Содержание

- 2. Precaution Feature and Specifications Installation Function Service Information Disassembly and Assembly Trouble shooting Circuit Diagram Wiring

- 3. 1. All repairs should be done in accordance with the procedures described in this manual. This

- 4. 8. Never defeat any of the B+ voltage interlocks. Do not apply AC power to the

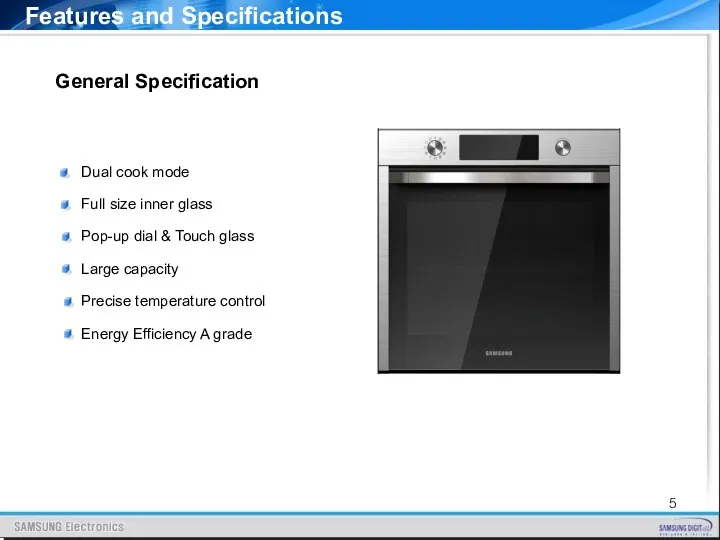

- 5. General Specification Dual cook mode Full size inner glass Pop-up dial & Touch glass Large capacity

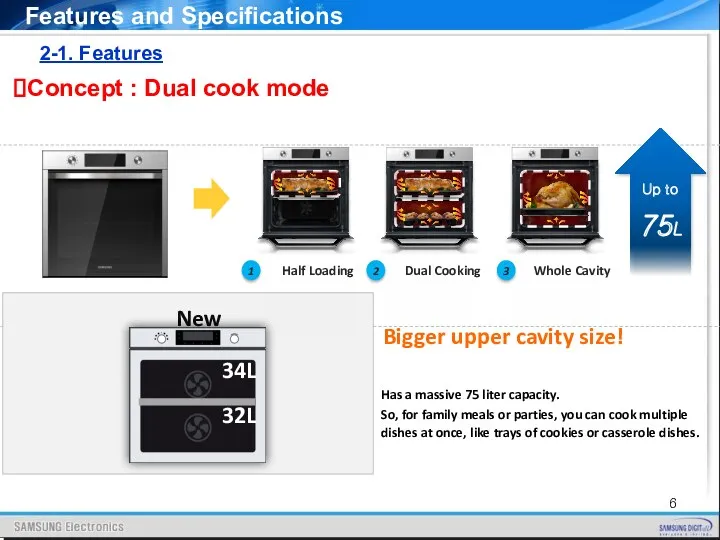

- 6. 2-1. Features Features and Specifications Concept : Dual cook mode Half Loading 1 Dual Cooking 2

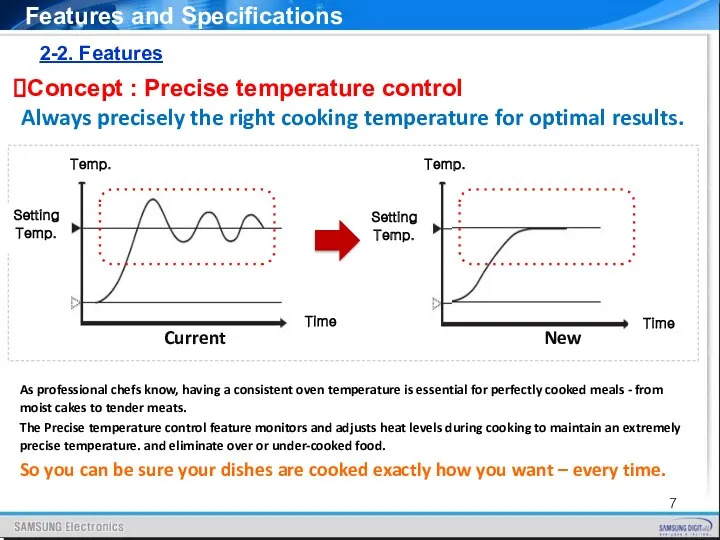

- 7. 2-2. Features Concept : Precise temperature control Always precisely the right cooking temperature for optimal results.

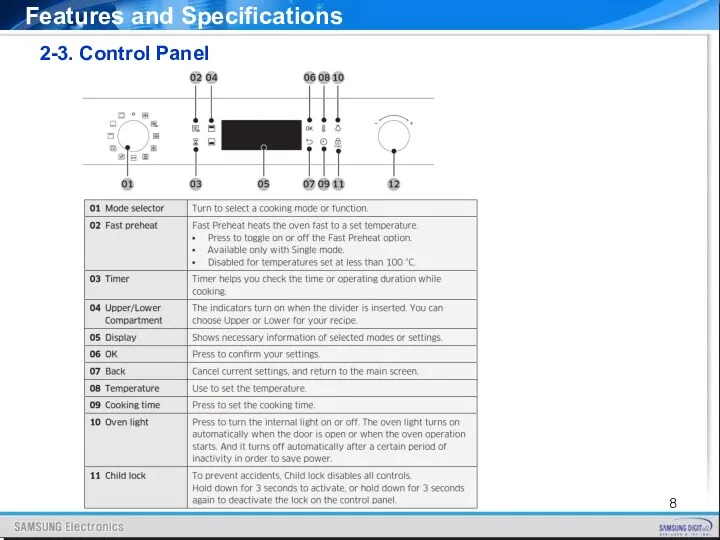

- 8. 2-3. Control Panel Features and Specifications

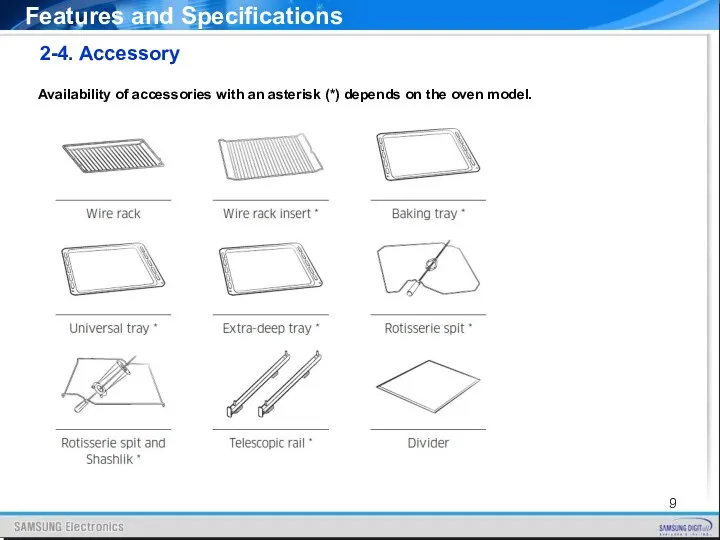

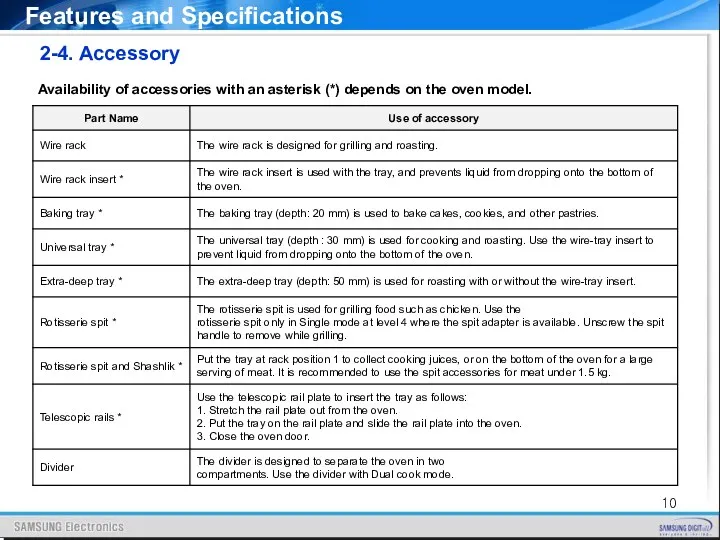

- 9. 2-4. Accessory Availability of accessories with an asterisk (*) depends on the oven model. Features and

- 10. 2-4. Accessory Availability of accessories with an asterisk (*) depends on the oven model. Features and

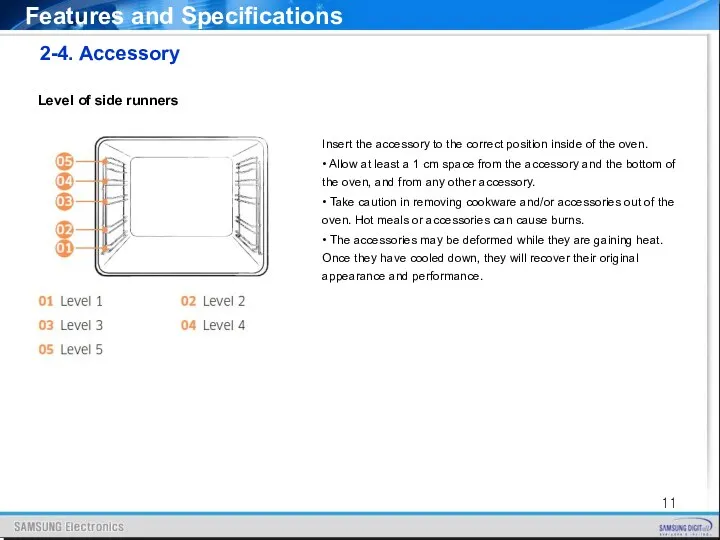

- 11. 2-4. Accessory Level of side runners Insert the accessory to the correct position inside of the

