Содержание

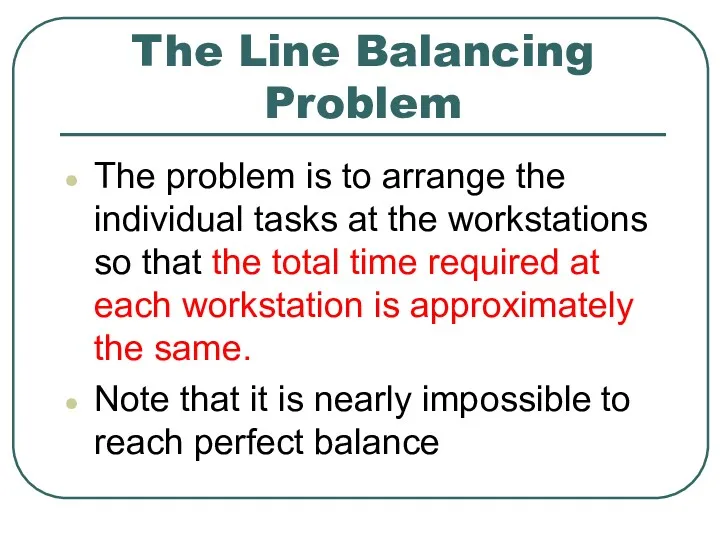

- 2. The Line Balancing Problem The problem is to arrange the individual tasks at the workstations so

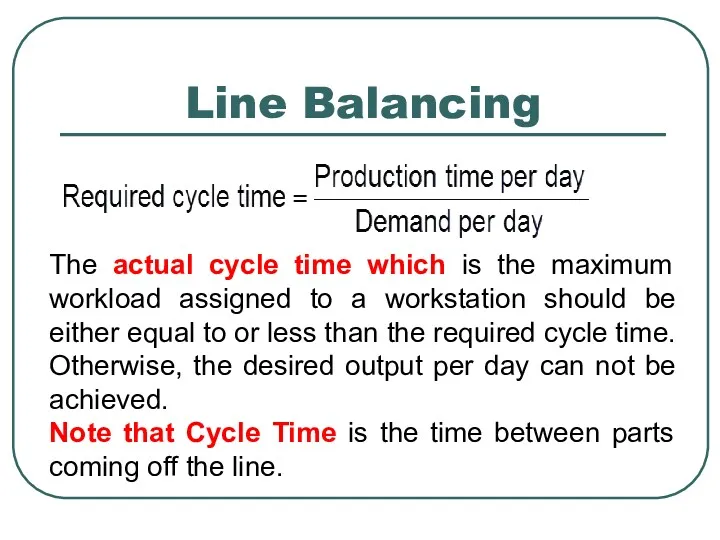

- 3. Line Balancing The actual cycle time which is the maximum workload assigned to a workstation should

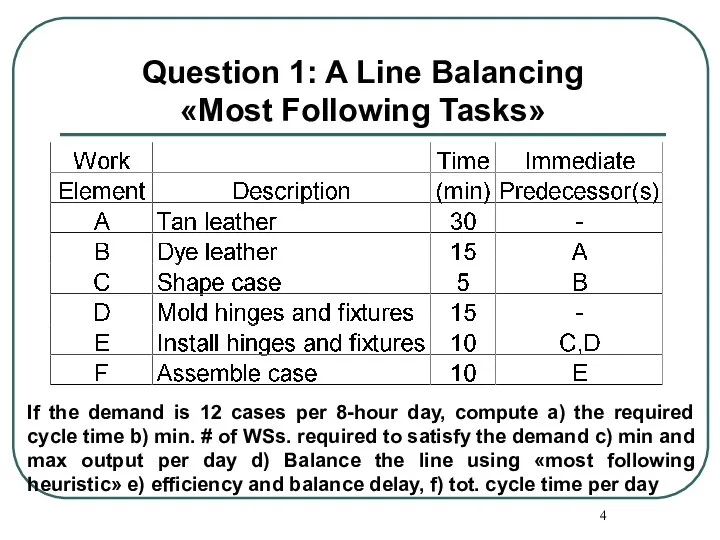

- 4. If the demand is 12 cases per 8-hour day, compute a) the required cycle time b)

