Содержание

- 2. Exercise 1. Answer the questions: What temperature does a creep show up at under the action

- 3. New words and expressions: Melting point – точка плавления – еру нүктесі, межесі Elongate – расстягиваться

- 4. Exercise 2. Make up sentences using the following words and word combinations: To elongate continuously, face-centered

- 5. GREEP. STRESS RUPTURE AND STRAIN HARDENING As metals are exposed to temperatures within 40 percent of

- 6. The usage range of temperature for steel ranges from – 460 F to almost 2000 F

- 7. The strain-hardening behavior of a metal depends on its lattice structure. In face-centered cubic crystallographic structures,

- 8. Severely strained metal may have a elongated grains with distorted and twisted lattices and a strong

- 9. Exercise 3. Complete the following sentences from the text The usage range of temperature for steel

- 11. Скачать презентацию

Механизмы и формы видообразования

Механизмы и формы видообразования Устройство и конструкция основных элементов холодного водопровода (Тема 2)

Устройство и конструкция основных элементов холодного водопровода (Тема 2) Единая система конструкторской документации

Единая система конструкторской документации Определение жесткости токарного станка производственным методом

Определение жесткости токарного станка производственным методом Методическая разработка презентации: Развитие анализа структуры предложения

Методическая разработка презентации: Развитие анализа структуры предложения Сырье для производства строительной керамики. Часть 2

Сырье для производства строительной керамики. Часть 2 Организация свободного времени подростка. Труд и отдых в летние каникулы

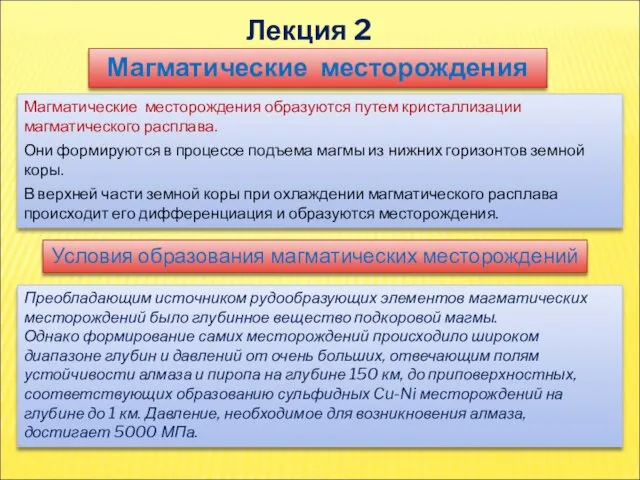

Организация свободного времени подростка. Труд и отдых в летние каникулы Магматические месторождения. (Лекция 2)

Магматические месторождения. (Лекция 2) Wybory sąmorzadowe

Wybory sąmorzadowe Проектирование программы духовно-нравственного воспитания

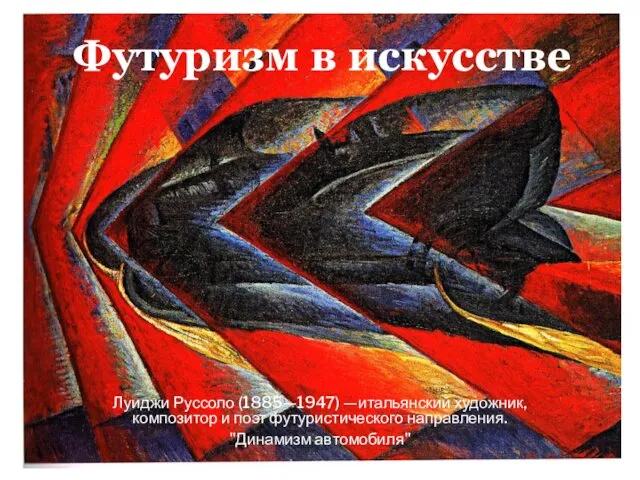

Проектирование программы духовно-нравственного воспитания Футуризм в искусстве

Футуризм в искусстве конспект занятия Определение азимута

конспект занятия Определение азимута Знаки-помощники

Знаки-помощники Развитие коммуникативной функции речи у дошкольников с ОНР

Развитие коммуникативной функции речи у дошкольников с ОНР Монолог-рассуждение о влиянии наркотических веществ на организм человека

Монолог-рассуждение о влиянии наркотических веществ на организм человека Изменения политической системы

Изменения политической системы Изменения в нормативном регулировании строительства. Практическое применение положений законодательства

Изменения в нормативном регулировании строительства. Практическое применение положений законодательства Треугольник. Равенство и подобие треугольников

Треугольник. Равенство и подобие треугольников Как стать добрым человеком

Как стать добрым человеком Имена существительные, которые имеют форму только единственного числа

Имена существительные, которые имеют форму только единственного числа Растительность Уссурийской тайги

Растительность Уссурийской тайги Железные дороги сложной конфигурации в горах

Железные дороги сложной конфигурации в горах Образцы основных документов управления

Образцы основных документов управления Использование роз в ландшафтной архитектуре музея-заповедника Ясная Поляна

Использование роз в ландшафтной архитектуре музея-заповедника Ясная Поляна Презентация к родительскому собранию Зелёная аптека на окне

Презентация к родительскому собранию Зелёная аптека на окне Кардиоэмболический инсульт

Кардиоэмболический инсульт Кормовые культуры в Северном регионе Казахстана

Кормовые культуры в Северном регионе Казахстана Безопасность в сети интернет

Безопасность в сети интернет