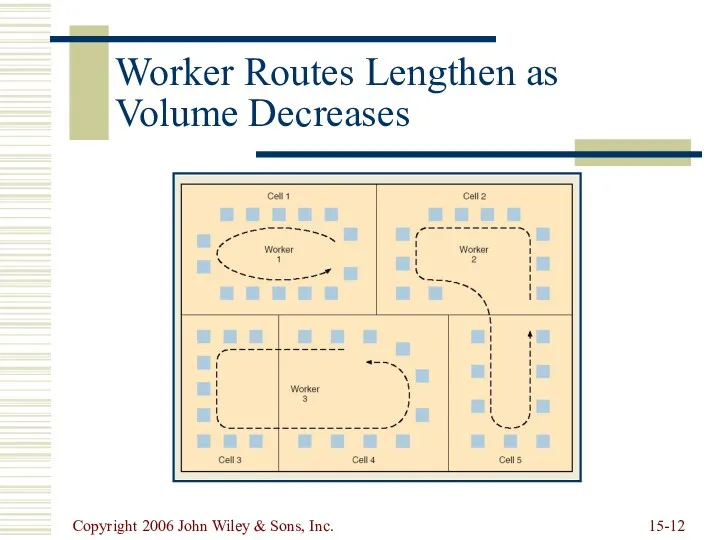

- 12. Copyright 2006 John Wiley & Sons, Inc. 15- Worker Routes Lengthen as Volume Decreases

- 13. Copyright 2006 John Wiley & Sons, Inc. 15- Pull System Material is pulled through the system

- 14. Copyright 2006 John Wiley & Sons, Inc. 15- Kanbans Card which indicates standard quantity of production

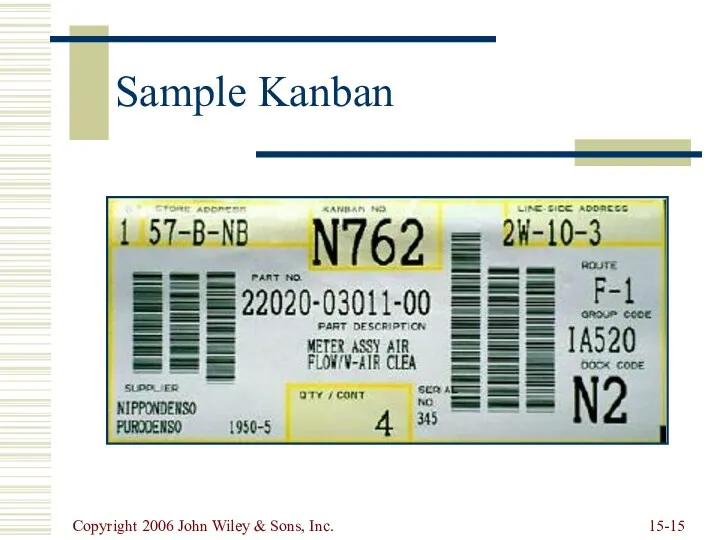

- 15. Copyright 2006 John Wiley & Sons, Inc. 15- Sample Kanban

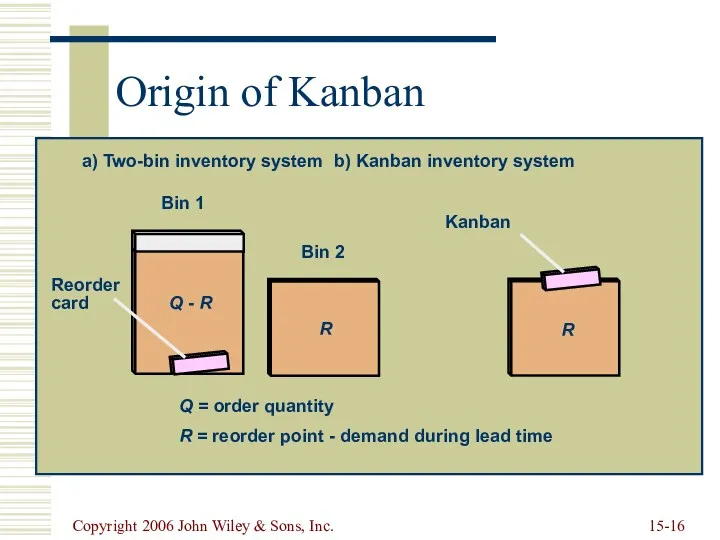

- 16. Copyright 2006 John Wiley & Sons, Inc. 15- Origin of Kanban

- 17. Copyright 2006 John Wiley & Sons, Inc. 15- Types of Kanban Production kanban authorizes production of

