Содержание

- 2. Introduction Supply Chain Sequences of firms, their facilities, functions and activities, that are involved in producing

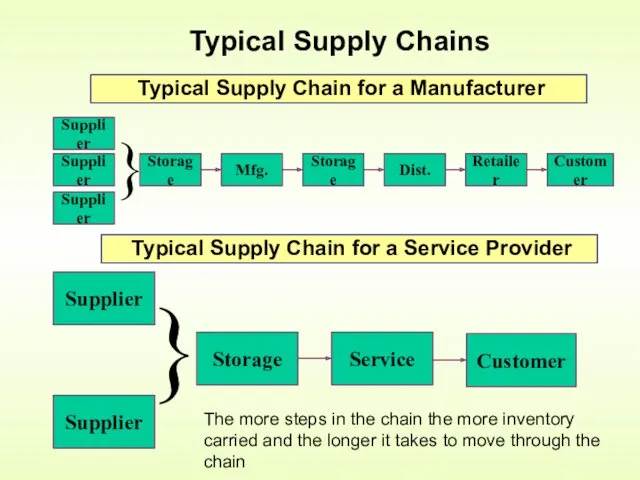

- 3. Typical Supply Chains Typical Supply Chain for a Manufacturer Typical Supply Chain for a Service Provider

- 4. Improve operations efficiency Increasing levels of outsourcing Competitive pressures – lower prices and costs Increasing globalization

- 5. Logistics Movement within the facility (flow) Incoming (raw materials) Outgoing (finished goods) Evaluating delivery alternatives –

- 6. Distribution Requirements Planning (DRP) Computerized system for inventory management and distribution planning of finished goods through

- 7. MRP: Determining raw materials requirements to support factory production of finished goods. What materials, how many

- 8. Reduction of paperwork 24/7 automated communication Lead time and inventory reduction Electronic transfer of funds Improved

- 9. E-Commerce: the use of internet to facilitate business transactions Applications include Internet buying and selling E-mail

- 10. Companies can: Have a global presence Improve competitiveness and quality Shorten supply chain response times Create

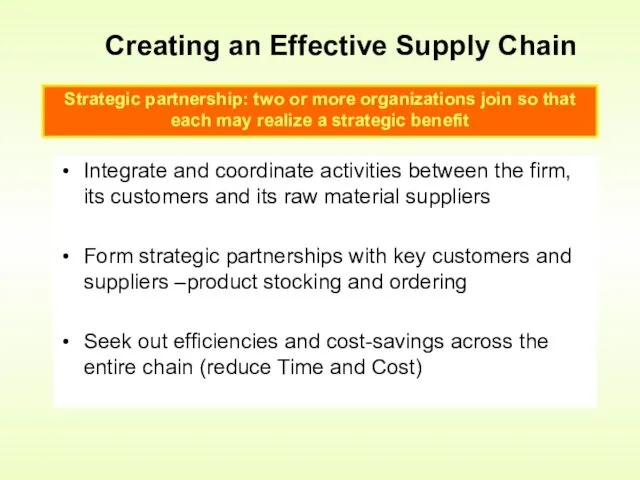

- 11. Integrate and coordinate activities between the firm, its customers and its raw material suppliers Form strategic

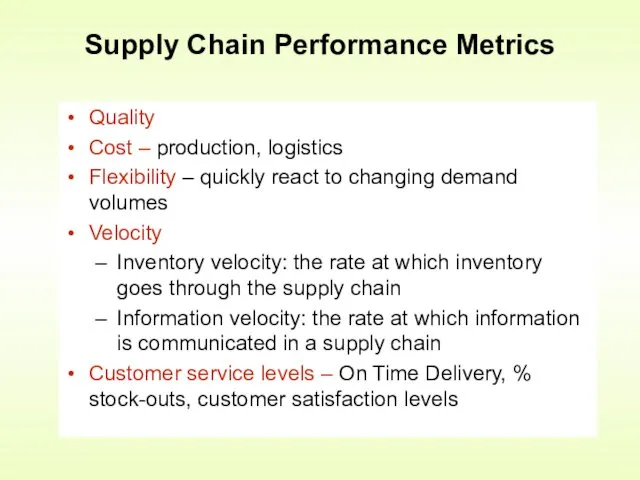

- 12. Quality Cost – production, logistics Flexibility – quickly react to changing demand volumes Velocity Inventory velocity:

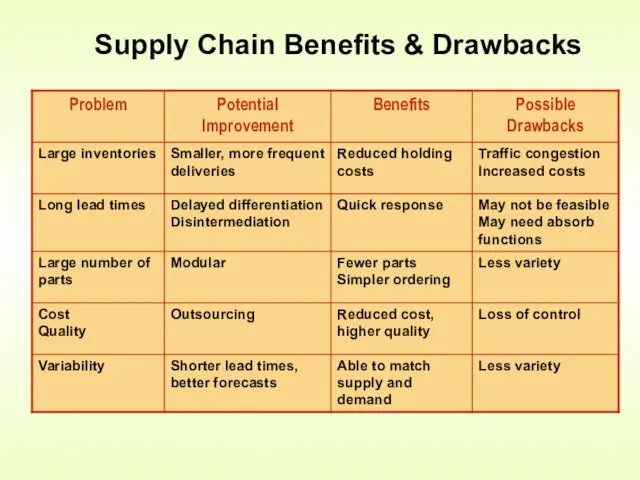

- 13. Supply Chain Benefits & Drawbacks

- 14. Purchasing: Responsible for obtaining all raw materials, parts supplies, machines and equipment, and services needed to

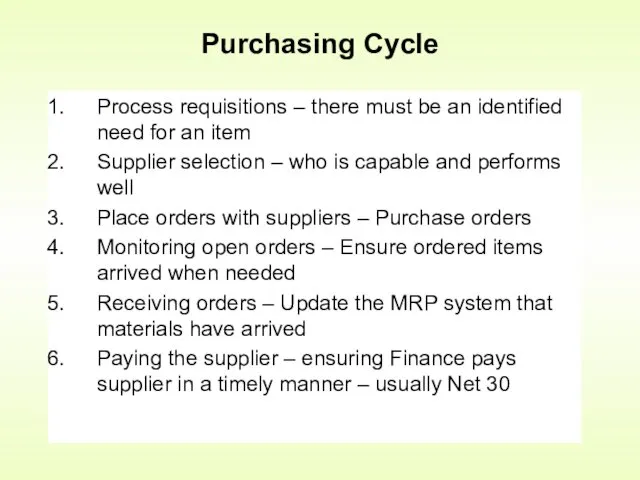

- 15. Process requisitions – there must be an identified need for an item Supplier selection – who

- 16. Value Analysis Value Analysis: examination of the function of purchased parts/components/products in an effort to reduce

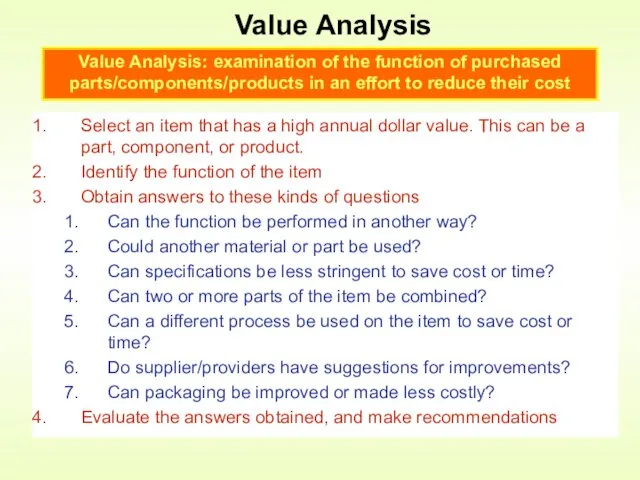

- 17. Main reasons for outsourcing (Purchasing) Ability of the outside source to provide materials, parts, or services

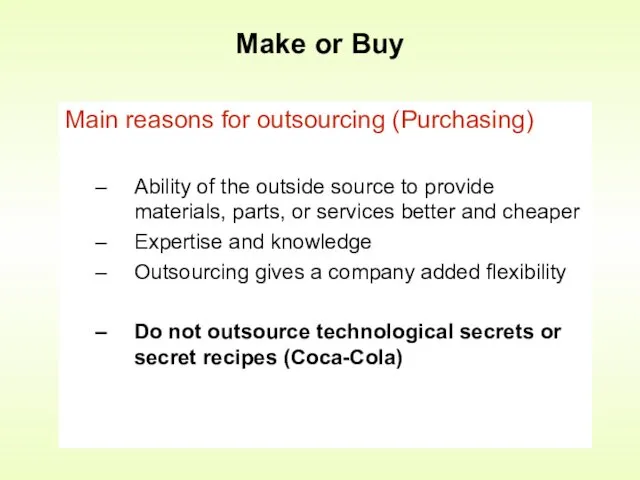

- 18. Myths concerning negotiated purchasing Negotiation is a win-lose confrontation The main goal is to obtain the

