Содержание

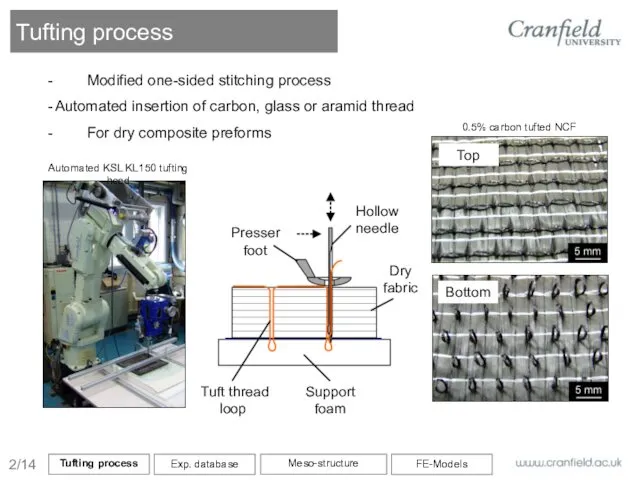

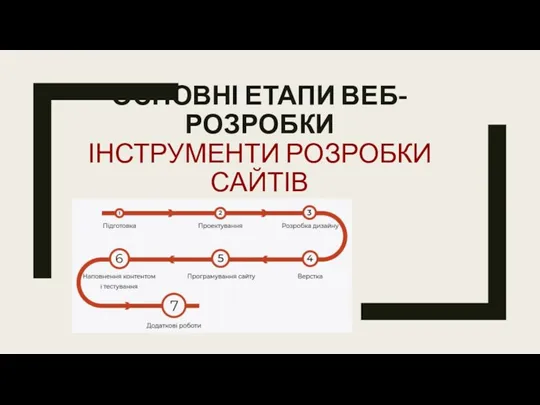

- 2. Tufting process - Modified one-sided stitching process - Automated insertion of carbon, glass or aramid thread

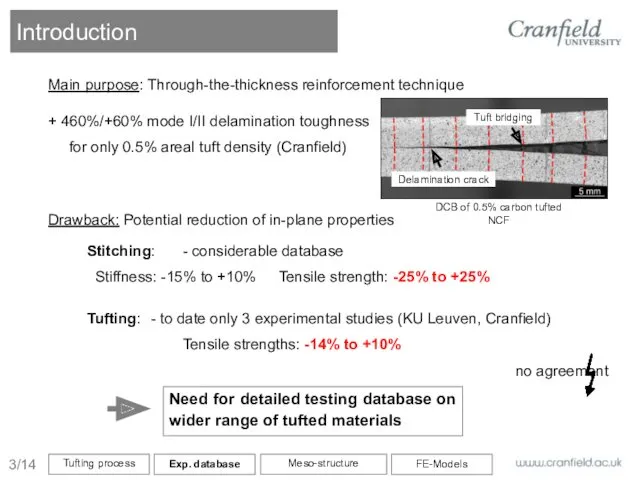

- 3. Need for detailed testing database on wider range of tufted materials Tufting process Exp. database Meso-structure

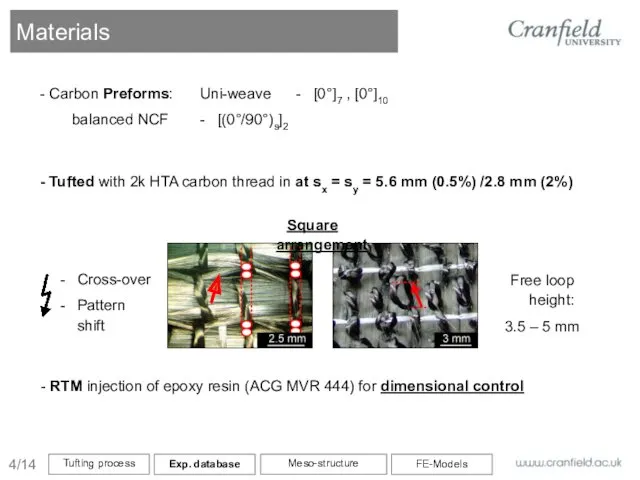

- 4. Tufting process Exp. database Meso-structure FE-Models Materials - Carbon Preforms: Uni-weave - [0°]7 , [0°]10 balanced

