Содержание

- 2. This presentation should be considered as the vehicle for all the facilitators and participants to lead

- 3. MARPOL and other legal requirements for the protection of the environment

- 4. A systematic and controlled way for ensuring that all seafarers meet or exceed the minimum requirements

- 5. Training Agenda MARPOL ANNEX I - Prevention of Pollution by Oil MARPOL ANNEX II - Prevention

- 6. MARPOL ANNEX I Prevention of Pollution by Oil Section 1

- 7. MARPOL ANNEX I Handling of Oil and Oily Mixtures from Machinery Spaces Applicable to all Ships

- 8. Definition of Oily Bilge Water - Oil Residue (Sludge) What is considered as oily bilge water?

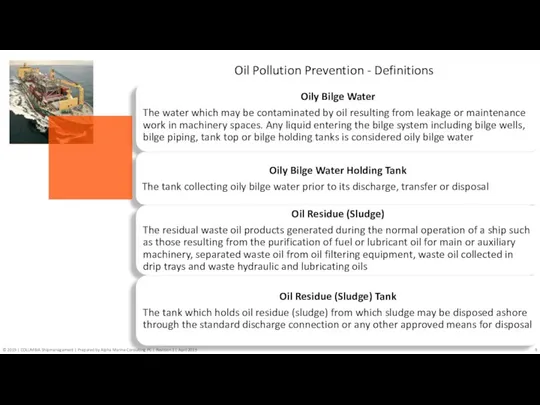

- 9. Oil Pollution Prevention - Definitions

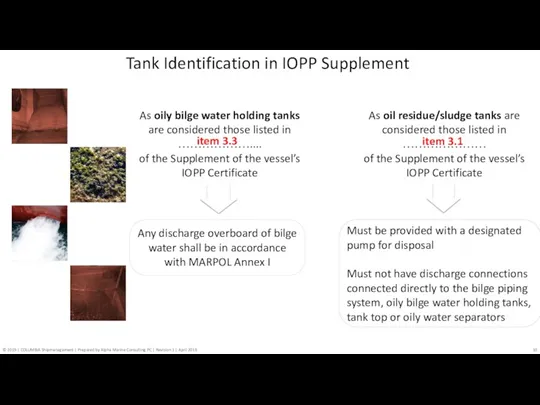

- 10. As oily bilge water holding tanks are considered those listed in ……………….... of the Supplement of

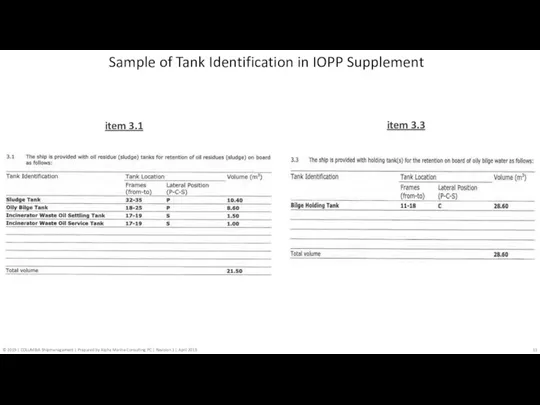

- 11. item 3.1 item 3.3 Sample of Tank Identification in IOPP Supplement

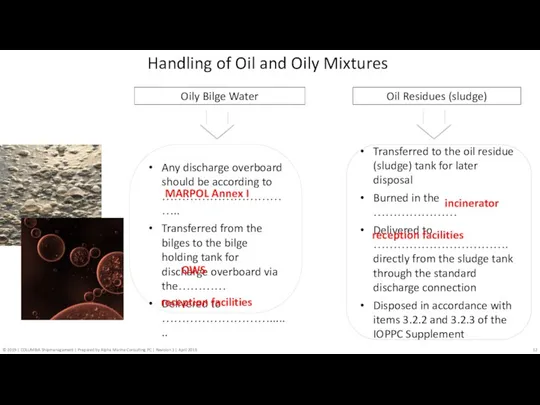

- 12. Handling of Oil and Oily Mixtures Oily Bilge Water Transferred to the oil residue (sludge) tank

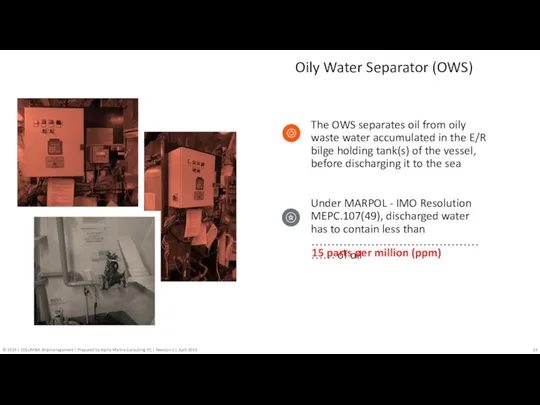

- 13. Oily Water Separator (OWS) The OWS separates oil from oily waste water accumulated in the E/R

- 14. The OWS must be: capable of handling any oily mixtures from the machinery space bilges effective

- 15. Who are allowed to operate the OWS as per MSOPR-11.2 ? Discussion Only the Chief Engineer

- 16. Discussion How can we ensure that there is no method to discharge bilges overboard by by-passing

- 17. The OCM is a monitoring equipment connected with the OWS, for measuring, indicating and continuously detecting

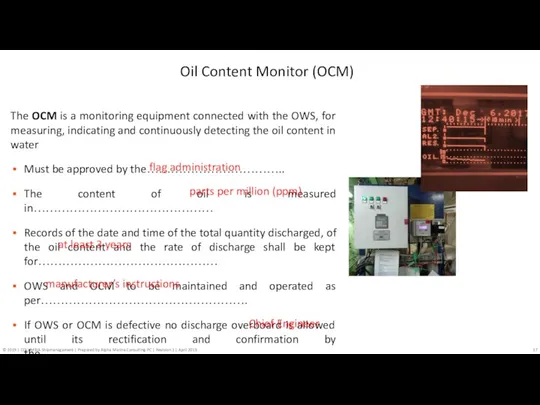

- 18. The OCM must be calibrated at intervals not exceeding 5 years after its commissioning, or as

- 19. Example of how an OWS with absorber works Rough separation: An eccentric spiral pump draws the

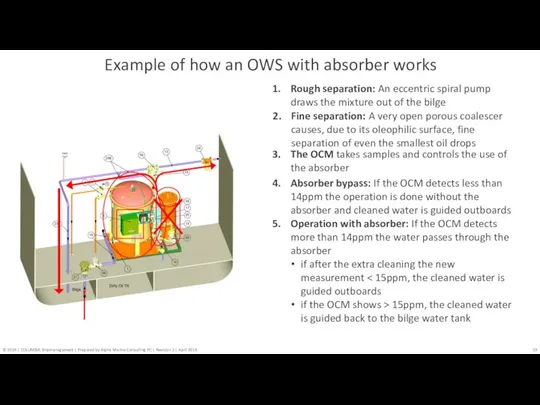

- 20. VIDEO PRESENTATION OF OWS Source : https://www.youtube.com/watch?v=1sQ3hAE6XQs

- 21. Certificates Required On Board IOPP (International Oil Pollution Prevention) Certificate and Supplement Validity for 5 years