- 18. Copyright 2006 John Wiley & Sons, Inc. 15-

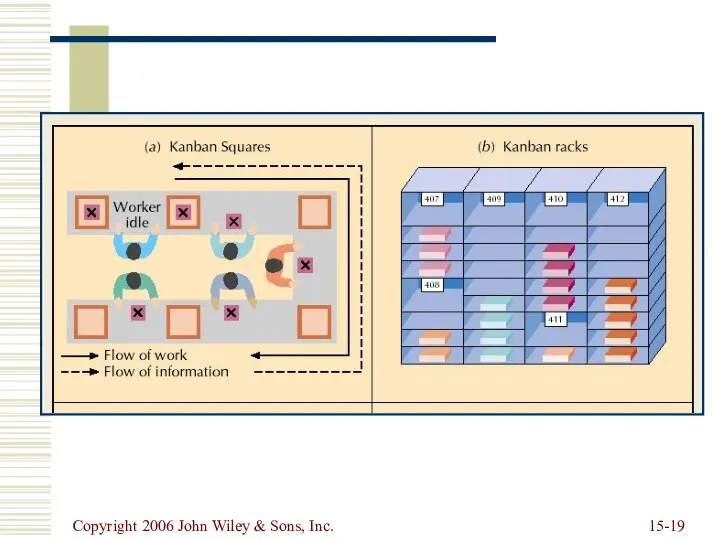

- 19. Copyright 2006 John Wiley & Sons, Inc. 15-

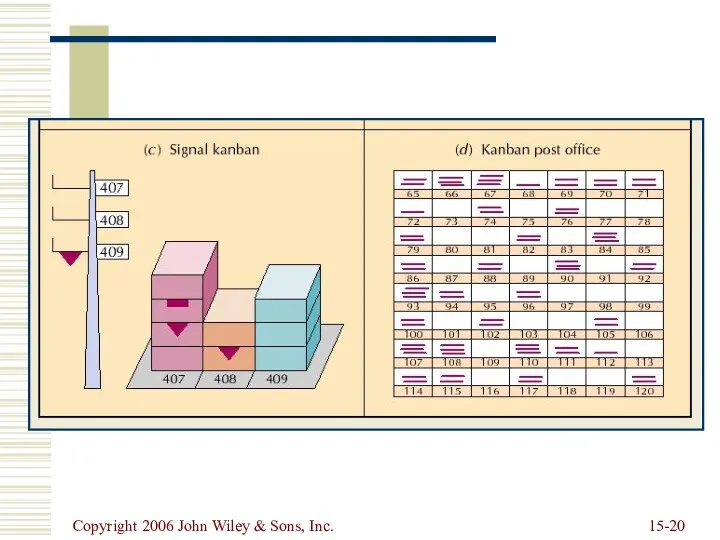

- 20. Copyright 2006 John Wiley & Sons, Inc. 15-

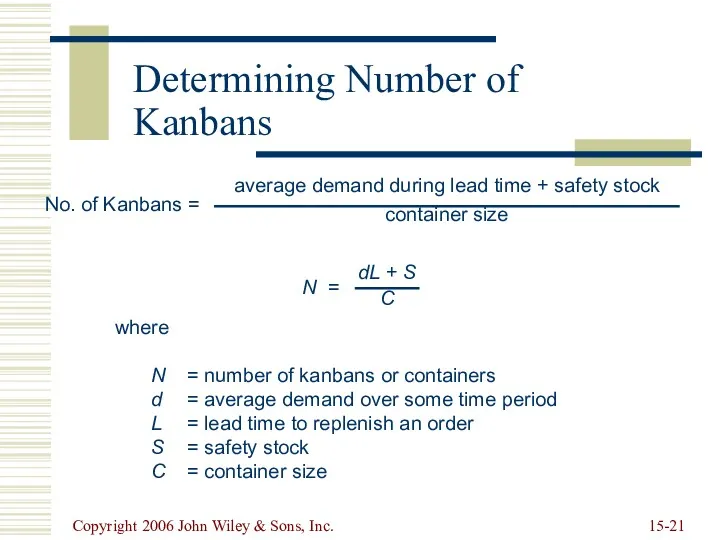

- 21. Copyright 2006 John Wiley & Sons, Inc. 15- Determining Number of Kanbans where N = number

