Содержание

- 2. Content Partitions Single wall diaphragm Full liftered double wall diaphragm Adjustable double wall diaphragm Outlet partitions

- 3. Content Partitions Single wall diaphragm Full liftered double wall diaphragm Adjustable double wall diaphragm Outlet partitions

- 4. Different types of partitions Partition between chambers Single wall diaphragm Double wall diaphragm full lifting Double

- 5. Purposes of a partition Main partition roles Keep grinding media in several compartments Material flow control

- 6. Content Partitions Single wall diaphragm Full liftered double wall diaphragm Adjustable double wall diaphragm Outlet partitions

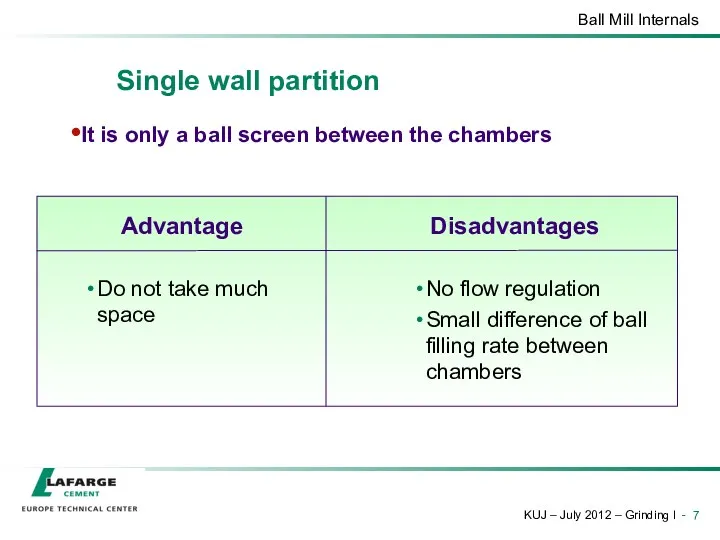

- 7. Single wall partition It is only a ball screen between the chambers Advantage Do not take

- 8. Content Partitions Single wall diaphragm Full liftered double wall diaphragm Adjustable double wall diaphragm Outlet partitions

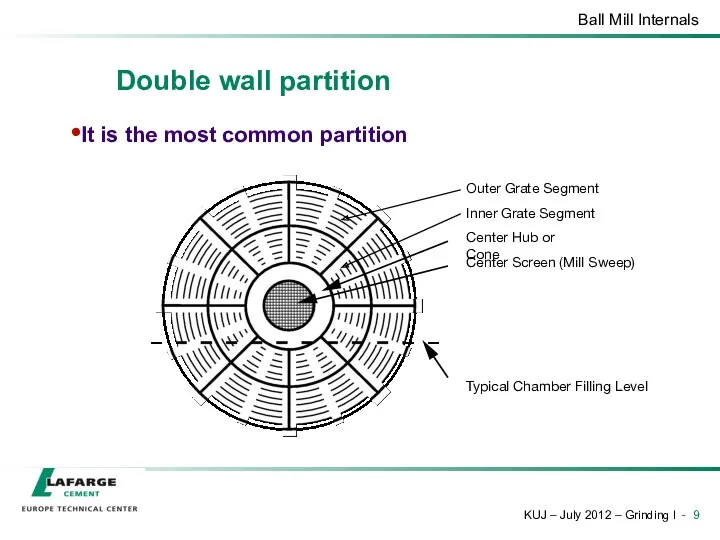

- 9. Double wall partition It is the most common partition Outer Grate Segment Inner Grate Segment Center

