Содержание

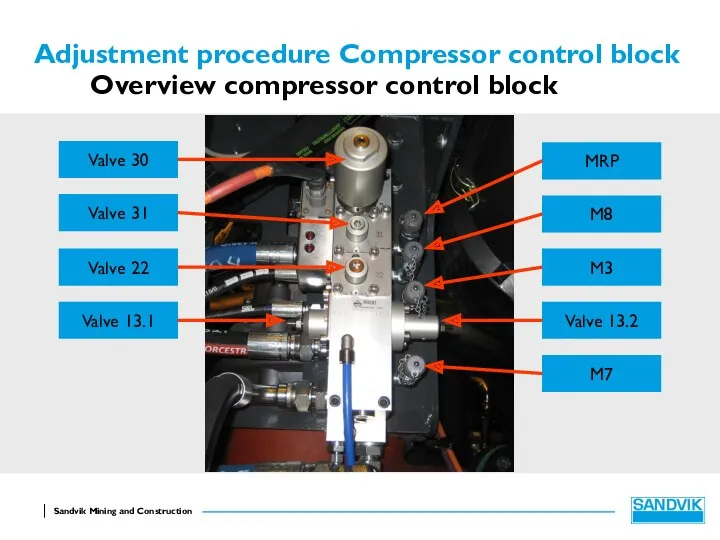

- 2. Adjustment procedure Compressor control block Overview compressor control block Valve 13.1 Valve 22 Valve 31 Valve

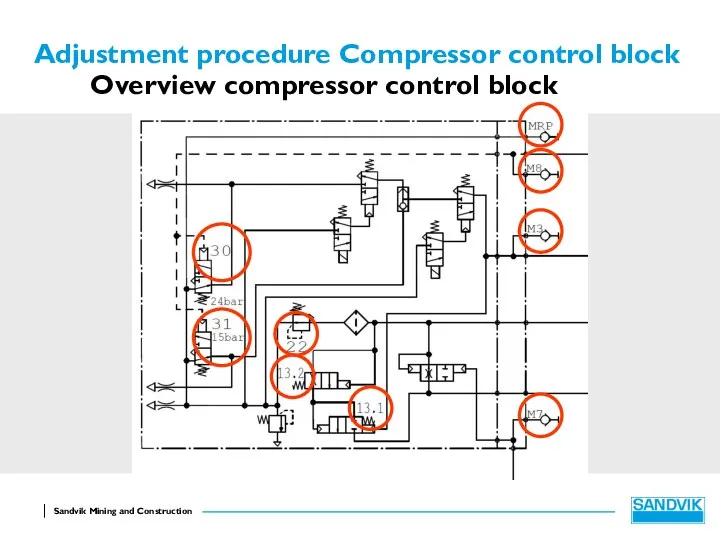

- 3. Adjustment procedure Compressor control block Overview compressor control block

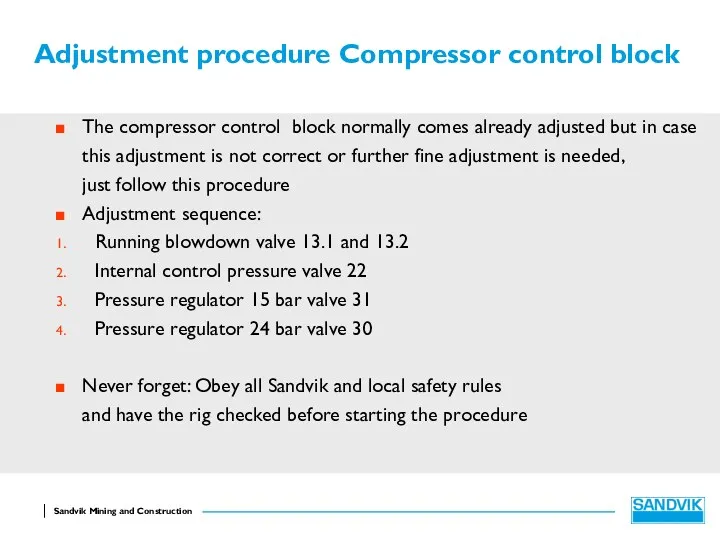

- 4. Adjustment procedure Compressor control block The compressor control block normally comes already adjusted but in case