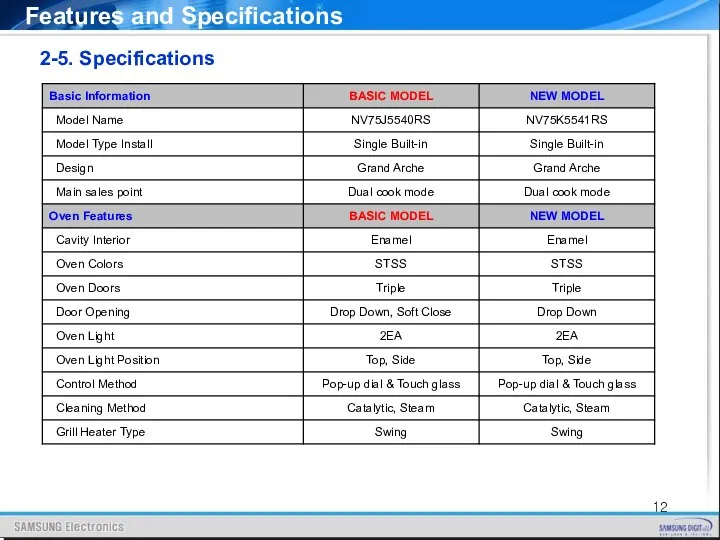

- 12. 2-5. Specifications Features and Specifications

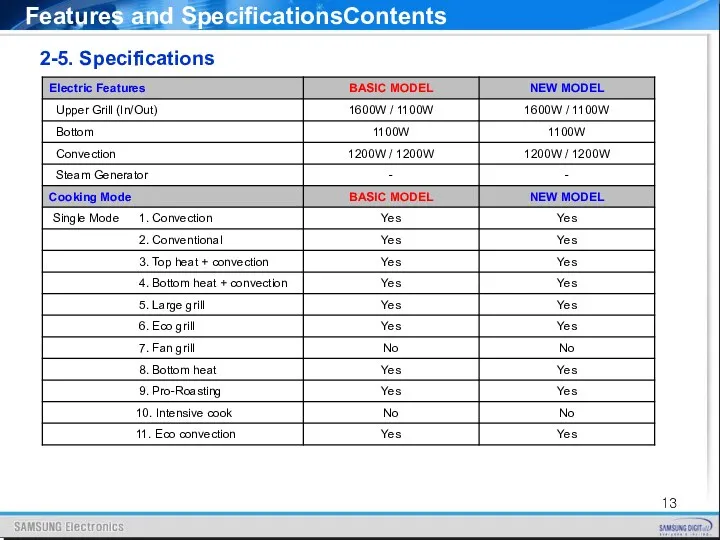

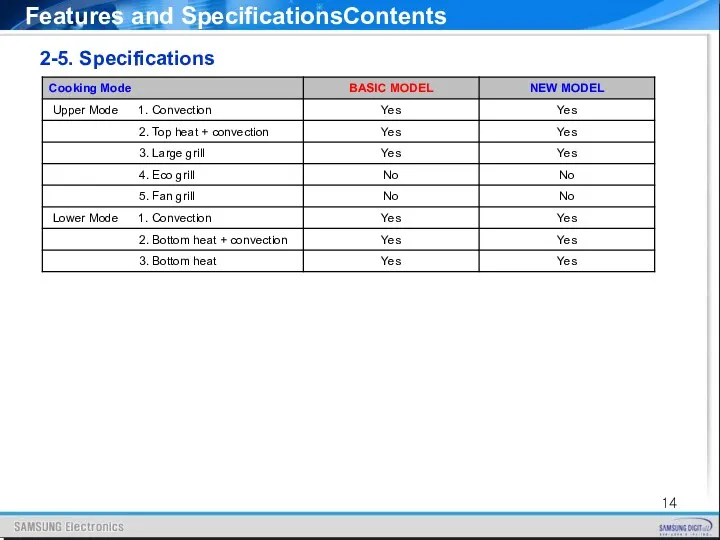

- 13. Features and SpecificationsContents 2-5. Specifications

- 14. Features and SpecificationsContents 2-5. Specifications

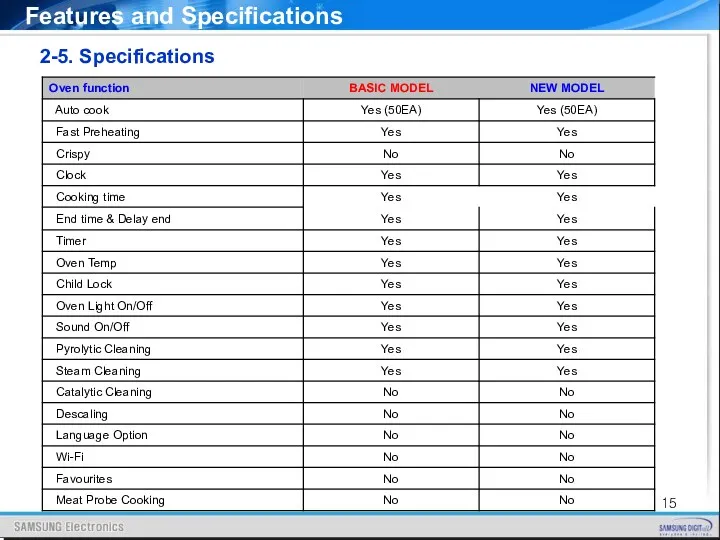

- 15. 2-5. Specifications Features and Specifications

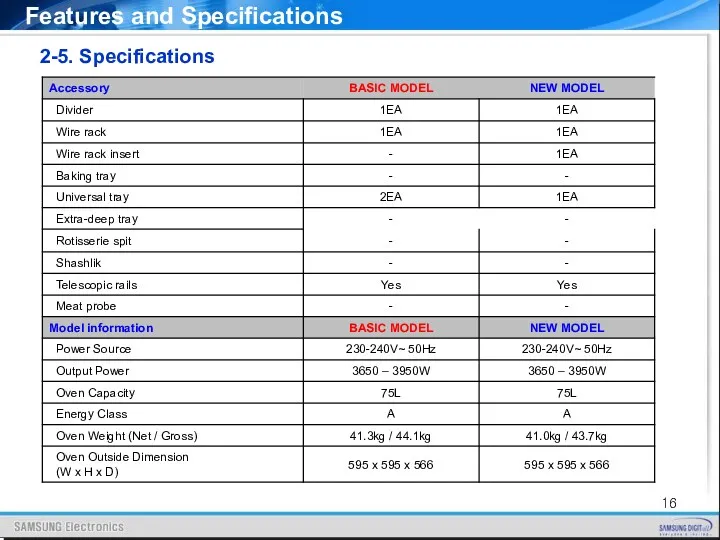

- 16. 2-5. Specifications Features and Specifications

- 17. IMPORTANT Any electrical installation work must be carried out by a qualified electrician / competent person.

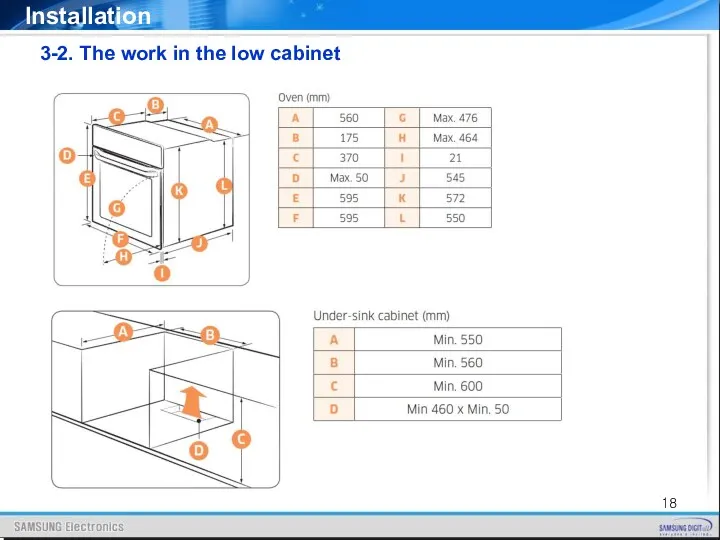

- 18. 3-2. The work in the low cabinet Installation

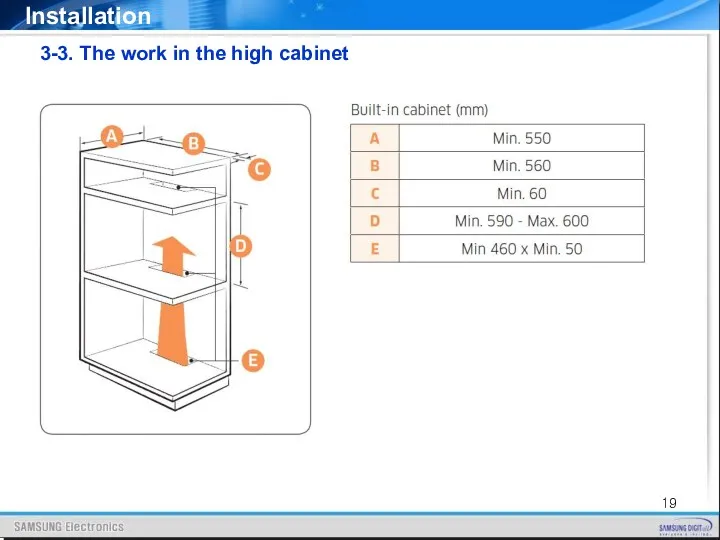

- 19. 3-3. The work in the high cabinet Installation

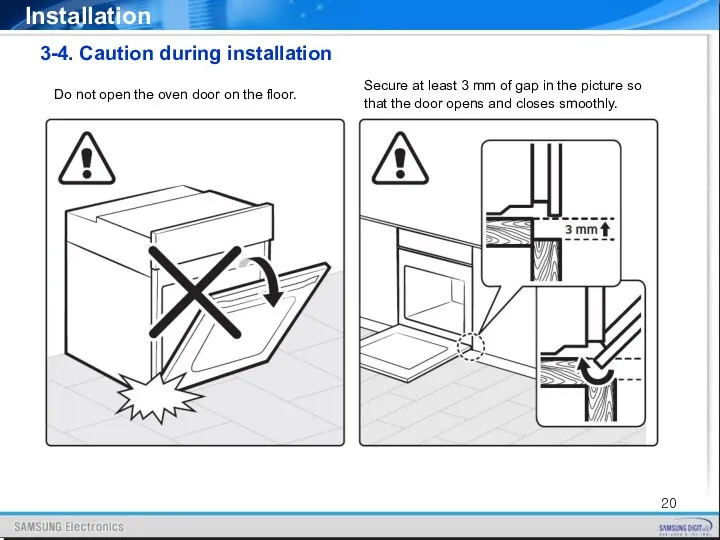

- 20. 3-4. Caution during installation Installation Secure at least 3 mm of gap in the picture so

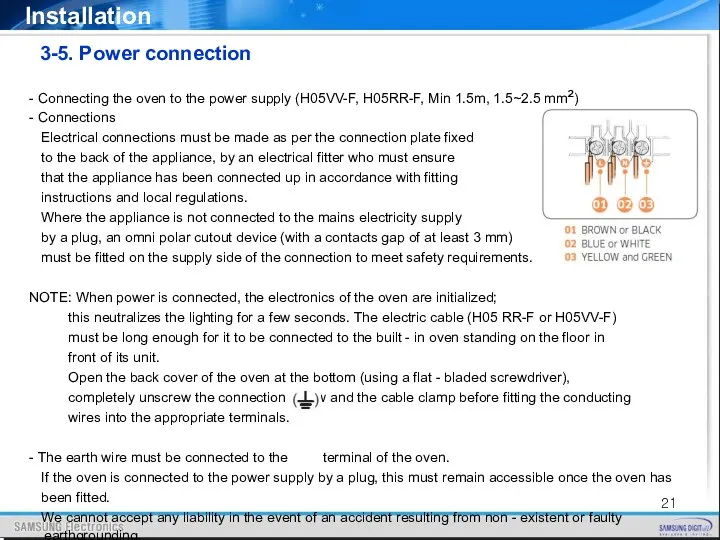

- 21. - Connecting the oven to the power supply (H05VV-F, H05RR-F, Min 1.5m, 1.5~2.5 mm²) - Connections

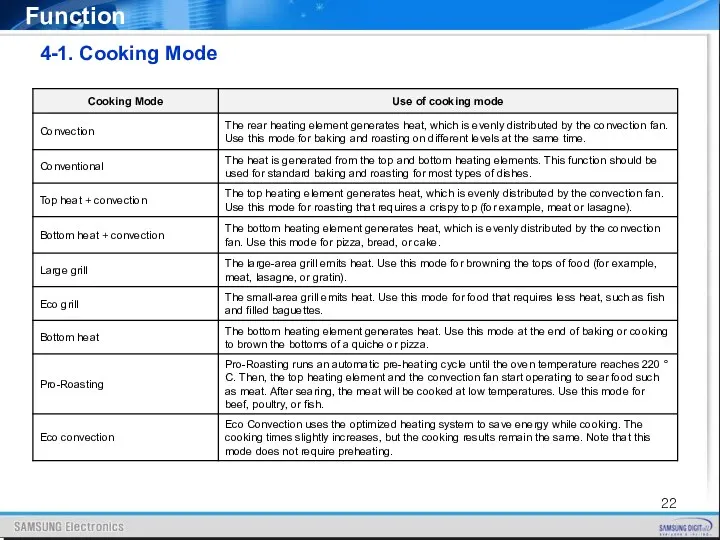

- 22. 4-1. Cooking Mode Function

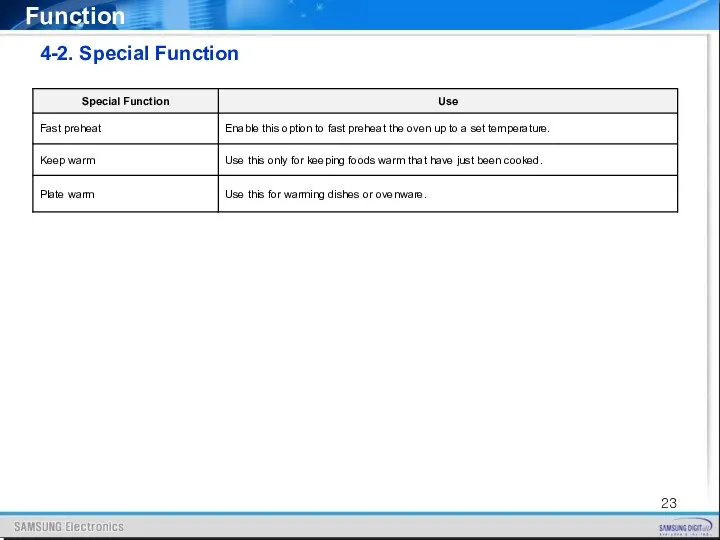

- 23. 4-2. Special Function Function

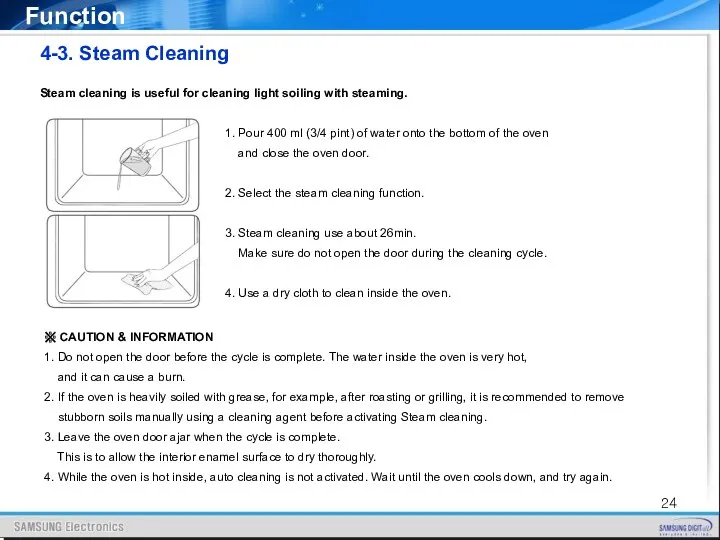

- 24. 4-3. Steam Cleaning Function Steam cleaning is useful for cleaning light soiling with steaming. 1. Pour

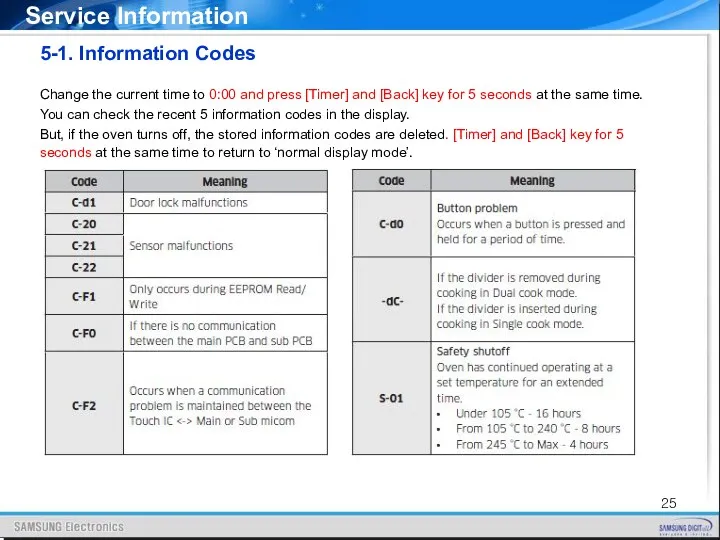

- 25. 5-1. Information Codes Service Information Change the current time to 0:00 and press [Timer] and [Back]

