Содержание

- 2. Li-ion Technology: where are we today Although tremendous progress has been made over the last couple

- 3. Sources of Thermal Instability The three main battery components (anode, cathode, electrolyte etc) all jointly contribute

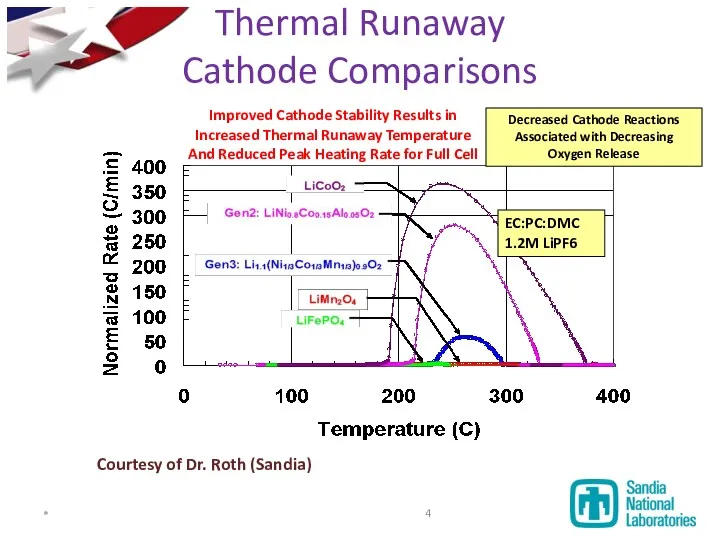

- 4. Improved Cathode Stability Results in Increased Thermal Runaway Temperature And Reduced Peak Heating Rate for Full

- 5. Potential path forward to overcoming the constraints Replacement of carbon materials with Nano-particulate metal, semi-metal, intermetallic

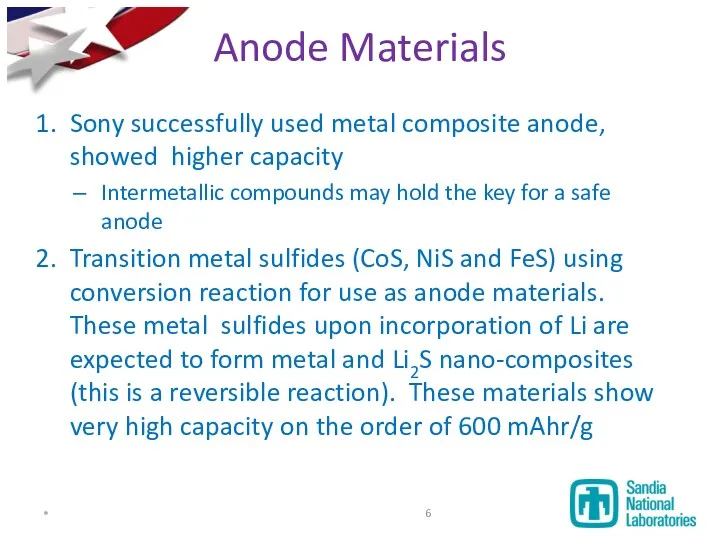

- 6. Sony successfully used metal composite anode, showed higher capacity Intermetallic compounds may hold the key for

- 7. Sony’s hybrid lithium-ion rechargeable battery *

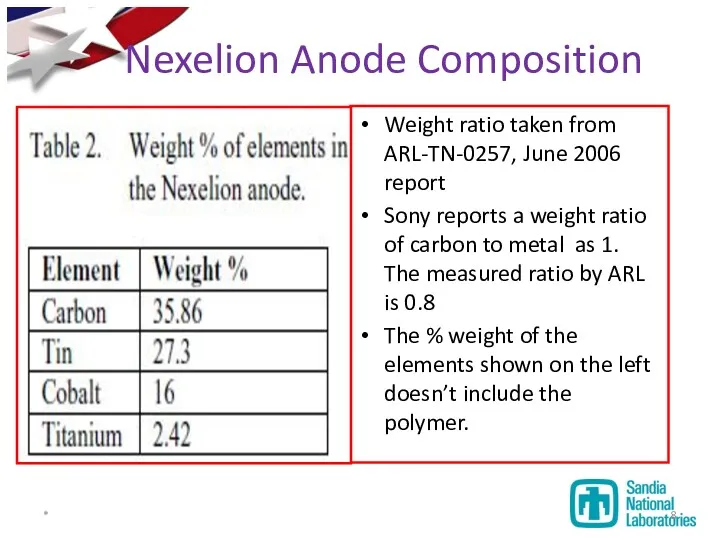

- 8. Weight ratio taken from ARL-TN-0257, June 2006 report Sony reports a weight ratio of carbon to

