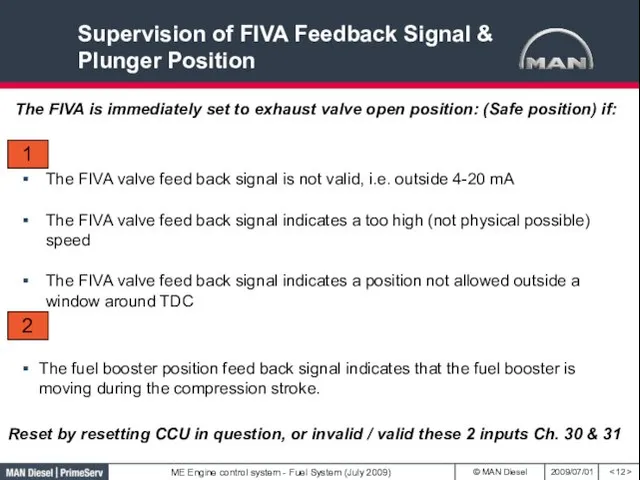

Supervision of FIVA Feedback Signal & Plunger Position

< >

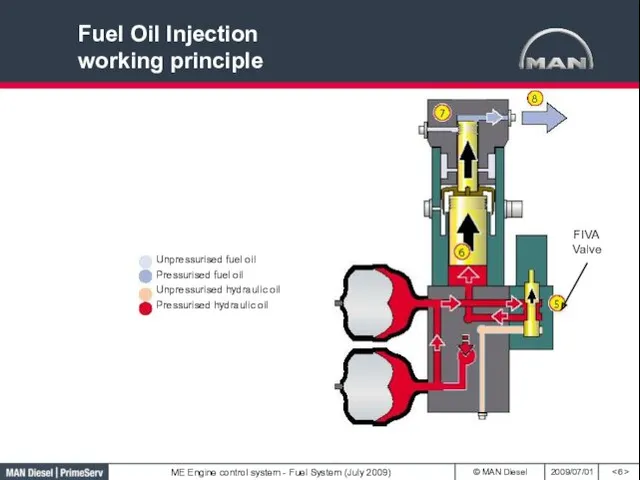

The FIVA valve

feed back signal is not valid, i.e. outside 4-20 mA

The FIVA valve feed back signal indicates a too high (not physical possible) speed

The FIVA valve feed back signal indicates a position not allowed outside a window around TDC

2

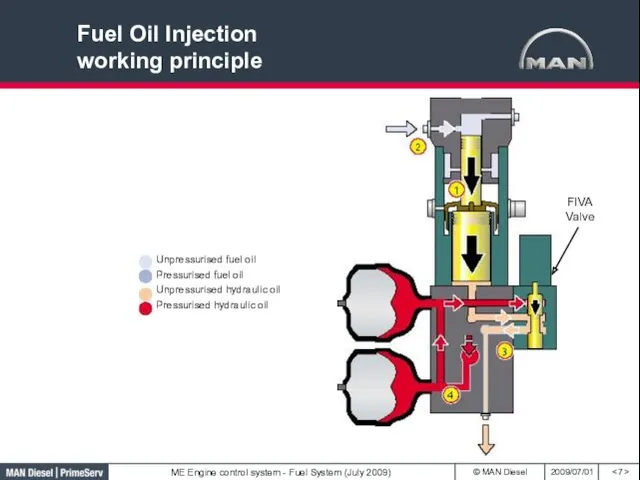

The fuel booster position feed back signal indicates that the fuel booster is moving during the compression stroke.

The FIVA is immediately set to exhaust valve open position: (Safe position) if:

1

Reset by resetting CCU in question, or invalid / valid these 2 inputs Ch. 30 & 31

Проект Мир театрав первой младшей группе

Проект Мир театрав первой младшей группе Отчет о прохождении производственной практики

Отчет о прохождении производственной практики Школьная студия Кадр 39

Школьная студия Кадр 39 Автоматизована система керування блоком живлення промислового робота-маніпулятора з сервоприводами постійного струму (АКБ)

Автоматизована система керування блоком живлення промислового робота-маніпулятора з сервоприводами постійного струму (АКБ) Презентация Олимпийские игры в Сочи 2014 г.

Презентация Олимпийские игры в Сочи 2014 г. Образовательная деятельность в разновозрастном детском сообществе Светлячок (Центр развития ребёнка - детский сад № 5 Колокольчик города Белёв Тульской области)

Образовательная деятельность в разновозрастном детском сообществе Светлячок (Центр развития ребёнка - детский сад № 5 Колокольчик города Белёв Тульской области) Российская империя в первой половине XIX века

Российская империя в первой половине XIX века Clinical impact of new data from AASLD 2015

Clinical impact of new data from AASLD 2015 Измерение площади

Измерение площади формирование ключевых компетенций

формирование ключевых компетенций Valooto Investor Deck - Apr23

Valooto Investor Deck - Apr23 Разливка и обработка сплавов. Способы разливки алюминиевых сплавов

Разливка и обработка сплавов. Способы разливки алюминиевых сплавов Мусульманские праздники

Мусульманские праздники Система счисления

Система счисления Мастер-класс Подарок своими руками.Поделки из кожи

Мастер-класс Подарок своими руками.Поделки из кожи Роль и значение тематического выездного туризма в мировом туроперейтинге

Роль и значение тематического выездного туризма в мировом туроперейтинге prezetantsia

prezetantsia релакс минутка Диск

релакс минутка Диск Качества члена команды

Качества члена команды Подготовка выпускников к ЕГЭ по проблемным заданиям курса ботаники

Подготовка выпускников к ЕГЭ по проблемным заданиям курса ботаники Суточный и годовой ход температуры. ВПР биология 6 класс 2018 г

Суточный и годовой ход температуры. ВПР биология 6 класс 2018 г Физические свойства Металлов

Физические свойства Металлов Классный час в начальной школе по теме При пожаре не сидим, набираем 01

Классный час в начальной школе по теме При пожаре не сидим, набираем 01 Педагогическая антропология в России

Педагогическая антропология в России Предмет астрономии

Предмет астрономии Романский стиль

Романский стиль презентация на тему Закрепляем правила дорожного движения.

презентация на тему Закрепляем правила дорожного движения. Теплообменные аппараты

Теплообменные аппараты