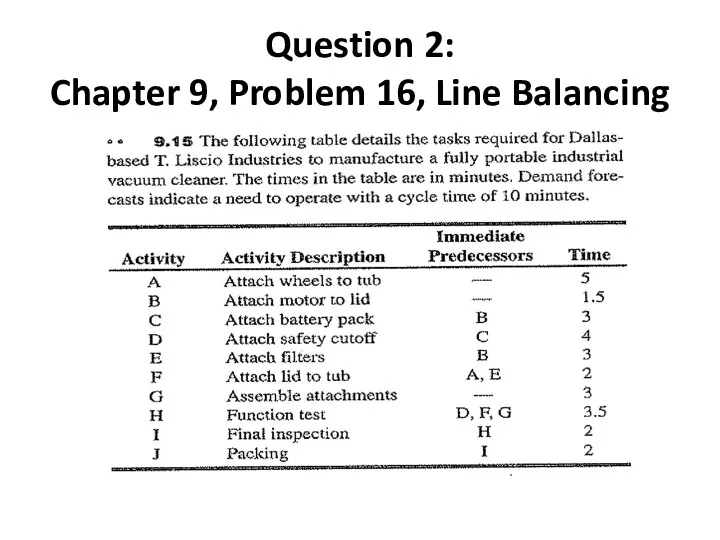

- 5. Question 2: Chapter 9, Problem 16, Line Balancing

- 6. Question 2: Chapter 9, Problem 16, Line Balancing a) Draw the precedence diagram b) Calculate the

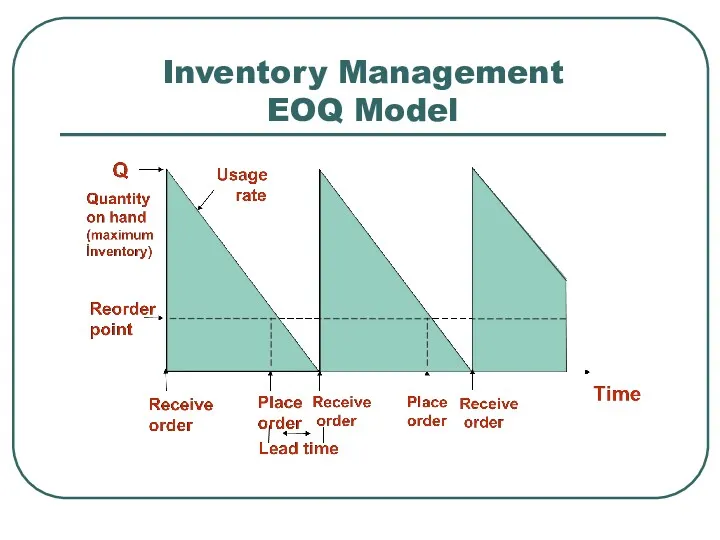

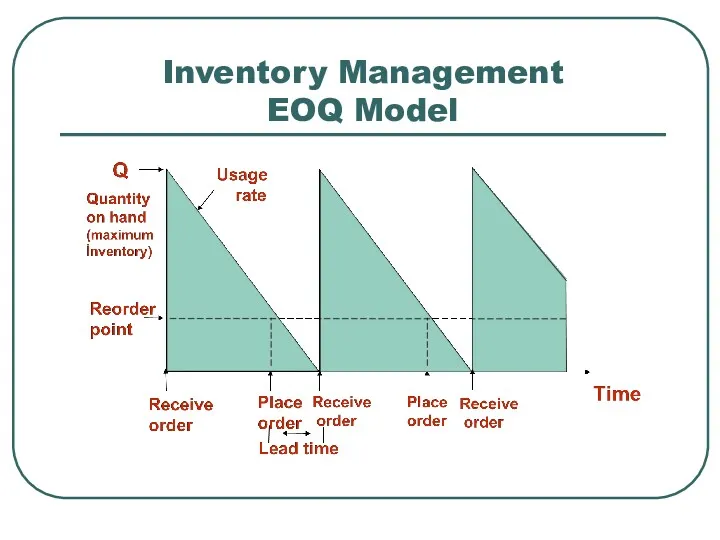

- 7. Inventory Management EOQ Model

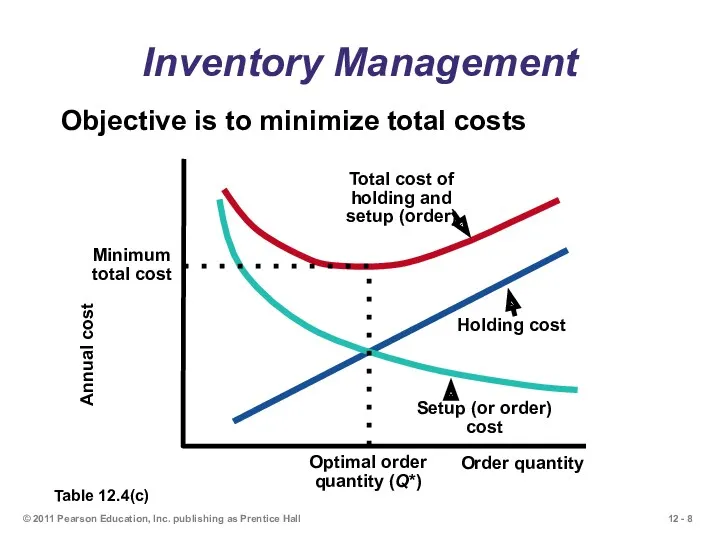

- 8. © 2011 Pearson Education, Inc. publishing as Prentice Hall Inventory Management Objective is to minimize total

