Слайд 2

General

CNC (Computerized Numerical Control) is an electronic method for control and

regulation of machine (CNC machines), or the equipment used (controller, computer).

The set-up and the numerical address of the sending control information is described in DIN 66025/ISO 6983, usually referred to DIN / ISO programming. DIN A program can run on any CNC machine. However, for almost all machine specific commands, such as cycles, which can only be interpreted by these machines. Cycles are global programs, with parameters / variables that can be used where "pockets" (square contours or similar bags) or describe holes etc.. This makes the programming cycles and increase the clarity.

Слайд 3

G-Code

In order to provide an easy way for programming geometric motion

profiles SoftMotion supports parts of the CNC language DIN66025. Since the whole SoftMotion concept is embedded in the much more powerful language IEC61131, only those parts of DIN66025 are supported, which serve to create a path.

Prescribed structure of a CNC program:

N G

Example:

% MyExample

N10 G01 X100 Y100 E100 F100 E-200

N20 G01 Z40 F20

N30 G03 X-100 R200 F100

Слайд 4

Fundamental of CNC-Technology 2D

2-D-control:

Allows machining with two axes in linear and

circular movements:

Supported by: C5 with CoDeSys V2.3

C6 with CoDeSys V3.4 (COMBIVIS studio)

Слайд 5

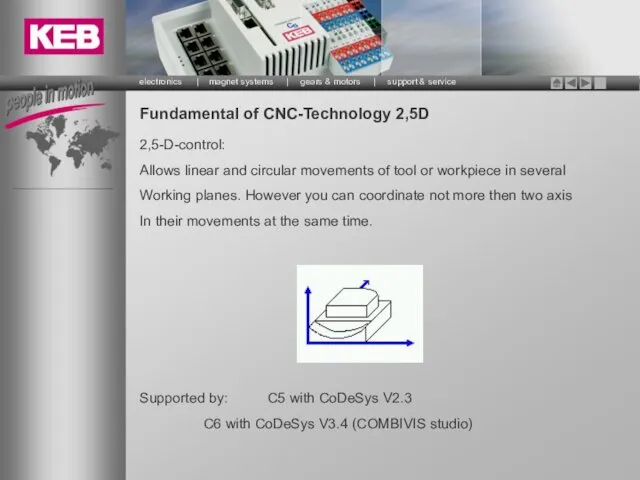

Fundamental of CNC-Technology 2,5D

2,5-D-control:

Allows linear and circular movements of tool or

workpiece in several

Working planes. However you can coordinate not more then two axis

In their movements at the same time.

Supported by: C5 with CoDeSys V2.3

C6 with CoDeSys V3.4 (COMBIVIS studio)

Слайд 6

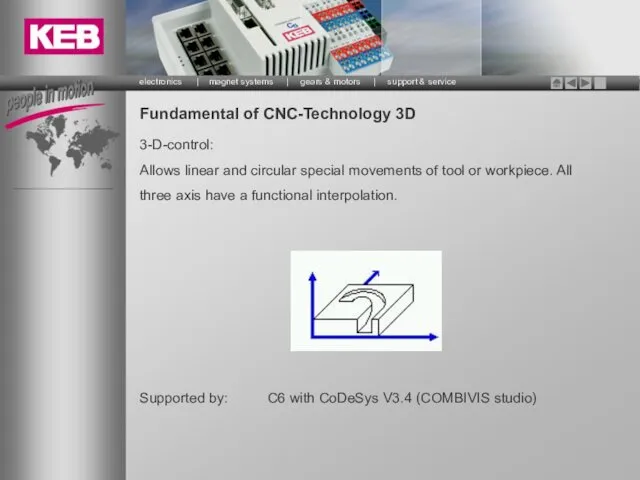

Fundamental of CNC-Technology 3D

3-D-control:

Allows linear and circular special movements of tool

or workpiece. All

three axis have a functional interpolation.

Supported by: C6 with CoDeSys V3.4 (COMBIVIS studio)

Познавательная игра:Знатоки природы

Познавательная игра:Знатоки природы Перифериялық құралдары. Перифериялық құралдардың техникалық мүмкіндіктері, құрылымы, қолданылуы. Ақпаратты енгізу құралдары

Перифериялық құралдары. Перифериялық құралдардың техникалық мүмкіндіктері, құрылымы, қолданылуы. Ақпаратты енгізу құралдары Закладка для книг

Закладка для книг презентация по теме Многоатомные спирты

презентация по теме Многоатомные спирты Развитие мелкой моторики у детей дошкольного возраста на занятиях по тестопластике.

Развитие мелкой моторики у детей дошкольного возраста на занятиях по тестопластике. Анализ источников финансирования некоммерческих организаций

Анализ источников финансирования некоммерческих организаций Шкала рН. Функции воды в организме

Шкала рН. Функции воды в организме Мы живём в культурной столице..

Мы живём в культурной столице.. Моя малая Родина.Карабаново.

Моя малая Родина.Карабаново. Деление клетки. Митоз

Деление клетки. Митоз Объекты всемирного культурного и природного наследия

Объекты всемирного культурного и природного наследия Программирование на Python: графика. Простые программы

Программирование на Python: графика. Простые программы 4. Трансакционные издержки

4. Трансакционные издержки Сплавы металлов

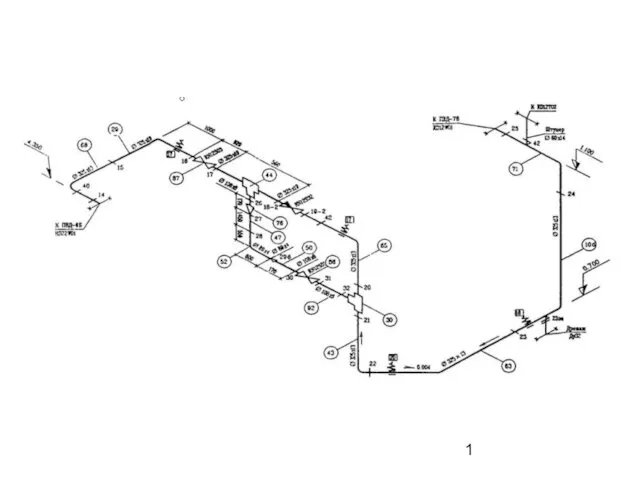

Сплавы металлов Трубопроводы на АЭС. Основные понятия и определения

Трубопроводы на АЭС. Основные понятия и определения Неделя русского языка и литературы в школе

Неделя русского языка и литературы в школе первый букварь

первый букварь Сбережение русского языка

Сбережение русского языка Национальная программа развития сети автомобильных дорог в России

Национальная программа развития сети автомобильных дорог в России Агата Крісті

Агата Крісті презентация Использование рукавиц в разных профессиях к проекту Кому нужны рукавицы?

презентация Использование рукавиц в разных профессиях к проекту Кому нужны рукавицы? Психологические аспекты воспитания в ДОЛ. Решение конфликтов в ДОЛ

Психологические аспекты воспитания в ДОЛ. Решение конфликтов в ДОЛ Русский космизм

Русский космизм Теория коллектива

Теория коллектива Фрезерное и токарное дело

Фрезерное и токарное дело Почему мы не можем отказаться от пластиковых пакетов

Почему мы не можем отказаться от пластиковых пакетов Ощущения и виды ощущений

Ощущения и виды ощущений Гимнастика для глаз.

Гимнастика для глаз.