Содержание

- 2. Control system: - Multi Purpose Controller - Control Network - Main Operating Panel - Local Operating

- 3. Control Systems Bridge Ctr System Engine Ctr System

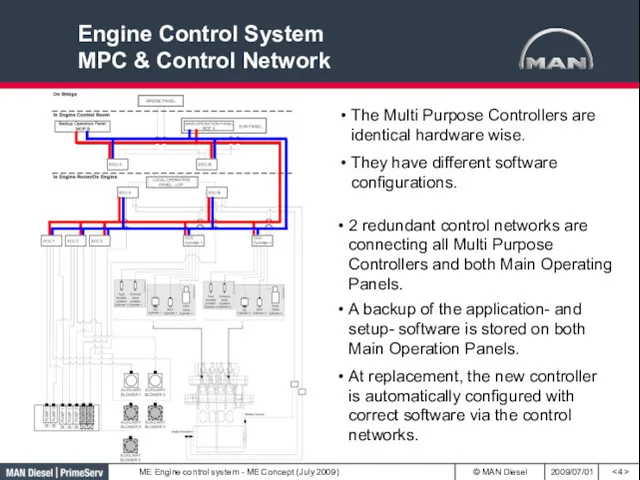

- 4. Engine Control System MPC & Control Network 2 redundant control networks are connecting all Multi Purpose

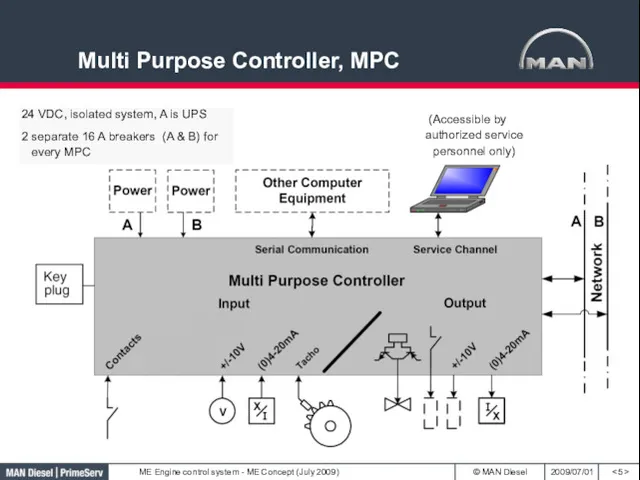

- 5. Multi Purpose Controller, MPC 24 VDC, isolated system, A is UPS 2 separate 16 A breakers

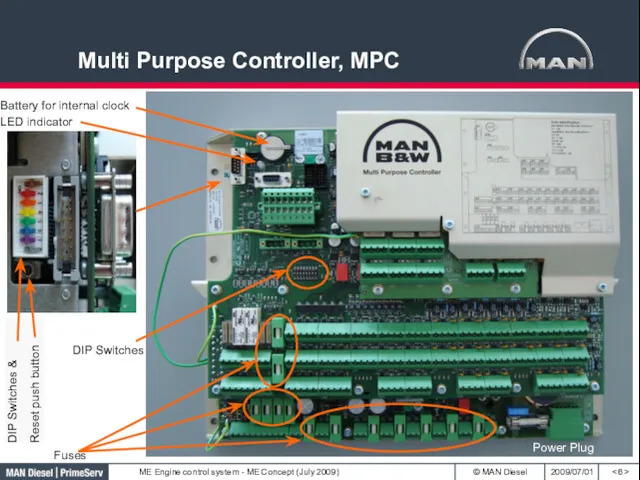

- 6. Multi Purpose Controller, MPC DIP Switches DIP Switches & Reset push button Power Plug

- 7. Multi Purpose Controller, MPC Amplifier for FIVA (CCU’s) and Hydraulic pumps (ACU’s) Multi Purpose Controller ’IP