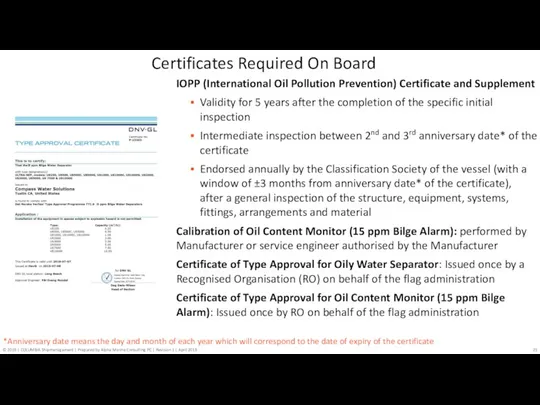

- 22. Discharge of Oil and Oily Mixtures Name the conditions that must be satisfied to discharge of

- 23. Discharge of Oil and Oily Mixtures What are the differences between discharging of oily bilge water

- 24. The Mediterranean sea area The Baltic sea area The Black sea area The Red sea area

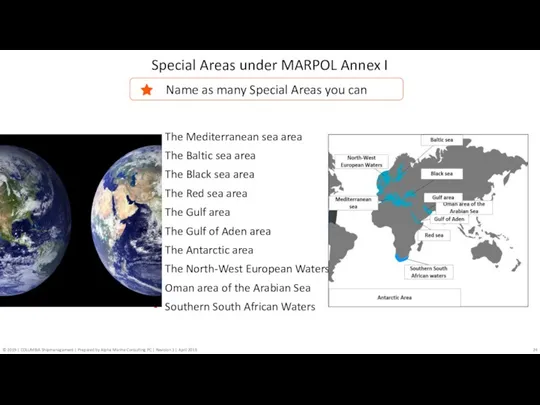

- 25. Posting General Practice for Documents Required to be Posted in the Vicinity of OWS: Bilge Piping

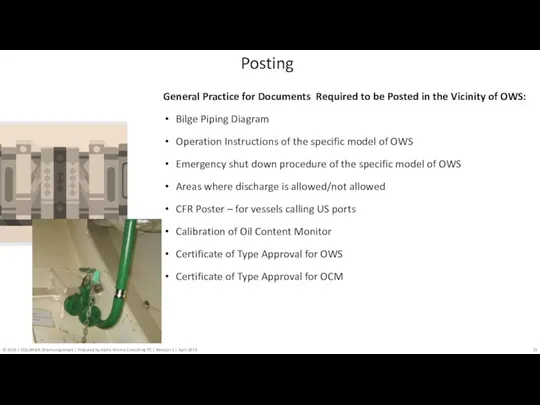

- 26. Discussion What should you do in the case that the bilge water tanks are full and

- 27. Discussion- possible reactions Transfer the bilges to other tank(s), approved by the Class, for later disposal

- 28. MARPOL ANNEX I Handling of Oil and Oily Mixtures from Cargo Spaces - Slops Applicable to

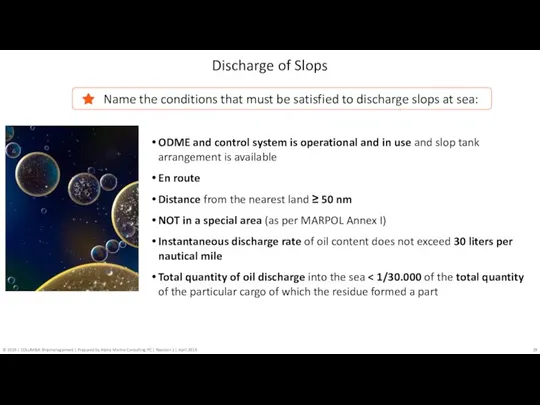

- 29. ODME and control system is operational and in use and slop tank arrangement is available En

- 30. Bilge - Sludge - Slop Management Record Keeping Company’s Policy Rough notes, sounding logs and/or other

- 31. Violation Consequences What do you think that the violations of MARPOL Annex I may result in

- 32. Discussion Why do you think that we must not pollute the marine environment?

- 33. Discussion – Possible answers Because: We destroy the environment It is against Company’s Environmental Policy and

- 34. MARPOL ANNEX II Prevention of Pollution by Noxious Liquid Substances in Bulk Section 2

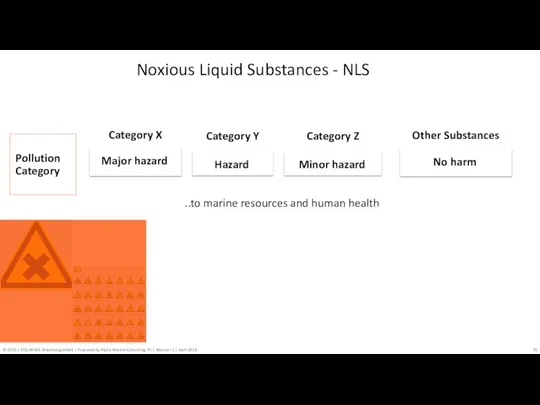

- 35. Noxious Liquid Substances - NLS Pollution Category ..to marine resources and human health

- 36. NLS Discharge Provisions En route ≥ 7 kn (for self-propelled ships) ≥ 4 kn (for not

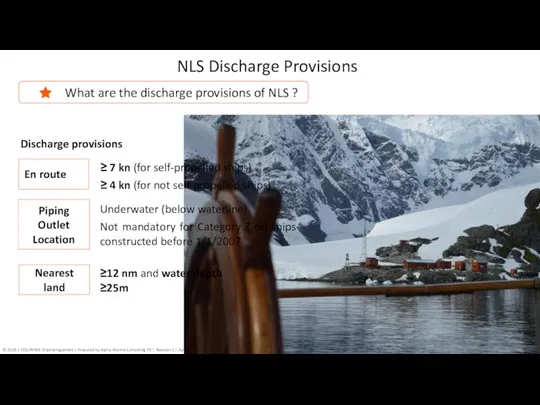

- 37. Certificates & Manuals on Board What Certificates & Manuals are on board the ship to ensure

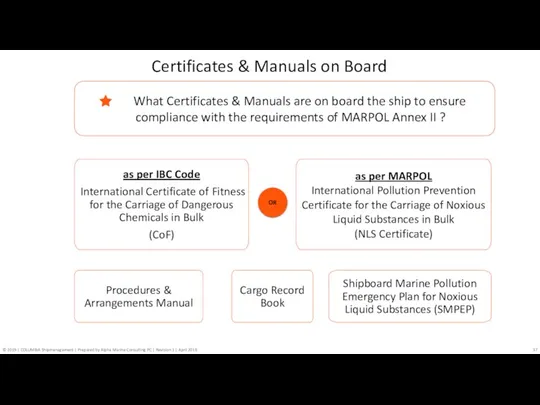

- 38. MARPOL ANNEX III Prevention of Pollution by Harmful Substances Carried by Sea in Packaged Form Section

- 39. Harmful substances: as identified by International Maritime Dangerous Goods (IMDG) Code Packaged form: the form of

- 40. MARPOL ANNEX IV Prevention of Pollution by Sewage Section 4

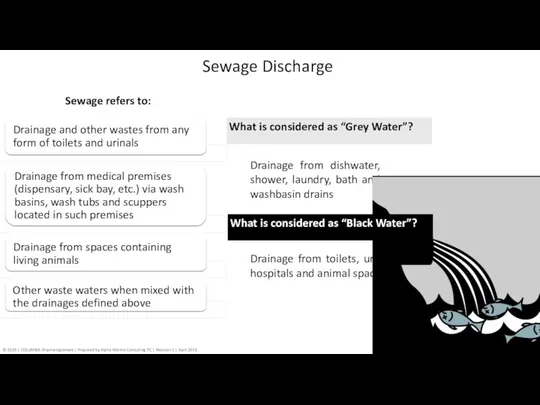

- 41. Sewage refers to: Drainage from dishwater, shower, laundry, bath and washbasin drains Sewage Discharge What is