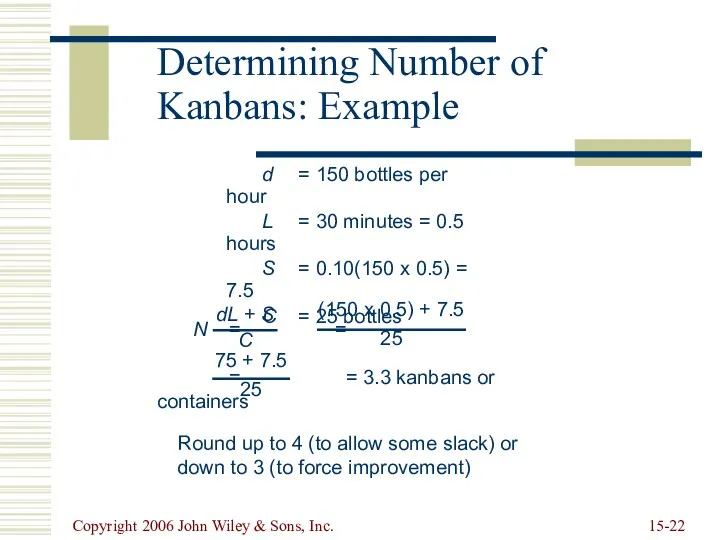

- 22. Copyright 2006 John Wiley & Sons, Inc. 15- Determining Number of Kanbans: Example d = 150

- 23. Copyright 2006 John Wiley & Sons, Inc. 15- Small Lots Require less space and capital investment