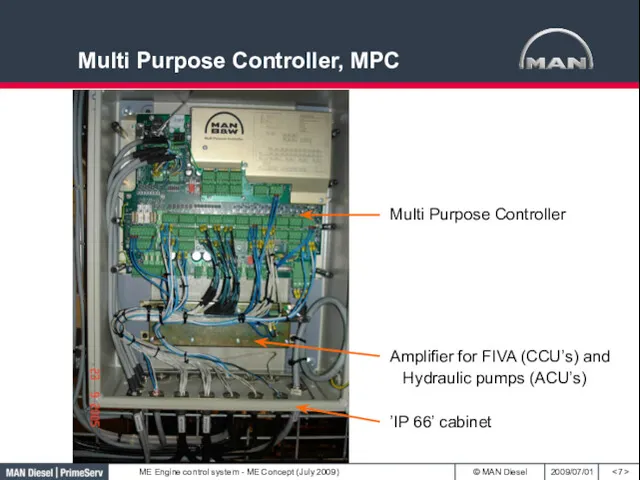

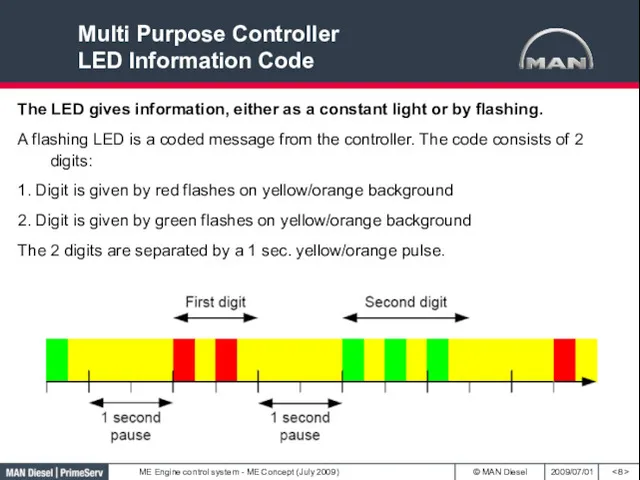

- 8. Multi Purpose Controller LED Information Code The LED gives information, either as a constant light or