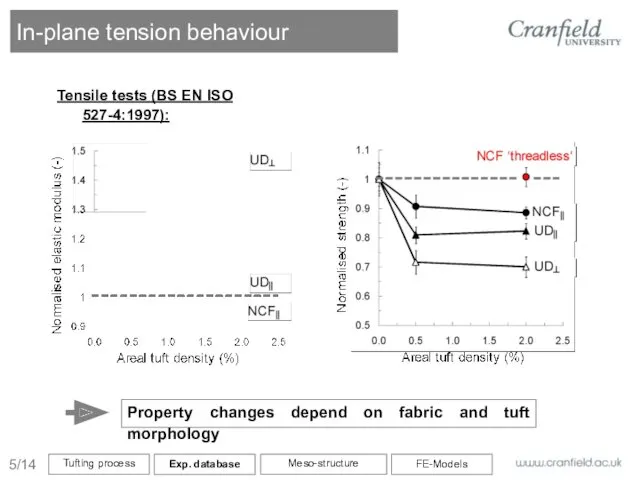

- 5. Tufting process Exp. database Meso-structure FE-Models In-plane tension behaviour Tensile tests (BS EN ISO 527-4:1997): Property

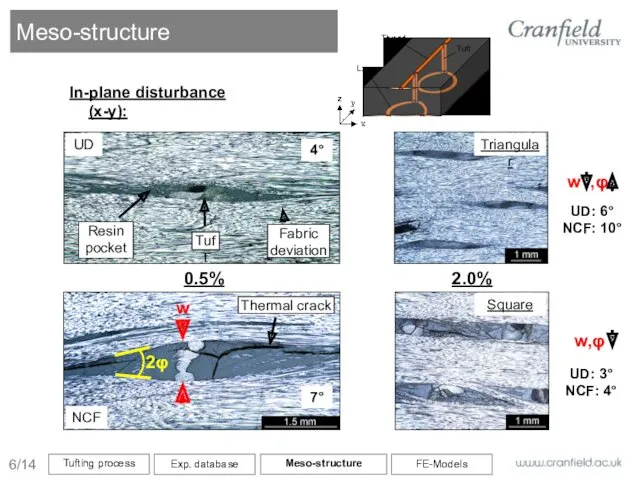

- 6. Meso-structure In-plane disturbance (x-y): Tufting process Exp. database Meso-structure FE-Models Resin pocket Tuft Thermal crack Fabric

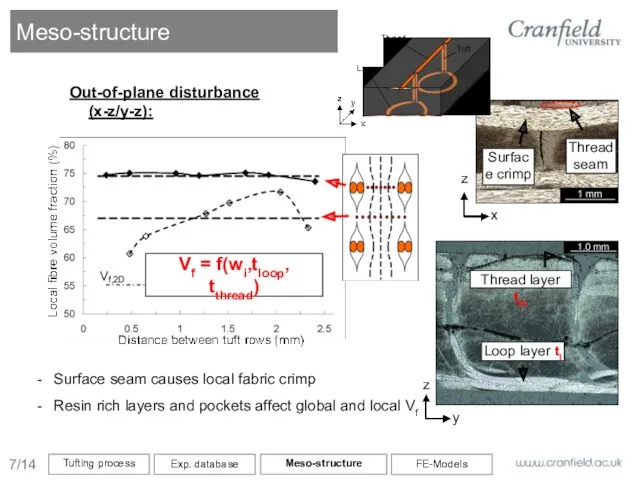

- 7. Meso-structure Tufting process Exp. database Meso-structure FE-Models Surface seam causes local fabric crimp Resin rich layers

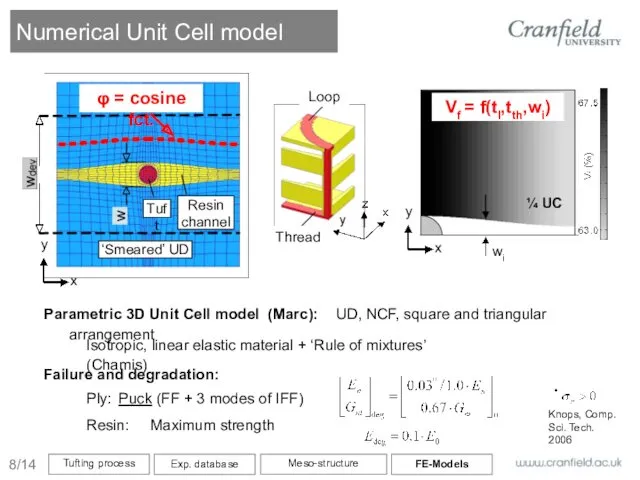

- 8. Tufting process Exp. database Meso-structure FE-Models Numerical Unit Cell model Parametric 3D Unit Cell model (Marc):