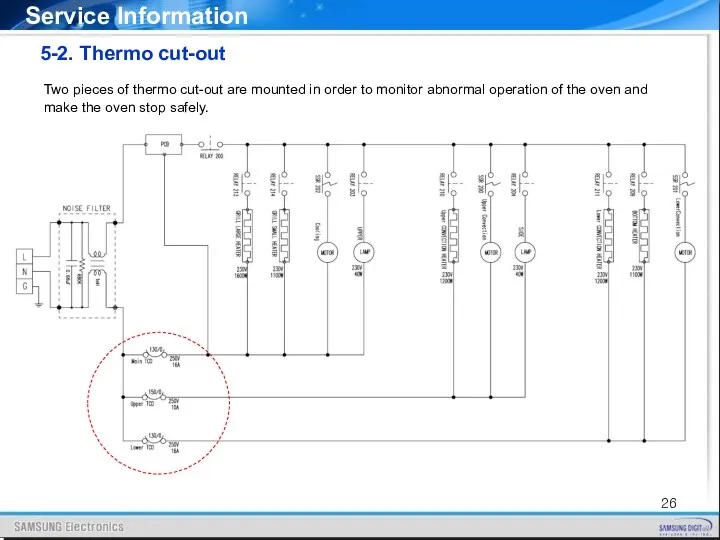

- 26. 5-2. Thermo cut-out Two pieces of thermo cut-out are mounted in order to monitor abnormal operation

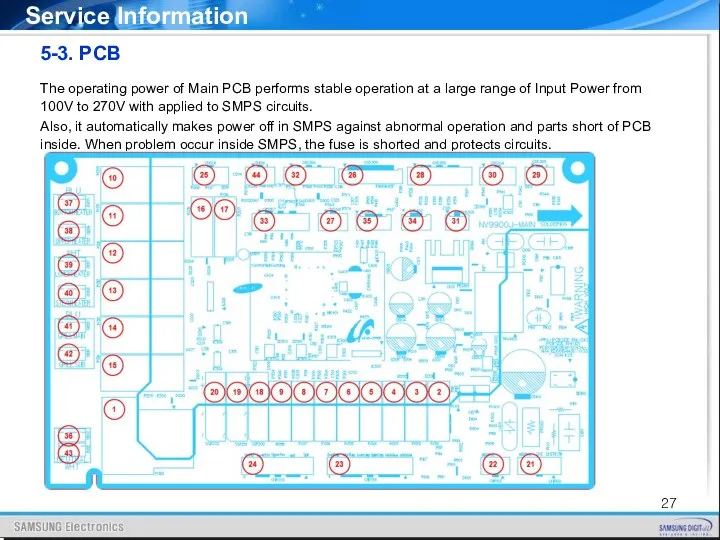

- 27. 5-3. PCB The operating power of Main PCB performs stable operation at a large range of

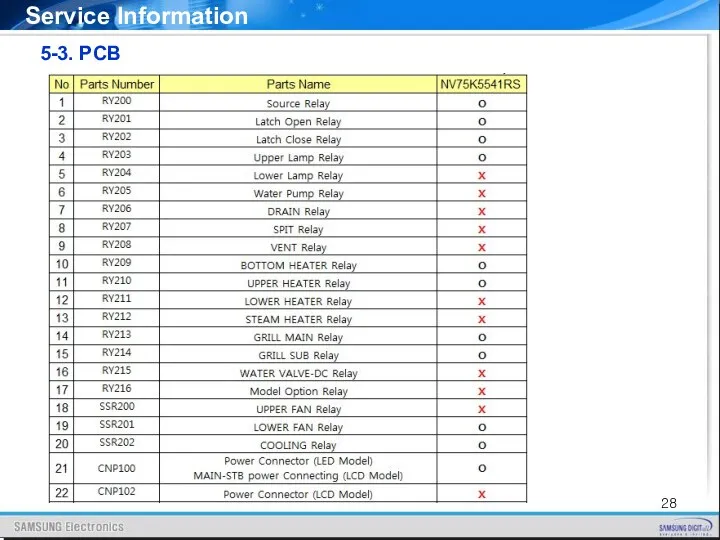

- 28. 5-3. PCB Service Information

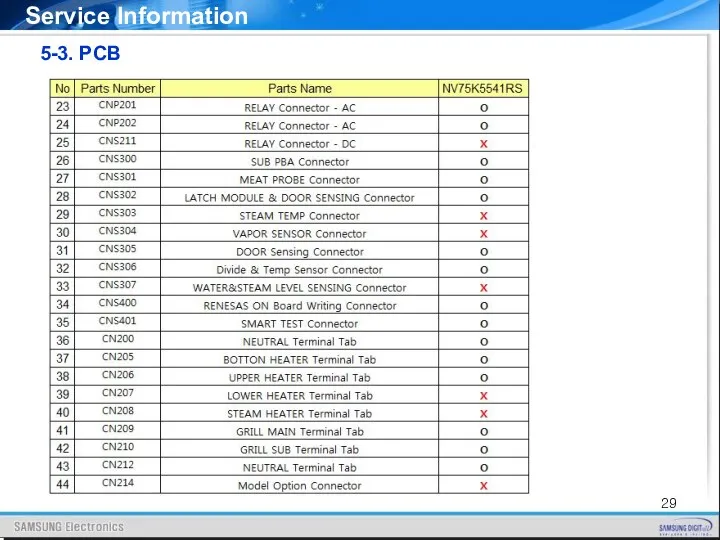

- 29. 5-3. PCB Service Information

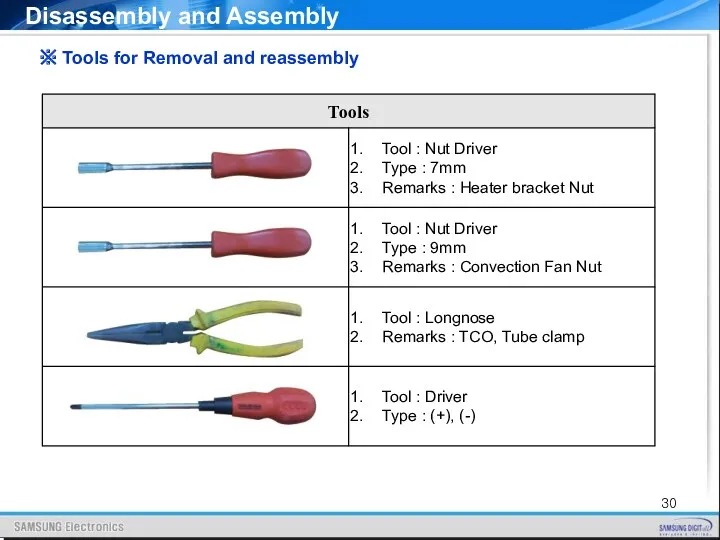

- 30. ※ Tools for Removal and reassembly Disassembly and Assembly

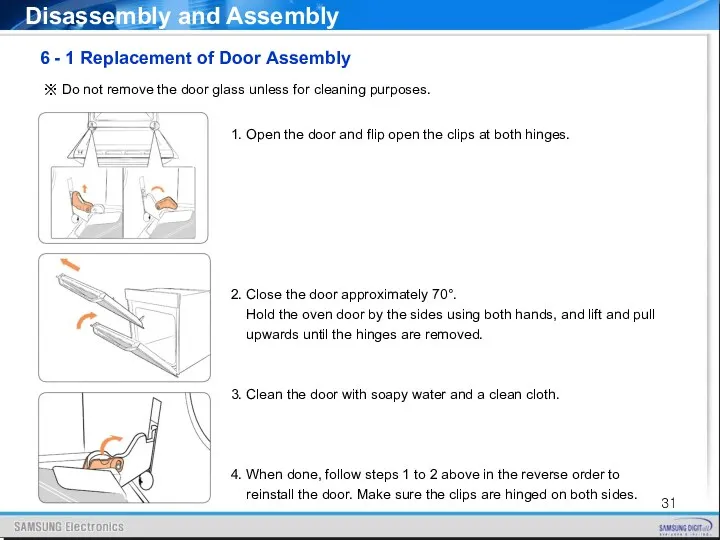

- 31. 6 - 1 Replacement of Door Assembly Disassembly and Assembly 1. Open the door and flip

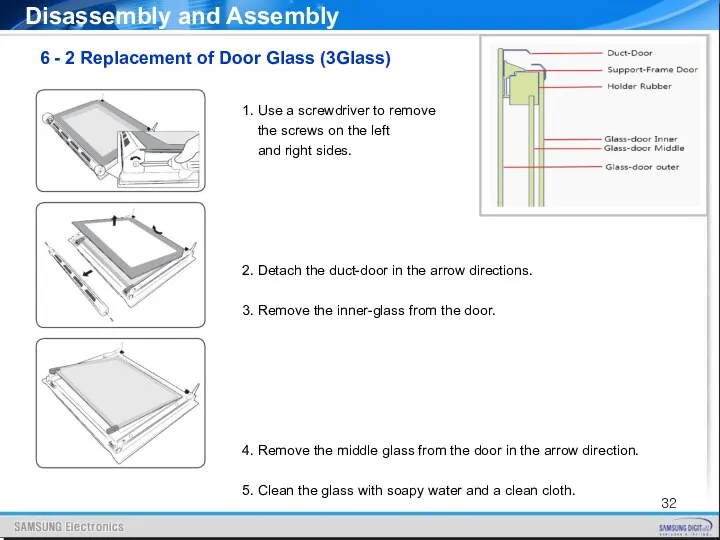

- 32. 6 - 2 Replacement of Door Glass (3Glass) Disassembly and Assembly 1. Use a screwdriver to

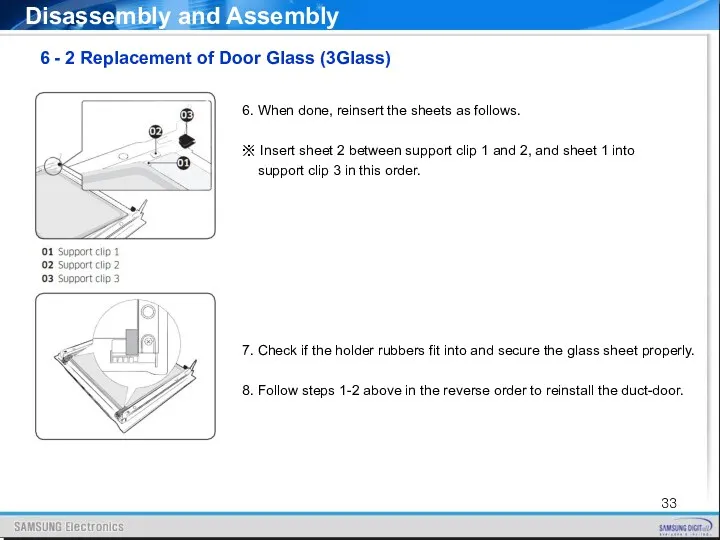

- 33. Disassembly and Assembly 6 - 2 Replacement of Door Glass (3Glass) 6. When done, reinsert the

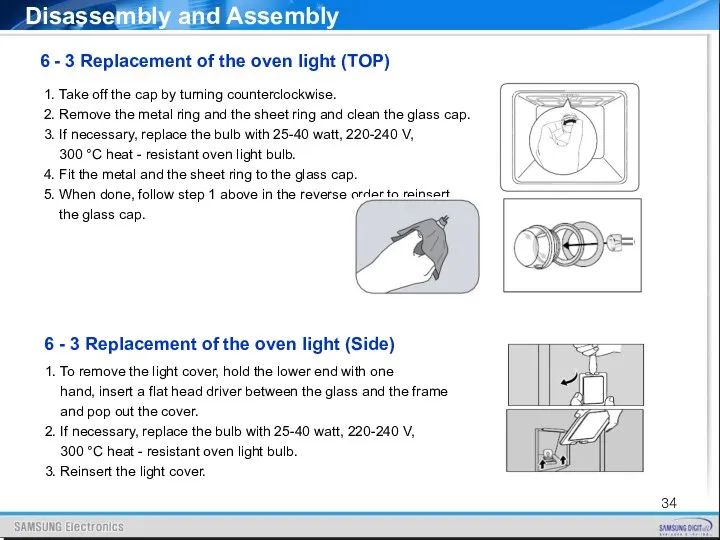

- 34. 1. Take off the cap by turning counterclockwise. 2. Remove the metal ring and the sheet

