Objectives in Scheduling Loading Sequencing. Monitoring. Advanced Planning and Scheduling Systems. Theory of Constraints презентация

Содержание

- 2. Copyright 2006 John Wiley & Sons, Inc. 16- Lecture Outline Objectives in Scheduling Loading Sequencing Monitoring

- 3. Copyright 2006 John Wiley & Sons, Inc. 16- What is Scheduling? Last stage of planning before

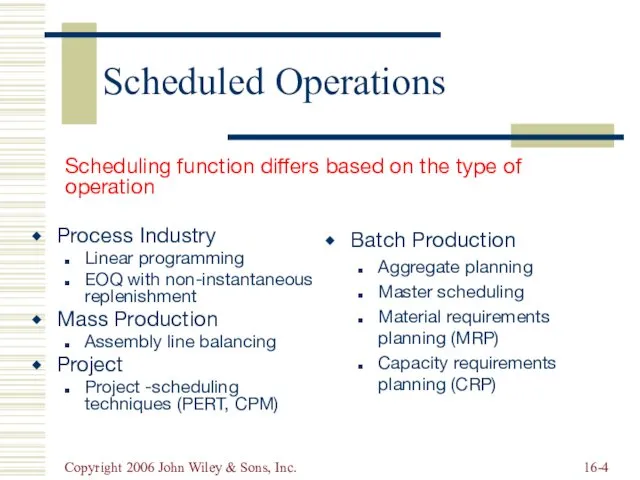

- 4. Copyright 2006 John Wiley & Sons, Inc. 16- Scheduled Operations Process Industry Linear programming EOQ with

- 5. Copyright 2006 John Wiley & Sons, Inc. 16- Objectives in Scheduling Meet customer due dates Minimize

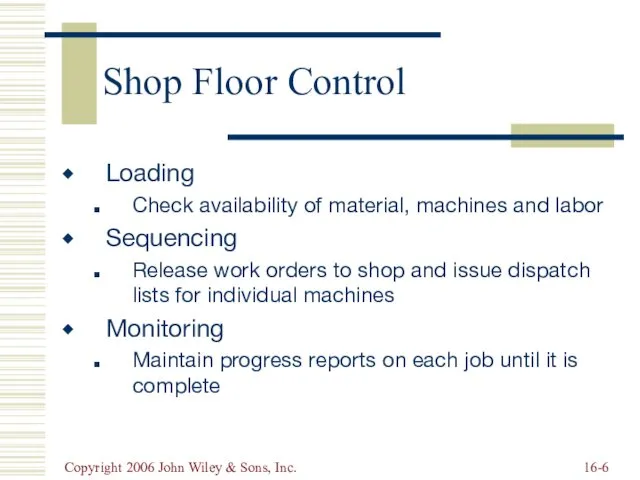

- 6. Copyright 2006 John Wiley & Sons, Inc. 16- Shop Floor Control Loading Check availability of material,

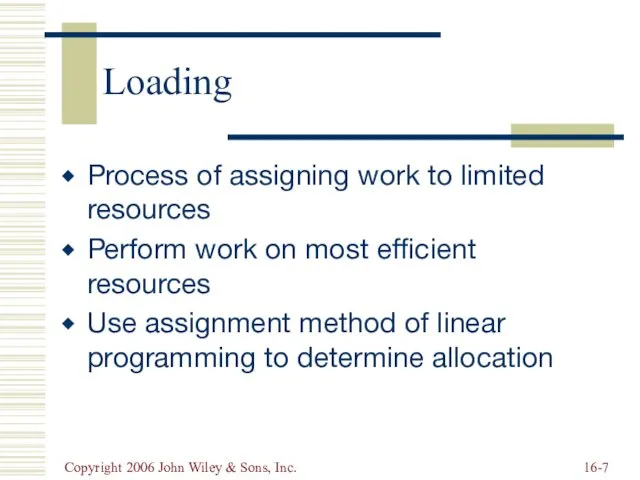

- 7. Copyright 2006 John Wiley & Sons, Inc. 16- Loading Process of assigning work to limited resources

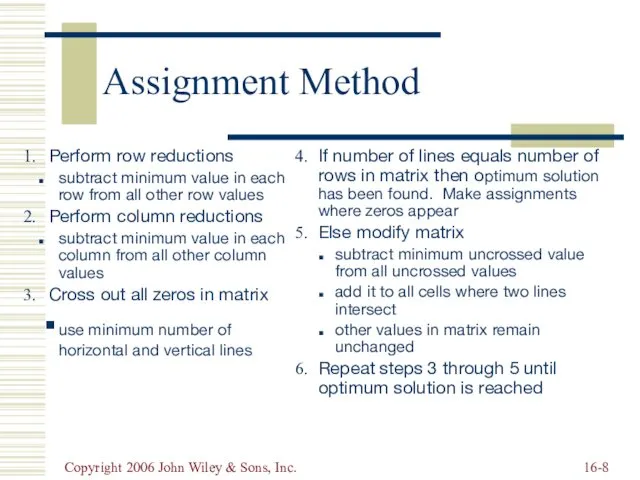

- 8. Copyright 2006 John Wiley & Sons, Inc. 16- Assignment Method Perform row reductions subtract minimum value