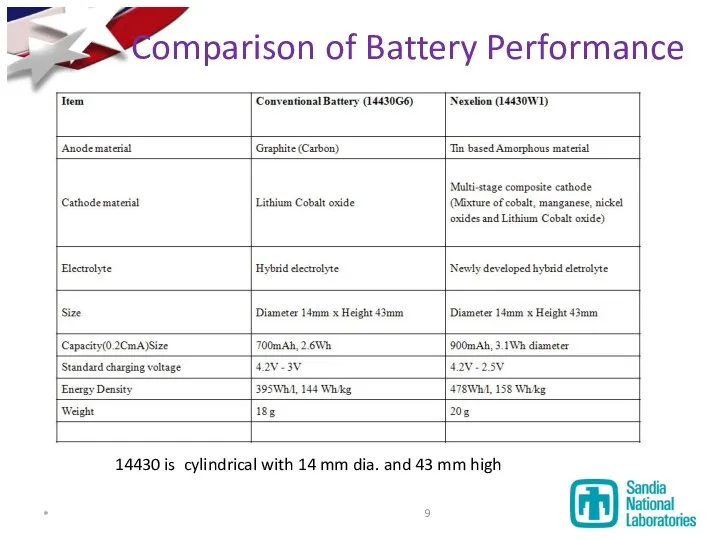

- 9. Comparison of Battery Performance 14430 is cylindrical with 14 mm dia. and 43 mm high *

- 10. Only 50% of the Li content can be taken out before the structure collapses Lower capacity

- 11. Ways to Improving Cathode Performance Increasing Energy Density Investigate high voltage cathodes that can deliver all

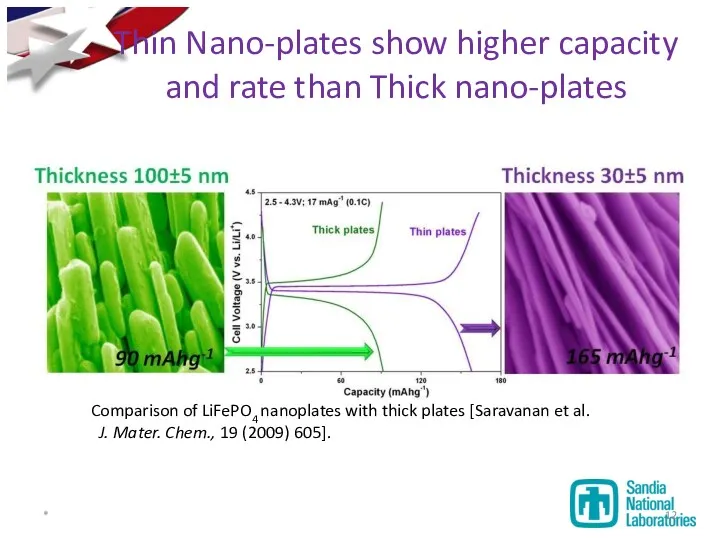

- 12. Thin Nano-plates show higher capacity and rate than Thick nano-plates *

- 13. AlF3 Coated Electrodes The surface coating of electrodes seem to improve capacity retention and performance over

- 14. Potential Cathode Materials Olivine based phosphates systems (LiMPO4 where M = Mn, Ni) that can deliver

- 15. Electrolyte (solvent + salt) The state-of-the-art electrolytes for Li-ion cells contain a blend of organic carbonate

- 16. New Solvents New fluoro solvents are being investigated as nonflammable solvents Solvent with a F to

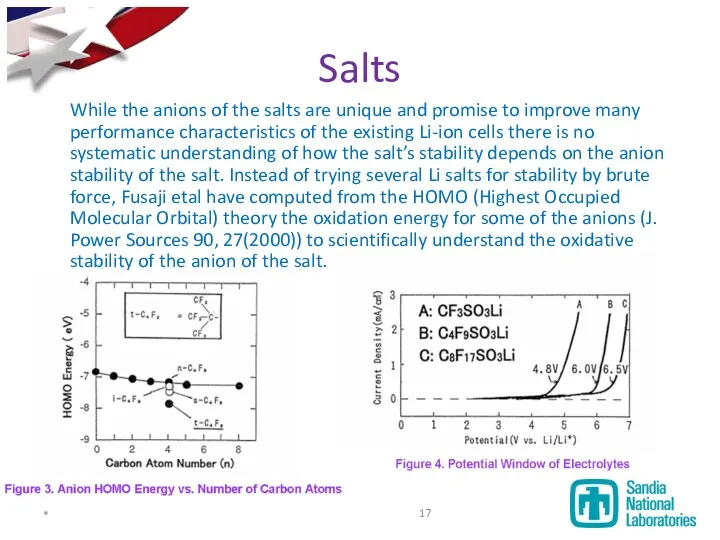

- 17. Salts While the anions of the salts are unique and promise to improve many performance characteristics