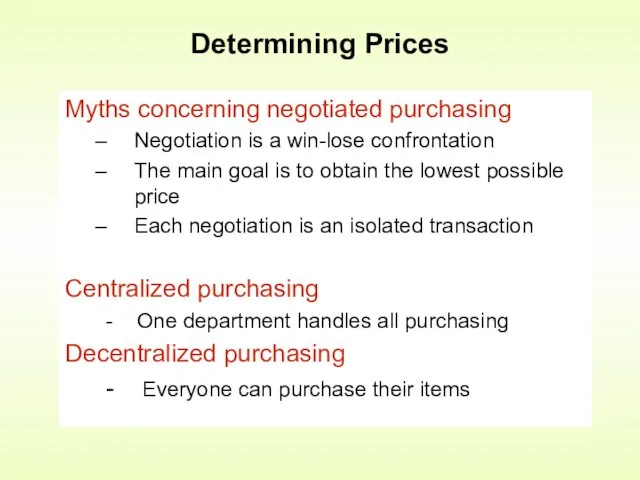

- 19. Ethics in Purchasing To consider first the interests of one’s organization in all transactions and to

- 21. Скачать презентацию

Ветераны Великой Отечественной войны - сотрудники САФУ

Ветераны Великой Отечественной войны - сотрудники САФУ презентация к статье Использование технологии критического мышления на уроках чтения и окружающего мира.

презентация к статье Использование технологии критического мышления на уроках чтения и окружающего мира. Подготовка кадрового состава для организаций отдыха и оздоровления детей в условиях педагогического вуза

Подготовка кадрового состава для организаций отдыха и оздоровления детей в условиях педагогического вуза 6.4. Системы управления оборудованием ТЗА

6.4. Системы управления оборудованием ТЗА Художественная культура России в XVIII веке

Художественная культура России в XVIII веке Роль медицинской сестры в охране репродуктивного здоровья и планирования семьи

Роль медицинской сестры в охране репродуктивного здоровья и планирования семьи Отдел продаж Skoda. Итоги за март 2018 года

Отдел продаж Skoda. Итоги за март 2018 года Измерение влажности воздуха

Измерение влажности воздуха Тибетский тест личности

Тибетский тест личности Дербес компьютер. Компьютердің құрылысы

Дербес компьютер. Компьютердің құрылысы Закят: очищение имущества и залог процветания общества

Закят: очищение имущества и залог процветания общества День знаний для 2 класса.

День знаний для 2 класса. Компетенция в процессе обучения

Компетенция в процессе обучения Образование, наука, техника и технологии. Методы научного познания

Образование, наука, техника и технологии. Методы научного познания Строительные грузы и их транспортировка

Строительные грузы и их транспортировка Александр II Освободитель 1855-1881

Александр II Освободитель 1855-1881 Нобелевская премия

Нобелевская премия Пи́ттсбург Пи́нгвинз— профессиональный хоккейный клуб

Пи́ттсбург Пи́нгвинз— профессиональный хоккейный клуб Основные виды дефектов, причины и способы их устранения

Основные виды дефектов, причины и способы их устранения Что такое текст? 5 класс

Что такое текст? 5 класс Проектирование цифровых устройств на ПЛИС

Проектирование цифровых устройств на ПЛИС Основные положения и принципы клинической эпидемиологии, связь клинической эпидемиологии с биостатистикой

Основные положения и принципы клинической эпидемиологии, связь клинической эпидемиологии с биостатистикой Ингибиторы протонной помпы

Ингибиторы протонной помпы Использование русских народных и шумовых инструментов на праздниках и развлечениях в ДОУ.

Использование русских народных и шумовых инструментов на праздниках и развлечениях в ДОУ. Количество вещества, число Авогадро, молярная масса, молярный объём, уравнение связи

Количество вещества, число Авогадро, молярная масса, молярный объём, уравнение связи Погрузчики. Виды погрузчиков

Погрузчики. Виды погрузчиков Краудфандинг - народное финансирование

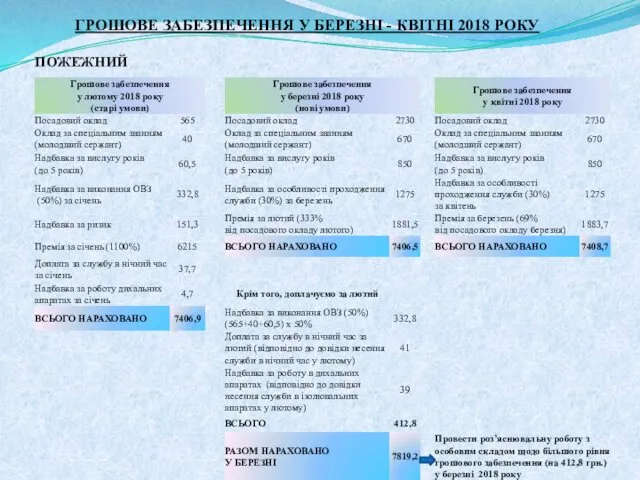

Краудфандинг - народное финансирование Грошове забезпечення у березні - квітні 2018 року

Грошове забезпечення у березні - квітні 2018 року