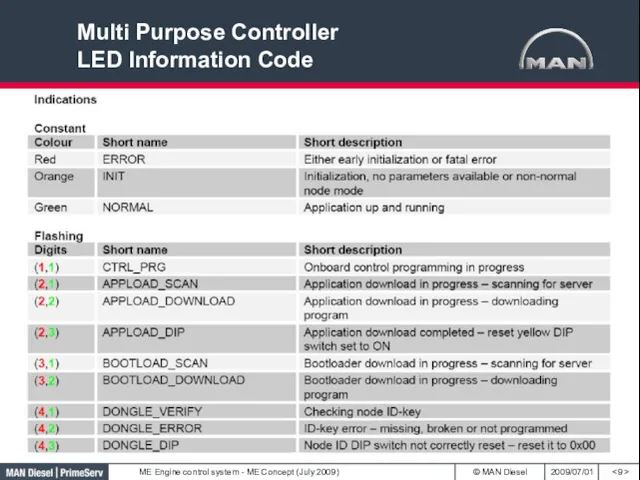

- 9. Multi Purpose Controller LED Information Code

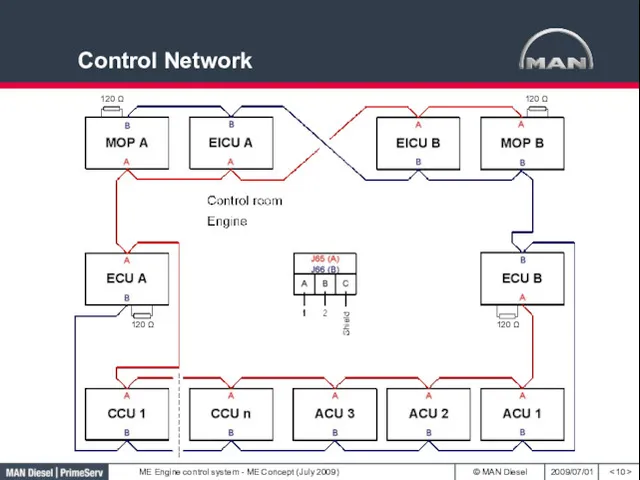

- 10. Control Network 120 Ω 120 Ω 120 Ω 120 Ω

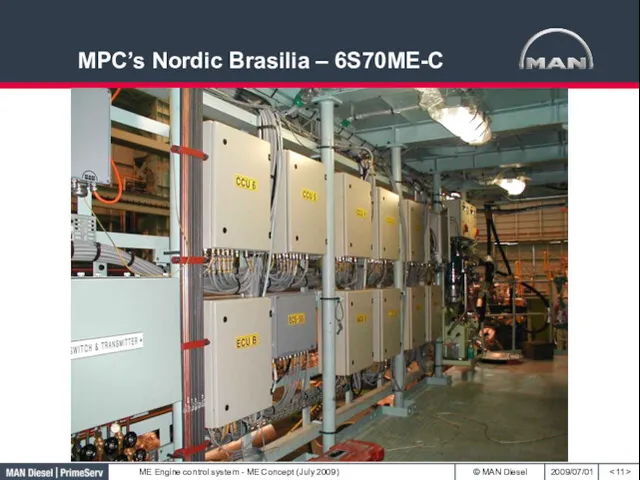

- 11. MPC’s Nordic Brasilia – 6S70ME-C

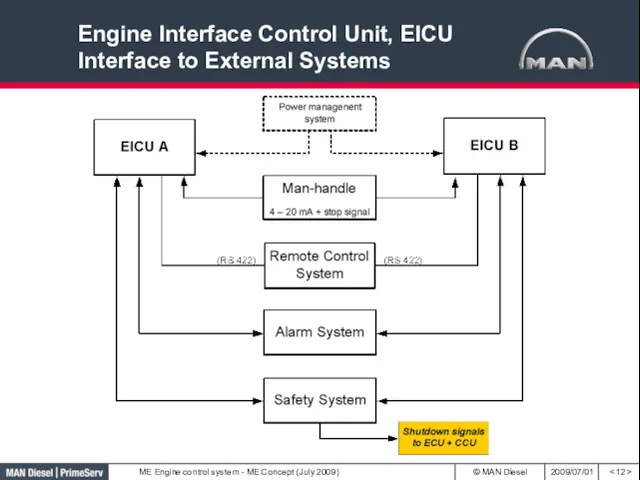

- 12. Engine Interface Control Unit, EICU Interface to External Systems

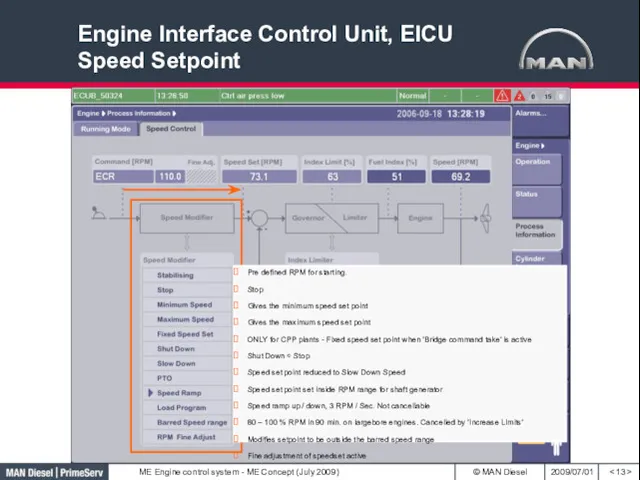

- 13. Engine Interface Control Unit, EICU Speed Setpoint Pre defined RPM for starting. Stop Gives the minimum