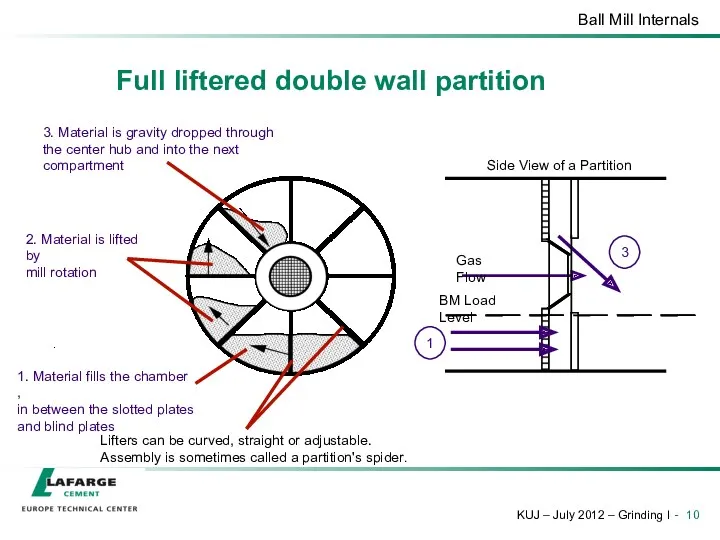

- 10. Full liftered double wall partition 3. Material is gravity dropped through the center hub and into

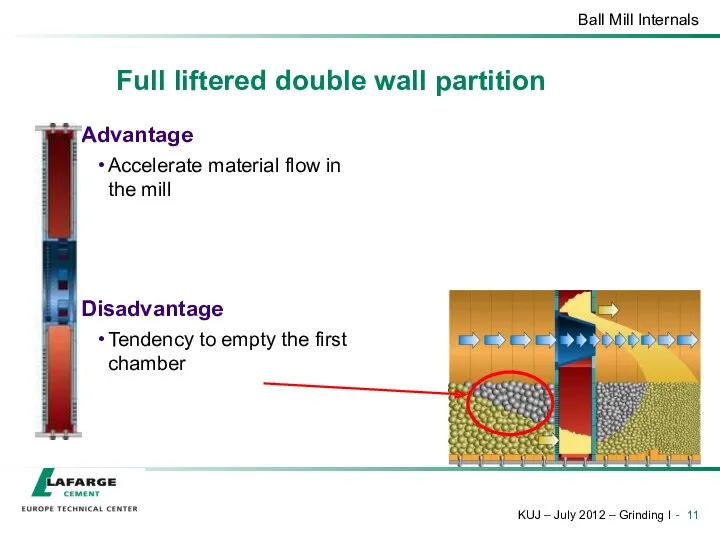

- 11. Full liftered double wall partition Advantage Accelerate material flow in the mill Disadvantage Tendency to empty

- 12. Content Partitions Single wall diaphragm Full liftered double wall diaphragm Adjustable double wall diaphragm Outlet partitions

- 13. Adjustable double wall partition Purpose Control the empty zone before the partition by regulating the material

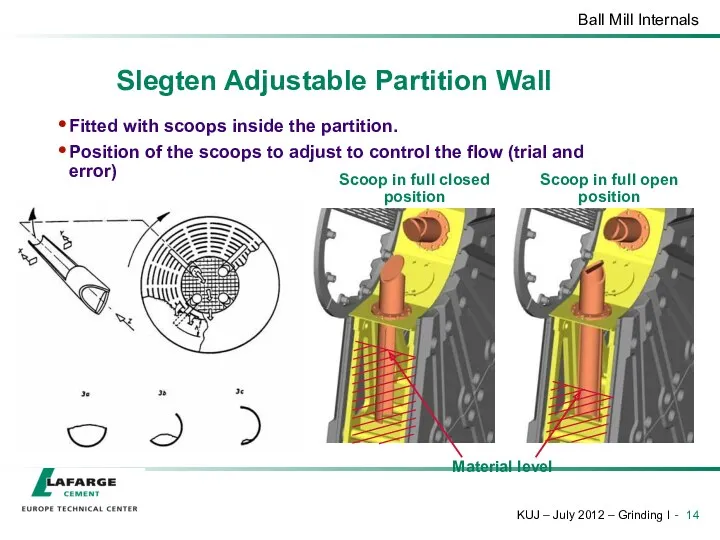

- 14. Slegten Adjustable Partition Wall Fitted with scoops inside the partition. Position of the scoops to adjust