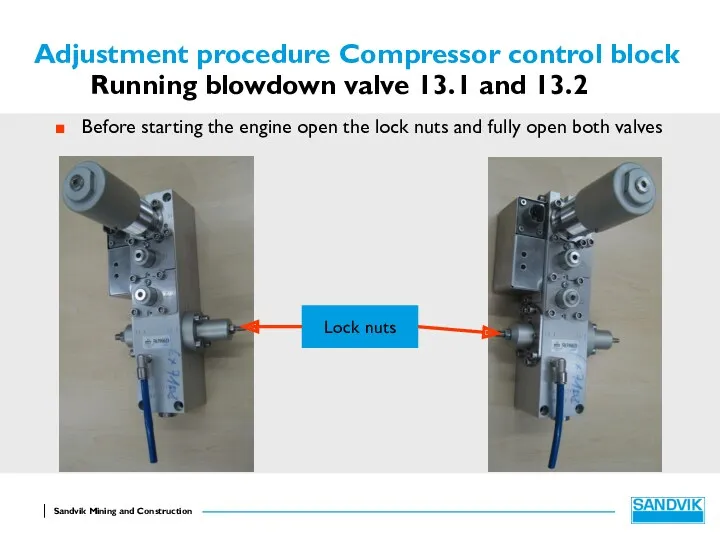

- 5. Adjustment procedure Compressor control block Running blowdown valve 13.1 and 13.2 Before starting the engine open

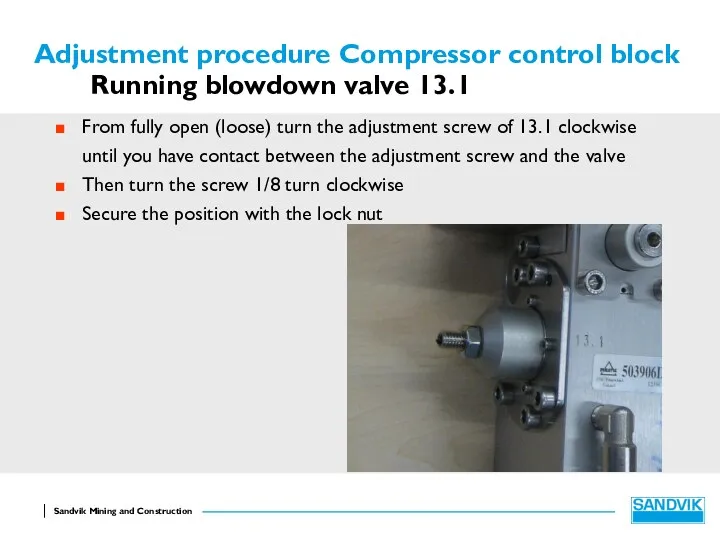

- 6. Adjustment procedure Compressor control block Running blowdown valve 13.1 From fully open (loose) turn the adjustment

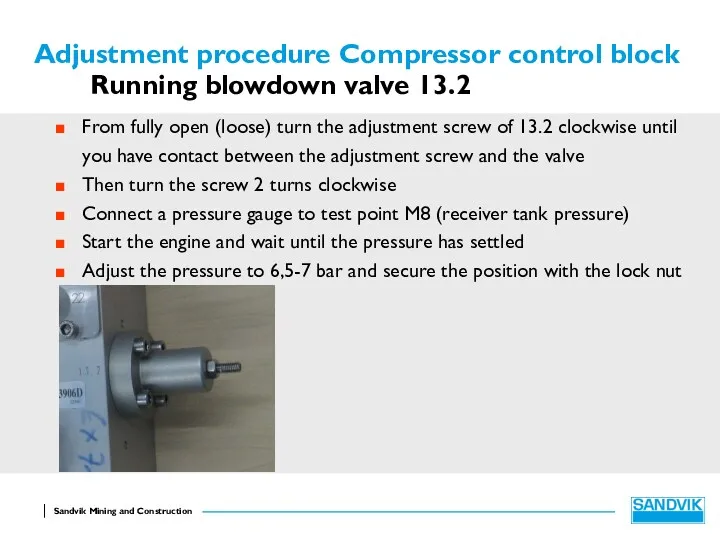

- 7. Adjustment procedure Compressor control block Running blowdown valve 13.2 From fully open (loose) turn the adjustment

