Слайд 2

Packaging Materials

Cans

Glass Containers

Rigid plastic containers

Flexible plastic packaging

Paper & board

Aluminium foil

& laminates

Styrofoam

Слайд 3

Cans

Advantages:

Cheap & widely used in Australia

Provides good protection of the contents

Easy

to handle during manufacture (filling stacking & packing)

Stack easily on supermarket shelves

Store for long periods of time

Steel cans:

coated in tin which acts as a barrier and prevents the food reacting with the steel.

Cans containing acidic ingredients are coated with a plastic lacquer to prevent a reaction with the metal

Used for solid & semi-solid foods.

Aluminium cans:

used for soft drinks & beer

Слайд 4

Слайд 5

Слайд 6

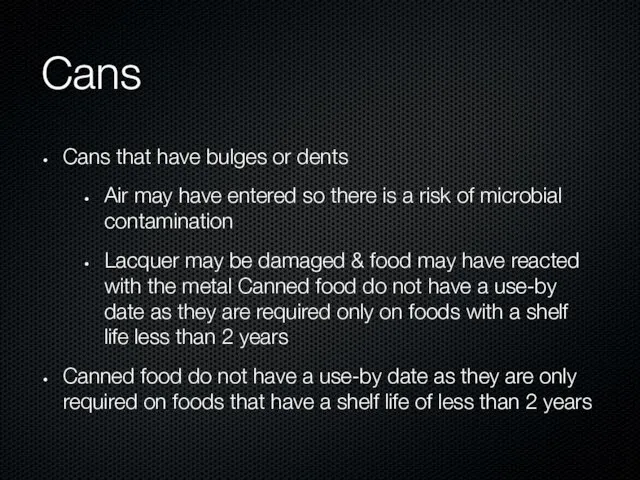

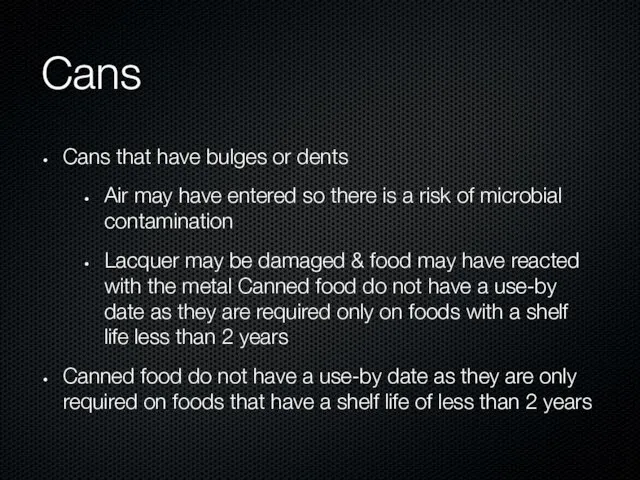

Cans

Cans that have bulges or dents

Air may have entered so there

is a risk of microbial contamination

Lacquer may be damaged & food may have reacted with the metal Canned food do not have a use-by date as they are required only on foods with a shelf life less than 2 years

Canned food do not have a use-by date as they are only required on foods that have a shelf life of less than 2 years

Слайд 7

Glass Containers

Characteristics:

Chemically inert - wont react with its contents

Non porous

Odourless &

hygienic

Contents can be seen as glass is transparent

Great strength (continually getting stronger & lighter)

Easy open & re-sealable

Variety of shapes & sizes

Long-term storage & extended shelf-life

Sustainable - can be recycled or re-used

Слайд 8

Glass Containers

Uses:

Semi-liquid, liquid & solid foods

Examples:

Preparation:

Air blowing, rinsing with warm water,

washing in detergent, sterilising (aseptic)

Слайд 9

Paper & Cardboard

Paper:

Used for a wide variety of products

Versatile & cost

effective

Variety of shapes, textures & thickness' available

Greaseproof paper can be used when packaging products such as confectionary & butter. They act as a barrier to odours & moisture