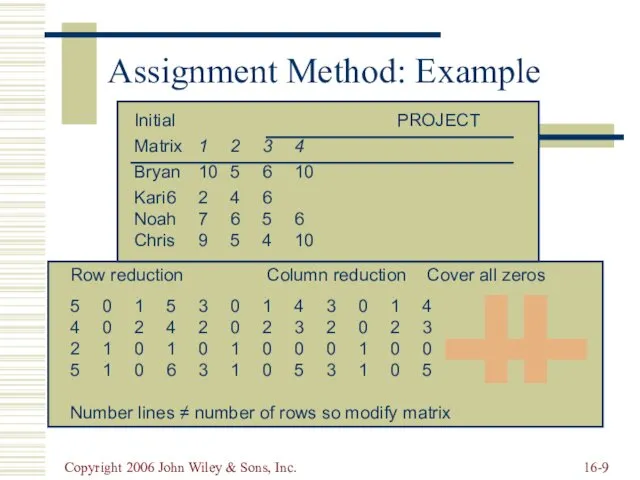

- 9. Copyright 2006 John Wiley & Sons, Inc. 16- Assignment Method: Example

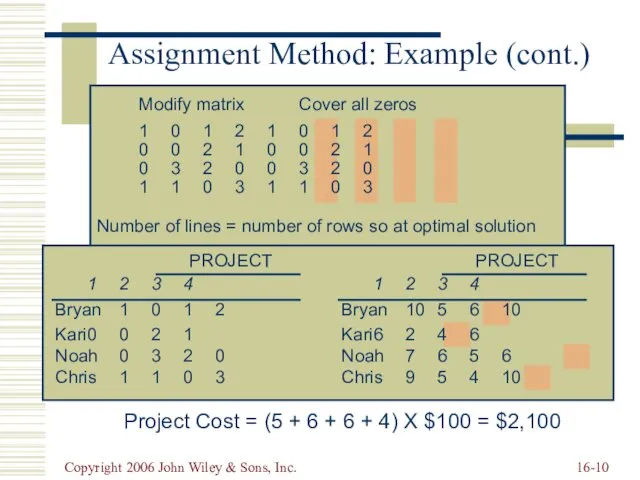

- 10. Copyright 2006 John Wiley & Sons, Inc. 16- Assignment Method: Example (cont.) Project Cost = (5

- 11. Copyright 2006 John Wiley & Sons, Inc. 16- Sequencing Prioritize jobs assigned to a resource If

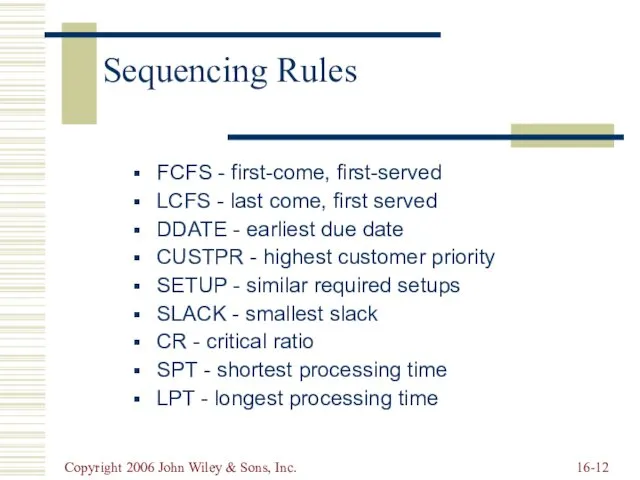

- 12. Copyright 2006 John Wiley & Sons, Inc. 16- Sequencing Rules FCFS - first-come, first-served LCFS -