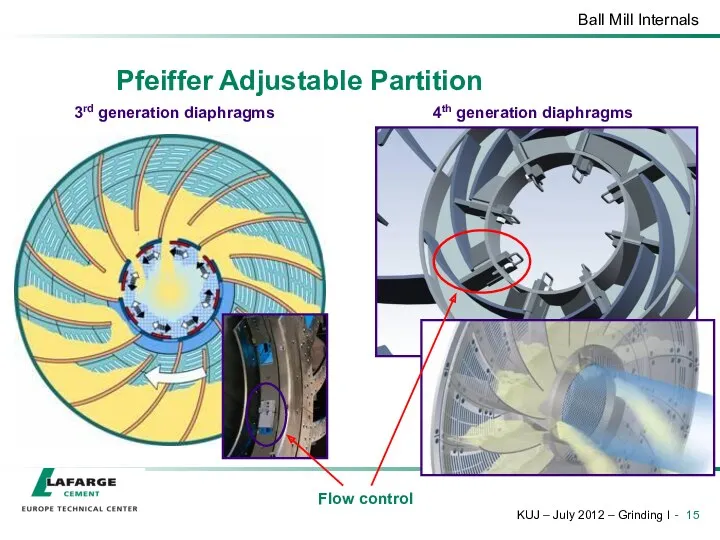

- 15. 3rd generation diaphragms 4th generation diaphragms Flow control Pfeiffer Adjustable Partition

- 16. Content Partitions Single wall diaphragm Full liftered double wall diaphragm Adjustable double wall diaphragm Outlet partitions

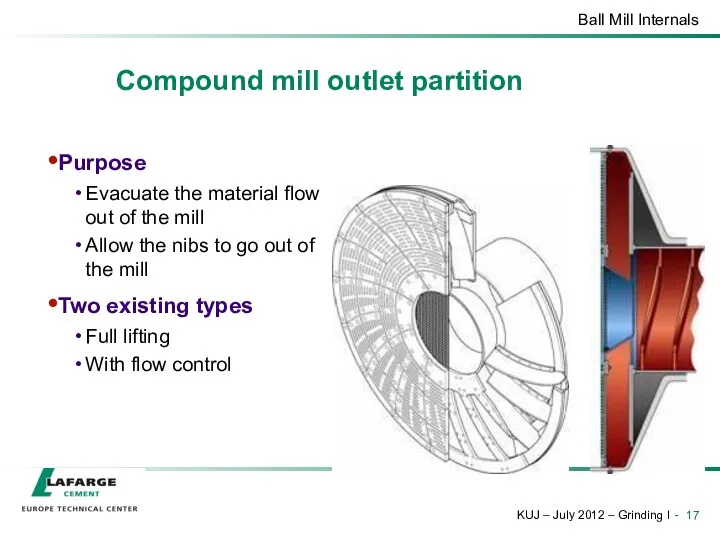

- 17. Compound mill outlet partition Purpose Evacuate the material flow out of the mill Allow the nibs

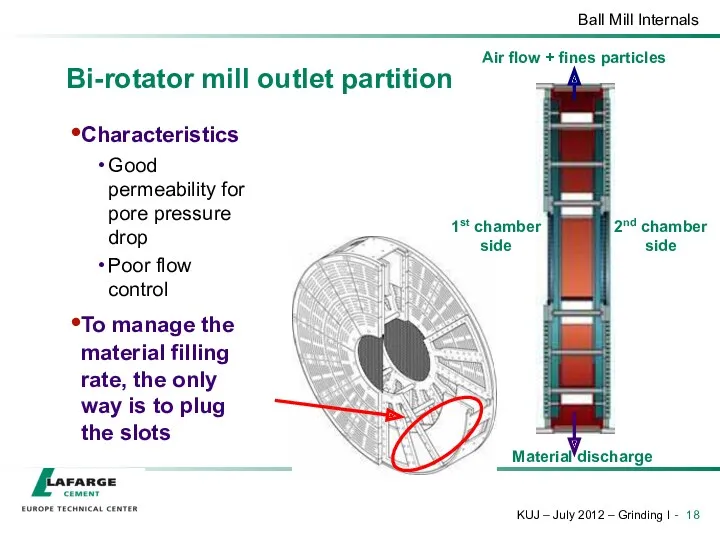

- 18. Bi-rotator mill outlet partition Characteristics Good permeability for pore pressure drop Poor flow control To manage