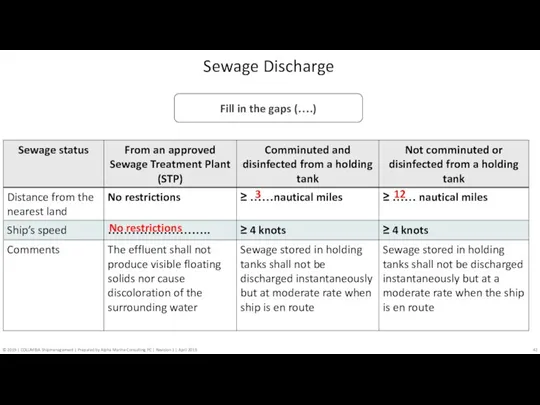

- 42. Sewage Discharge Fill in the gaps (….) 3 12 No restrictions

- 43. For example, in the United States, specific waters are designated as "no discharge zones" where treated

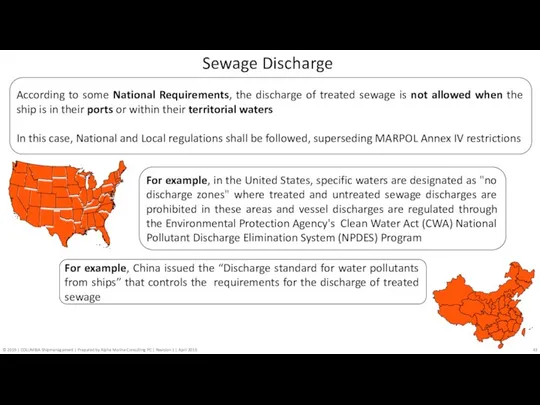

- 44. STP Operation and Maintenance Sewage spills into bilge tanks must be prevented In case STP is

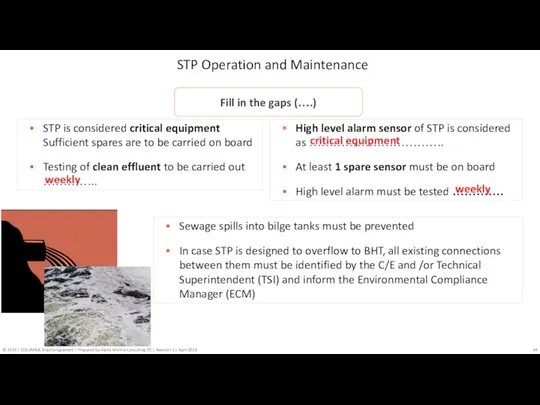

- 45. Grey Water Management and Other Ports Specific Requirements No existing requirement under MARPOL Regulated under Vessel

- 46. MARPOL ANNEX V Prevention of Pollution by Garbage Section 5

- 47. All kinds of food wastes, domestic wastes and operational wastes, all plastics, cargo residues, incinerator ashes,

- 48. 100 GT and Above Certified to carry 15 or more persons All ships Shall carry a

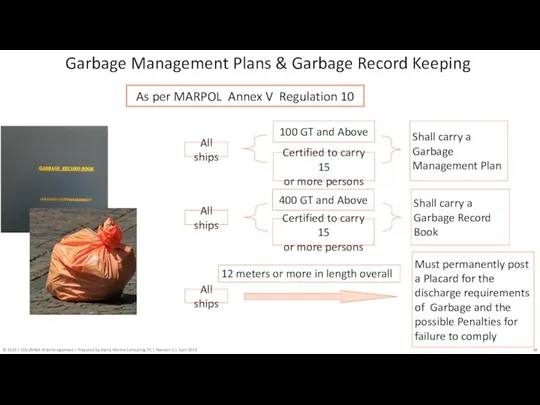

- 49. Garbage Categories According to the Garbage Management Plan, which color corelates to each type of the

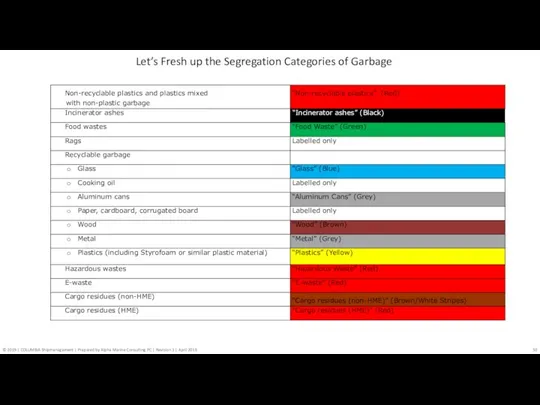

- 50. Let’s Fresh up the Segregation Categories of Garbage

- 51. Garbage Categories A. Plastics B. Food Waste C. Domestic waste D. Cooking Oil E. Incinerator ashes

- 52. All solid waste, including slurries from the normal maintenance or operations of the ship, or used

- 53. As E-waste is considered all the electrical and electronic equipment used for the normal operation of

- 54. Amendments concerning the Garbage Record Book GRB - PART I All ships For all garbage except

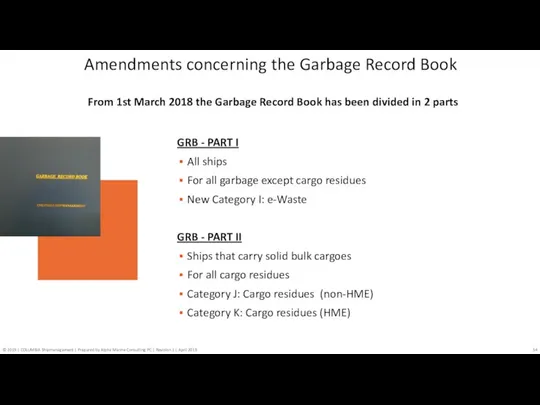

- 55. Special Areas under Annex V: Garbage

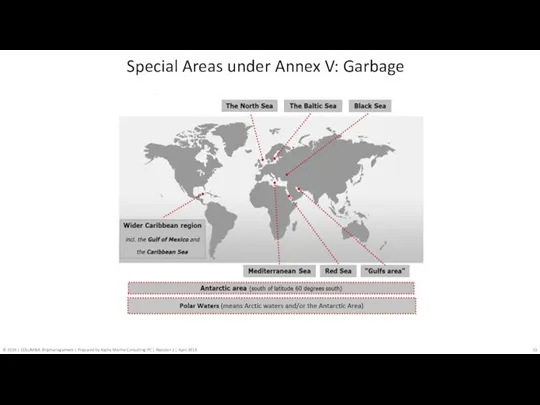

- 56. Garbage must be kept in metal rust free containers or plastic non-combustible containers only inside the

- 57. Discussion What actions should you take if you notice a crewmember not to comply with the

- 58. Discussion – Possible actions Stop the crewmember in case an environmental breach is imminent Inform the

- 59. MARPOL ANNEX VI Prevention of Air Pollution Section 6

- 60. All vessels with diesel engines installed onboard on or after 1/1/2000 with power output more than

- 61. Engine Certification and Survey Requirements Reduction of NOx emissions Engine Technical File Contains the identification of

- 62. Engine International Air Pollution Prevention Certificate Sample Reduction of NOx emissions

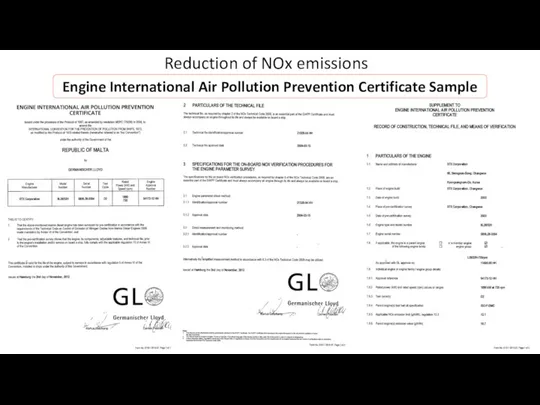

- 63. The EIAPP certificate of each engine Whether the Engine NOx emission affecting components, as detailed in