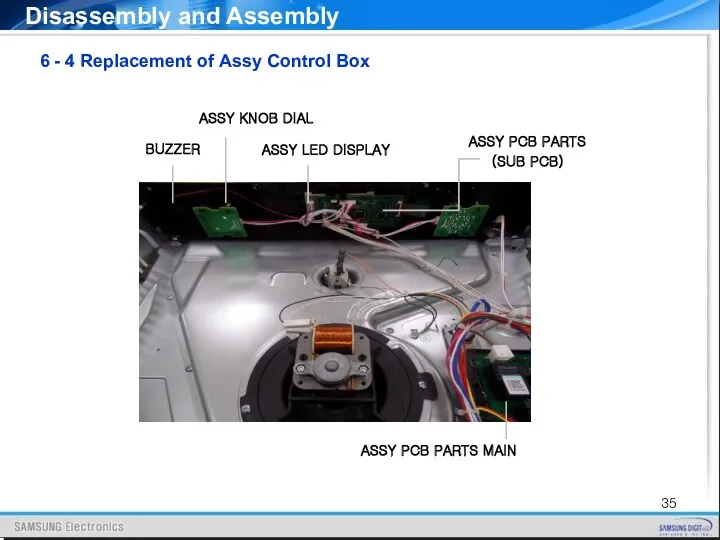

- 35. 6 - 4 Replacement of Assy Control Box Disassembly and Assembly

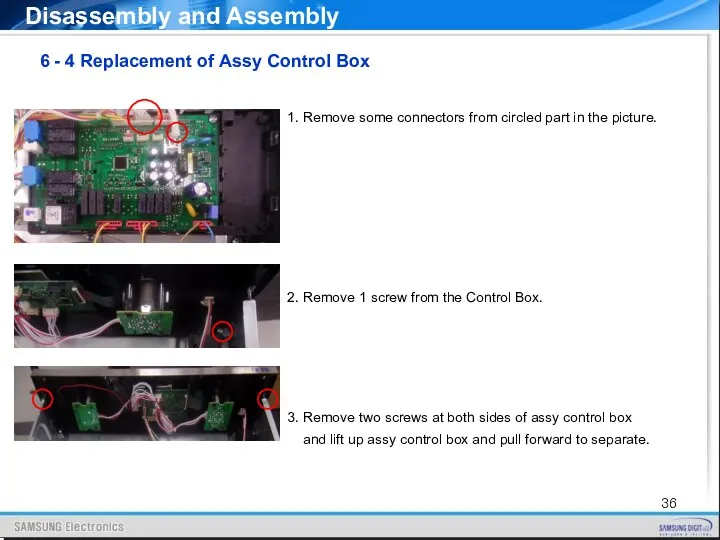

- 36. Disassembly and Assembly 1. Remove some connectors from circled part in the picture. 2. Remove 1

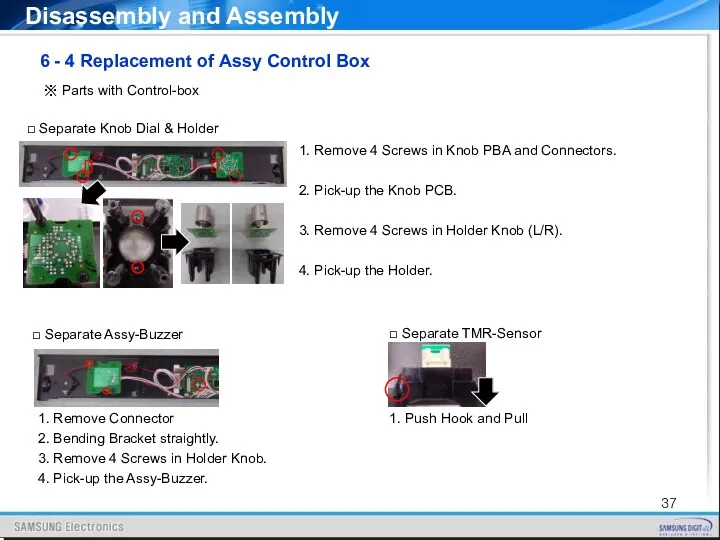

- 37. Disassembly and Assembly ※ Parts with Control-box 6 - 4 Replacement of Assy Control Box 1.

- 38. Disassembly and Assembly 6 - 4 Replacement of Assy Control Box □ Separate Main PCB &

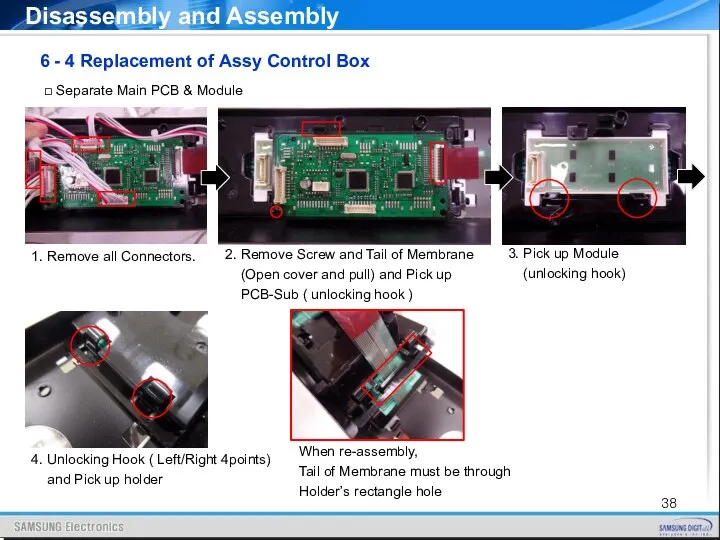

- 39. Disassembly and Assembly ※ Parts with Control-box 6 - 4 Replacement of Assy Control Box

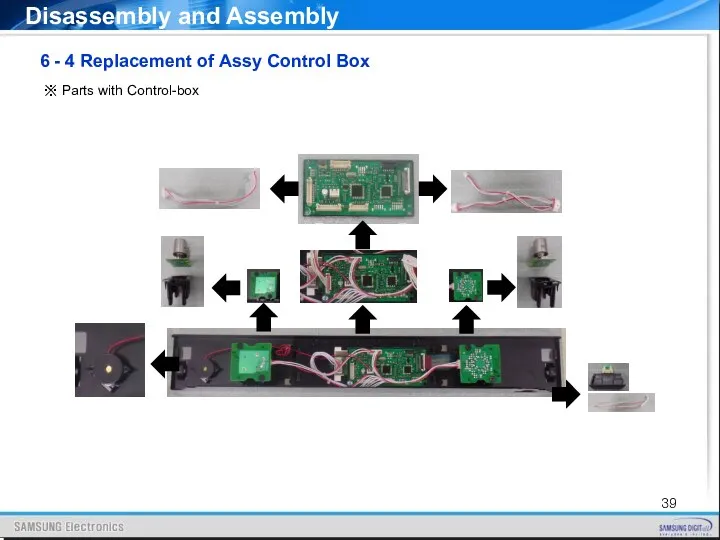

- 40. Disassembly and Assembly 6 – 5 Replacement of Motor fan cooling 1. Remove the Motor Connector.

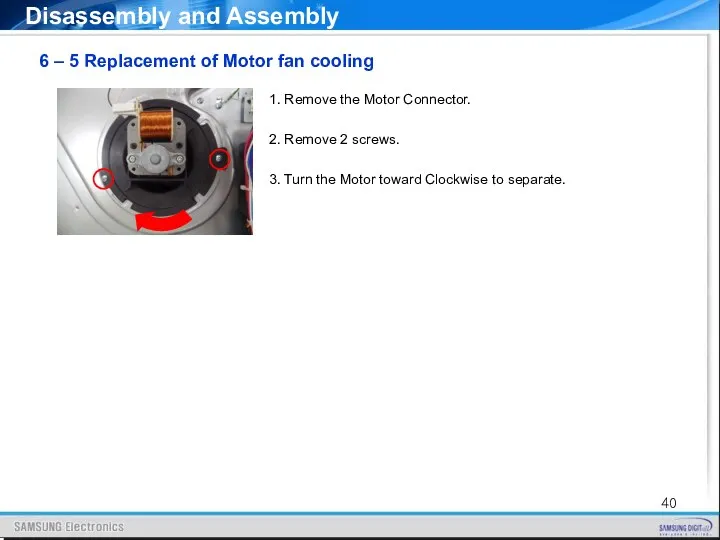

- 41. 6 - 6 Replacement of Assy cover Air Disassembly and Assembly 1. Remove Assy Control Box.

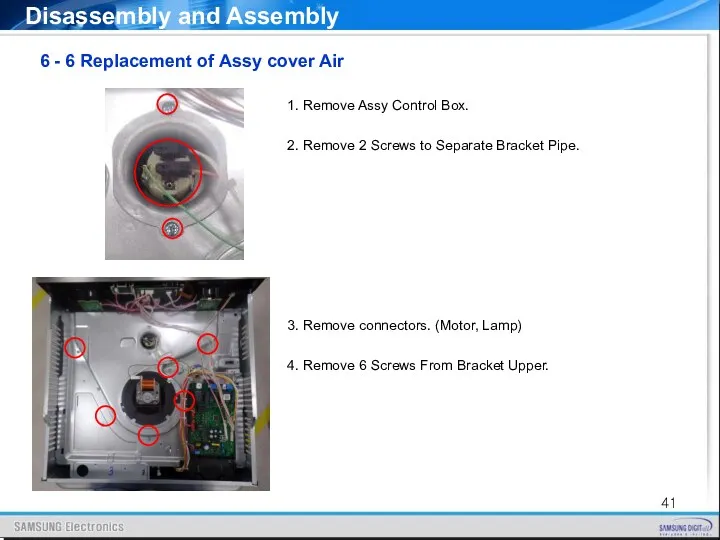

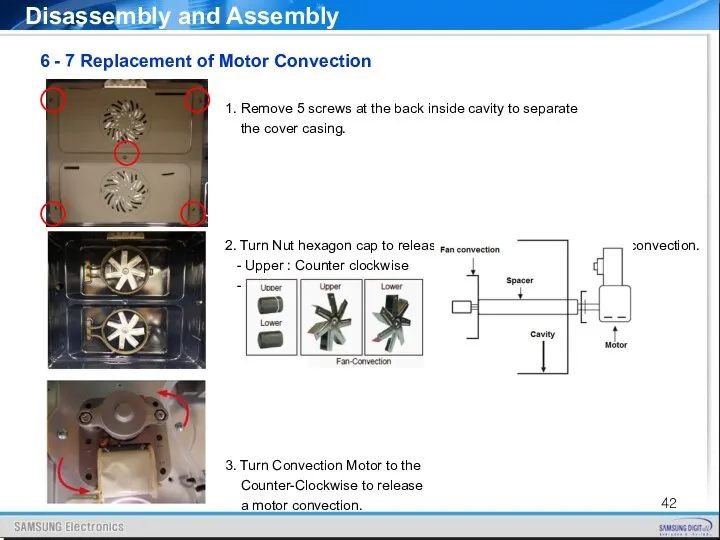

- 42. 1. Remove 5 screws at the back inside cavity to separate the cover casing. 2. Turn

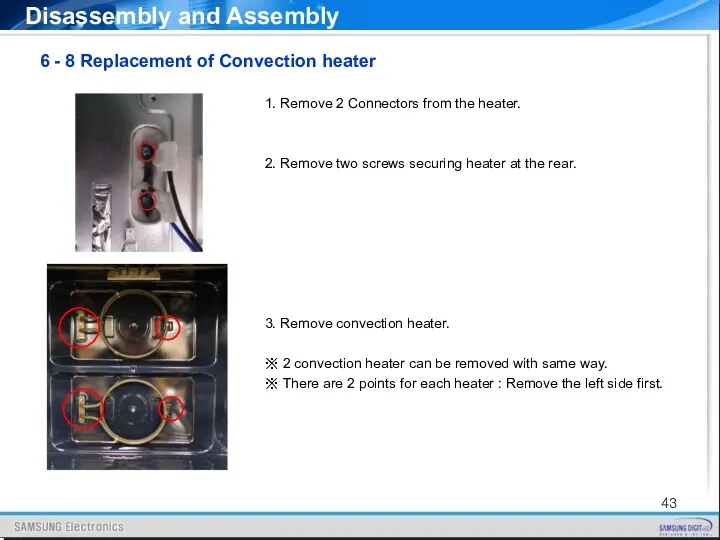

- 43. 6 - 8 Replacement of Convection heater Disassembly and Assembly 1. Remove 2 Connectors from the

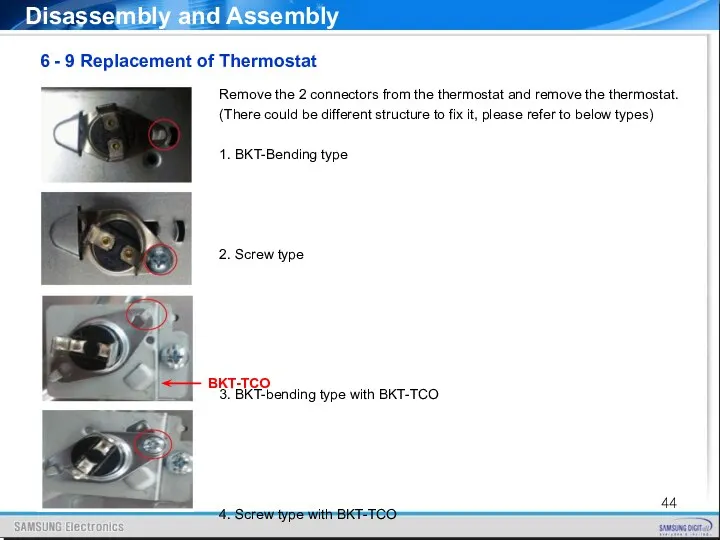

- 44. 6 - 9 Replacement of Thermostat Disassembly and Assembly Remove the 2 connectors from the thermostat