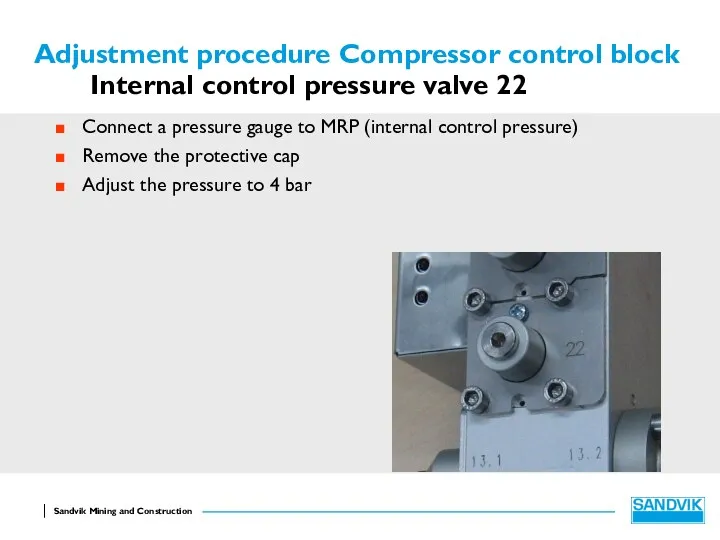

- 8. Adjustment procedure Compressor control block Internal control pressure valve 22 Connect a pressure gauge to MRP

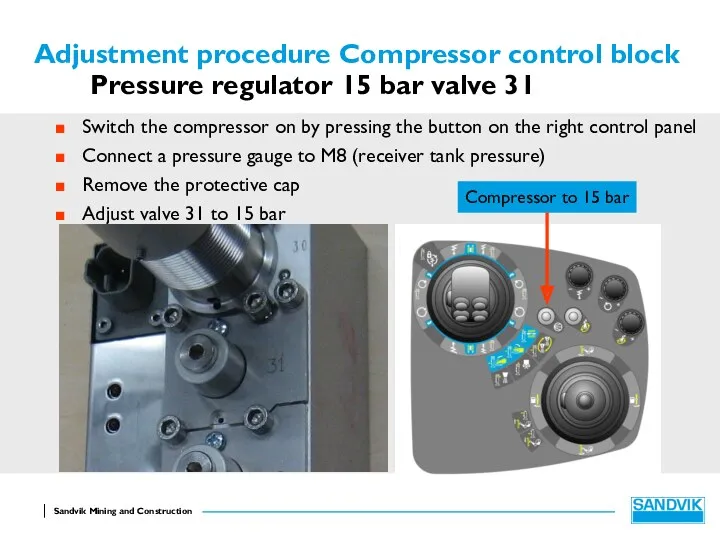

- 9. Adjustment procedure Compressor control block Pressure regulator 15 bar valve 31 Switch the compressor on by

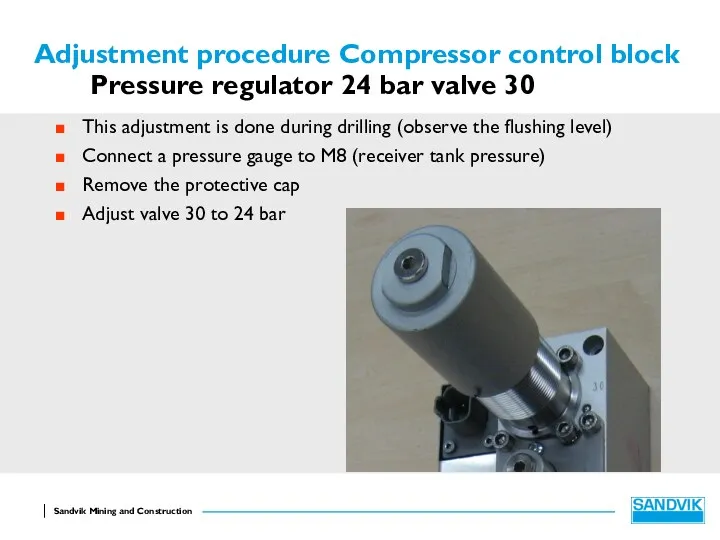

- 10. Adjustment procedure Compressor control block Pressure regulator 24 bar valve 30 This adjustment is done during