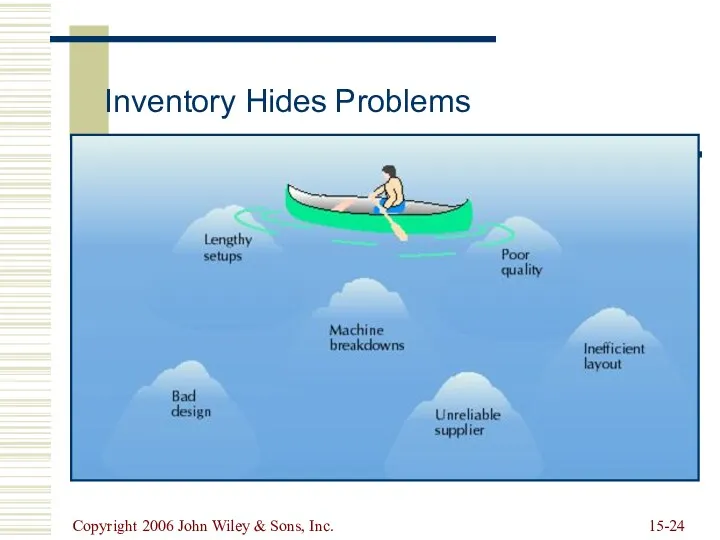

- 24. Copyright 2006 John Wiley & Sons, Inc. 15-

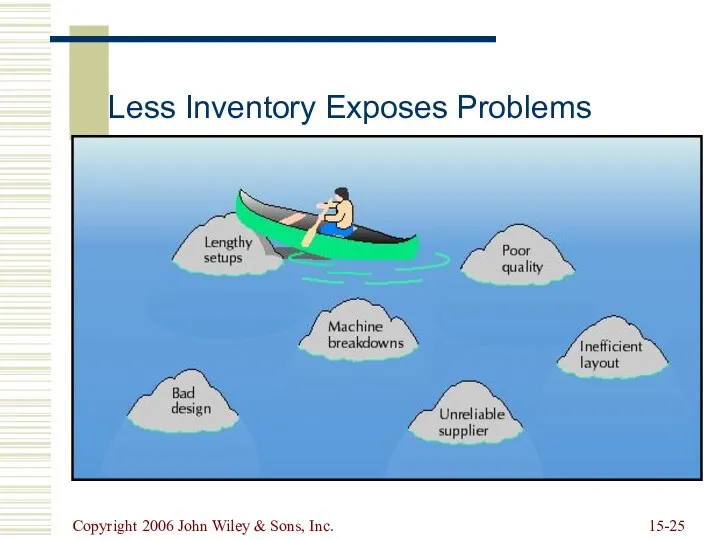

- 25. Copyright 2006 John Wiley & Sons, Inc. 15-

- 26. Copyright 2006 John Wiley & Sons, Inc. 15- Components of Lead Time Processing time Reduce number

- 27. Copyright 2006 John Wiley & Sons, Inc. 15- Quick Setups Internal setup Can be performed only

- 28. Copyright 2006 John Wiley & Sons, Inc. 15- Common Techniques for Reducing Setup Time

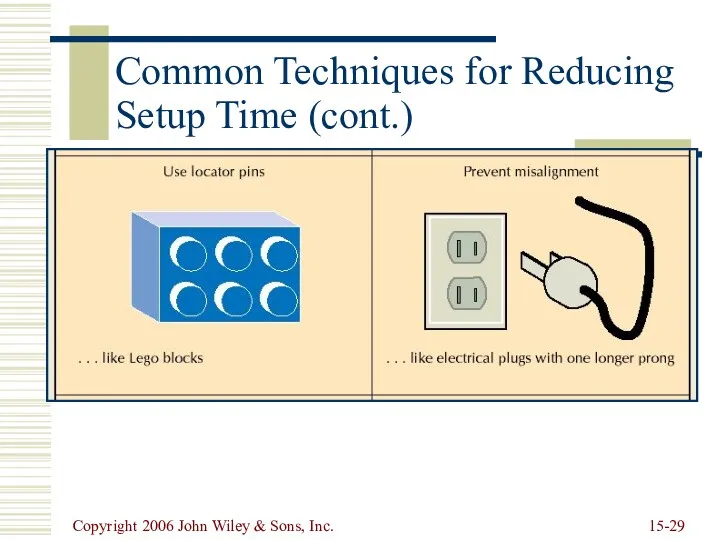

- 29. Copyright 2006 John Wiley & Sons, Inc. 15- Common Techniques for Reducing Setup Time (cont.)

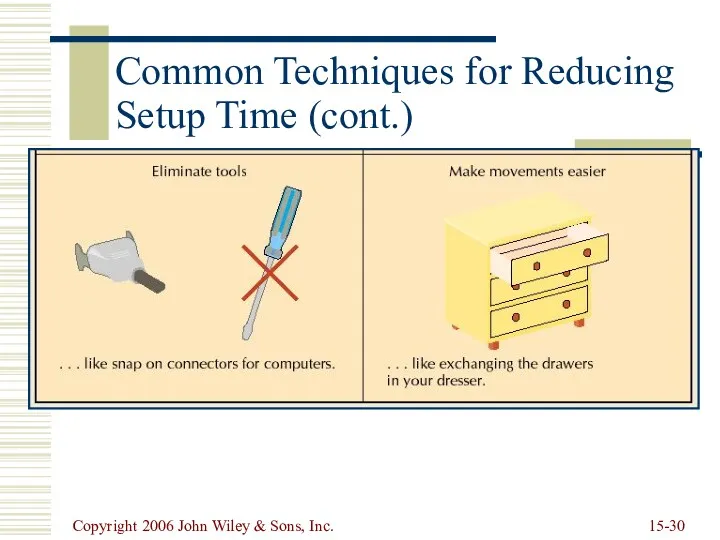

- 30. Copyright 2006 John Wiley & Sons, Inc. 15- Common Techniques for Reducing Setup Time (cont.)