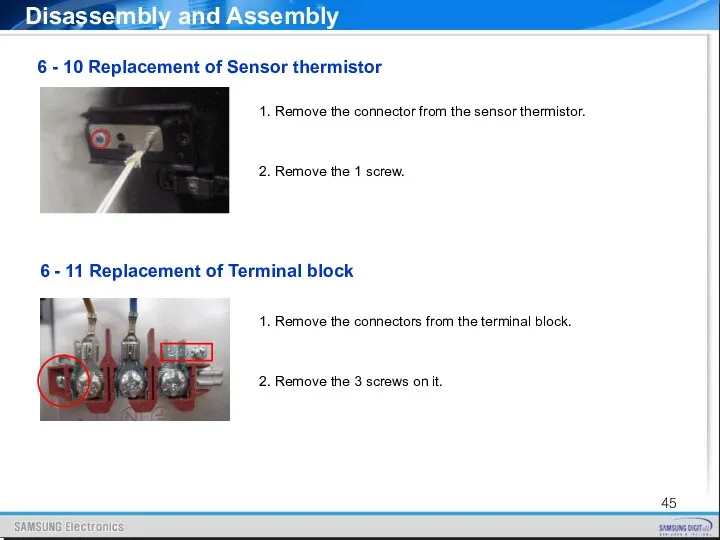

- 45. 6 - 11 Replacement of Terminal block Disassembly and Assembly 6 - 10 Replacement of Sensor

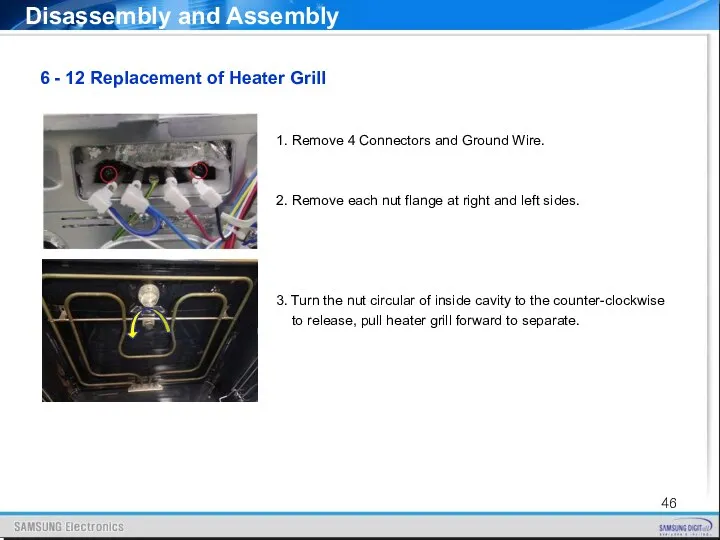

- 46. 1. Remove 4 Connectors and Ground Wire. 2. Remove each nut flange at right and left

- 47. 6 - 13 Replacement of PCB Main Disassembly and Assembly 1. Remove the all connectors from

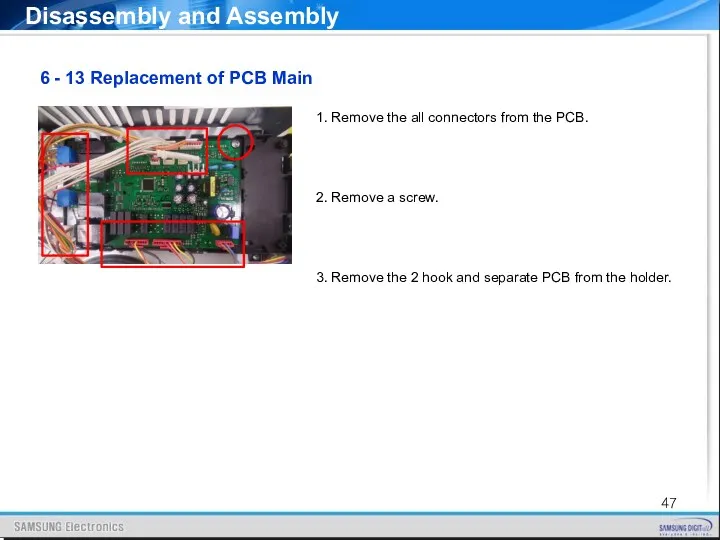

- 48. 1. Remove one screw and pull forward to separate it. ※ Heater should be located above

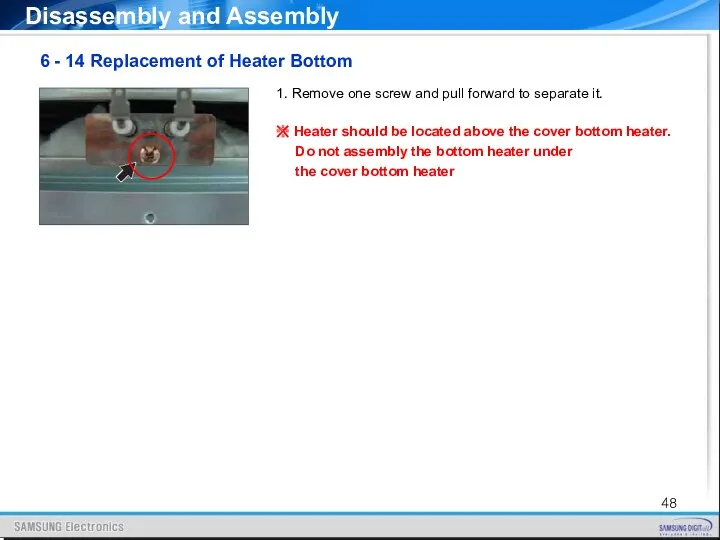

- 49. 6 - 16 Replacement of Side runners Disassembly and Assembly 1. Press the top line of

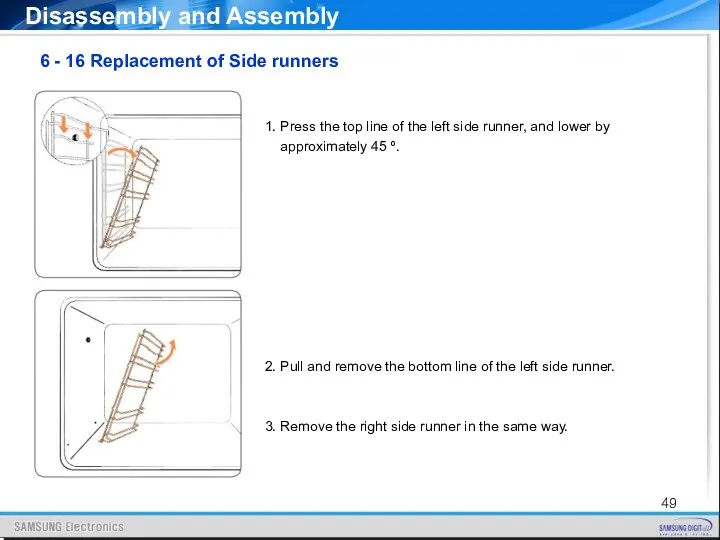

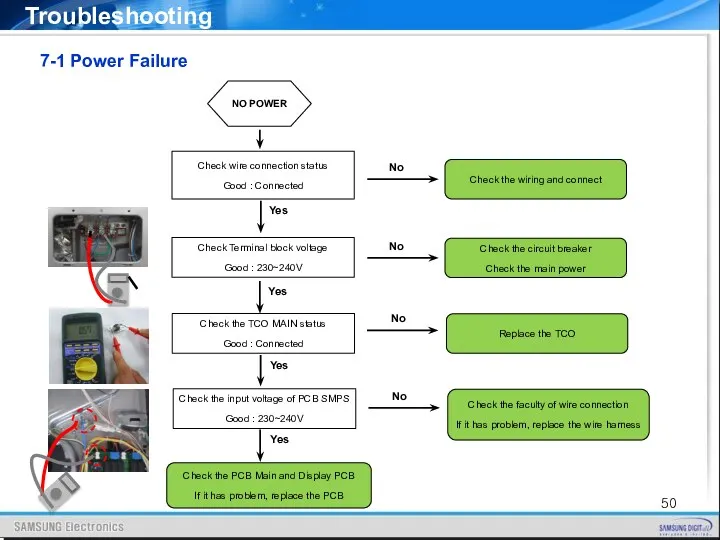

- 50. 7-1 Power Failure Troubleshooting NO POWER Check Terminal block voltage Good : 230~240V Check the circuit

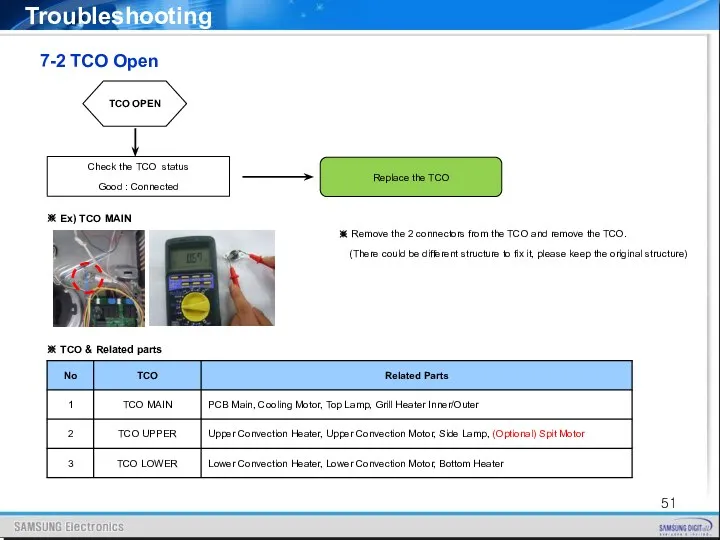

- 51. 7-2 TCO Open Troubleshooting TCO OPEN Check the TCO status Good : Connected Replace the TCO

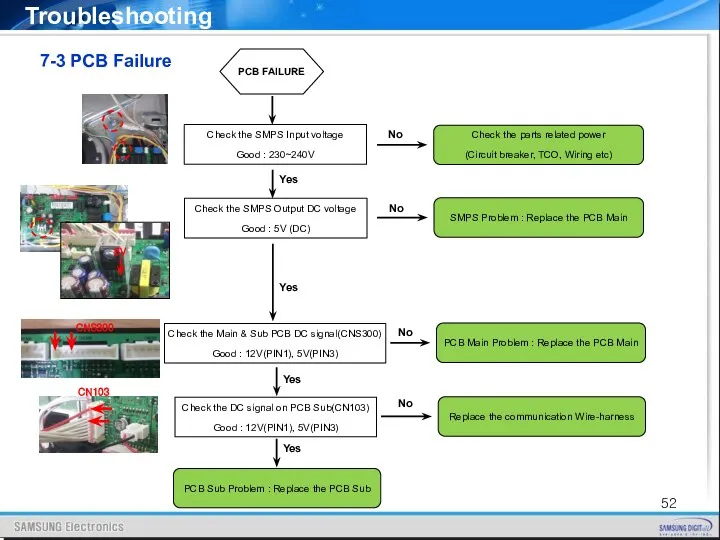

- 52. 7-3 PCB Failure Troubleshooting PCB FAILURE Check the SMPS Input voltage Good : 230~240V Check the

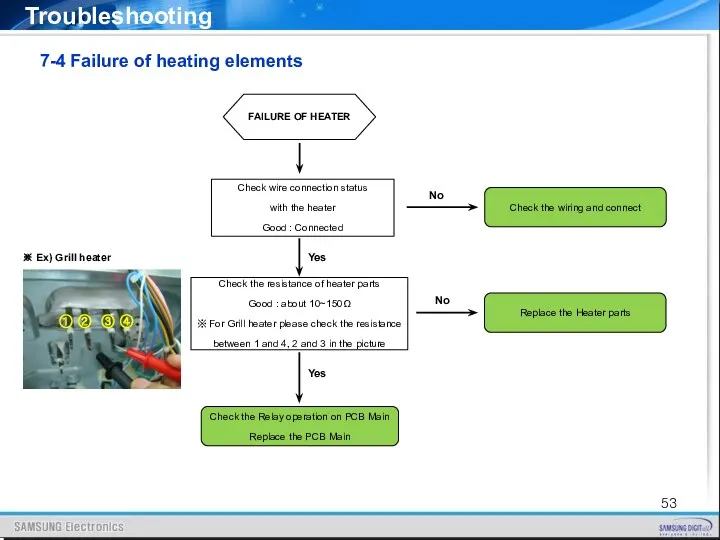

- 53. 7-4 Failure of heating elements Troubleshooting FAILURE OF HEATER Check wire connection status with the heater

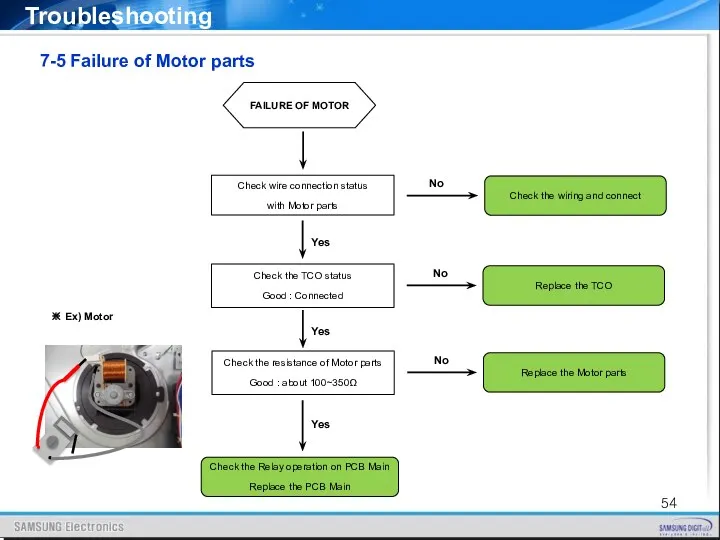

- 54. 7-5 Failure of Motor parts Troubleshooting FAILURE OF MOTOR Check wire connection status with Motor parts