- 19. Content Partitions Single wall diaphragm Full liftered double wall diaphragm Adjustable double wall diaphragm Outlet partitions

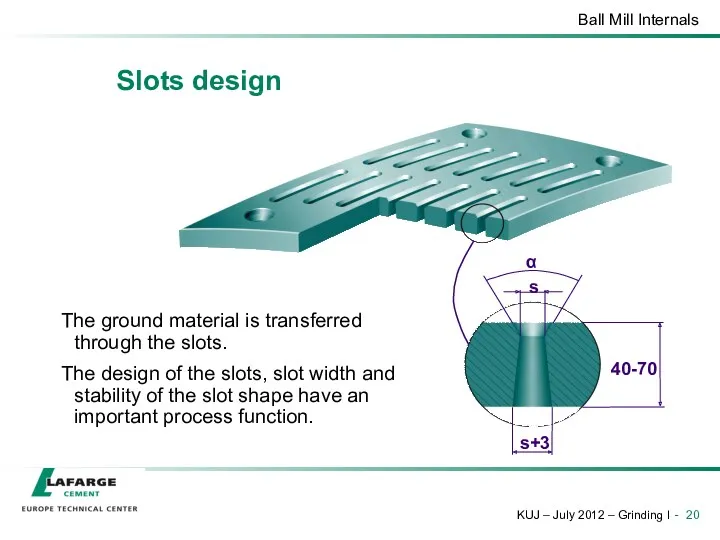

- 20. Slots design The ground material is transferred through the slots. The design of the slots, slot

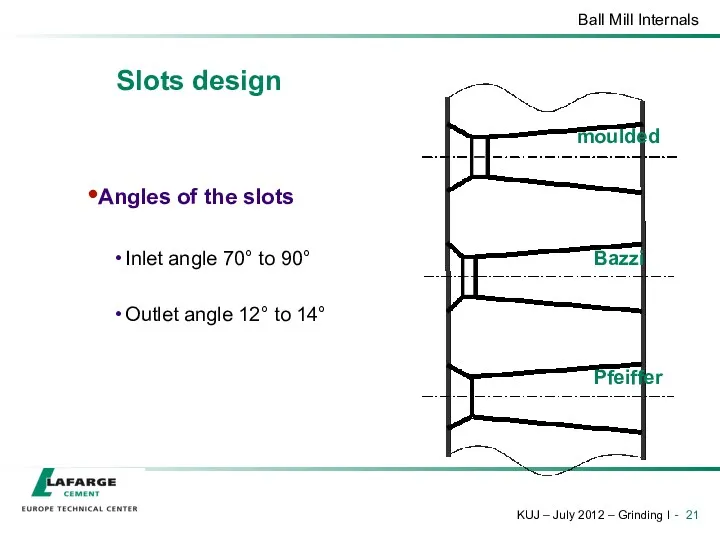

- 21. Slots design Angles of the slots Inlet angle 70° to 90° Outlet angle 12° to 14°