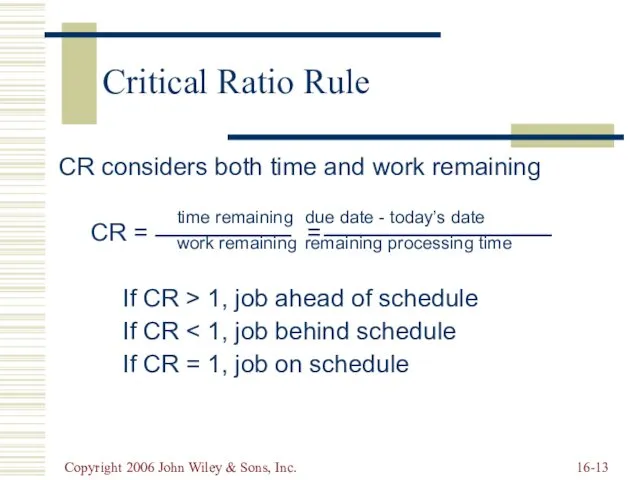

- 13. Copyright 2006 John Wiley & Sons, Inc. 16- Critical Ratio Rule

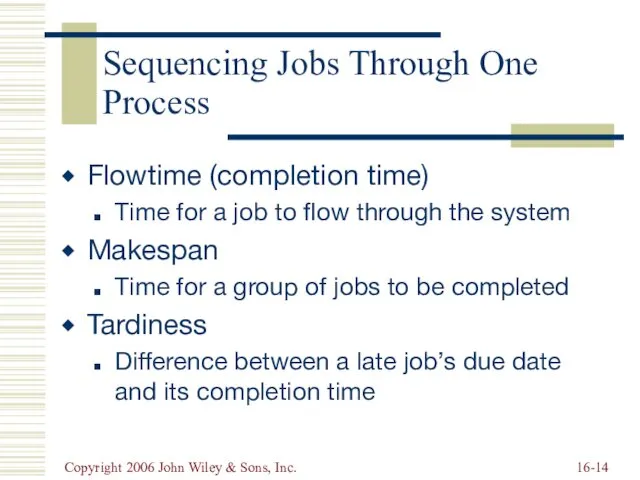

- 14. Copyright 2006 John Wiley & Sons, Inc. 16- Sequencing Jobs Through One Process Flowtime (completion time)