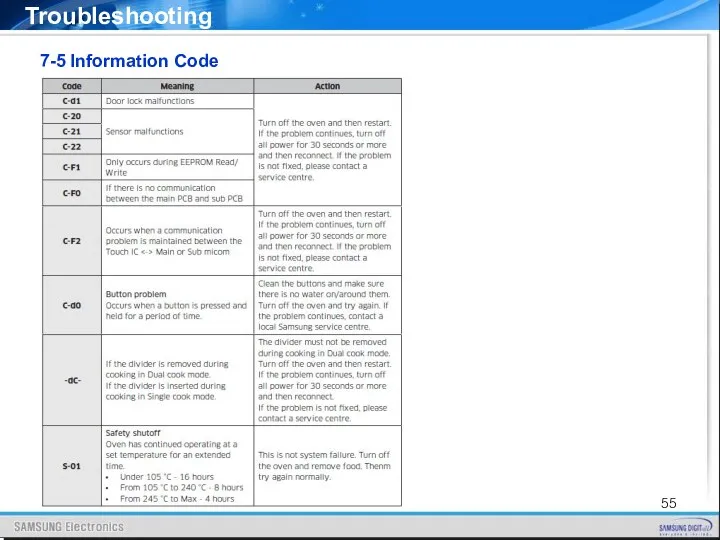

- 55. 7-5 Information Code Troubleshooting

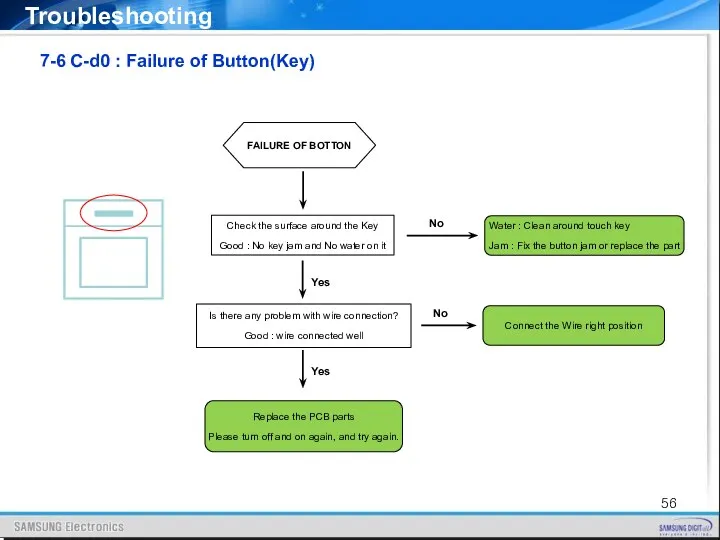

- 56. 7-6 C-d0 : Failure of Button(Key) Troubleshooting FAILURE OF BOTTON Check the surface around the Key

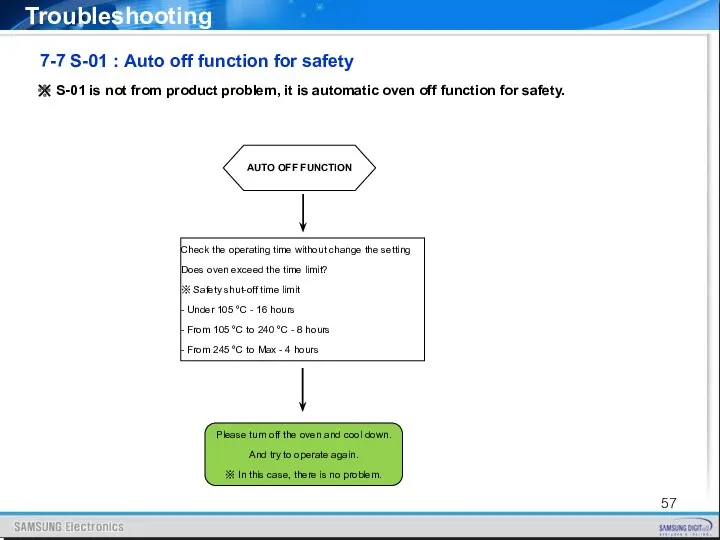

- 57. 7-7 S-01 : Auto off function for safety Troubleshooting AUTO OFF FUNCTION Check the operating time

- 58. 7-8 C-20 : Sensor problem Troubleshooting SENSOR PROBLEM Check if there is damage on the wire

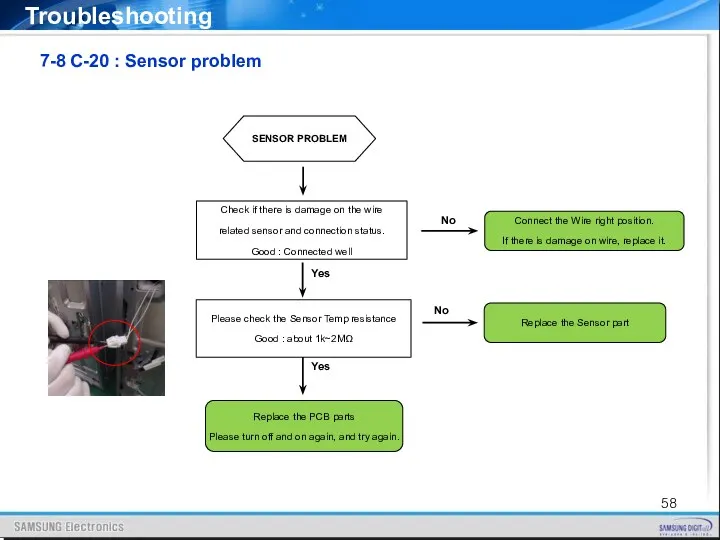

- 59. 7-9 C-21 : Over heating problem Troubleshooting OVER HEAT PROBLEM Check if the heater operates even

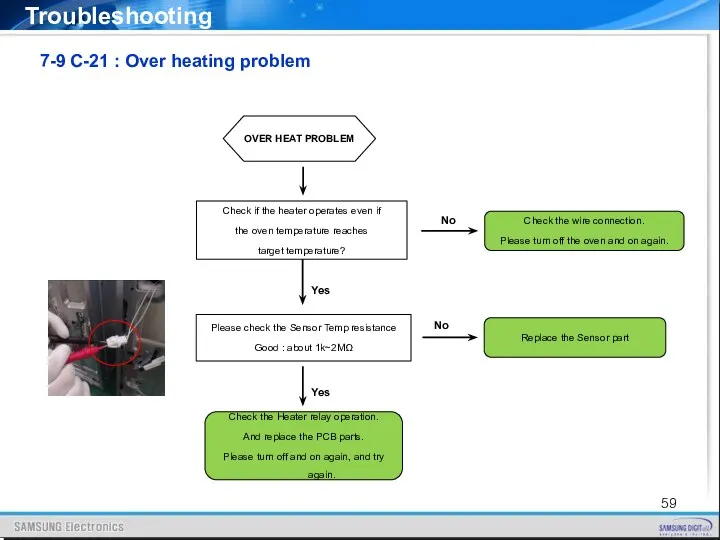

- 60. 7-10 C-22 : PCB Sensor problem Troubleshooting PCB SENSOR PROBLEM Check if cooling motor operate well

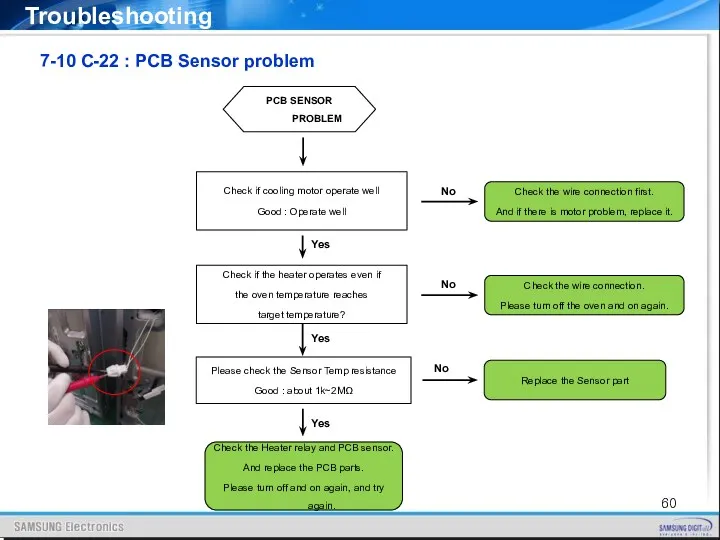

- 61. 7-11 C-d1 : Door lock problem (Pyrolytic Model only) Troubleshooting DOOR LOCK PROBLEM Check the connector

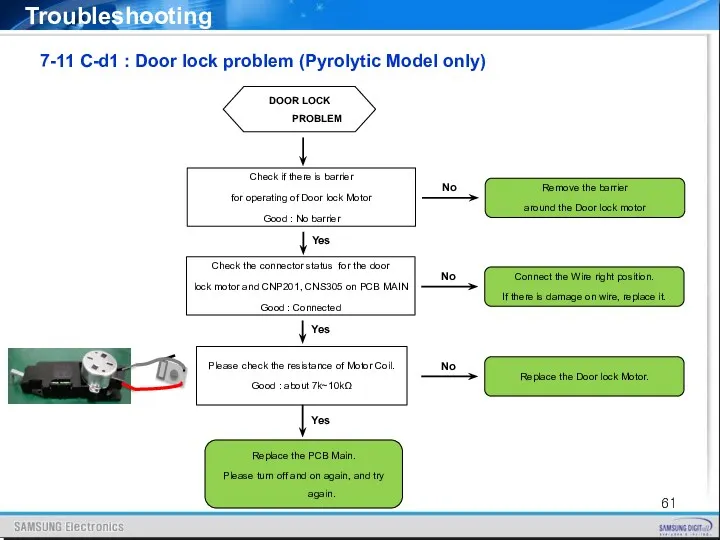

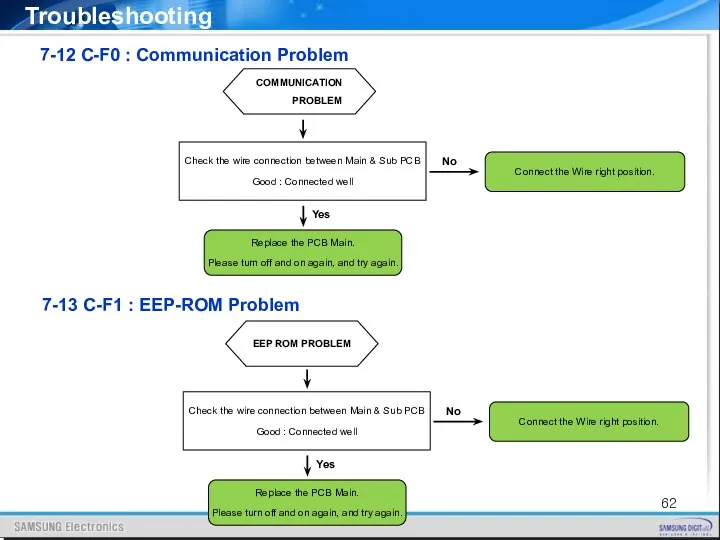

- 62. 7-12 C-F0 : Communication Problem Troubleshooting COMMUNICATION PROBLEM 7-13 C-F1 : EEP-ROM Problem EEP ROM PROBLEM

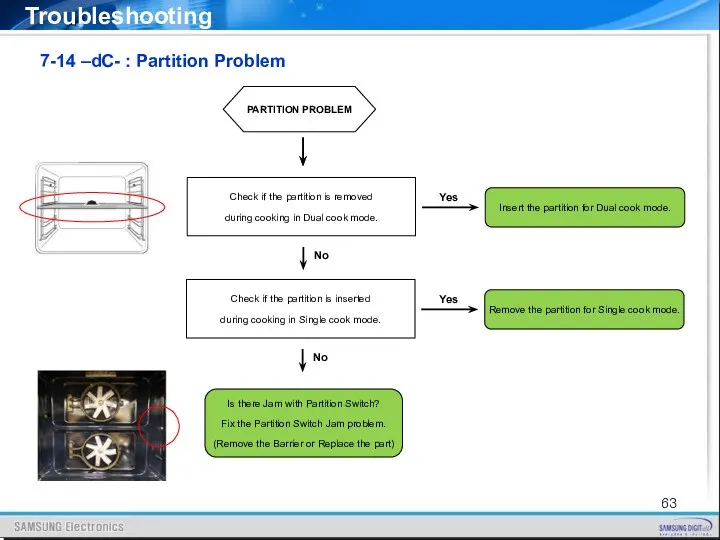

- 63. 7-14 –dC- : Partition Problem Troubleshooting PARTITION PROBLEM Check if the partition is inserted during cooking