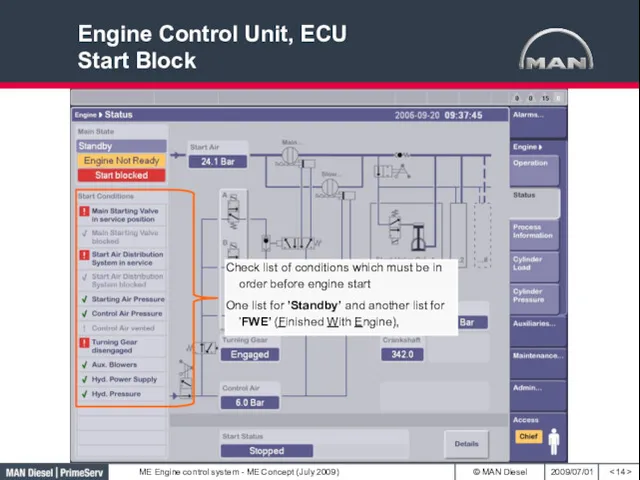

- 14. Engine Control Unit, ECU Start Block

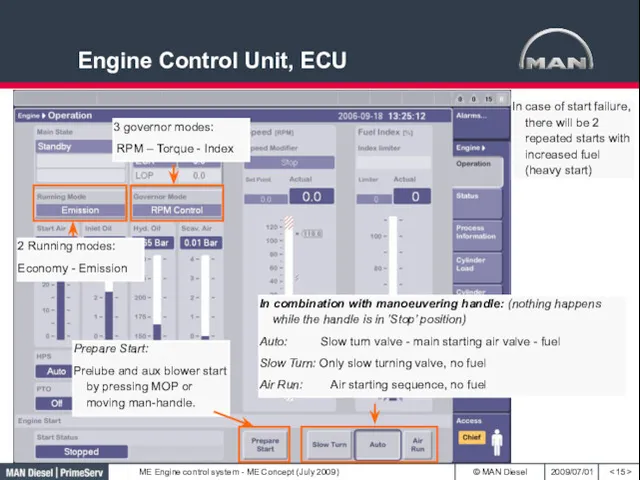

- 15. Engine Control Unit, ECU 3 governor modes: RPM – Torque - Index 2 Running modes: Economy

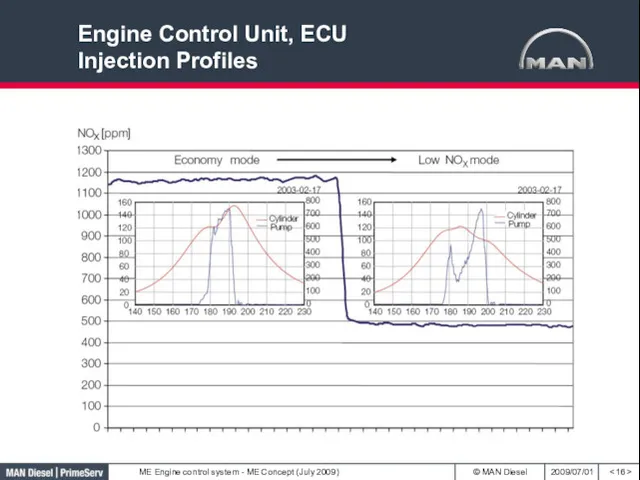

- 16. Engine Control Unit, ECU Injection Profiles

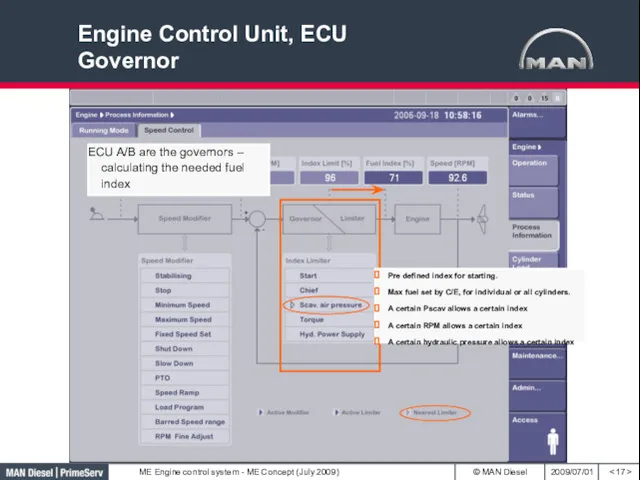

- 17. Engine Control Unit, ECU Governor Pre defined index for starting. Max fuel set by C/E, for

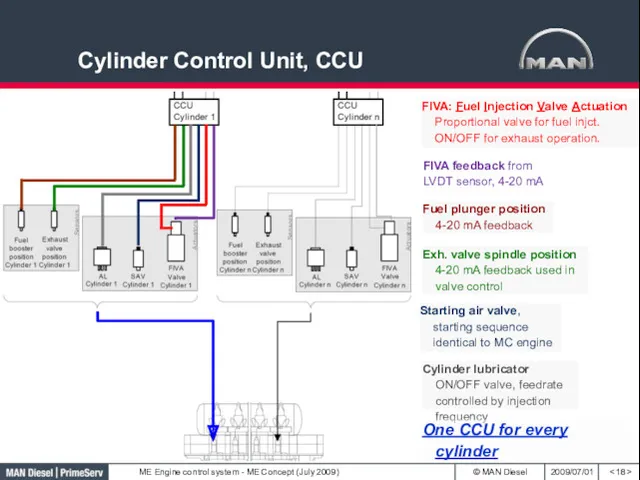

- 18. Cylinder Control Unit, CCU Fuel plunger position 4-20 mA feedback Exh. valve spindle position 4-20 mA