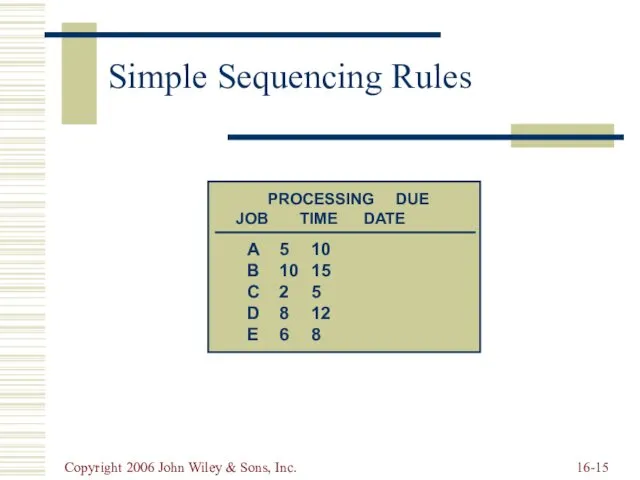

- 15. Copyright 2006 John Wiley & Sons, Inc. 16- Simple Sequencing Rules

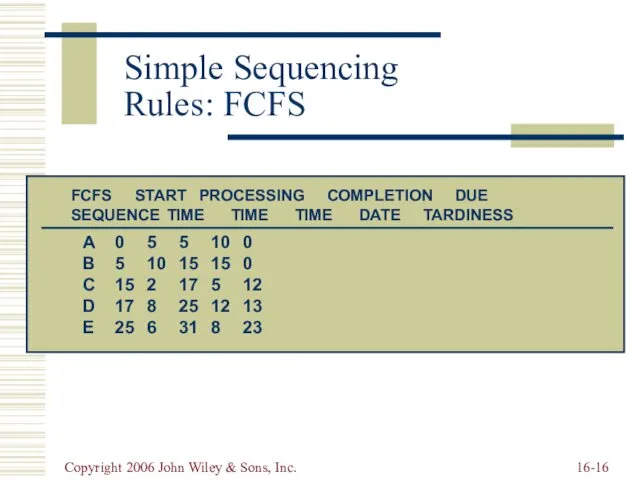

- 16. Copyright 2006 John Wiley & Sons, Inc. 16- Simple Sequencing Rules: FCFS

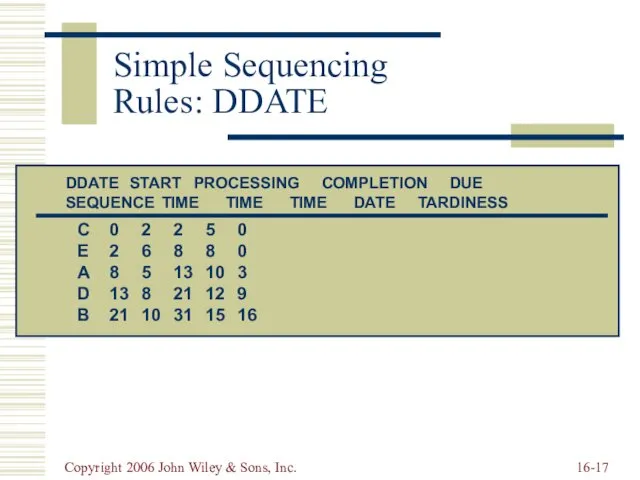

- 17. Copyright 2006 John Wiley & Sons, Inc. 16- Simple Sequencing Rules: DDATE

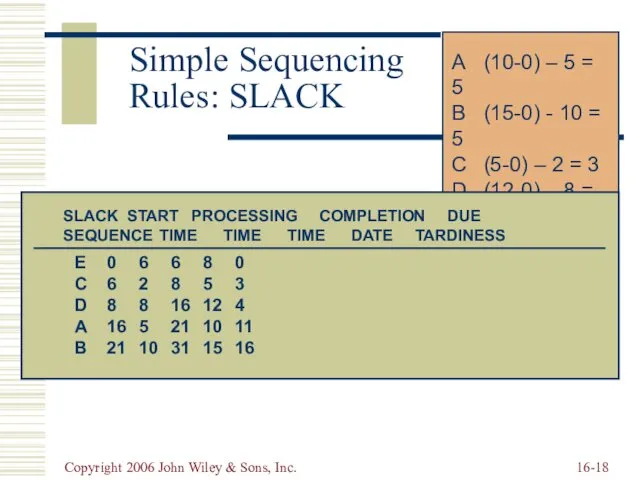

- 18. Copyright 2006 John Wiley & Sons, Inc. 16- Simple Sequencing Rules: SLACK

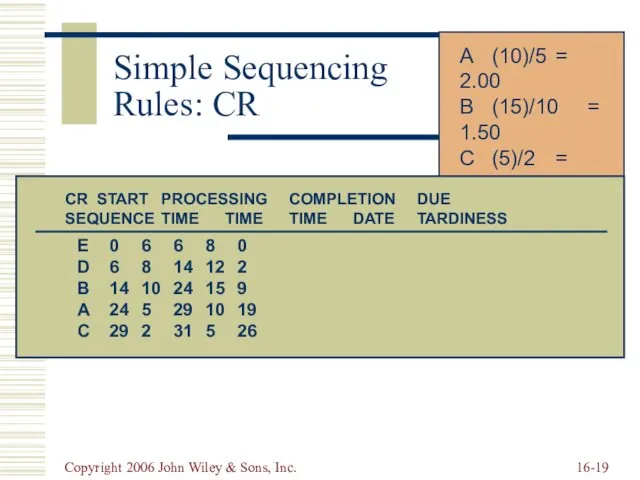

- 19. Copyright 2006 John Wiley & Sons, Inc. 16- Simple Sequencing Rules: CR

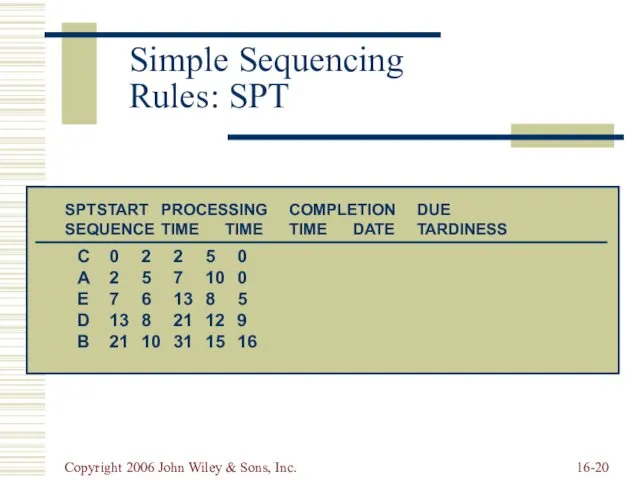

- 20. Copyright 2006 John Wiley & Sons, Inc. 16- Simple Sequencing Rules: SPT

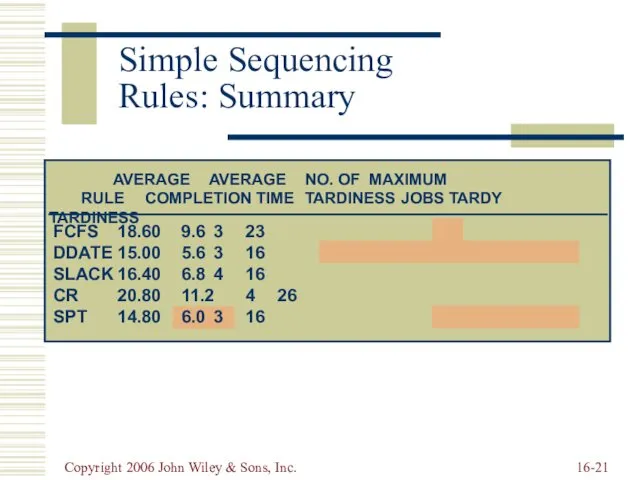

- 21. Copyright 2006 John Wiley & Sons, Inc. 16- Simple Sequencing Rules: Summary

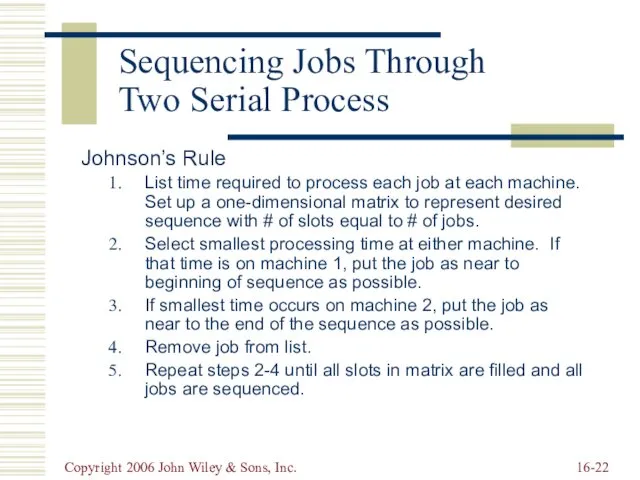

- 22. Copyright 2006 John Wiley & Sons, Inc. 16- Sequencing Jobs Through Two Serial Process Johnson’s Rule