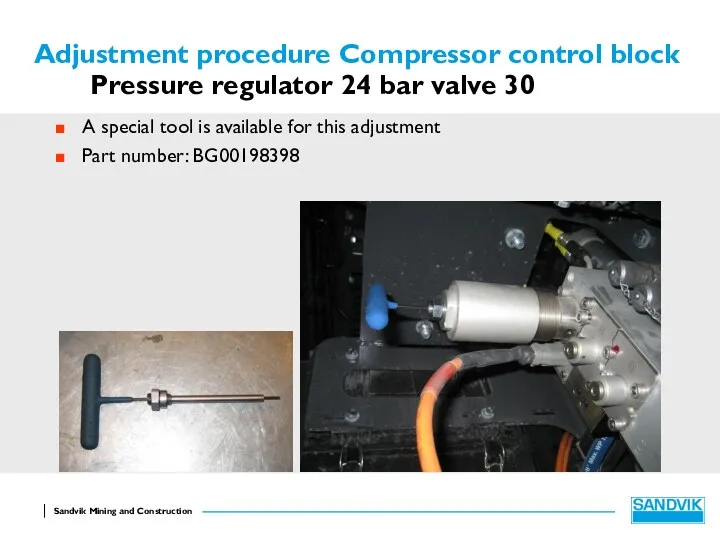

- 11. Adjustment procedure Compressor control block Pressure regulator 24 bar valve 30 A special tool is available

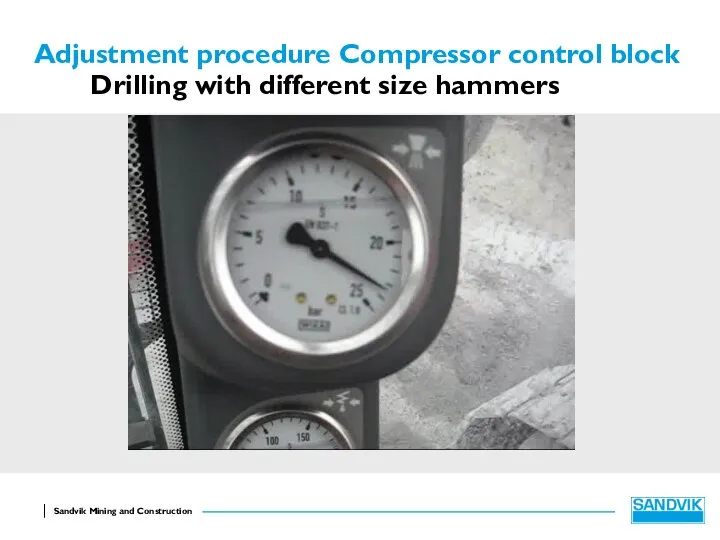

- 12. Adjustment procedure Compressor control block Drilling with different size hammers