- 9. Inventory Management EOQ Model

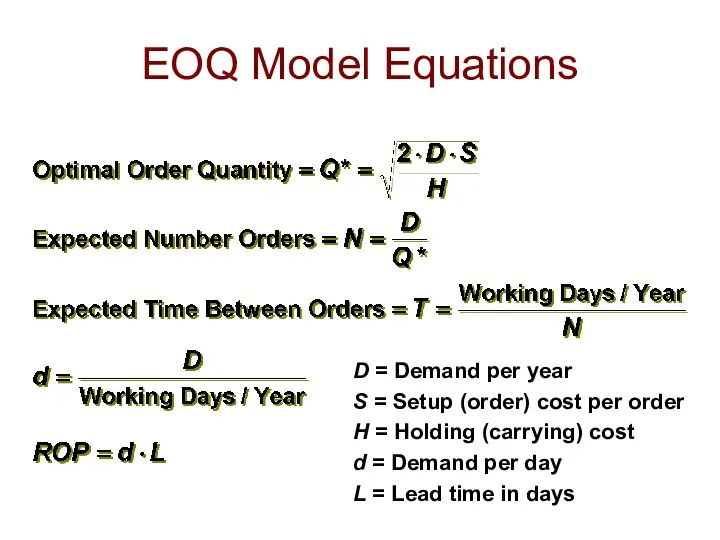

- 10. EOQ Model Equations D = Demand per year S = Setup (order) cost per order H

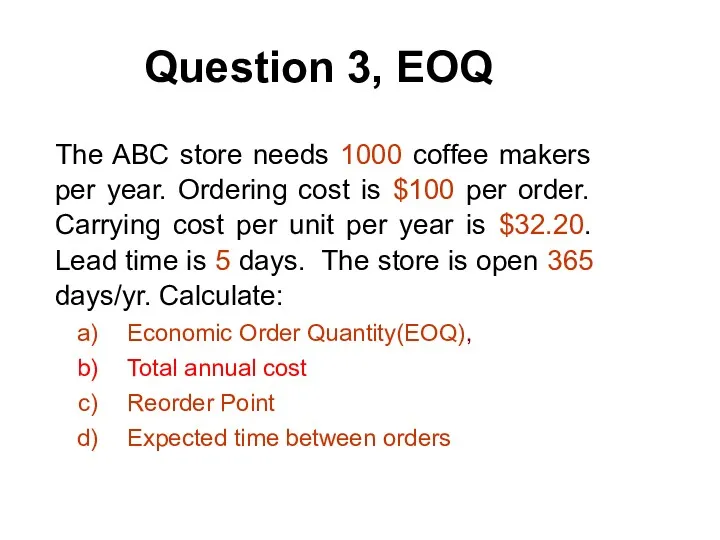

- 11. Question 3, EOQ The ABC store needs 1000 coffee makers per year. Ordering cost is $100

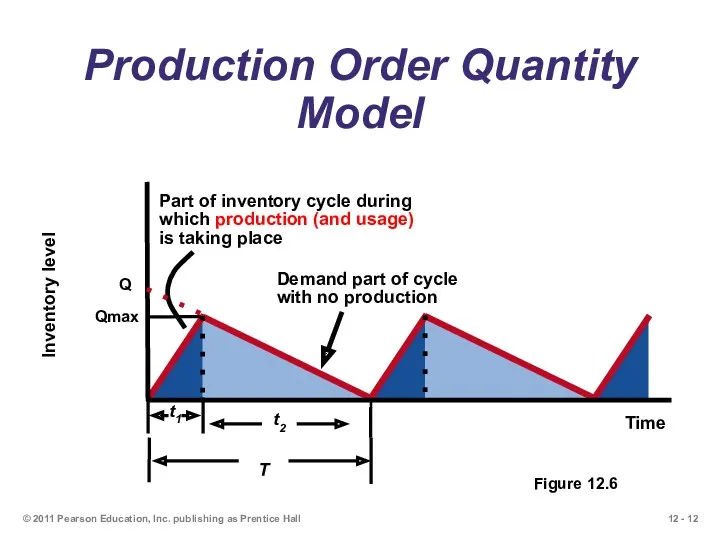

- 12. © 2011 Pearson Education, Inc. publishing as Prentice Hall Production Order Quantity Model Figure 12.6