Paperboard (thicker paper-based packaging)

Can be laminated with other materials to create strength & moisture resistance E.g. Tetra packs

Pulped Fibreboard

Offers protection for products such as eggs because of the airsplace between the particles

Refer to table 11.2 Pg 218

Слайд 10

Слайд 11

Слайд 12

Слайд 13

Rigid Plastic Packaging

Advantages:

Lightweight & strong

High resistance to breakage

Available in a wide

variety of colours, shapes, sizes & textures

Can add to the sale appeal of the product

Cheap and easy to produce compared to other packaging materials

Слайд 14

Слайд 15

Rigid Plastic Packaging

Types of plastic used:

polyethylene terephalate (PET) - used clear

as colouring has an impact on the strength. E.g. soft drink, water & oil

high density polyethylene (HDPE) - stronger when colour is added. Used for products with a shorter shelf life E.g. milk

Polypropylene (PP) - high melting point so is useful for hot fill products such as soups & fruits in syrup. Can be moulded easily E.g. yoghurt & ice cream

Polystyrene (PS) - Aerated texture allows package to protect the product from physical damage. Also provide thermal retention E.g. trays & cups

Слайд 16

Слайд 17

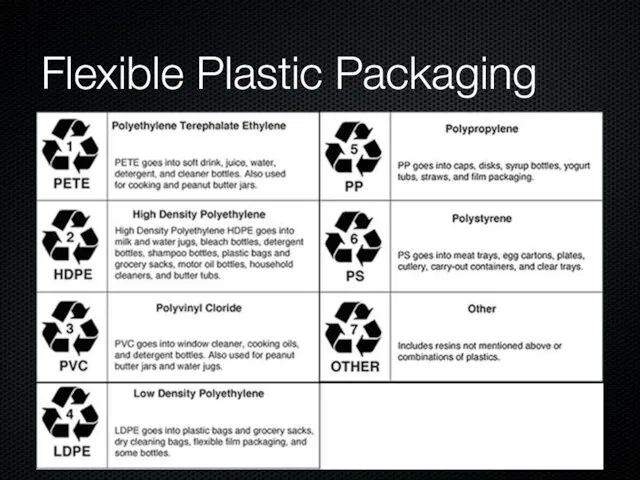

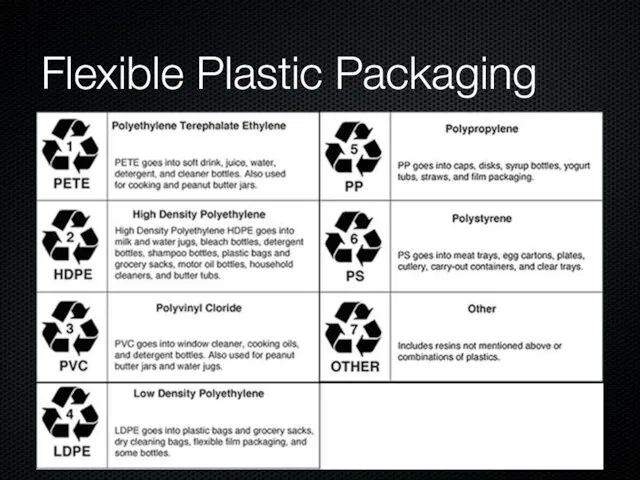

Flexible Plastic Packaging

Any plastic that is formed into a sheet or

reel with a thickness os up to 0.375mm

Plastic films & Bags:

Polyethylene (PET) E.g. cling wrap

High-density polyethylene (HDPE) E.g. Cereal bags

Low-density polyethylene (LDPE) E.g. Kraft singles wrappers

Polypropylene (PP) E.g. chip, biscuit, 2 minute noodle wrappers

Слайд 18

Flexible Plastic Packaging

Plastics are made by melting a pellet and forcing

it out into the desired shape. This process is known as EXTRUSION

Слайд 19

Слайд 20

Flexible Plastic Packaging

Слайд 21

Flexible Plastic Packaging

Laminations (composite plastics):