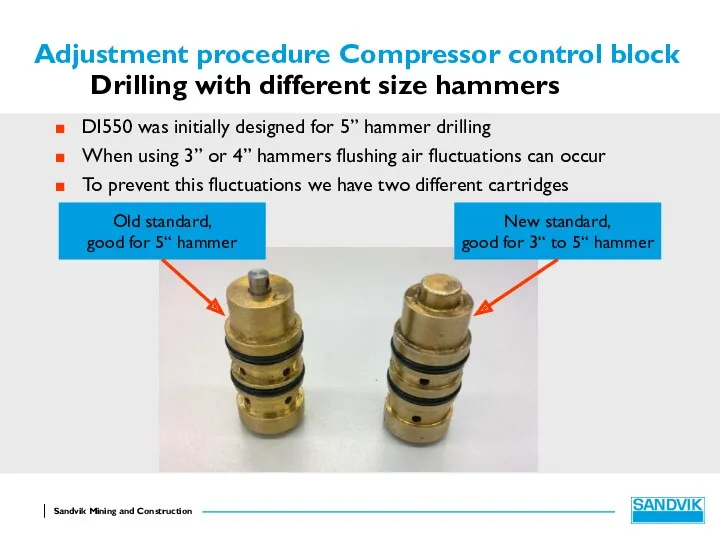

- 13. Adjustment procedure Compressor control block Drilling with different size hammers DI550 was initially designed for 5”

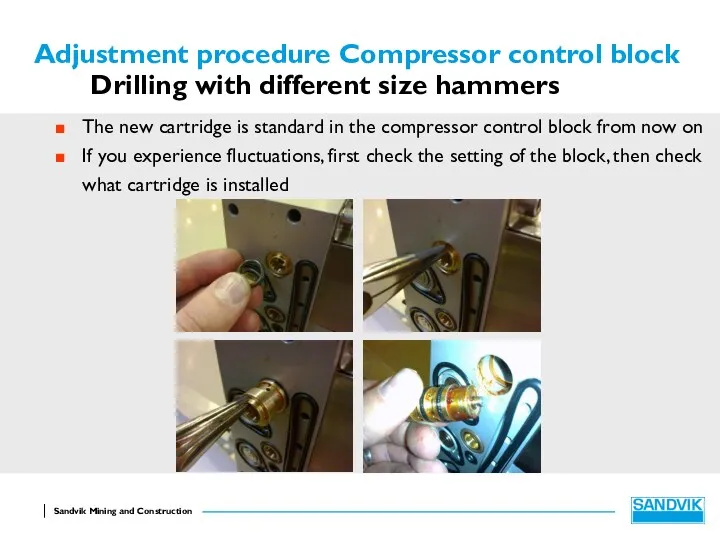

- 14. Adjustment procedure Compressor control block Drilling with different size hammers The new cartridge is standard in

- 15. Adjustment procedure Compressor control block Drilling with small size hammers When drilling with 3” or 4”