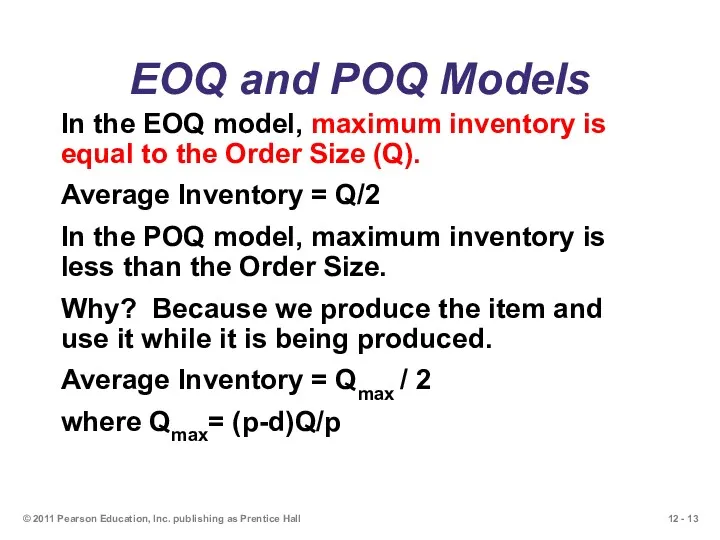

- 13. EOQ and POQ Models In the EOQ model, maximum inventory is equal to the Order Size

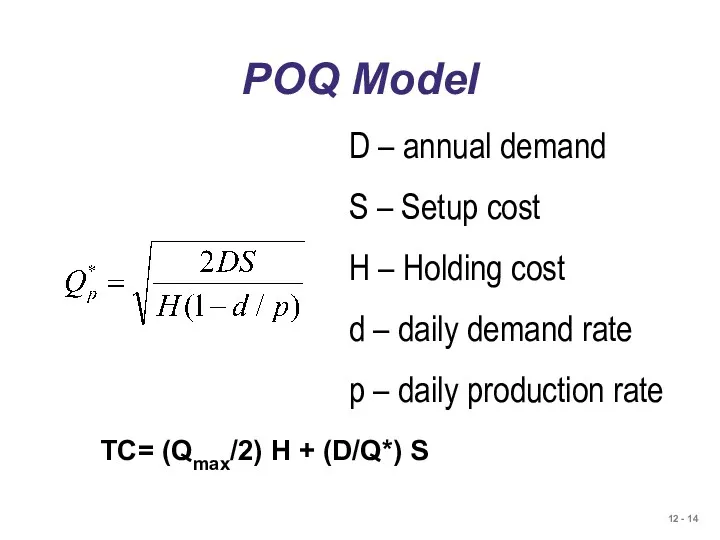

- 14. POQ Model D – annual demand S – Setup cost H – Holding cost d –

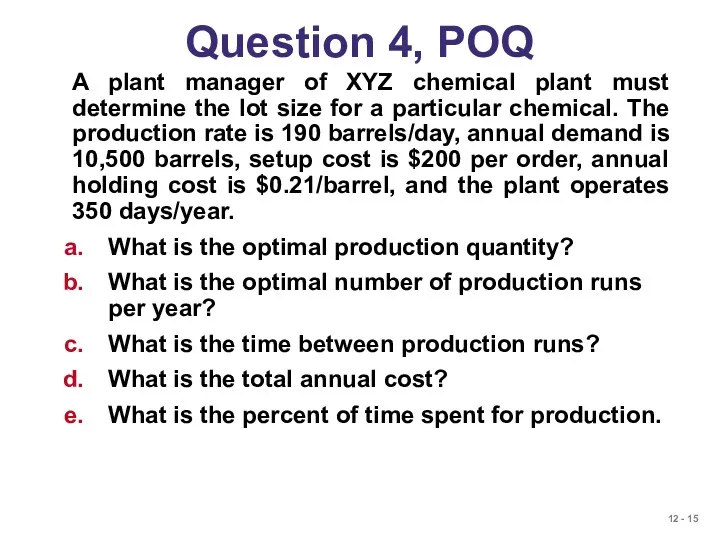

- 15. Question 4, POQ A plant manager of XYZ chemical plant must determine the lot size for