- 31. Copyright 2006 John Wiley & Sons, Inc. 15- Uniform Production Levels Result from smoothing production requirements

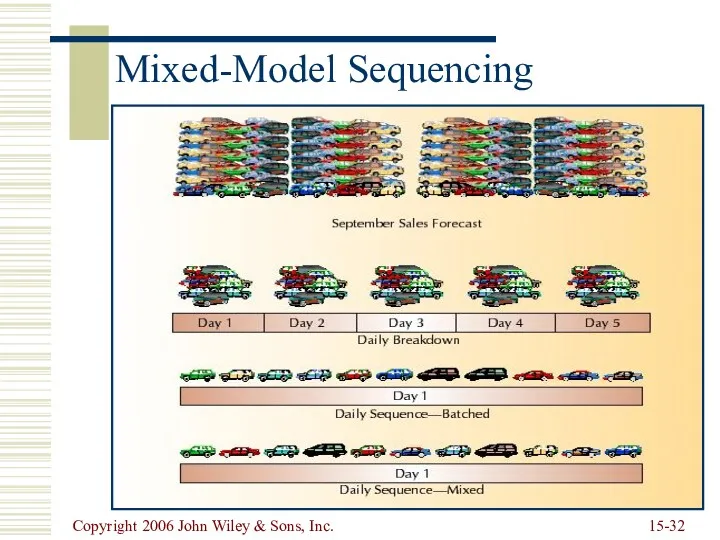

- 32. Copyright 2006 John Wiley & Sons, Inc. 15- Mixed-Model Sequencing

- 33. Copyright 2006 John Wiley & Sons, Inc. 15- Quality at the Source Visual control makes problems