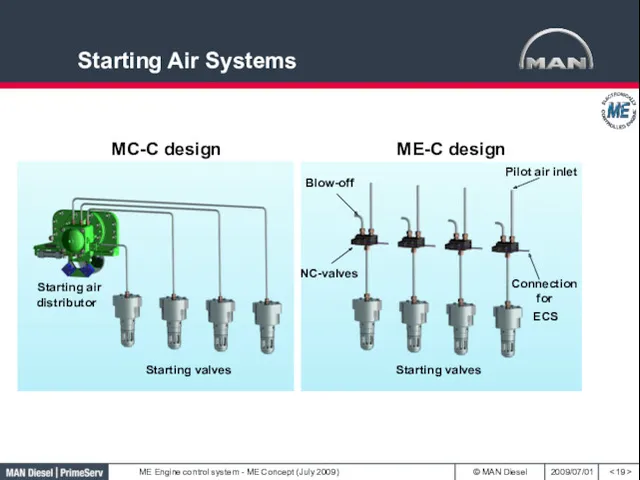

- 19. Starting Air Systems

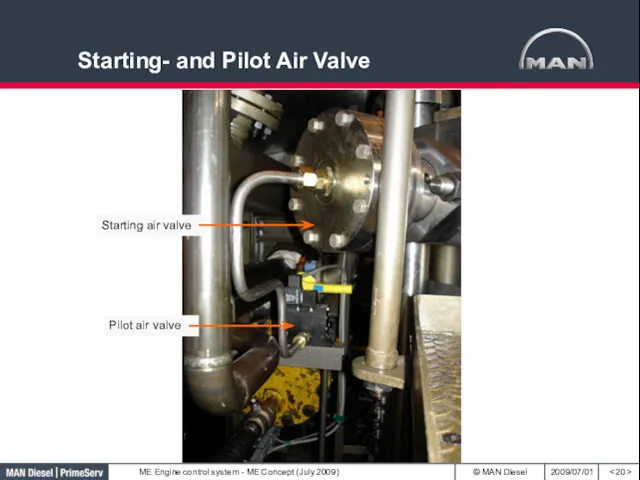

- 20. Starting- and Pilot Air Valve

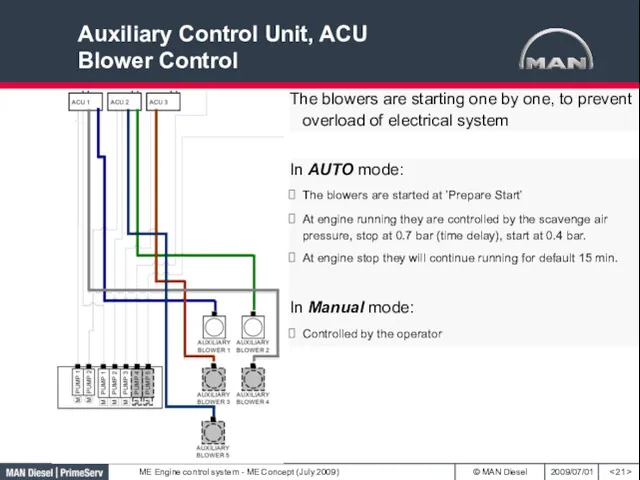

- 21. Auxiliary Control Unit, ACU Blower Control The blowers are starting one by one, to prevent overload