- 64. Since the “Engine Parameter Check’’ is an indirect method, the following additional documents should become available

- 65. Maintaining the engines according to NOx regulations Check that the operational parameters are logged and are

- 66. The Baltic Sea Area The North Sea Area The North American Area The US Caribbean Sea

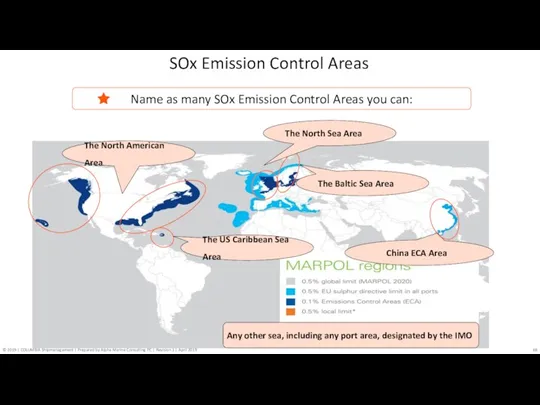

- 67. Maximum Permitted Sulphur Content of Fuel

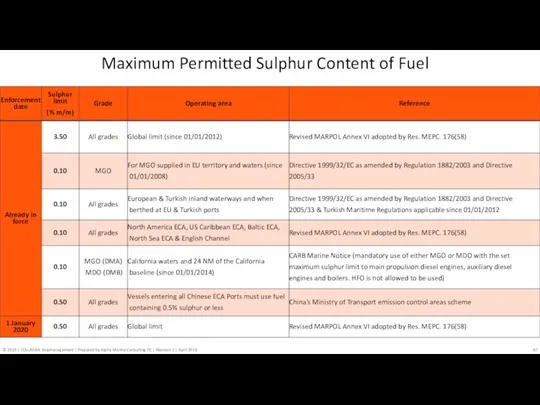

- 68. Ensure that vessels operations will fully comply with the MARPOL Annex VI requirements regarding SOx emissions,

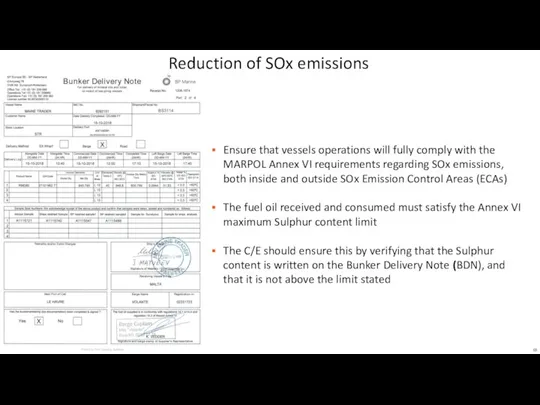

- 69. http:/www.seatrade-maritime.com/news/europe/denmark-to-deploy-sniffer-drone-to-help-enforce-sulphur-cap-regulation.html http://sulphur2020.online/blog/norway-orders-more-drones-to-enforce-sulfur-regs/ https://www.ukpandi.com/fileadmin/uploads/uk-pi/Documents/Legal_sources/Sulphur_Emissions2.pdf Useful Links with Articles About Monitoring Compliance with IMO 2020 Sulphur Global Fuel

- 70. Start enough time prior to entering the ECA, to ensure that upon crossing the ECA border

- 71. General Practice for Change-over Procedures Where is the Company’s Change-over Procedure From High Sulphur Fuel Oil

- 72. Change-over procedure calculation The MSOF-2.2 FOBAS Change-Over Calculator What tool is available on board to calculate

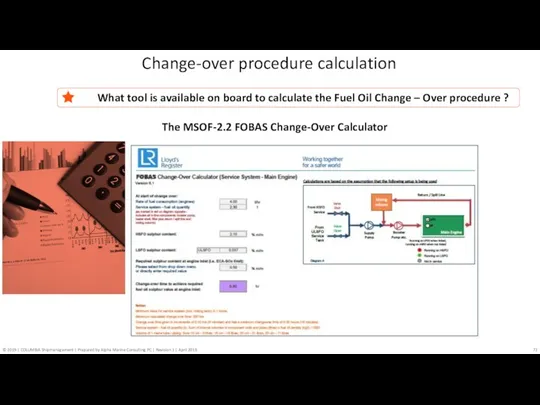

- 73. SHIP IMPLEMENTATION PLAN The Ship Implementation Plan (SIP) is outlining how the ship may prepare in

- 74. Control of Volatile Organic Compounds (VOCs) Vessels carrying crude oil and trading in terminals at which

- 75. Control of Incineration Emissions Incineration of the following substances is prohibited Cargo residues of crude oil

- 76. Chlorofluorocarbons (CFC) Halon Carbon tetrachloride, Methyl chloroform Hydrobromofluorocarbons (HBFCs) Hydrochlorofluorocarbons (HCFCS) (R22, R141b) Methyl Bromide Bromochloromethane

- 77. Recover and reuse refrigerants by using a recovery unit, together with an empty gas bottle which

- 78. SEEMP Ship Energy Efficiency Management Plan Section 7

- 79. SEEMP Part I – Applicability According to MARPOL Annex VI Chapter 4 Regulations 19 & 22:

- 80. SEEMP Part I Improved voyage planning Weather routing Just in time Speed optimization Optimized shaft power

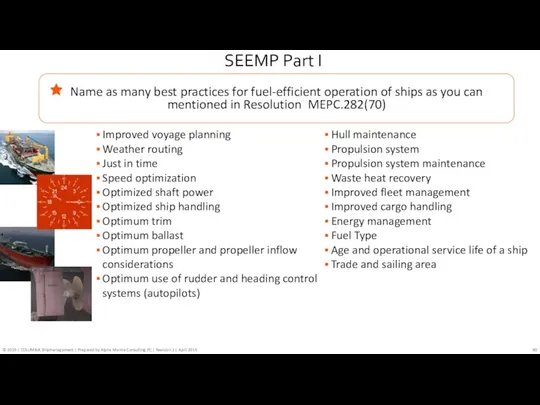

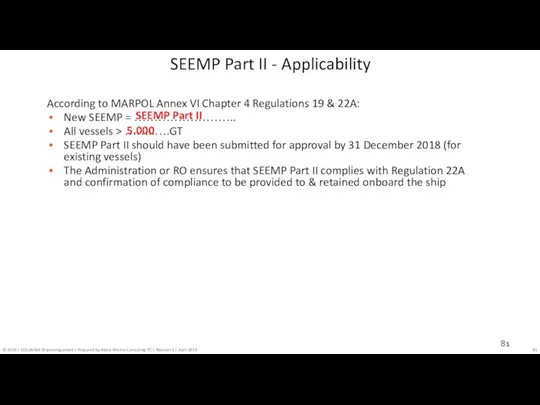

- 81. According to MARPOL Annex VI Chapter 4 Regulations 19 & 22A: New SEEMP = …………………….. All

- 82. Introduction (Emission Factors, etc.) Methodology Fuel Consumption Conversion factor CF Distance Travelled Hours Underway Data Quality