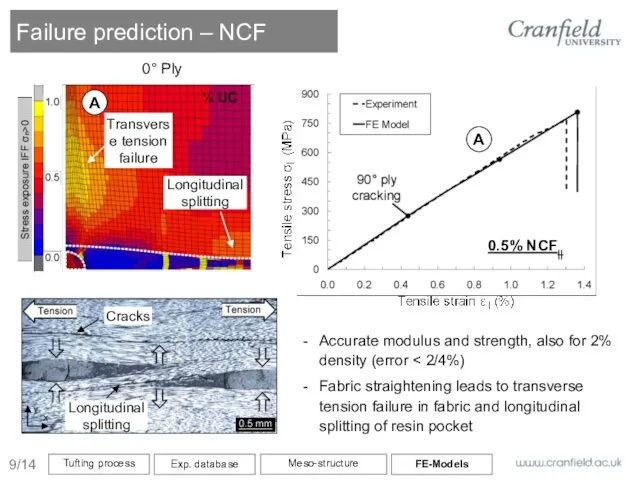

- 9. 0° Ply A Tufting process Exp. database Meso-structure FE-Models A Accurate modulus and strength, also for

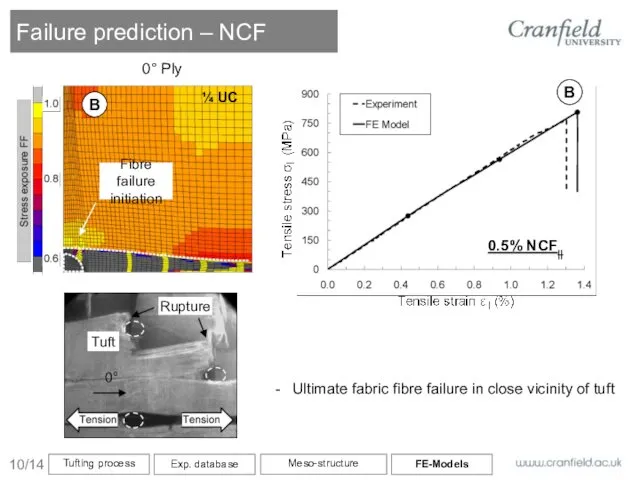

- 10. Tufting process Exp. database Meso-structure FE-Models Ultimate fabric fibre failure in close vicinity of tuft B

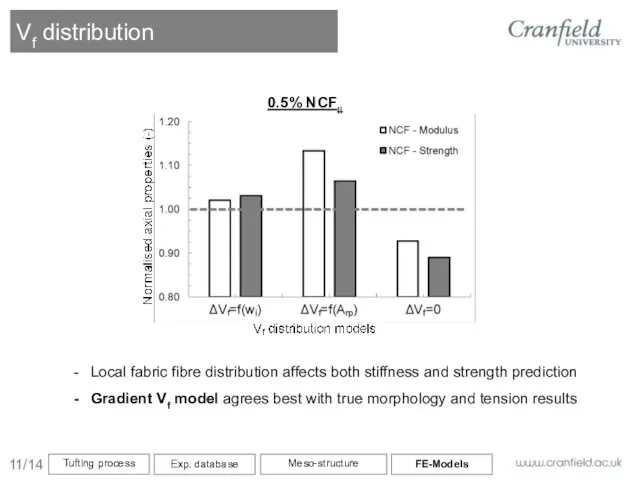

- 11. Tufting process Exp. database Meso-structure FE-Models Vf distribution 0.5% NCF|| Local fabric fibre distribution affects both

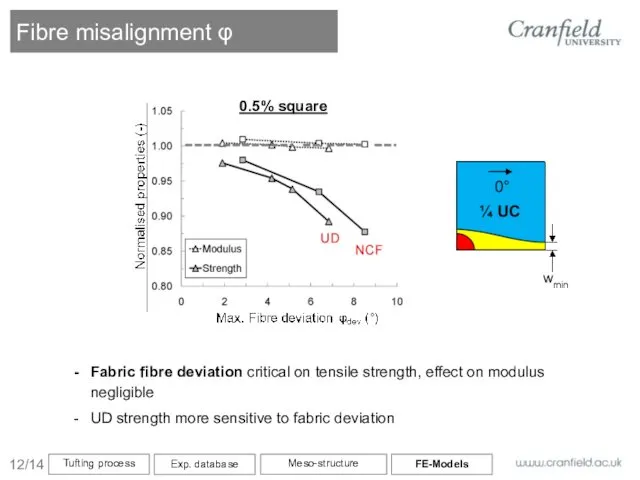

- 12. Tufting process Exp. database Meso-structure FE-Models Fibre misalignment φ 0.5% square Fabric fibre deviation critical on