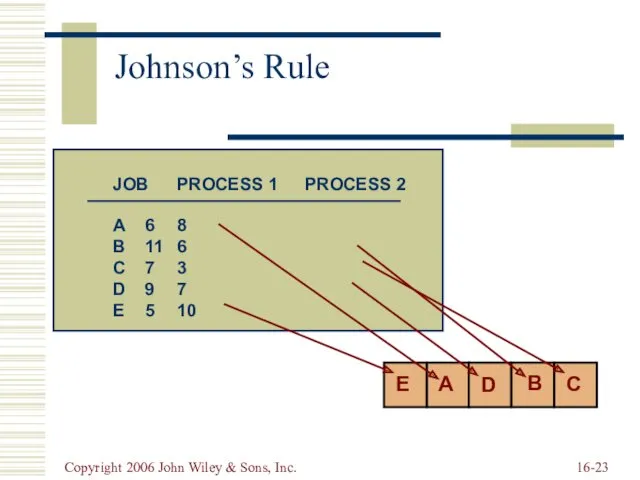

- 23. Copyright 2006 John Wiley & Sons, Inc. 16- Johnson’s Rule

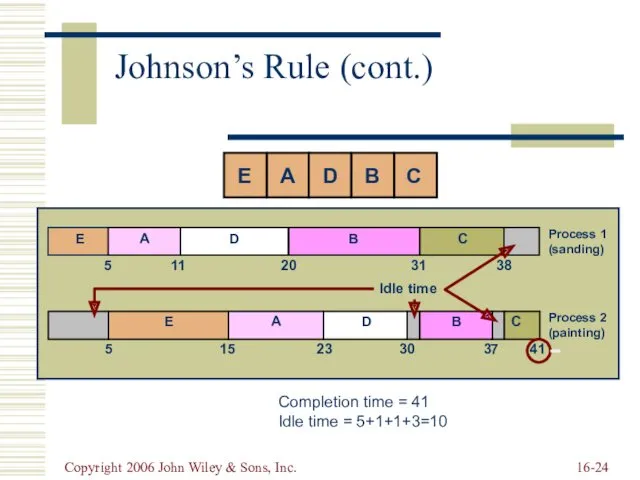

- 24. Copyright 2006 John Wiley & Sons, Inc. 16- Johnson’s Rule (cont.) A B C D E

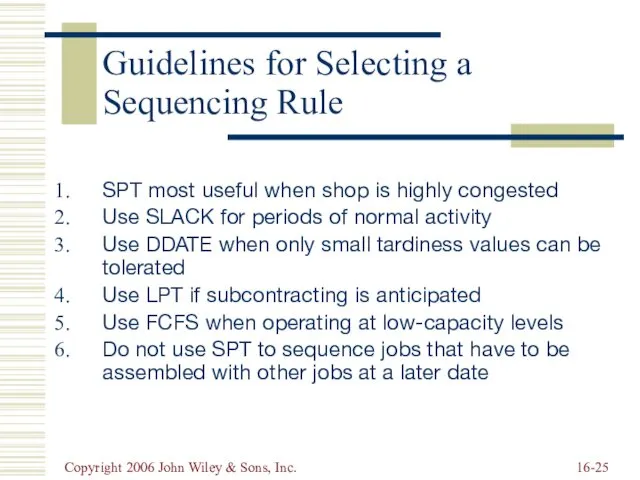

- 25. Copyright 2006 John Wiley & Sons, Inc. 16- Guidelines for Selecting a Sequencing Rule SPT most

- 26. Copyright 2006 John Wiley & Sons, Inc. 16- Monitoring Work package Shop paperwork that travels with