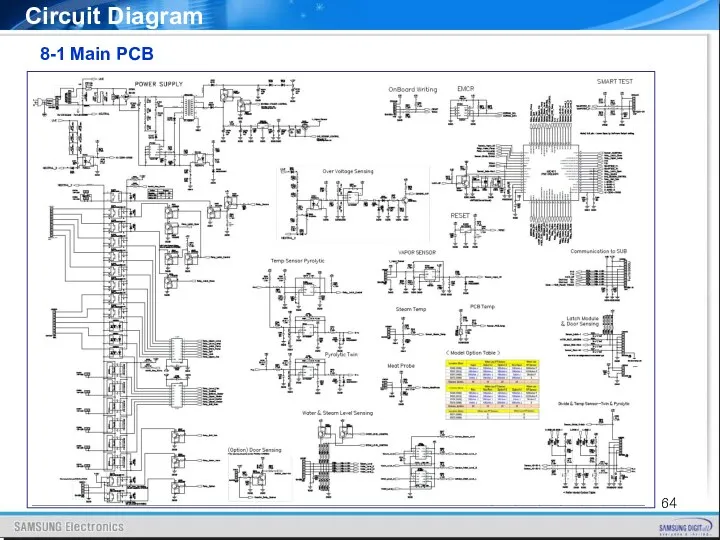

- 64. 8-1 Main PCB Circuit Diagram

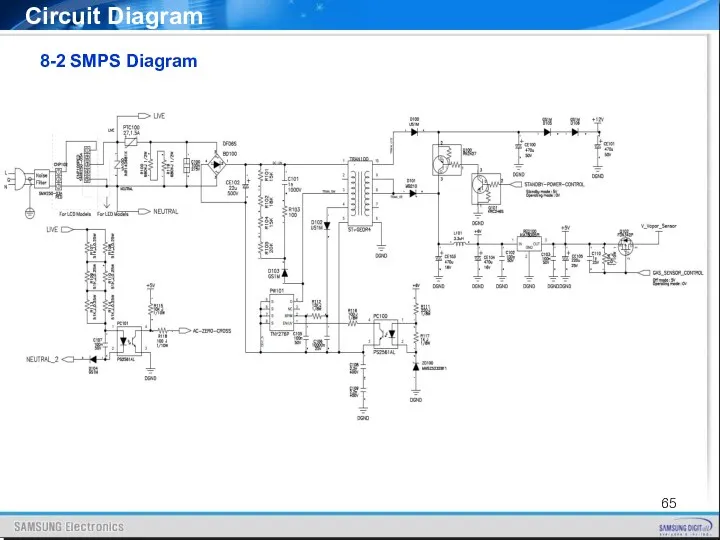

- 65. 8-2 SMPS Diagram Circuit Diagram

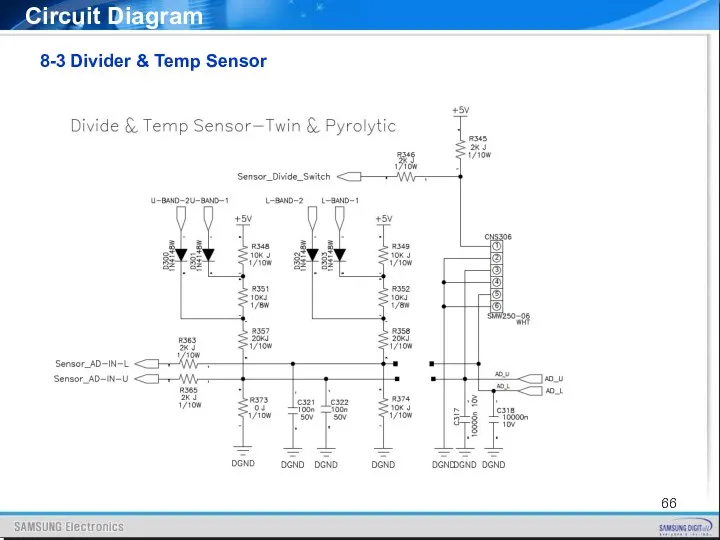

- 66. 8-3 Divider & Temp Sensor Circuit Diagram

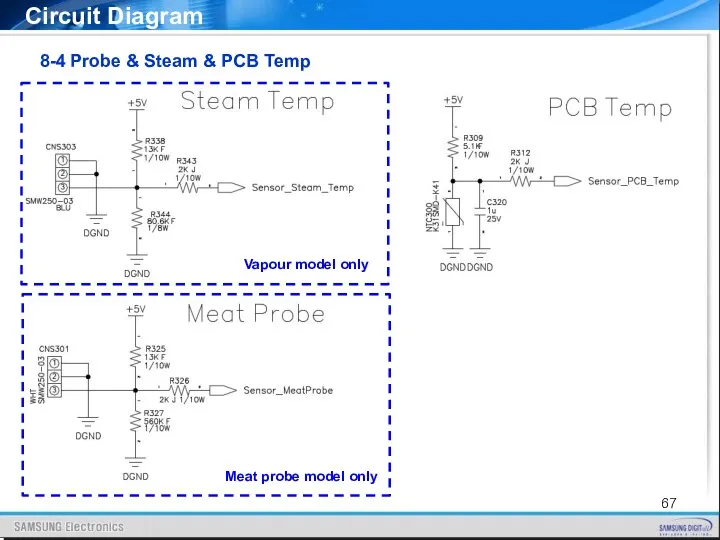

- 67. 8-4 Probe & Steam & PCB Temp Circuit Diagram Vapour model only Meat probe model only