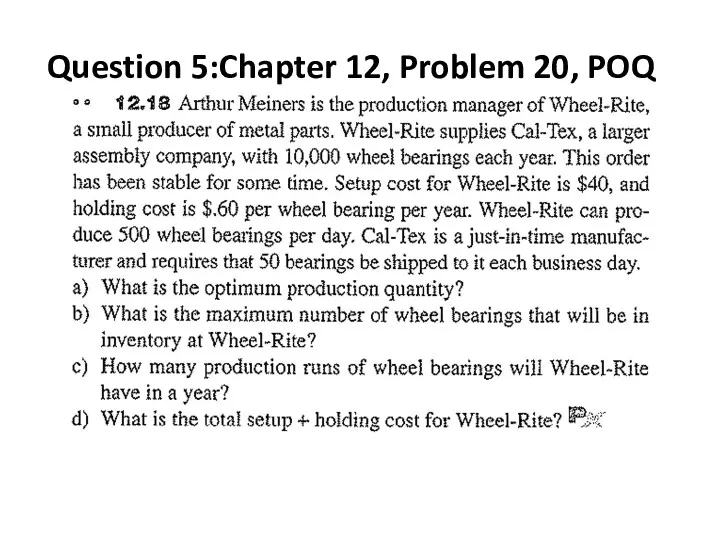

- 16. Question 5:Chapter 12, Problem 20, POQ

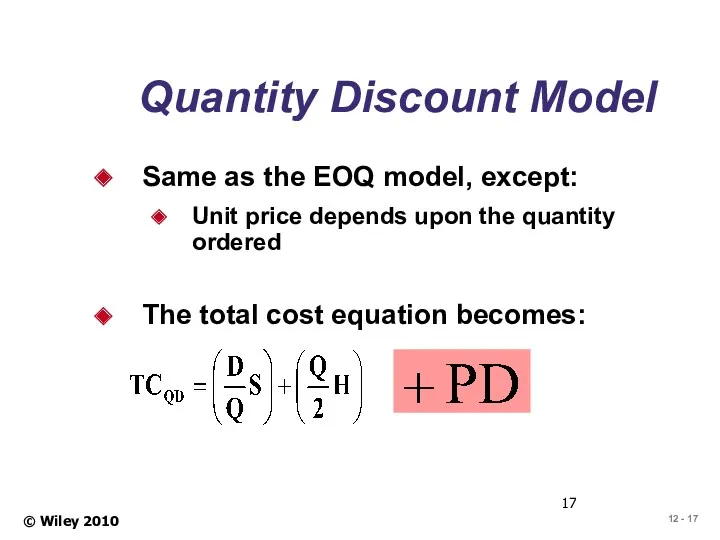

- 17. © Wiley 2010 Quantity Discount Model Same as the EOQ model, except: Unit price depends upon

- 18. Question 6: Quantity Discount Model ABC Sport store is considering going to a different hat supplier.

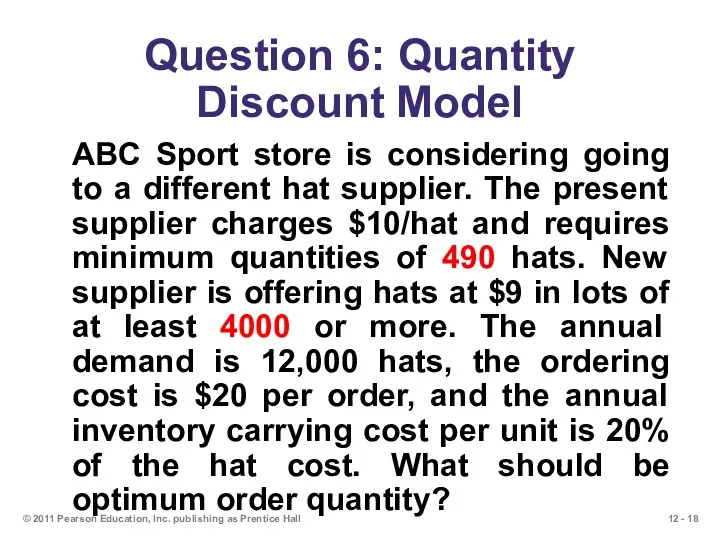

- 19. © 2011 Pearson Education, Inc. publishing as Prentice Hall Holding Cost= 0.20 x Purchasing price