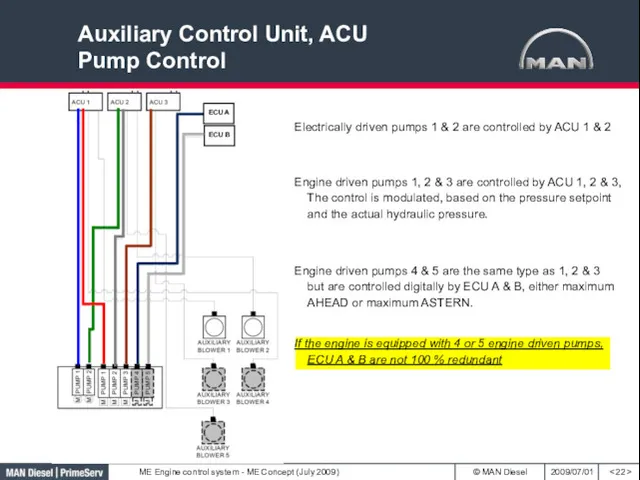

- 22. Auxiliary Control Unit, ACU Pump Control Electrically driven pumps 1 & 2 are controlled by ACU

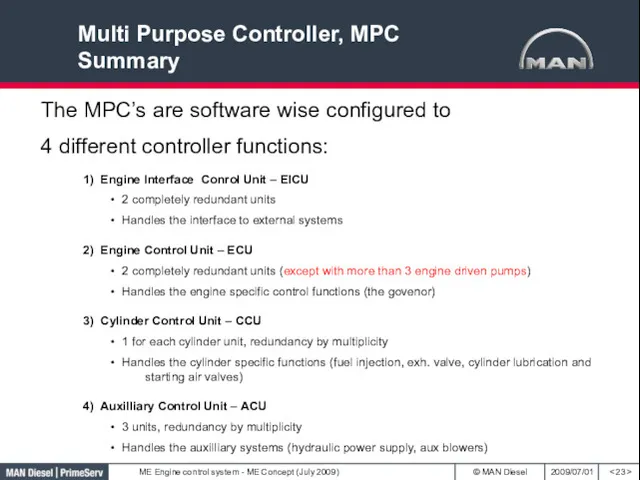

- 23. Multi Purpose Controller, MPC Summary The MPC’s are software wise configured to 4 different controller functions:

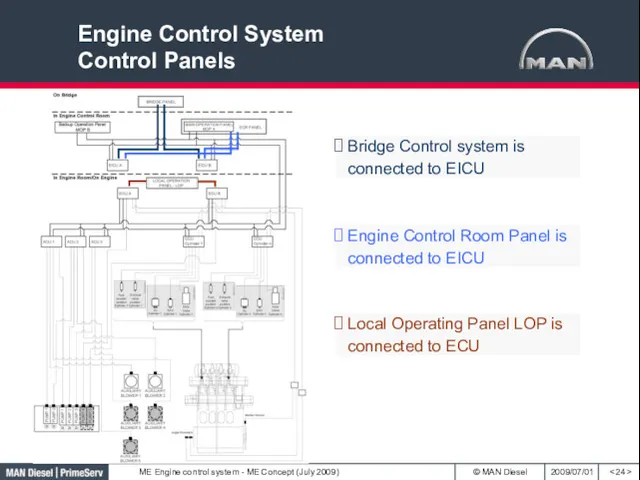

- 24. Engine Control System Control Panels Bridge Control system is connected to EICU Engine Control Room Panel