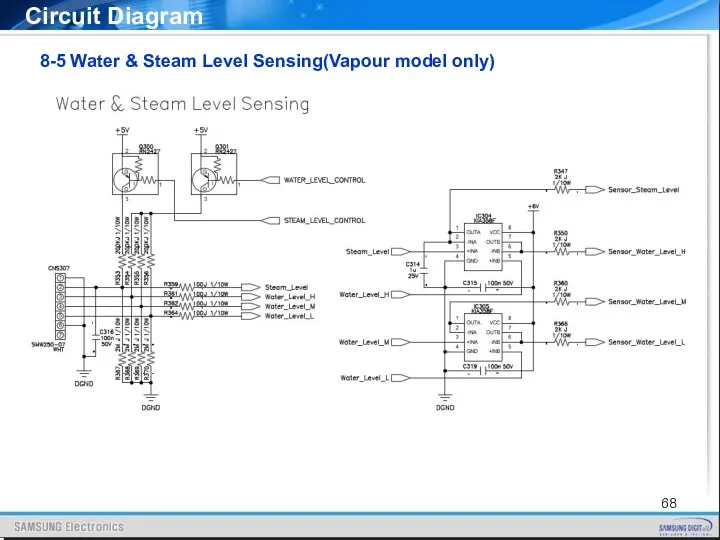

- 68. 8-5 Water & Steam Level Sensing(Vapour model only) Circuit Diagram

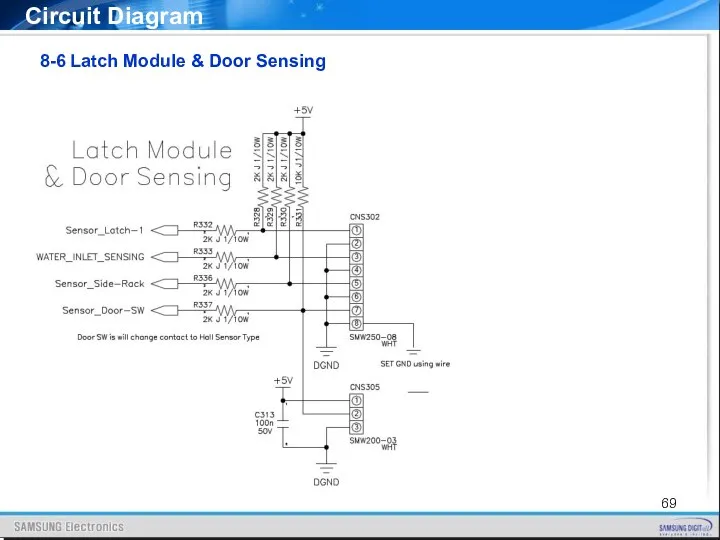

- 69. 8-6 Latch Module & Door Sensing Circuit Diagram

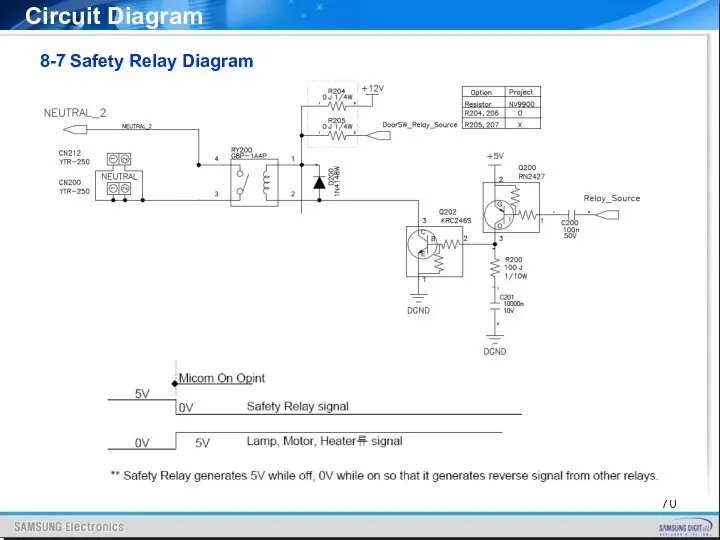

- 70. 8-7 Safety Relay Diagram Circuit Diagram

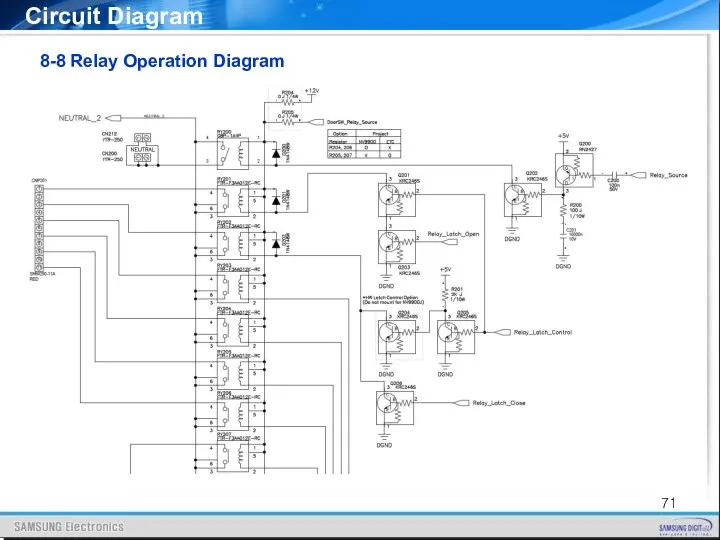

- 71. 8-8 Relay Operation Diagram Circuit Diagram

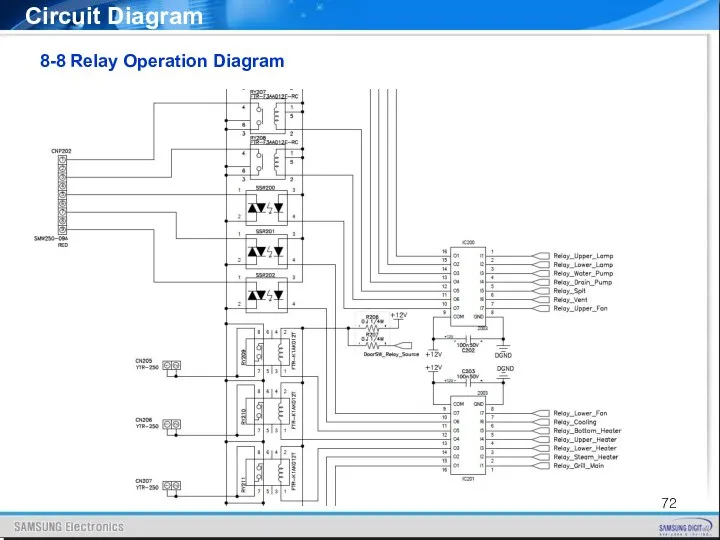

- 72. 8-8 Relay Operation Diagram Circuit Diagram

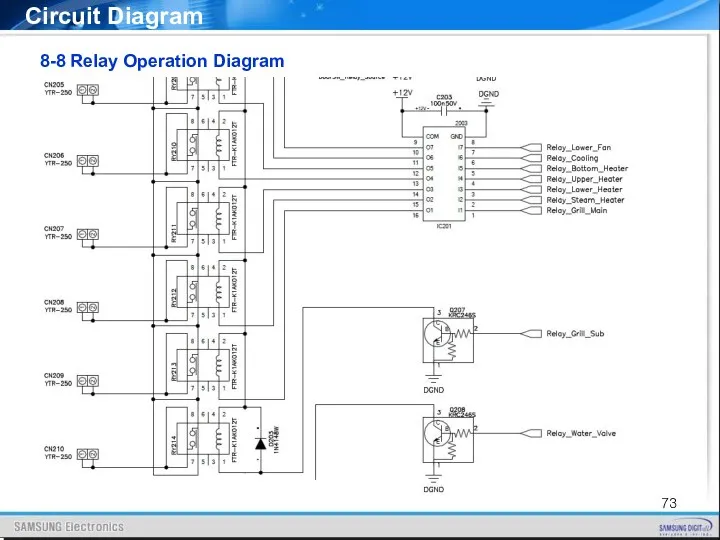

- 73. 8-8 Relay Operation Diagram Circuit Diagram

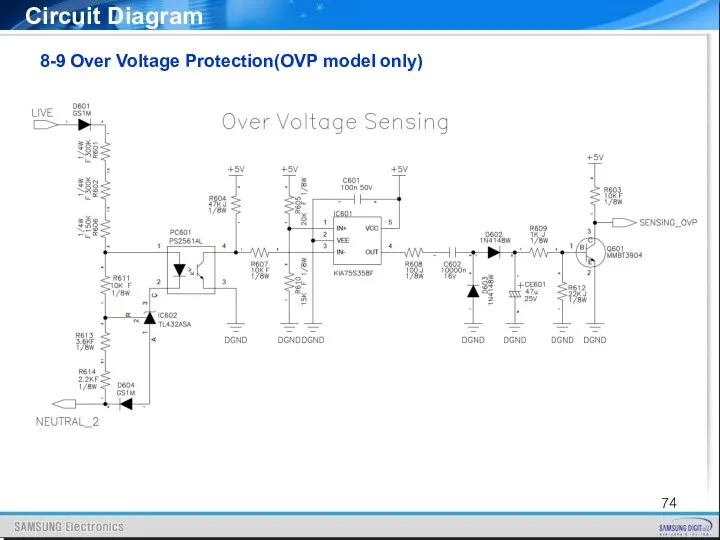

- 74. 8-9 Over Voltage Protection(OVP model only) Circuit Diagram

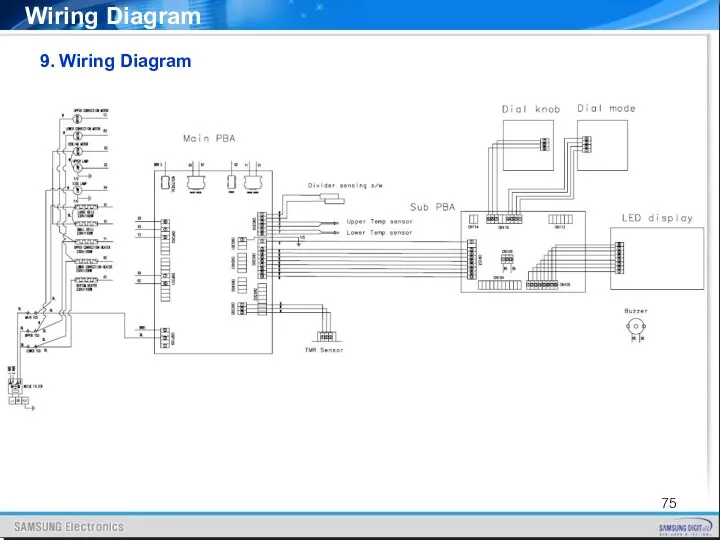

- 75. 9. Wiring Diagram Wiring Diagram

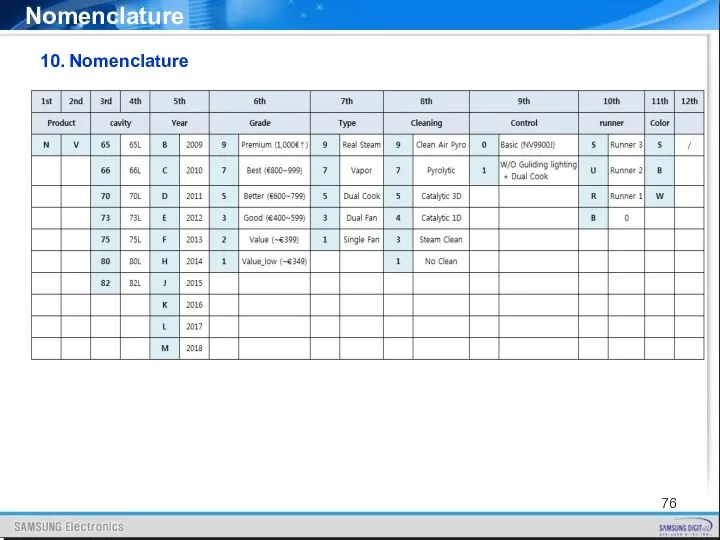

- 76. 10. Nomenclature Nomenclature

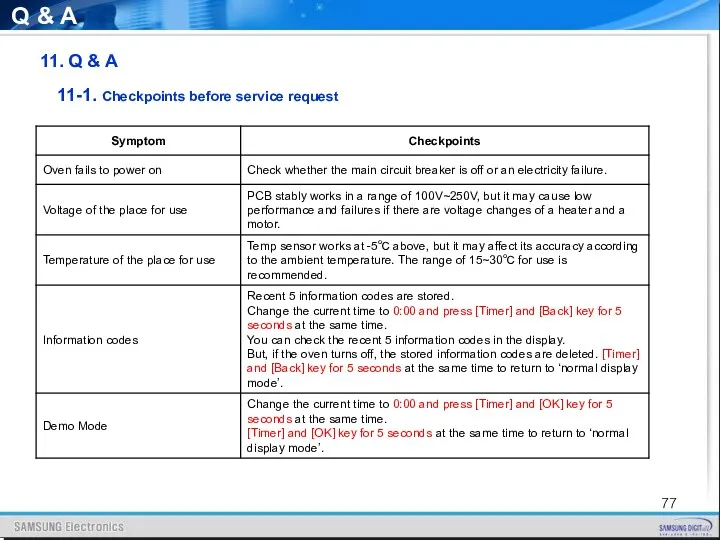

- 77. 11. Q & A Q & A 11-1. Checkpoints before service request

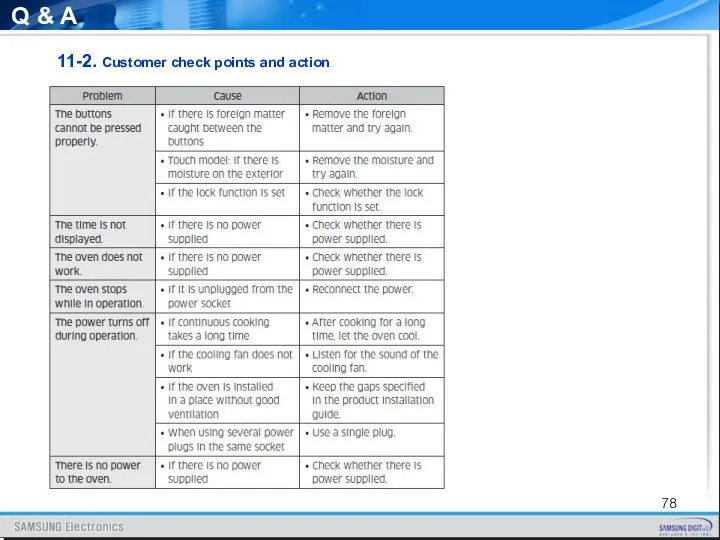

- 78. Q & A 11-2. Customer check points and action

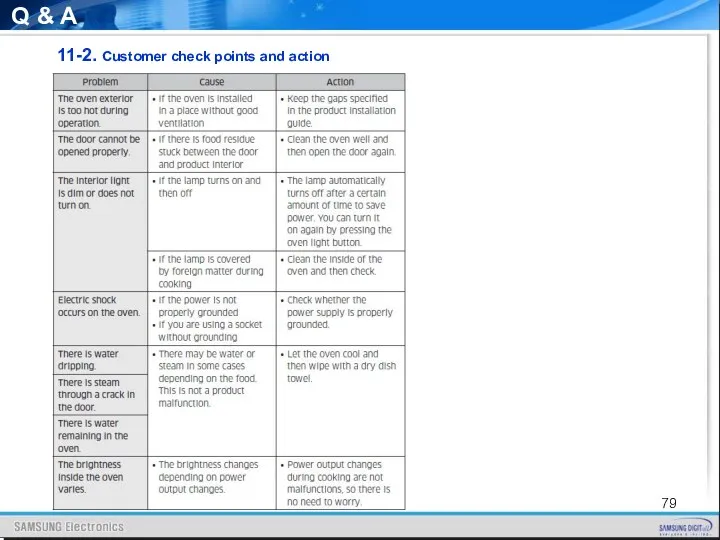

- 79. Q & A 11-2. Customer check points and action

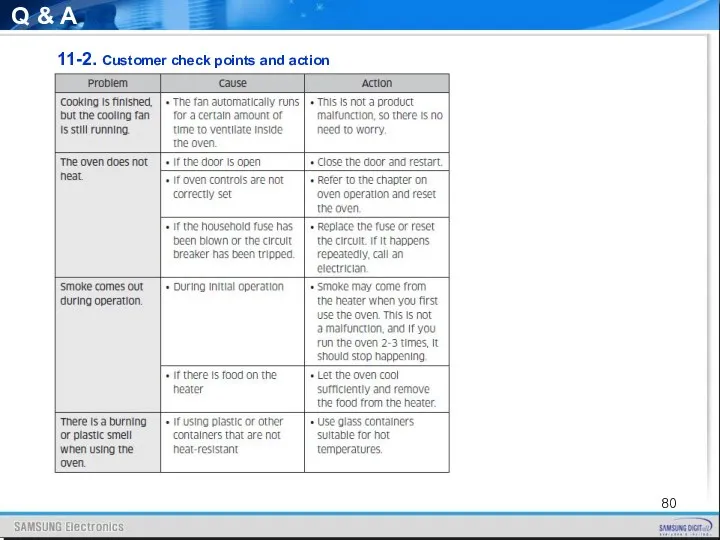

- 80. Q & A 11-2. Customer check points and action

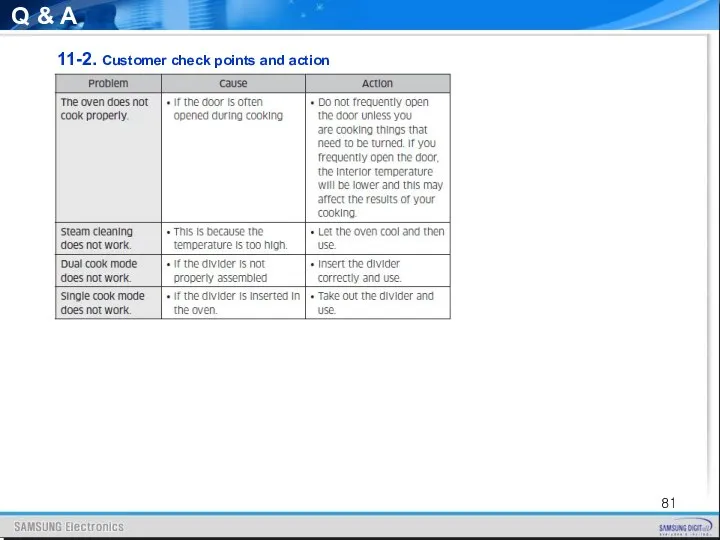

- 81. Q & A 11-2. Customer check points and action

- 83. Скачать презентацию

Уроженцы Бабушкинского района - Герои Советского Союза

Уроженцы Бабушкинского района - Герои Советского Союза Парадоксы жизни

Парадоксы жизни Тест по теме Арктические пустыни, тундра, лесотундра

Тест по теме Арктические пустыни, тундра, лесотундра Образовательной программы дошкольной образовательной организации

Образовательной программы дошкольной образовательной организации ТРЕНАЖЕРНО- ИНФОРМАЦИОННАЯ СИСТЕМА ТИСА В ШКОЛЬНОЙ ПРОГРАММЕ НА УРОКАХ ЛФК

ТРЕНАЖЕРНО- ИНФОРМАЦИОННАЯ СИСТЕМА ТИСА В ШКОЛЬНОЙ ПРОГРАММЕ НА УРОКАХ ЛФК Dwayne Douglas Johnson

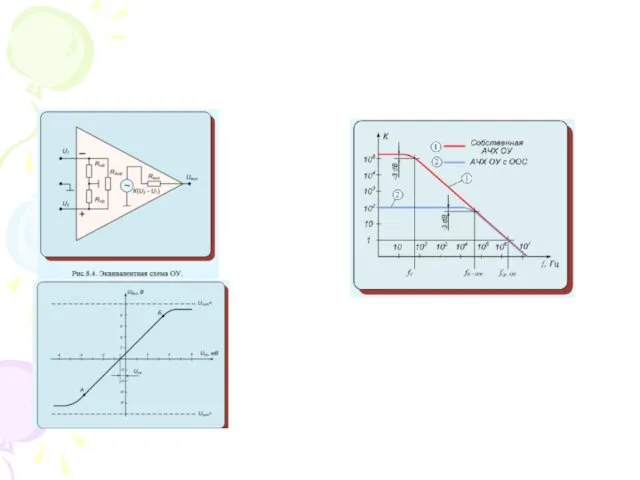

Dwayne Douglas Johnson Операционные усилители

Операционные усилители Бизнес-планирование. Модуль 6

Бизнес-планирование. Модуль 6 Похититель рассудка

Похититель рассудка Осложнения повреждений опорно-двигательного аппарата

Осложнения повреждений опорно-двигательного аппарата Past Simple

Past Simple speakout

speakout Жилища народов России в старину

Жилища народов России в старину Спектры и спектральный анализ

Спектры и спектральный анализ Заболевания сердечно-сосудистой системы

Заболевания сердечно-сосудистой системы Достижения педагога

Достижения педагога Эксперту: Структура и содержание устной части

Эксперту: Структура и содержание устной части дыхательная недостаточность

дыхательная недостаточность fb-5fa0bf70

fb-5fa0bf70 Презентация Развиваем мелкую моторику рук

Презентация Развиваем мелкую моторику рук Презентация Озера

Презентация Озера Массаж

Массаж Дополнительные авторские программы художественно - эстетической направленности: ХУДОЖЕСТВЕННЫЙ ЯЗЫК ИЗОБРАЗИТЕЛЬНОГО ИСКУССТВА, СМОТРЮ НА МИР ГЛАЗАМИ ХУДОЖНИКА, ВОЛШЕБНЫЕ СЕКРЕТЫ ХУДОЖНИКА, В МИРЕ ХУДОЖ

Дополнительные авторские программы художественно - эстетической направленности: ХУДОЖЕСТВЕННЫЙ ЯЗЫК ИЗОБРАЗИТЕЛЬНОГО ИСКУССТВА, СМОТРЮ НА МИР ГЛАЗАМИ ХУДОЖНИКА, ВОЛШЕБНЫЕ СЕКРЕТЫ ХУДОЖНИКА, В МИРЕ ХУДОЖ Tsesnabank

Tsesnabank Технология культурных практик (коллекционирование)

Технология культурных практик (коллекционирование) Военно-промышленный комплекс

Военно-промышленный комплекс Понятие об органах растений. Корень

Понятие об органах растений. Корень РАЗВИВАЮЩАЯ СРЕДА В КОРРЕКЦИОННОЙ ГРУППЕ ЗНАЙКИ ПО ФГОС

РАЗВИВАЮЩАЯ СРЕДА В КОРРЕКЦИОННОЙ ГРУППЕ ЗНАЙКИ ПО ФГОС