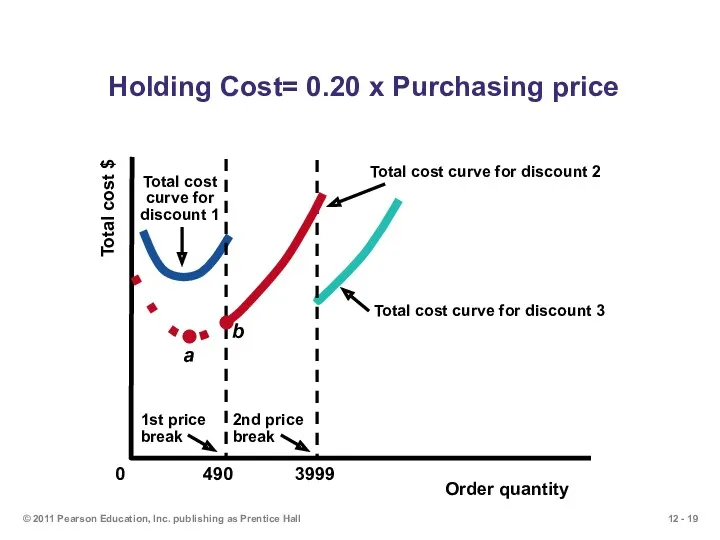

- 20. Question 7: Quantity Discount Model A company has a chance to reduce their inventory ordering costs

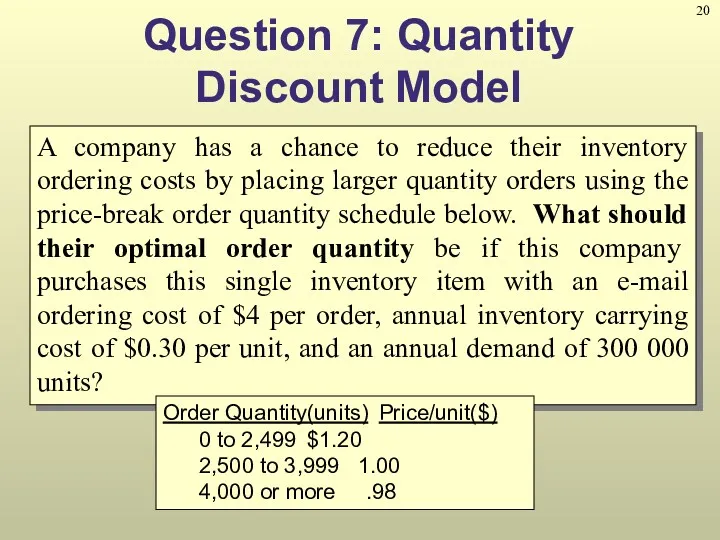

- 21. Total Cost with Constant Holding Costs In this case there is a single minimum point; all

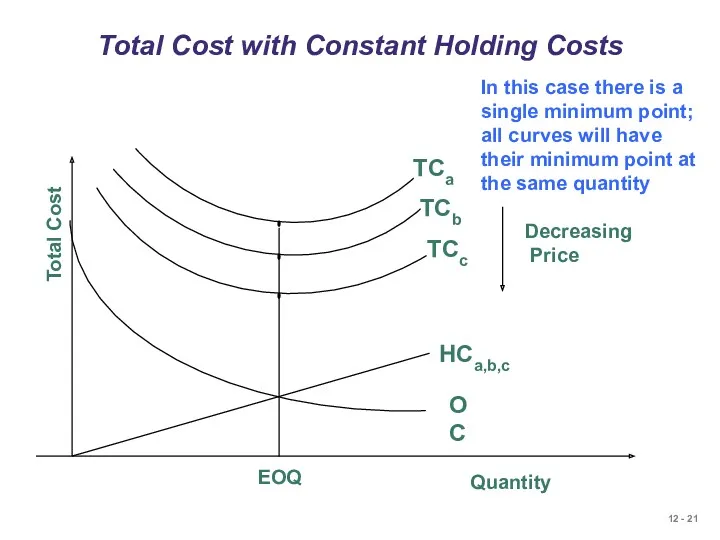

- 22. Question 8: Reorder Point for Variable Demand The manager of a carpet store wants to determine