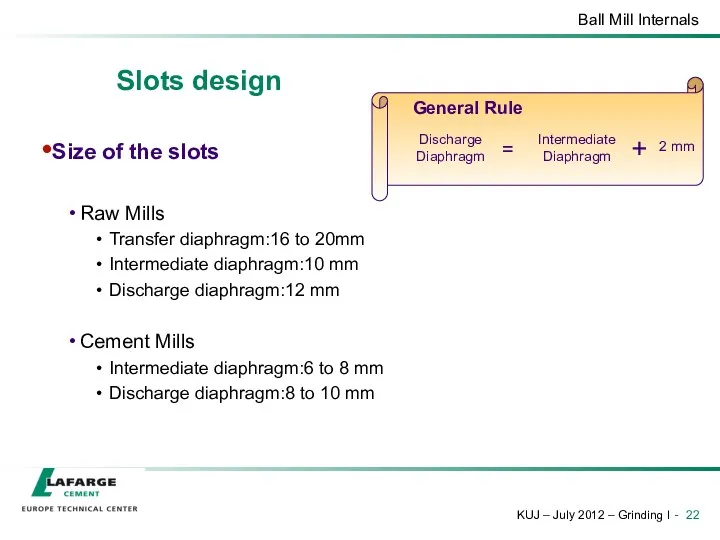

- 22. Slots design Size of the slots Raw Mills Transfer diaphragm:16 to 20mm Intermediate diaphragm:10 mm Discharge

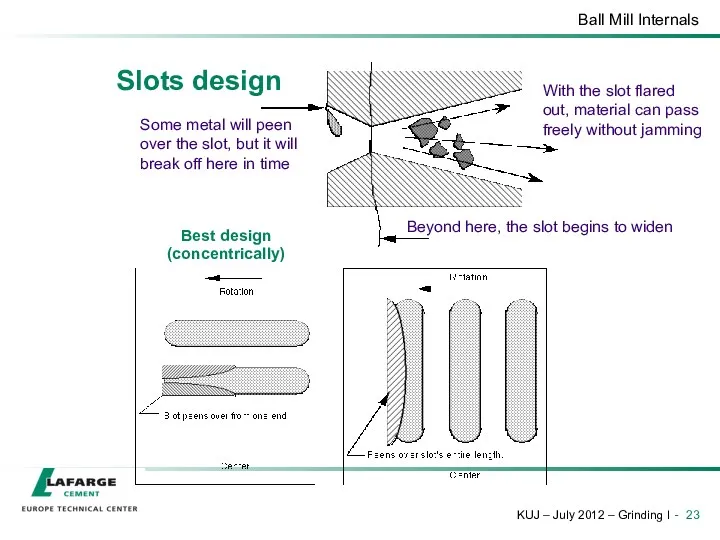

- 23. Slots design Best design (concentrically) Beyond here, the slot begins to widen With the slot flared

- 24. Peening of slots Consequence: slots have to be opened by manual grinding Slots design

- 25. Outer Grate Casting Cast grooves to protect slots

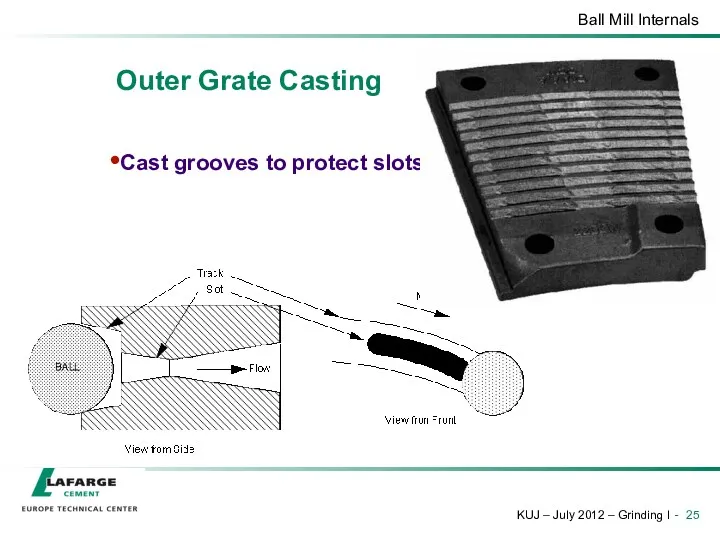

- 26. Lifter bar on partition Role: avoid wear of the partition by ball rotation on the surface