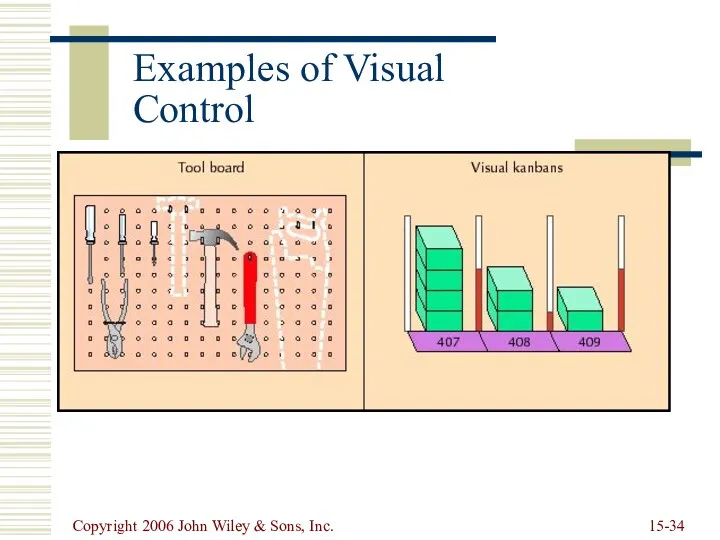

- 34. Copyright 2006 John Wiley & Sons, Inc. 15- Examples of Visual Control

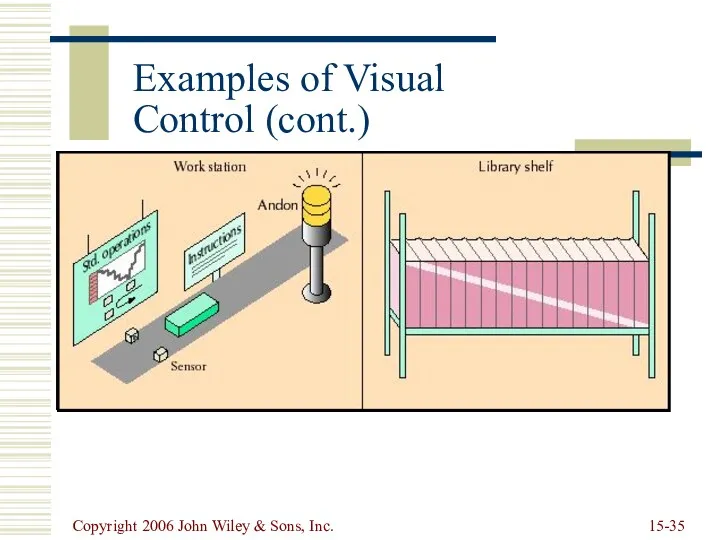

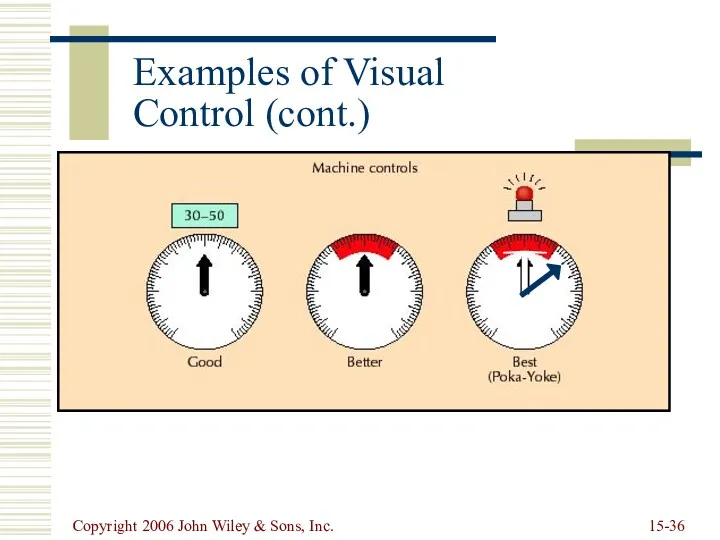

- 35. Copyright 2006 John Wiley & Sons, Inc. 15- Examples of Visual Control (cont.)

- 36. Copyright 2006 John Wiley & Sons, Inc. 15- Examples of Visual Control (cont.)

- 37. Copyright 2006 John Wiley & Sons, Inc. 15- Total Productive Maintenance (TPM) Breakdown maintenance Repairs to

- 38. Copyright 2006 John Wiley & Sons, Inc. 15- TPM Requirements Design products that can be easily

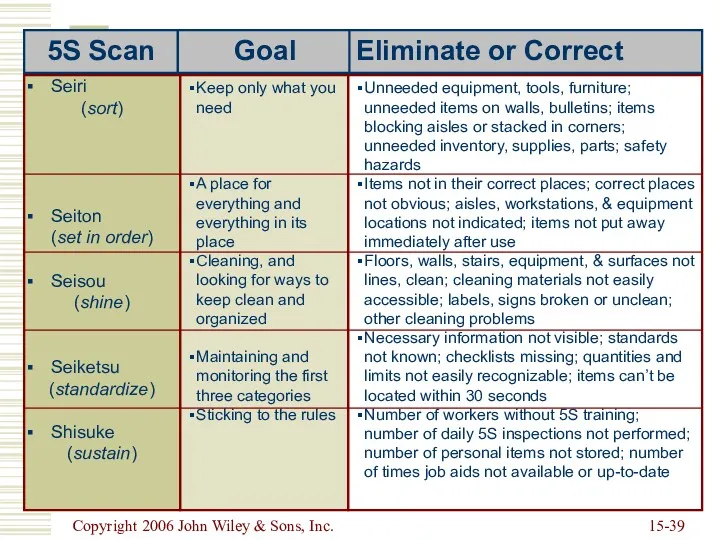

- 39. Copyright 2006 John Wiley & Sons, Inc. 15- Unneeded equipment, tools, furniture; unneeded items on walls,

- 40. Copyright 2006 John Wiley & Sons, Inc. 15- Supplier Networks Long-term supplier contracts Synchronized production Supplier

- 41. Copyright 2006 John Wiley & Sons, Inc. 15- Benefits of Lean Production Reduced inventory Improved quality

- 42. Copyright 2006 John Wiley & Sons, Inc. 15- Benefits of Lean Production (cont.) Greater flexibility Better

- 43. Copyright 2006 John Wiley & Sons, Inc. 15- Implementing Lean Production Use lean production to finely