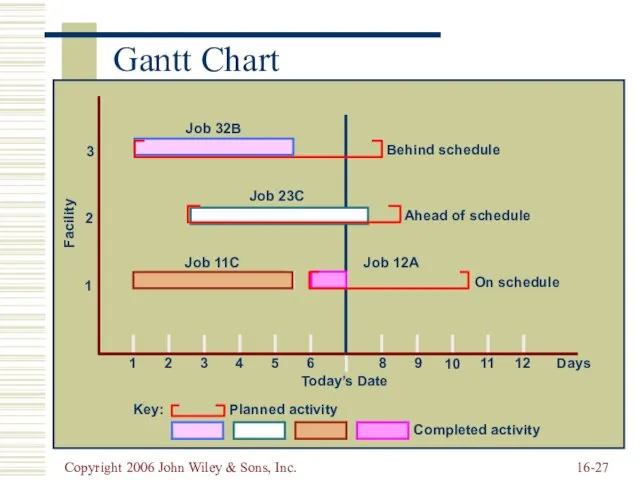

- 27. Copyright 2006 John Wiley & Sons, Inc. 16- Gantt Chart

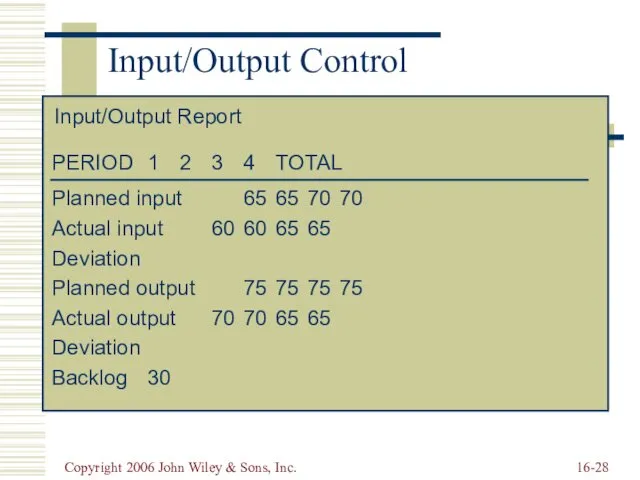

- 28. Copyright 2006 John Wiley & Sons, Inc. 16- Input/Output Control

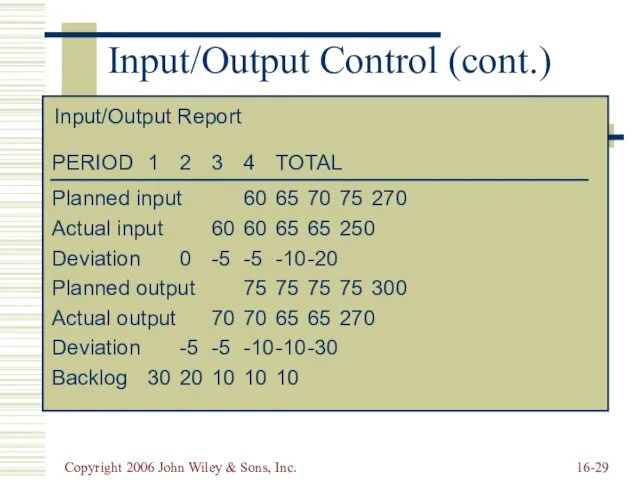

- 29. Copyright 2006 John Wiley & Sons, Inc. 16- Input/Output Control (cont.)

- 30. Copyright 2006 John Wiley & Sons, Inc. 16- Advanced Planning and Scheduling Systems Infinite - assumes

- 31. Copyright 2006 John Wiley & Sons, Inc. 16- Advanced Planning and Scheduling Systems (cont.) Advanced planning

- 32. Copyright 2006 John Wiley & Sons, Inc. 16- Theory of Constraints Not all resources are used

- 33. Copyright 2006 John Wiley & Sons, Inc. 16- Drum-Buffer-Rope Drum Bottleneck, beating to set the pace

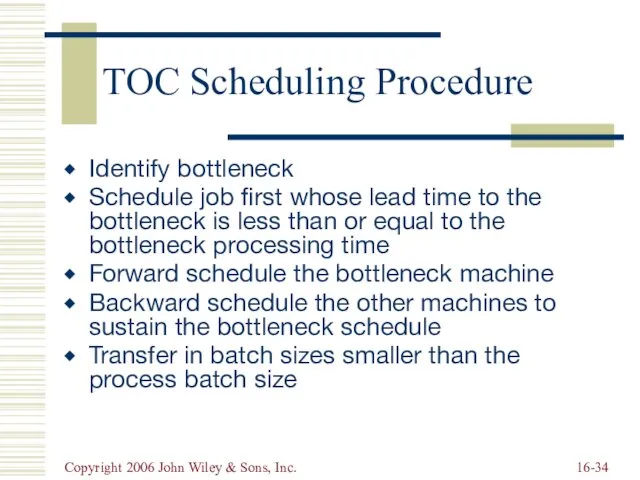

- 34. Copyright 2006 John Wiley & Sons, Inc. 16- TOC Scheduling Procedure Identify bottleneck Schedule job first