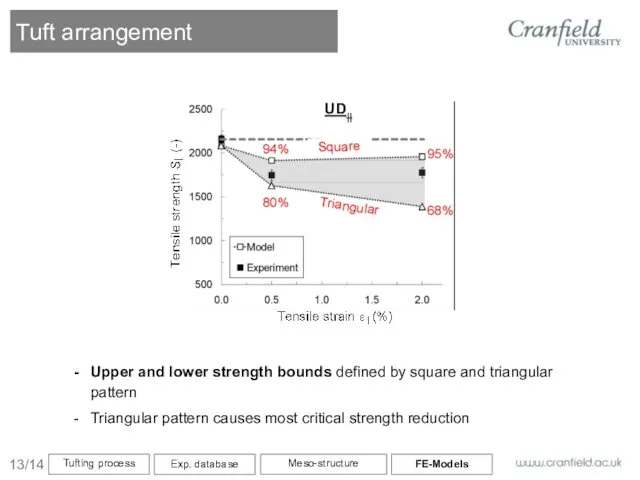

- 13. Tufting process Exp. database Meso-structure FE-Models Tuft arrangement UD|| Upper and lower strength bounds defined by

- 15. Скачать презентацию

Кузов. Диагностика двигателя, электрики, ходовой

Кузов. Диагностика двигателя, электрики, ходовой Демієлінізуючі захворювання нервової системи (бічний аміотрофічний склероз, розсіяний склероз)

Демієлінізуючі захворювання нервової системи (бічний аміотрофічний склероз, розсіяний склероз) План воспитательной работы.

План воспитательной работы. Городецкая роспись

Городецкая роспись Кафе Встреча

Кафе Встреча Творчество В.Г. Перова

Творчество В.Г. Перова Огород на окне. Педагогический проект

Огород на окне. Педагогический проект Устройство и ремонт асинхронного электродвигателя с короткозамкнутым ротором

Устройство и ремонт асинхронного электродвигателя с короткозамкнутым ротором Здание гостиницы Амур

Здание гостиницы Амур ҰБТ-ға баратын оқушыларға психологиялық көмек беру жолдары

ҰБТ-ға баратын оқушыларға психологиялық көмек беру жолдары Многофункциональное пособие

Многофункциональное пособие 249633

249633 презентация на тему:Красная книга народов России к уроку Население России

презентация на тему:Красная книга народов России к уроку Население России Атрибуция музейного предмета

Атрибуция музейного предмета Класс Млекопитающие

Класс Млекопитающие Презентация для родителей Речевое развитие одно из главных показателей готовности ребёнка к обучению в школе.

Презентация для родителей Речевое развитие одно из главных показателей готовности ребёнка к обучению в школе. Измерения при испытаниях холодильного оборудования. Роль измерении в холодильной технике

Измерения при испытаниях холодильного оборудования. Роль измерении в холодильной технике Диагностика и лечение эпилепсии

Диагностика и лечение эпилепсии Инженерные коммуникации в доме. 8 класс

Инженерные коммуникации в доме. 8 класс Профилактика агрессивного поведения подростков: гендерный аспект

Профилактика агрессивного поведения подростков: гендерный аспект Основные условные графические обозначения и изображения элементов генерального плана и сооружений транспорта

Основные условные графические обозначения и изображения элементов генерального плана и сооружений транспорта Методическая система Модель химического образования на основе технологического подхода

Методическая система Модель химического образования на основе технологического подхода Видеоролик

Видеоролик Маркетинг план

Маркетинг план Лагерь труда и отдыха ВИТА Оргетской общеобразовательной школы имени Т.И. Петрова

Лагерь труда и отдыха ВИТА Оргетской общеобразовательной школы имени Т.И. Петрова Адамның даму кезеңдері

Адамның даму кезеңдері Дизартрия

Дизартрия Основные аспекты логопедической работы в коррекционной школе VII и VIII вида

Основные аспекты логопедической работы в коррекционной школе VII и VIII вида