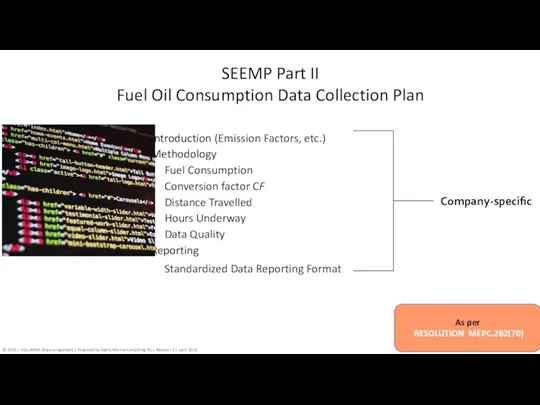

- 83. The EEOI is an approach to assess the efficiency of a ship with respect to CO2

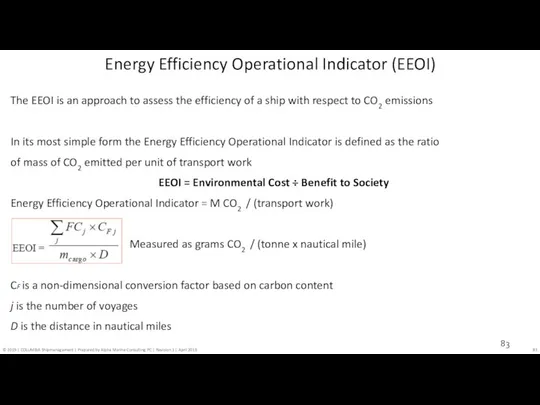

- 84. Energy Efficiency Operational Indicator (EEOI) CF for HFO : 3.1144 CF for LFO : 3.151 CF

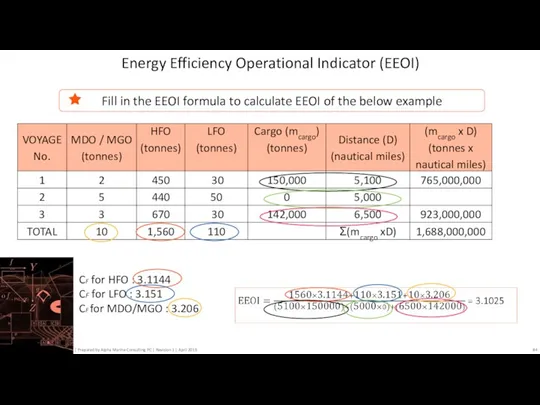

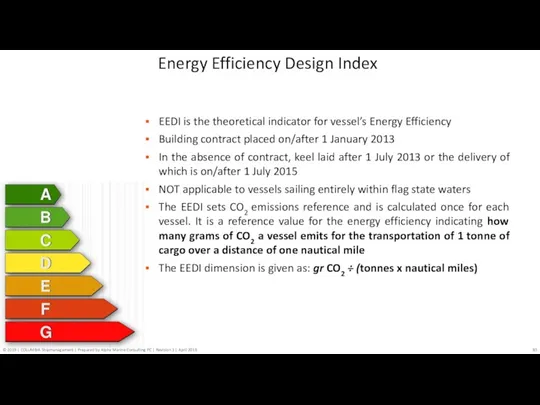

- 85. EEDI is the theoretical indicator for vessel’s Energy Efficiency Building contract placed on/after 1 January 2013

- 86. Main engine(s) Aux. engine(s) Energy saving technology for auxiliary power Energy saving technology for main power

- 87. EU MRV - IMO DCS Section 8

- 88. Carbon Dioxide (CO2 ) An inevitable product when we get energy from burning the carbon in

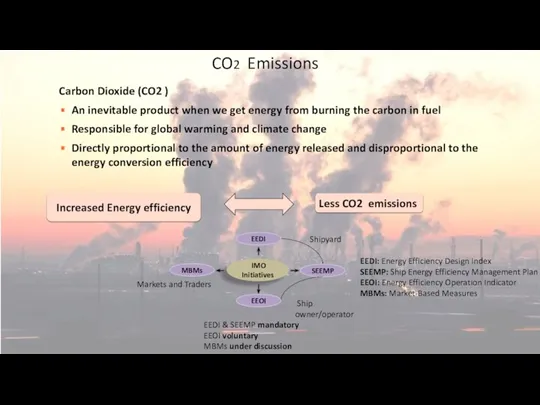

- 89. What does EU MRV stand for and what is it scope? What does IMO DCS stand

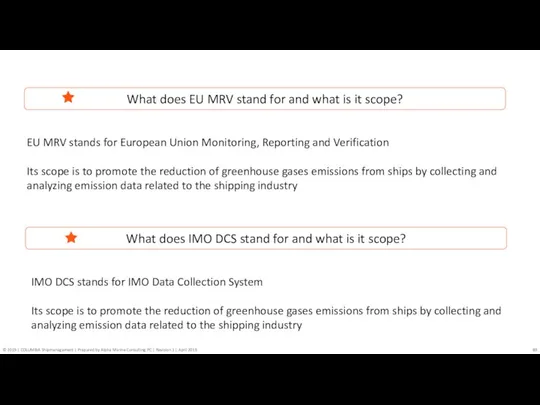

- 90. The EU scheme has focus on CO2 emissions from shipping activities to, from and within the

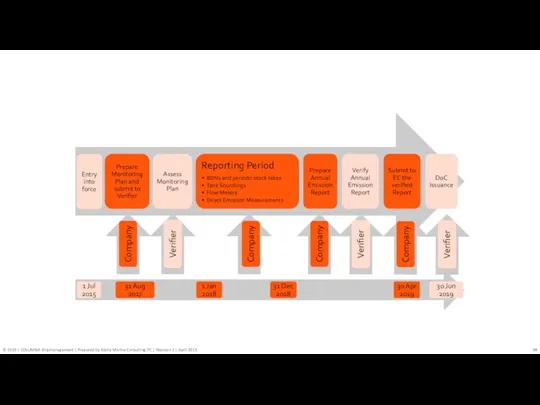

- 91. Reporting only for voyages to / from EU ports Reporting for all voyages Monitoring commenced on

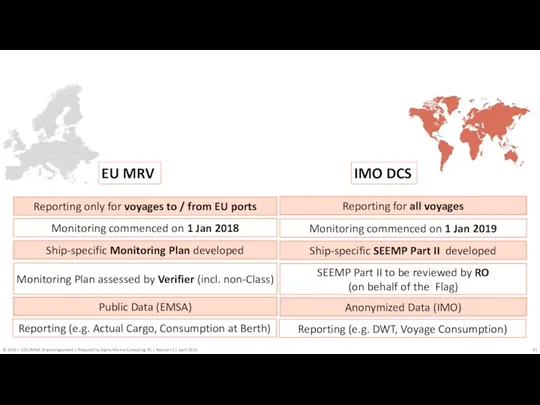

- 92. Actual Cargo Carried over each voyage Summer DWT (as per approved T&S Booklet) Consumption at Berth

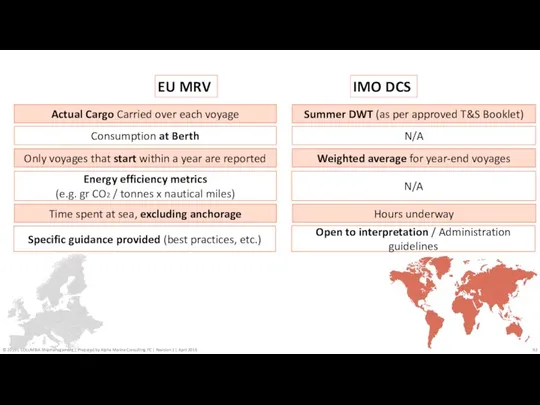

- 93. For all vessels >5000 GT: Include all voyages to and from an EU port and EFTA