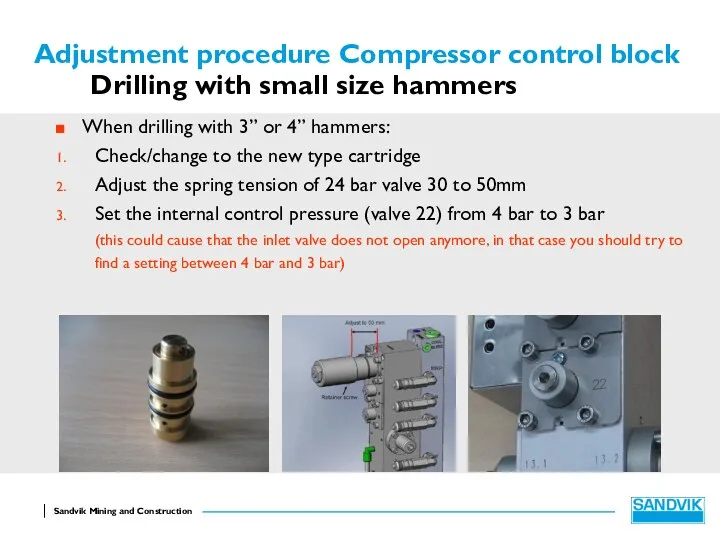

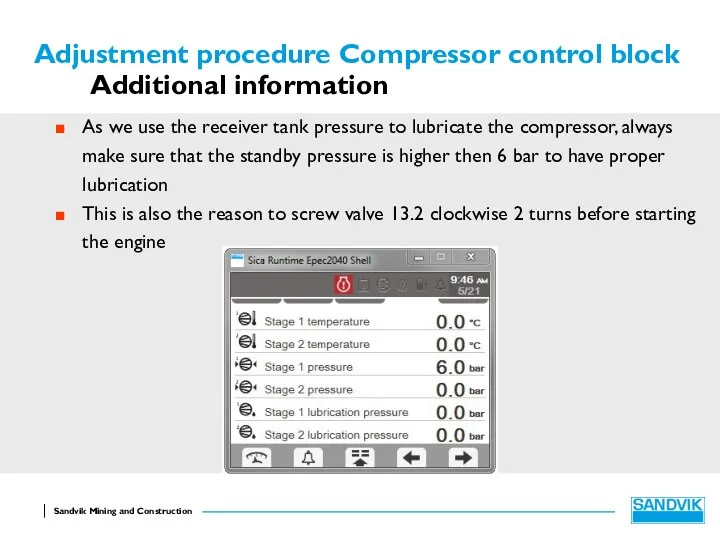

- 16. Adjustment procedure Compressor control block Additional information As we use the receiver tank pressure to lubricate

- 18. Скачать презентацию

Презентация с картинками по пдд

Презентация с картинками по пдд Йод р-н 5% . Нітроглицерин

Йод р-н 5% . Нітроглицерин Своя игра. География

Своя игра. География Стратегическое развитие предприятия: выбор и обоснование направлений

Стратегическое развитие предприятия: выбор и обоснование направлений ИППП (хламидиоз)

ИППП (хламидиоз) Назначение и классификация общесудовых систем. Тема 2.1

Назначение и классификация общесудовых систем. Тема 2.1 ЭЛОУ-АТ-6 (блок ЭЛОУ). Электродегидратор

ЭЛОУ-АТ-6 (блок ЭЛОУ). Электродегидратор Оригами. Геометрия бумажного листа

Оригами. Геометрия бумажного листа Деловой этикет в Италии

Деловой этикет в Италии часть

часть НЕПРЕРЫВНОЕ ПРОФИЛЬНОЕХУДОЖЕСТВЕННО-ЭСТЕТИЧЕСКОЕ ОБРАЗОВАНИЕВ ШКОЛЕ ИСКУССТВ С УГЛУБЛЕННЫМ ИЗУЧЕНИЕМПРЕДМЕТОВ ИСКУССТВА

НЕПРЕРЫВНОЕ ПРОФИЛЬНОЕХУДОЖЕСТВЕННО-ЭСТЕТИЧЕСКОЕ ОБРАЗОВАНИЕВ ШКОЛЕ ИСКУССТВ С УГЛУБЛЕННЫМ ИЗУЧЕНИЕМПРЕДМЕТОВ ИСКУССТВА Методологические принципы проектирования организационных структур

Методологические принципы проектирования организационных структур Государственные символы России. Конституция РФ

Государственные символы России. Конституция РФ Лекарственная проблематика лечения метастатических поражений головного мозга

Лекарственная проблематика лечения метастатических поражений головного мозга Подготовка к ЕГЭ по органической химии.

Подготовка к ЕГЭ по органической химии. Обзор книги Брайана Трейси Выйди из зоны комфорта. Измени свою жизнь. 21 метод повышения личной эффективности

Обзор книги Брайана Трейси Выйди из зоны комфорта. Измени свою жизнь. 21 метод повышения личной эффективности Шахтоуправление Добропольское

Шахтоуправление Добропольское Презентация Образовательные программы в системе дополнительного образования детей

Презентация Образовательные программы в системе дополнительного образования детей Синхронный генератор

Синхронный генератор История дизайна. Архитектурно-художественное творчество в Советской России

История дизайна. Архитектурно-художественное творчество в Советской России Народная педагогика конца XIX века

Народная педагогика конца XIX века Стартап - ресторан 100 юаней

Стартап - ресторан 100 юаней презентация к классному часу Курить - здоровью вредить

презентация к классному часу Курить - здоровью вредить Лечение аномалий окклюзии зубных рядов

Лечение аномалий окклюзии зубных рядов Презентация Русские народные костюмы

Презентация Русские народные костюмы Презентация Основы коррекционной работы по ФФН Диск

Презентация Основы коррекционной работы по ФФН Диск Шаблон игры Учись различать звонкие и глухие согласные звуки

Шаблон игры Учись различать звонкие и глухие согласные звуки Акцентуации черт характера

Акцентуации черт характера