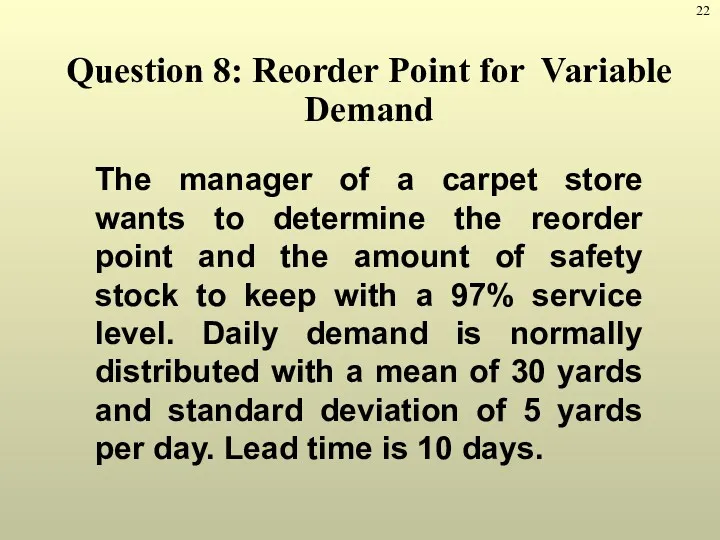

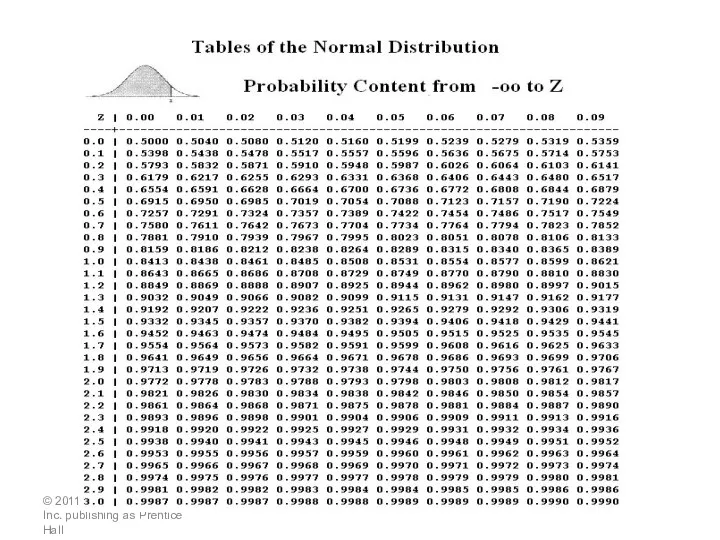

- 23. Demand per day is variable and lead time (in days) is constant ROP =(Average daily demand)

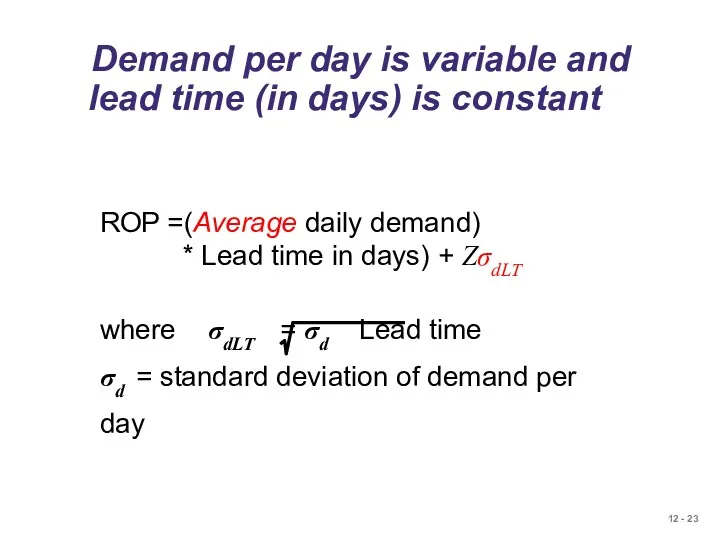

- 24. © 2011 Pearson Education, Inc. publishing as Prentice Hall

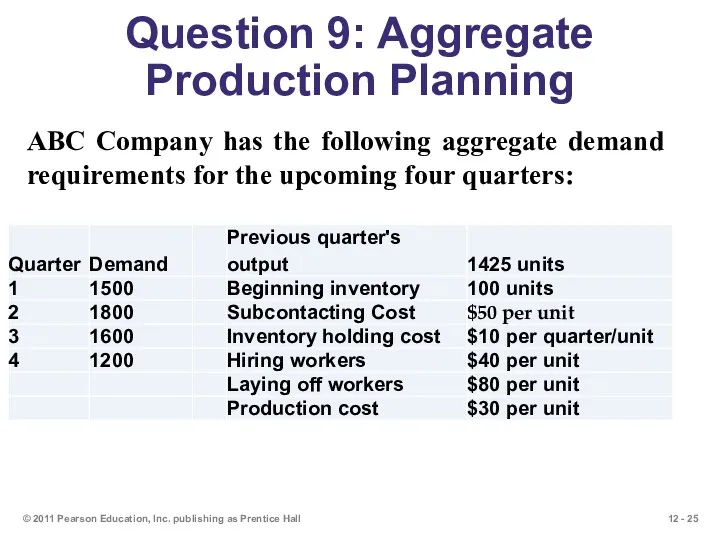

- 25. Question 9: Aggregate Production Planning © 2011 Pearson Education, Inc. publishing as Prentice Hall ABC Company