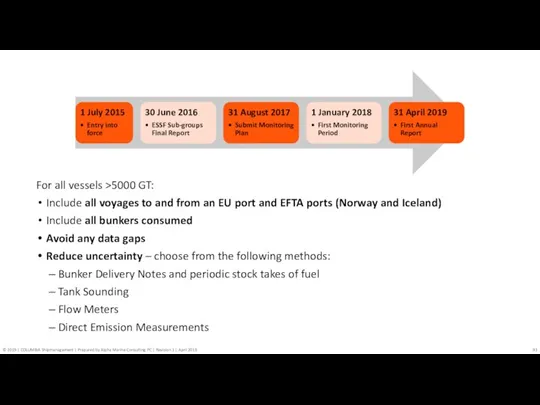

- 94. Which ships fall under the scope of the EU MRV – IMO DCS regulations? Which voyages

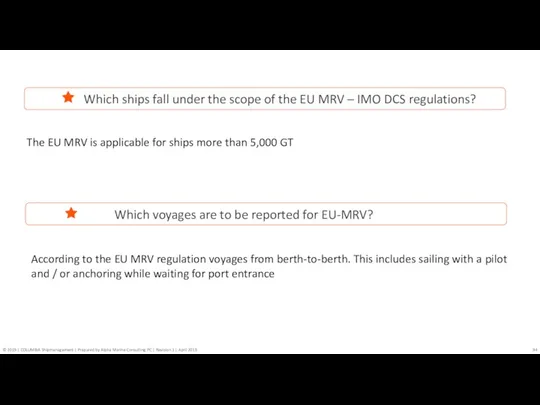

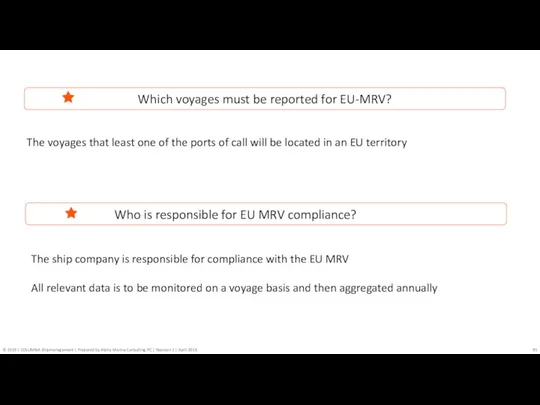

- 95. Which voyages must be reported for EU-MRV? Who is responsible for EU MRV compliance? The voyages

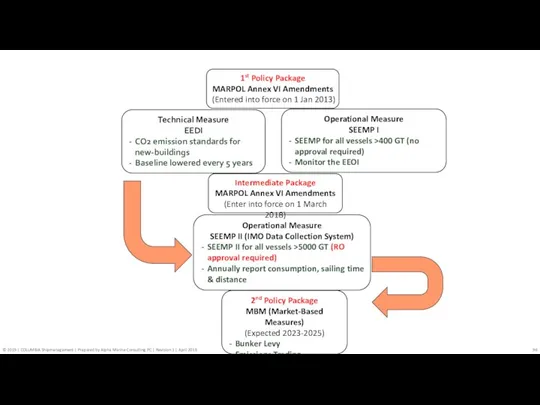

- 96. 1st Policy Package MARPOL Annex VI Amendments (Entered into force on 1 Jan 2013) Technical Measure

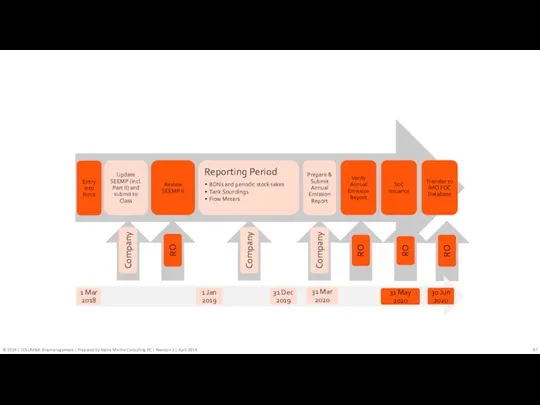

- 97. 31 May 2020

- 99. Vessel General Permit 2013 (VGP) Section 9

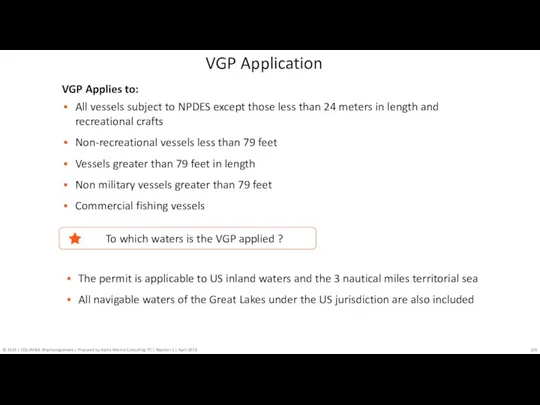

- 100. VGP Applies to: All vessels subject to NPDES except those less than 24 meters in length

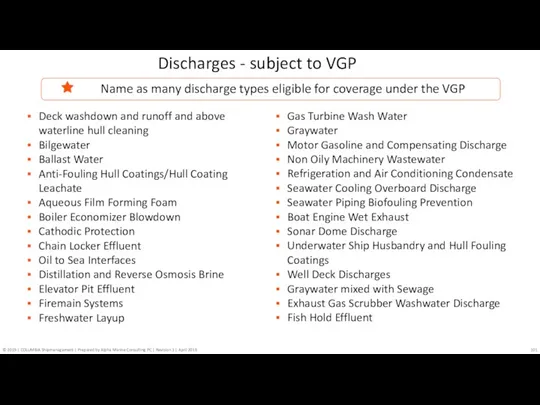

- 101. Discharges - subject to VGP Name as many discharge types eligible for coverage under the VGP

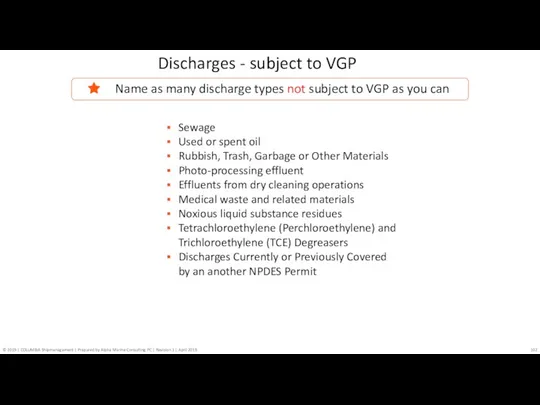

- 102. Discharges - subject to VGP Name as many discharge types not subject to VGP as you

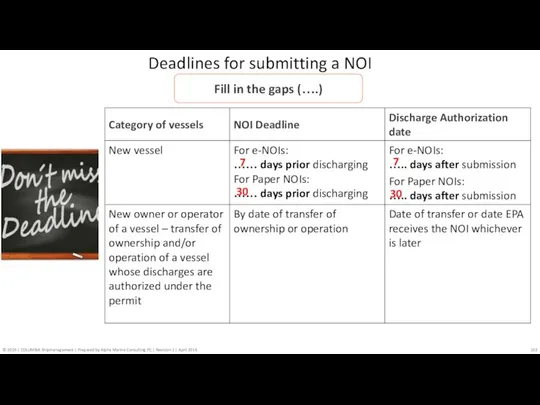

- 103. Deadlines for submitting a NOI 30 30 7 7 Fill in the gaps (….)