- 19. Скачать презентацию

Качество Кубани

Качество Кубани Суть управления в обществе и его уровни

Суть управления в обществе и его уровни Пятна

Пятна Асептика и антисептика 222

Асептика и антисептика 222 Характеристика проблемного поля состояния социального предпринимательства в регионах Российской Федерации

Характеристика проблемного поля состояния социального предпринимательства в регионах Российской Федерации Презентация Метод детского экспериментирования

Презентация Метод детского экспериментирования Физкультминутка к уроку татарского языка Диск

Физкультминутка к уроку татарского языка Диск 20231203_cash_flow_denezhnyy_potok_1

20231203_cash_flow_denezhnyy_potok_1 Чувствительная функция нервной системы. Чувствительность и ее расстройства. Боль. Ноцицептивные и антиноцицептивные системы мозга

Чувствительная функция нервной системы. Чувствительность и ее расстройства. Боль. Ноцицептивные и антиноцицептивные системы мозга Классификация холодильных машин

Классификация холодильных машин Акционерное общество Всероссийский нефтегазовый научно-исследовательский институт имени академика А.П.Крылова

Акционерное общество Всероссийский нефтегазовый научно-исследовательский институт имени академика А.П.Крылова Балалардағы жүрек ырғағының бұзылысы

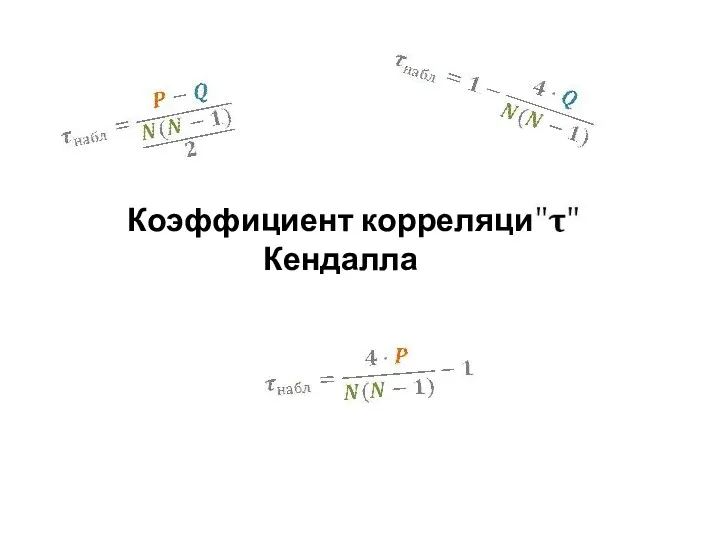

Балалардағы жүрек ырғағының бұзылысы Коэффициент корреляции τ Кендалла

Коэффициент корреляции τ Кендалла Миссия и цели организации

Миссия и цели организации Арбитраж. 9 поток

Арбитраж. 9 поток С годом российского депутата

С годом российского депутата Президентские гранты на развитие гражданского общества. Социальное проектирование

Президентские гранты на развитие гражданского общества. Социальное проектирование Компания LG Group

Компания LG Group Новые технологии дорожного строительства97-2003

Новые технологии дорожного строительства97-2003 Сельское хозяйство, его отраслевая структура

Сельское хозяйство, его отраслевая структура Корпоративное управление

Корпоративное управление Методические рекомендации по разработке и оформлению дополнительной общеобразовательной общеразвивающей программы

Методические рекомендации по разработке и оформлению дополнительной общеобразовательной общеразвивающей программы Взаимодействие с родителями при работе над проектом:Наш родной город -Колпино.

Взаимодействие с родителями при работе над проектом:Наш родной город -Колпино. Немного о своей работе

Немного о своей работе 5 игр на знакомство

5 игр на знакомство Работа в MS Visio 2016. Фигуры (часть 2)

Работа в MS Visio 2016. Фигуры (часть 2) Камера приема очистного устройства трубопроводов

Камера приема очистного устройства трубопроводов Жалобная книга природы

Жалобная книга природы