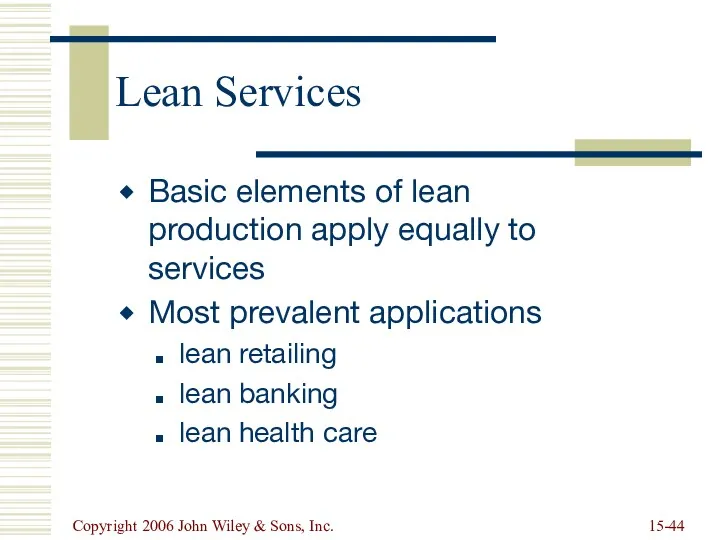

- 44. Copyright 2006 John Wiley & Sons, Inc. 15- Lean Services Basic elements of lean production apply

- 46. Скачать презентацию

Інформаційний менеджмент

Інформаційний менеджмент Пять этапов управления рисками. Курс для субъектов малого и среднего предпринимательства

Пять этапов управления рисками. Курс для субъектов малого и среднего предпринимательства Value Creation Through HR

Value Creation Through HR Международные стандарты и руководства в области КСО

Международные стандарты и руководства в области КСО Методы изучения затрат рабочего времени

Методы изучения затрат рабочего времени Адміністратор салону. Вимоги та його обов’язки

Адміністратор салону. Вимоги та його обов’язки Стратегический менеджмент

Стратегический менеджмент Управленческие решения

Управленческие решения Ethical theories and business ethics

Ethical theories and business ethics Обучение Визажист. Базовый курс

Обучение Визажист. Базовый курс Этика государственной и муниципальной службы. Административная этика. (Лекция 5)

Этика государственной и муниципальной службы. Административная этика. (Лекция 5) Понятие и процесс коммуникации. (Лекция 16)

Понятие и процесс коммуникации. (Лекция 16) Развитие персонала. Современные понятия развития персонала

Развитие персонала. Современные понятия развития персонала Процессный, системный, ситуационный подходы

Процессный, системный, ситуационный подходы Заявка на разработку проекта Производительность труда и поддержка занятости

Заявка на разработку проекта Производительность труда и поддержка занятости Anxiety. How to handle anxiety. Presentation sequence

Anxiety. How to handle anxiety. Presentation sequence Функции управления. Тема 3

Функции управления. Тема 3 Документационное обеспечение управления

Документационное обеспечение управления Критерии эффективности внутреннего контроля в организации

Критерии эффективности внутреннего контроля в организации Көшбасшы және көшбасшылық

Көшбасшы және көшбасшылық Анализ рыночной ситуации и конкуренции в отрасли. (Лекция 3)

Анализ рыночной ситуации и конкуренции в отрасли. (Лекция 3) Бизнес-планирование в ИС Project Expert

Бизнес-планирование в ИС Project Expert Ведение деловых переговоров

Ведение деловых переговоров Технологическая стандартизация и унификация

Технологическая стандартизация и унификация How to use the scores achieved by university graduates under CEPAS as reference in hiring the right employees

How to use the scores achieved by university graduates under CEPAS as reference in hiring the right employees Агентская проблема в организациях

Агентская проблема в организациях Зарубежный опыт управления персоналом

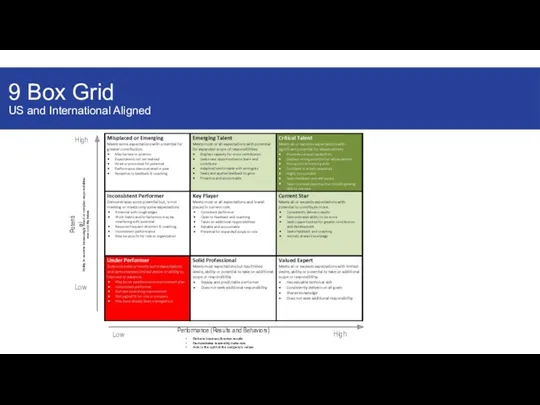

Зарубежный опыт управления персоналом 9 Box Grid.US and International Aligned

9 Box Grid.US and International Aligned