- 26. Question 9: Aggregate Production Planning Which of the following production plans is better: Plan A–chase demand

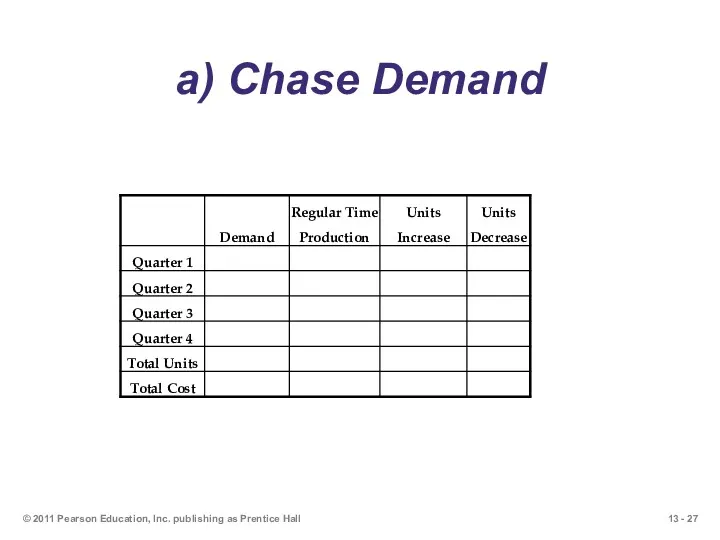

- 27. a) Chase Demand © 2011 Pearson Education, Inc. publishing as Prentice Hall

- 29. Скачать презентацию

Понятие и роль документационного обеспечения управления персоналом

Понятие и роль документационного обеспечения управления персоналом Программа рекомендаций. Referral program confidentia

Программа рекомендаций. Referral program confidentia Стандарт управления проектами. Процессы управления проектом

Стандарт управления проектами. Процессы управления проектом ВКР: Разработка прототипа информационной системы производственной логистики промышленного предприятия

ВКР: Разработка прототипа информационной системы производственной логистики промышленного предприятия Современное делопроизводство. Документационное обеспечение управления

Современное делопроизводство. Документационное обеспечение управления Разработка мероприятий по развитию событийного туризма в Тульской области

Разработка мероприятий по развитию событийного туризма в Тульской области В поиске работы

В поиске работы Управление человеческими ресурсами. Компетенция

Управление человеческими ресурсами. Компетенция Организационная структура управления

Организационная структура управления Диаграмма Парето

Диаграмма Парето Модели деловой карьеры

Модели деловой карьеры Транспортно-экспедиционное обслуживание при международных автомобильных перевозках

Транспортно-экспедиционное обслуживание при международных автомобильных перевозках Использование процессного подхода как средства совершенствования системы управления организацией

Использование процессного подхода как средства совершенствования системы управления организацией Модуль Управление персоналом (Нuman Resources). Управление организационными структурами

Модуль Управление персоналом (Нuman Resources). Управление организационными структурами Кейс-технологии

Кейс-технологии Концепция Точно в срок

Концепция Точно в срок Методологические основы менеджмента. Раздел 1

Методологические основы менеджмента. Раздел 1 Организация работы закусочной Блинная на 75 мест

Организация работы закусочной Блинная на 75 мест Zarządzanie agile

Zarządzanie agile Отчетная презентация СМС Санкт-Петербург-Балтийской дистанции пути за 3 квартал 2017 года

Отчетная презентация СМС Санкт-Петербург-Балтийской дистанции пути за 3 квартал 2017 года Личность в системе управления

Личность в системе управления Организационная структура управления проектом. Глава 4

Организационная структура управления проектом. Глава 4 Управління якістю води у виробництві харчових продуктів. Лекції № 7-8

Управління якістю води у виробництві харчових продуктів. Лекції № 7-8 Сущность и основные школы менеджмента

Сущность и основные школы менеджмента Тема 2. Альтернативные логистические стратегии: проблема выбора

Тема 2. Альтернативные логистические стратегии: проблема выбора Управление многоквартирным домом, управляющими организациями

Управление многоквартирным домом, управляющими организациями Баскет-метод

Баскет-метод Тайм-менджмент

Тайм-менджмент