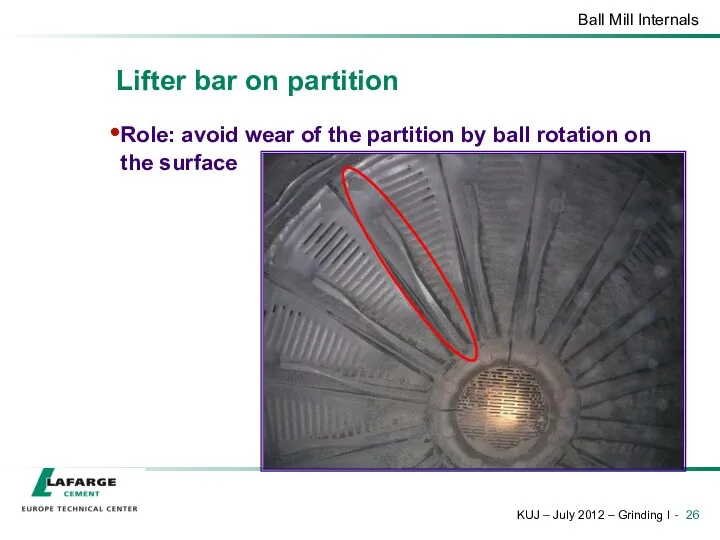

- 27. Content Partitions Single wall diaphragm Full liftered double wall diaphragm Adjustable double wall diaphragm Outlet partitions

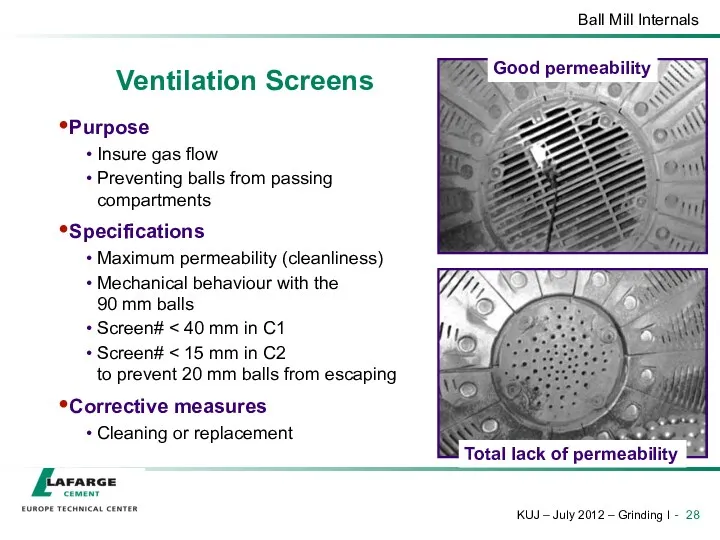

- 28. Ventilation Screens Purpose Insure gas flow Preventing balls from passing between compartments Specifications Maximum permeability (cleanliness)

- 30. Скачать презентацию

Уравнение состояния идеального газа

Уравнение состояния идеального газа Разъемные соединения для передачи крутящего момента. Лекция № 17

Разъемные соединения для передачи крутящего момента. Лекция № 17 Решение задач по теме Силы. 7 класс

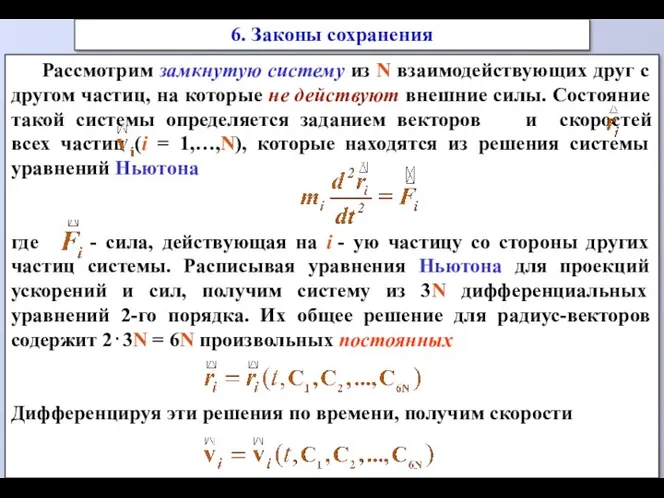

Решение задач по теме Силы. 7 класс Законы сохранения

Законы сохранения Ремонт системы питания ВАЗ 2170-1

Ремонт системы питания ВАЗ 2170-1 Презентация к уроку на тему Кристаллические тела и их применение