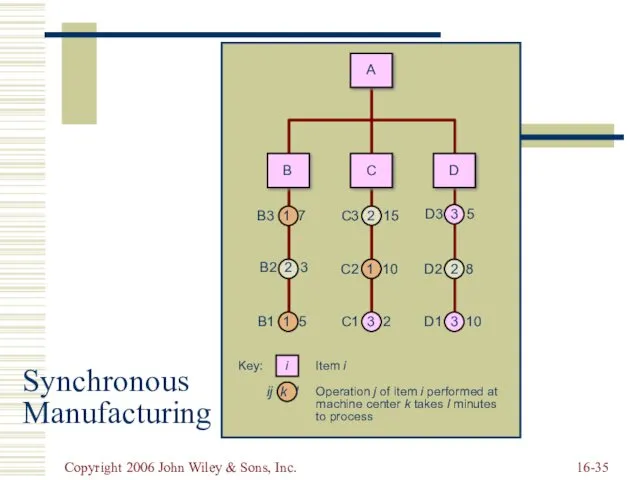

- 35. Copyright 2006 John Wiley & Sons, Inc. 16- Synchronous Manufacturing

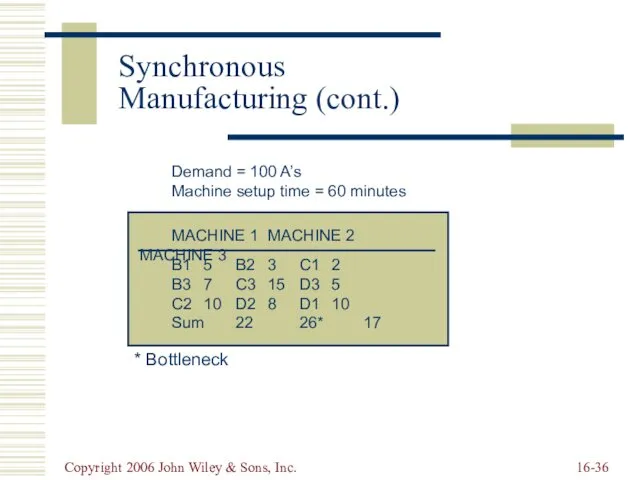

- 36. Copyright 2006 John Wiley & Sons, Inc. 16- Synchronous Manufacturing (cont.)

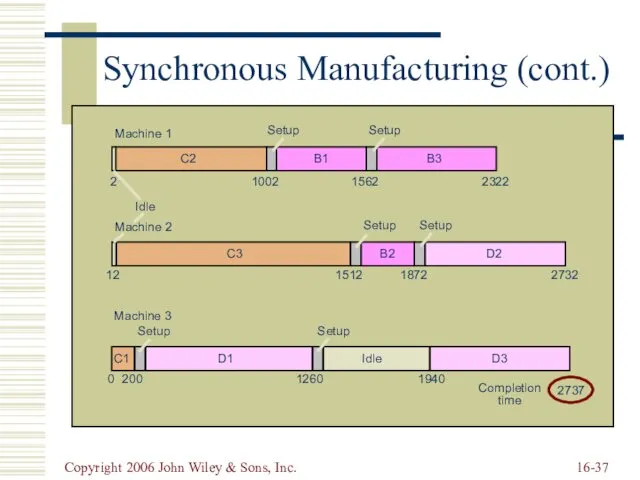

- 37. Copyright 2006 John Wiley & Sons, Inc. 16- Synchronous Manufacturing (cont.)

- 38. Copyright 2006 John Wiley & Sons, Inc. 16- Employee Scheduling Labor is very flexible resource Scheduling

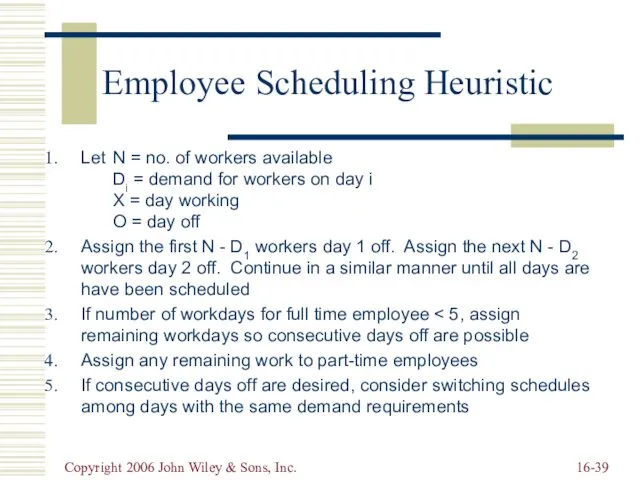

- 39. Copyright 2006 John Wiley & Sons, Inc. 16- Employee Scheduling Heuristic Let N = no. of