Combining 2 or more plastic materials from

separate reels that are glued together with adhesive

Plastics are extruded and glued together at the same time

MAP packaged and vacuum packages can use 3-11 layers

Слайд 22

Flexible Plastic Packaging

Слайд 23

Flexible Plastic packaging

Слайд 24

Aluminium Foils

Most foils made from aluminium

Advantages:

light

flexible

strong

Able to withstand moderate heat

Examples:

Tubes -

condensed milk

Trays - frozen foods

Product seals - sour cream, butter & yoghurt

Wrappers - Cadbury chocolate block

Слайд 25

Laminations

Aluminium foil joined with other materials such as plastic and paper

to create a stronger packaging material.

Example:

Muesli bar wrapper (paper, foil & plastic)

Tetra Packs:

Multi-layered laminations known as composite packages

Each layer provides a different purpose

Metallising:

Plastic coated in a fine layer of metal. E.g. Twisties chip packets

Слайд 26

Презентация по природоведению к уроку по теме Организм и его свойства. Клеточное строение организмов. Разнообразие организмов (приложение к конспекту урока)

Презентация по природоведению к уроку по теме Организм и его свойства. Клеточное строение организмов. Разнообразие организмов (приложение к конспекту урока) Классификация театрализованных игр

Классификация театрализованных игр Единая государственная система предупреждения и ликвидации чрезвычайных ситуаций

Единая государственная система предупреждения и ликвидации чрезвычайных ситуаций Первый признак равенства треугольников. 7 класс

Первый признак равенства треугольников. 7 класс Электронные генераторы

Электронные генераторы Презентация И будет помнить вся Россия...

Презентация И будет помнить вся Россия... Классификация древесных плит. Лекция №1

Классификация древесных плит. Лекция №1 Промоактивность в поддержку 3G от Киевстар

Промоактивность в поддержку 3G от Киевстар Политическая реклама как форма непрямой коммуникации

Политическая реклама как форма непрямой коммуникации Процессы изготовления швейных изделий пальтово-костюмного ассортимента (ПКА)

Процессы изготовления швейных изделий пальтово-костюмного ассортимента (ПКА) Природный газ

Природный газ Презентация по технологии - модульное оригами Стрекозы.

Презентация по технологии - модульное оригами Стрекозы. Линейная парная регрессия

Линейная парная регрессия Портфолио педагога- Биккиняевой Рамили Абдрякиповны

Портфолио педагога- Биккиняевой Рамили Абдрякиповны Mixture Separation (Qualitative Analysis)

Mixture Separation (Qualitative Analysis) Презентация Качество образования к докладу. Четвертая часть Диск

Презентация Качество образования к докладу. Четвертая часть Диск Системные платы

Системные платы Приспособление и компенсация. Лекция по патанатомии

Приспособление и компенсация. Лекция по патанатомии Здоровьесберегающие технологии в начальной школе.

Здоровьесберегающие технологии в начальной школе. Предмет термодинамики

Предмет термодинамики Размерные цепи

Размерные цепи Скрининговые тесты в диагностике состояния системы гемостаза

Скрининговые тесты в диагностике состояния системы гемостаза Жизнь практикантов в гимназии

Жизнь практикантов в гимназии Мектептегі эдістемелік жумыстын негізгі багыттары

Мектептегі эдістемелік жумыстын негізгі багыттары Приглашение для первоклассников. Диск

Приглашение для первоклассников. Диск Пример анализа маркетинг-микс товара

Пример анализа маркетинг-микс товара Zhda_Rakhit_Khr_Rasstroystva_Pitania

Zhda_Rakhit_Khr_Rasstroystva_Pitania Презентация Русская народная кукла

Презентация Русская народная кукла