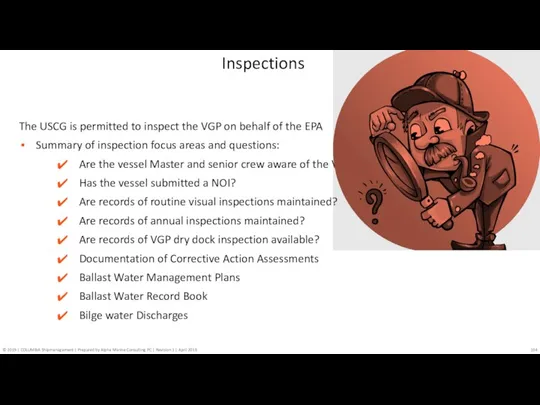

- 104. Inspections The USCG is permitted to inspect the VGP on behalf of the EPA Summary of

- 105. Ballast Water Management (BWM) Section 10

- 106. The IMO Ballast Water Management Convention What is the aim of the Ballast Water Management Convention

- 107. BALLAST WATER TREATMENT The aim of the Ballast Water Treatment is to actively remove, kill and

- 108. Dealing with ballast water Regulation D-1 : Exchange Standard 95% Exchange 200 nautical miles & 200

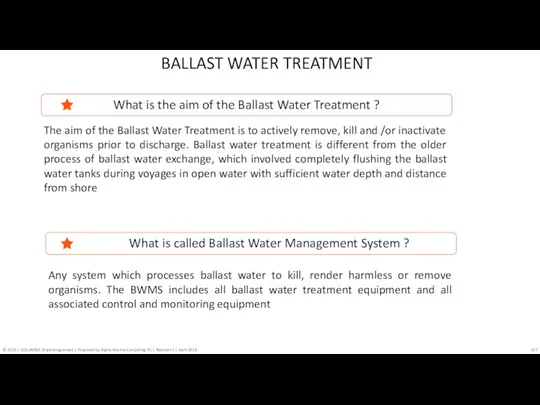

- 109. Ballast Water Treatment System In the following link you may watch a small film about the

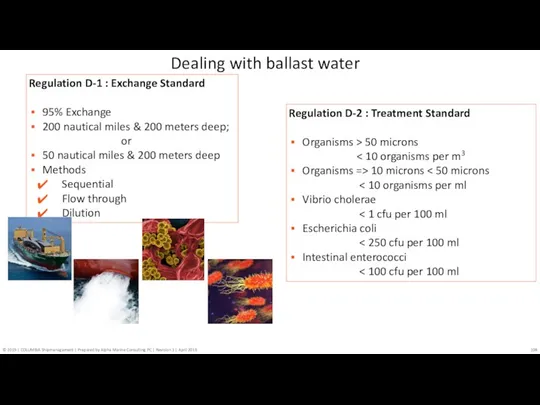

- 110. Or If The IMO implementation schedule for BWTS requires the ship to install a type approved

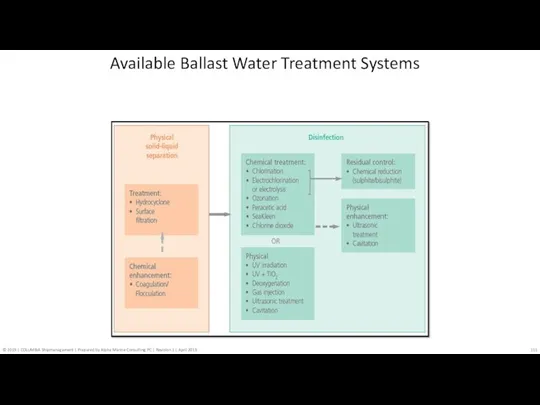

- 111. Available Ballast Water Treatment Systems

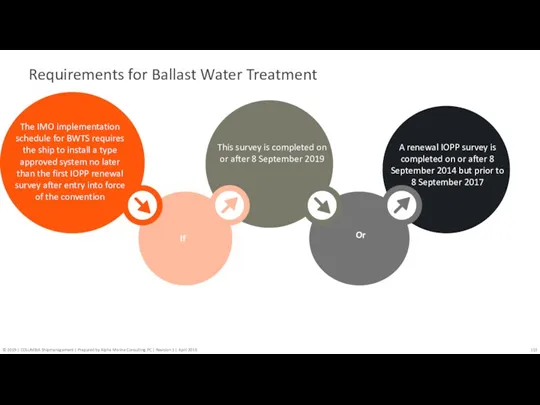

- 112. Ballast Water Management Plan What are the main characteristics of a Ballast Water Management Plan ?

- 113. What kind of records is required to be kept regarding the Ballast Water Management Plan ?

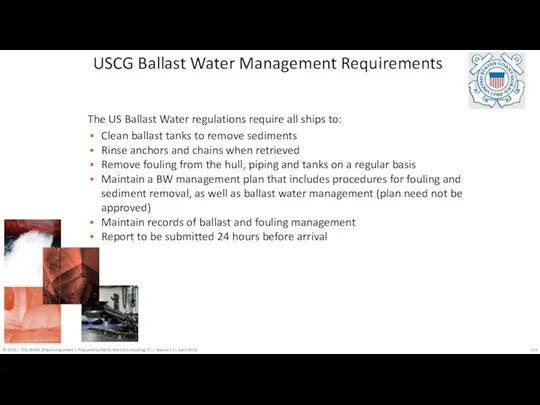

- 114. USCG Ballast Water Management Requirements The US Ballast Water regulations require all ships to: Clean ballast

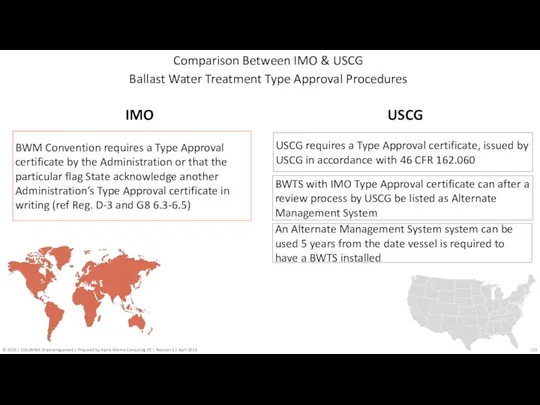

- 115. Comparison Between IMO & USCG Ballast Water Treatment Type Approval Procedures BWM Convention requires a Type

- 116. Biofouling Management Plan (BFMP) Section 11

- 117. The BFMP provides effective procedures and practical guidance to the vessel’s crew on biofouling management measures

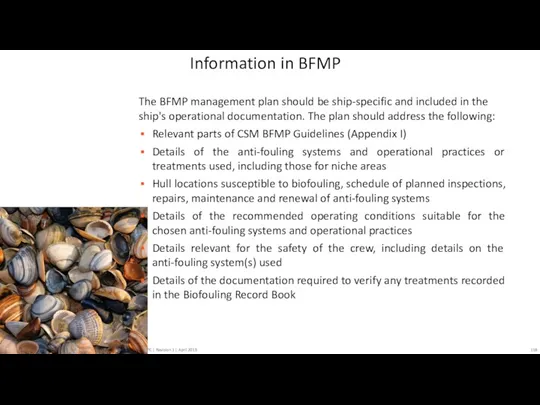

- 118. Information in BFMP The BFMP management plan should be ship-specific and included in the ship's operational

- 119. The Biofouling Management Officer The Chief Engineer is the designated Biofouling Management Officer He is responsible

- 120. Types of Anti-fouling coatings Biocidal coatings that release chemicals such as copper compounds or other pesticides

- 121. Propeller thrusters and propulsion units Sea chests Rudder stock and hinge Stabilizer fin apertures Rope guards,

- 122. In-water inspection, cleaning and maintenance In-water inspections to be undertaken periodically augmented by specific inspections to