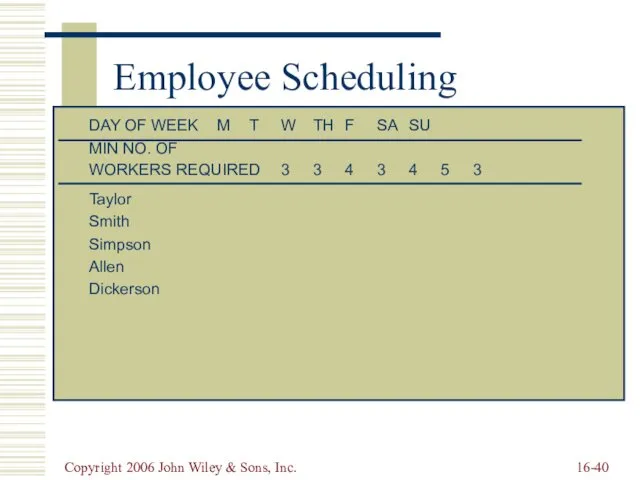

- 40. Copyright 2006 John Wiley & Sons, Inc. 16- Employee Scheduling

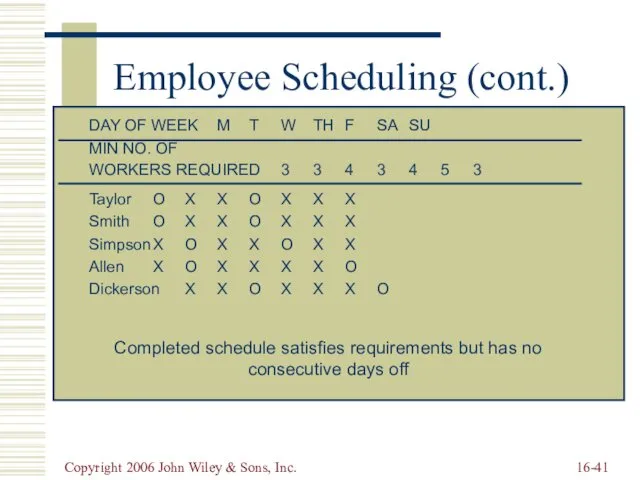

- 41. Copyright 2006 John Wiley & Sons, Inc. 16- Employee Scheduling (cont.)

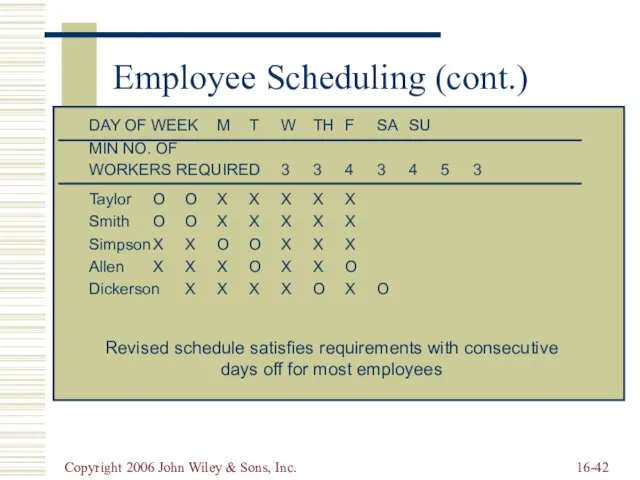

- 42. Copyright 2006 John Wiley & Sons, Inc. 16- Employee Scheduling (cont.)

- 43. Copyright 2006 John Wiley & Sons, Inc. 16- Automated Scheduling Systems Staff Scheduling Schedule Bidding Schedule

- 45. Скачать презентацию

Организационный план. Управленческий персонал

Организационный план. Управленческий персонал Damu Logistics Алматы логистикалық компаниясы

Damu Logistics Алматы логистикалық компаниясы Характеристика организационной культуры компании IKEA по Харрису и Морану

Характеристика организационной культуры компании IKEA по Харрису и Морану Conceptul de decizie managerială. Definirea şi structura sistemului decizional. Metode şi tehnici decizionale

Conceptul de decizie managerială. Definirea şi structura sistemului decizional. Metode şi tehnici decizionale ВКР: Разработка технологии управления кадровым резервов в Эксплуатационном локомотивном депо Свердловск-Сортировочный

ВКР: Разработка технологии управления кадровым резервов в Эксплуатационном локомотивном депо Свердловск-Сортировочный Managers and managing. (Session 1)

Managers and managing. (Session 1) Управление социально-культурным разнообразием персонала в практике международных и российских компаний

Управление социально-культурным разнообразием персонала в практике международных и российских компаний Стандартные фразы в работе с клиентами

Стандартные фразы в работе с клиентами Развитие ситуационного центра губернатора Челябинской области

Развитие ситуационного центра губернатора Челябинской области Who is a leader. Кто такой лидер

Who is a leader. Кто такой лидер Как оптимизировать управление финансами на предприятии

Как оптимизировать управление финансами на предприятии Основные понятия логистики

Основные понятия логистики Ранние теории мотивации: классические теории управления, человеческих отношений, человеческих ресурсов

Ранние теории мотивации: классические теории управления, человеческих отношений, человеческих ресурсов Лекція 3 (частина 1). Персонал на підприємстві

Лекція 3 (частина 1). Персонал на підприємстві Управление проектами

Управление проектами Принципы и стили управления

Принципы и стили управления Таможенная процедура таможенного склада

Таможенная процедура таможенного склада Самоменеджмент

Самоменеджмент Оперативті басқару, жоспарлау, басқару шешімдерін қабылдау

Оперативті басқару, жоспарлау, басқару шешімдерін қабылдау Персональный менеджмент

Персональный менеджмент Планирование работы с человеческими ресурсами организации

Планирование работы с человеческими ресурсами организации Деловая карьера

Деловая карьера Особистість підлеглого, як обєкт управлінської дії. (Тема 1)

Особистість підлеглого, як обєкт управлінської дії. (Тема 1) Учебное пособие для кассиров ресторанов Burger King

Учебное пособие для кассиров ресторанов Burger King Менеджмент организации

Менеджмент организации Понятие менеджмента в туризме и его особенности

Понятие менеджмента в туризме и его особенности Роль менеджера в процессе коммуникаций

Роль менеджера в процессе коммуникаций “Эйр Астана” АҚ тәуекелдерді басқару саясаты

“Эйр Астана” АҚ тәуекелдерді басқару саясаты