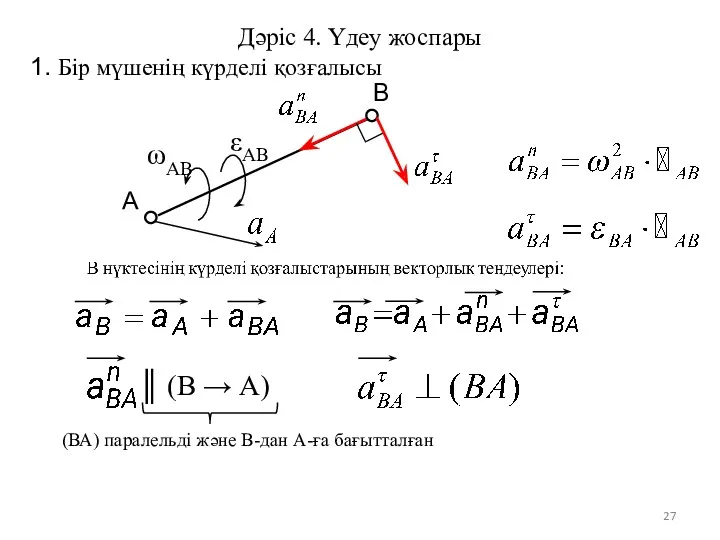

Презентация к уроку на тему Кристаллические тела и их применение Үдеу жоспары

Үдеу жоспары Наука в творчестве А.С.Пушкина

Наука в творчестве А.С.Пушкина Материаловедение. Материалы

Материаловедение. Материалы Монтаж и техническая эксплуатация теплообменника с плавающей головкой

Монтаж и техническая эксплуатация теплообменника с плавающей головкой Спутниковые системы связи

Спутниковые системы связи Назначение и состав космического комплекса. Лекция №2

Назначение и состав космического комплекса. Лекция №2 Становление и развитие паротурбинных установок. (Тема 4)

Становление и развитие паротурбинных установок. (Тема 4) Разъемные и неразъемные соединения

Разъемные и неразъемные соединения Презентация Викторина. Экология и физика

Презентация Викторина. Экология и физика Формирование информационной компетенции учащихся при изучении темы Элементы квантовой физики. 9 класс

Формирование информационной компетенции учащихся при изучении темы Элементы квантовой физики. 9 класс Техническое обслуживание и ремонт генератора автомобиля КамАЗ-5320

Техническое обслуживание и ремонт генератора автомобиля КамАЗ-5320 Получение и передача переменного электрического тока. Трансформатор

Получение и передача переменного электрического тока. Трансформатор Источники оптического импульсного когерентного излучения для информационных систем II. Полупроводниковые лазеры

Источники оптического импульсного когерентного излучения для информационных систем II. Полупроводниковые лазеры Танцующая монета

Танцующая монета Лазер. Области применения лазеров

Лазер. Области применения лазеров Хромов_В_И_ПМ-101_радиация

Хромов_В_И_ПМ-101_радиация Простые механизмы. Рычаги. Виды рычагов. Технология. 5 класс

Простые механизмы. Рычаги. Виды рычагов. Технология. 5 класс Тепловые машины. Тема 07

Тепловые машины. Тема 07 Течение вязких жидкостей

Течение вязких жидкостей Synthetic-Aperture Radar (SAR) Image Formation Processing

Synthetic-Aperture Radar (SAR) Image Formation Processing Неразъемные соединения

Неразъемные соединения Уравнения Лагранжа ii рода. Обобщённые координаты, скорости и силы

Уравнения Лагранжа ii рода. Обобщённые координаты, скорости и силы