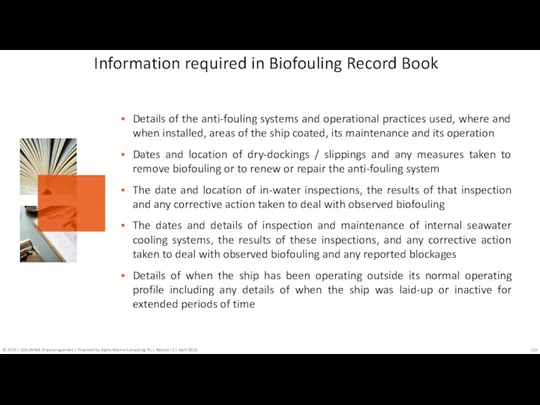

- 123. Information required in Biofouling Record Book Details of the anti-fouling systems and operational practices used, where

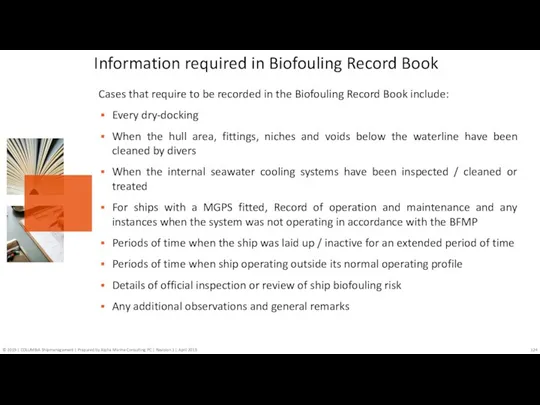

- 124. Information required in Biofouling Record Book Cases that require to be recorded in the Biofouling Record

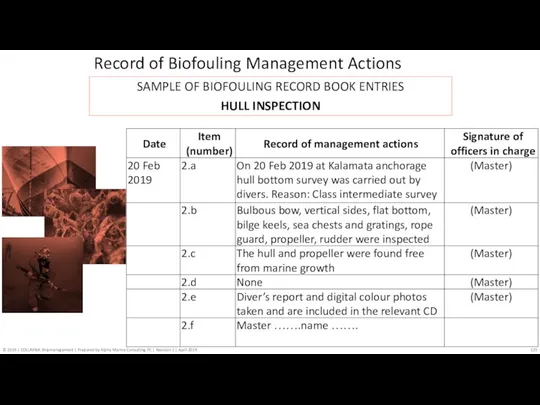

- 125. Record of Biofouling Management Actions SAMPLE OF BIOFOULING RECORD BOOK ENTRIES HULL INSPECTION

- 126. Useful Links with Videos About MARPOL Violations https://www.maritime-executive.com/article/greek-shipping-company-fined-for-oil-pollution-charges https://www.youtube.com/watch?v=ZLwmFprGSUI https://vimeo.com/311063622

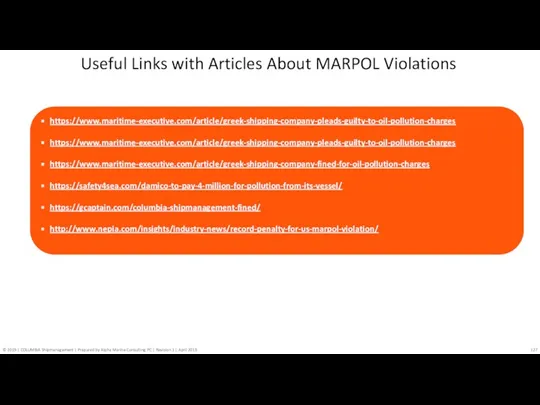

- 127. Useful Links with Articles About MARPOL Violations https://www.maritime-executive.com/article/greek-shipping-company-pleads-guilty-to-oil-pollution-charges https://www.maritime-executive.com/article/greek-shipping-company-pleads-guilty-to-oil-pollution-charges https://www.maritime-executive.com/article/greek-shipping-company-fined-for-oil-pollution-charges https://safety4sea.com/damico-to-pay-4-million-for-pollution-from-its-vessel/ https://gcaptain.com/columbia-shipmanagement-fined/ http://www.nepia.com/insights/industry-news/record-penalty-for-us-marpol-violation/

- 129. Скачать презентацию

Своя игра

Своя игра Асортимент виробів з бісквітного тіста, та їх реалізація в підприємствах ресторанного господарства

Асортимент виробів з бісквітного тіста, та їх реалізація в підприємствах ресторанного господарства Лечебно-профилактическое питание

Лечебно-профилактическое питание Схемы газопроводов и газового оборудования газорегуляторных пунктов

Схемы газопроводов и газового оборудования газорегуляторных пунктов Морфологический анализ слов. Части речи

Морфологический анализ слов. Части речи Виды симметрии

Виды симметрии Операционная технология возделывания и уборки гречихи с разработкой операции по основной обработке почвы

Операционная технология возделывания и уборки гречихи с разработкой операции по основной обработке почвы Заболевания сердечно-сосудистой системы

Заболевания сердечно-сосудистой системы Лирика

Лирика История развития картографии

История развития картографии организация предметно - развивающей среды в группе раннего возраста

организация предметно - развивающей среды в группе раннего возраста Педагогический проект

Педагогический проект Проектирование и технология ЭКБ

Проектирование и технология ЭКБ Золотые ворота в Киеве

Золотые ворота в Киеве Теоретические основы товароведения продовольственных товаров

Теоретические основы товароведения продовольственных товаров Климат африки

Климат африки Приготування страв до фуршету на 30 персон. Сервірування

Приготування страв до фуршету на 30 персон. Сервірування Ремонт пешеходного моста через р. Демьянку

Ремонт пешеходного моста через р. Демьянку Приготування концентрату квасного сусла

Приготування концентрату квасного сусла Робот STR-17 на платформе Аrduino

Робот STR-17 на платформе Аrduino Живопись эпохи Ренессанс

Живопись эпохи Ренессанс Основы стандартизации и сертификации

Основы стандартизации и сертификации Структура нормативной правовой базы системы военного образования

Структура нормативной правовой базы системы военного образования Федеральная государственная информационная система Росаккредитации

Федеральная государственная информационная система Росаккредитации Понятие - наука

Понятие - наука Основные положения теории транспортного потока

Основные положения теории транспортного потока Лавсан. Історія досліджень. Властисвості

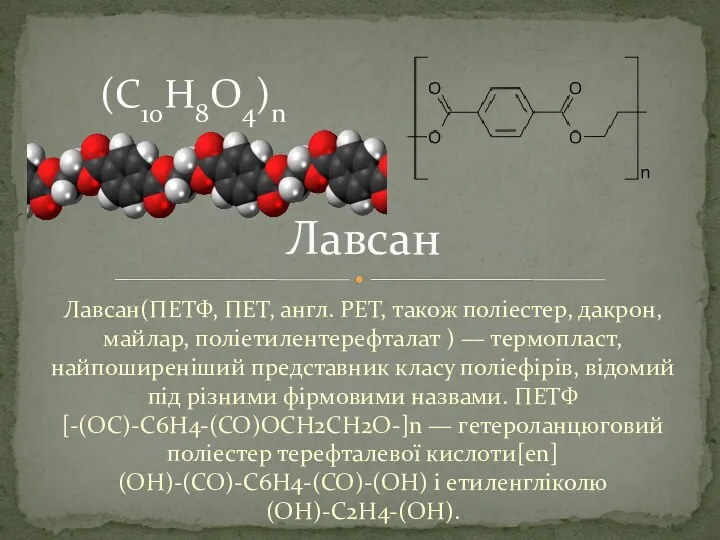

Лавсан. Історія досліджень. Властисвості Воздействие организмов на земные оболочки

Воздействие организмов на земные оболочки