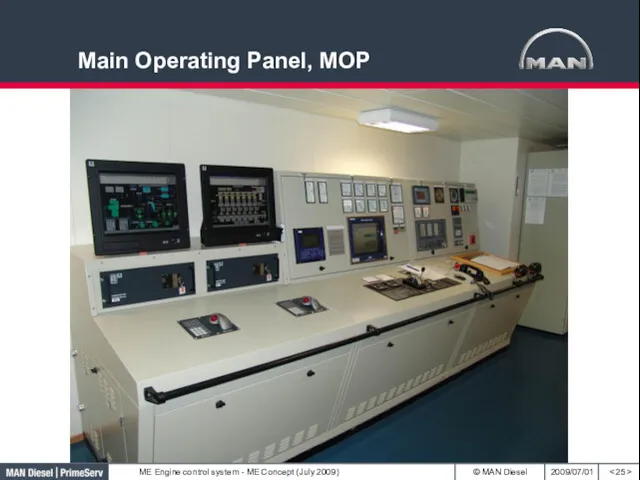

- 25. Main Operating Panel, MOP

- 26. Local Operating Panel (LOP) FPP

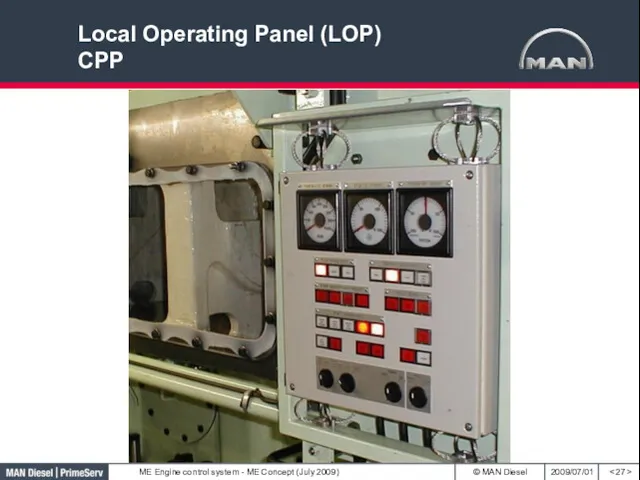

- 27. Local Operating Panel (LOP) CPP

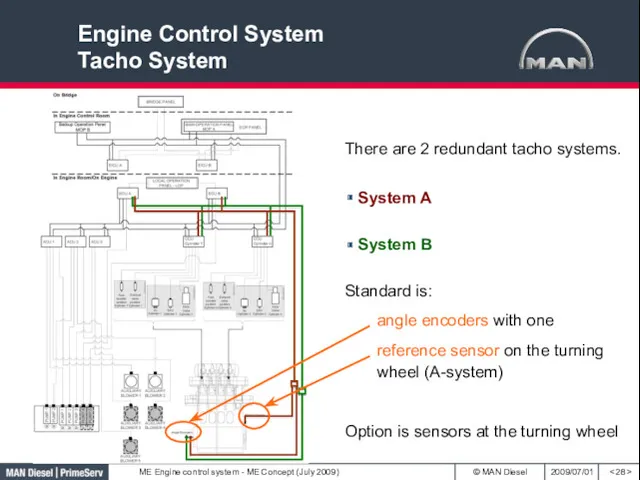

- 28. Engine Control System Tacho System There are 2 redundant tacho systems. System B System A Standard

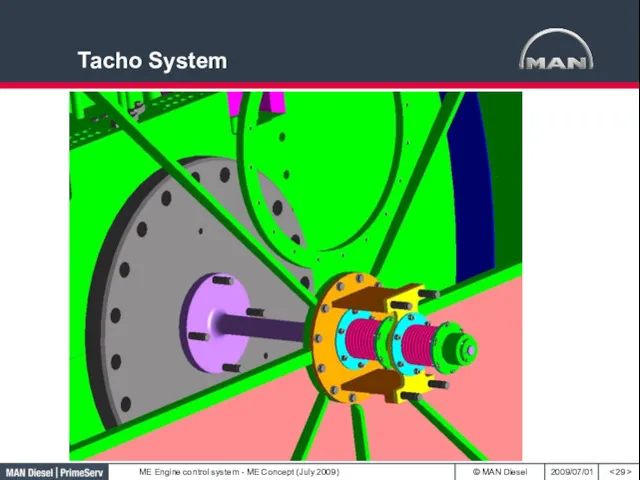

- 29. Tacho System

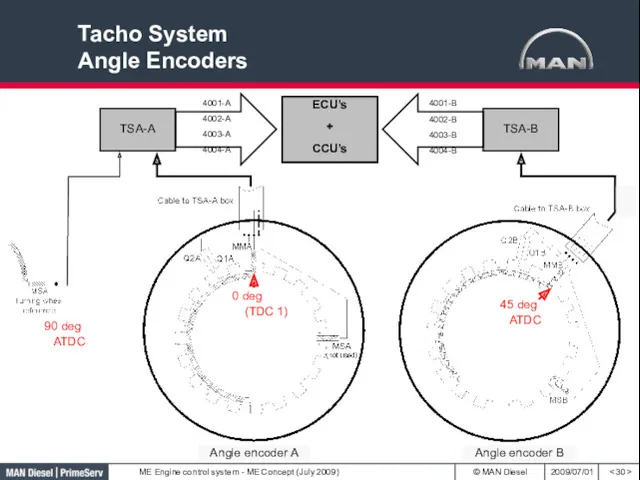

- 30. Tacho System Angle Encoders 90 deg ATDC Angle encoder A Angle encoder B

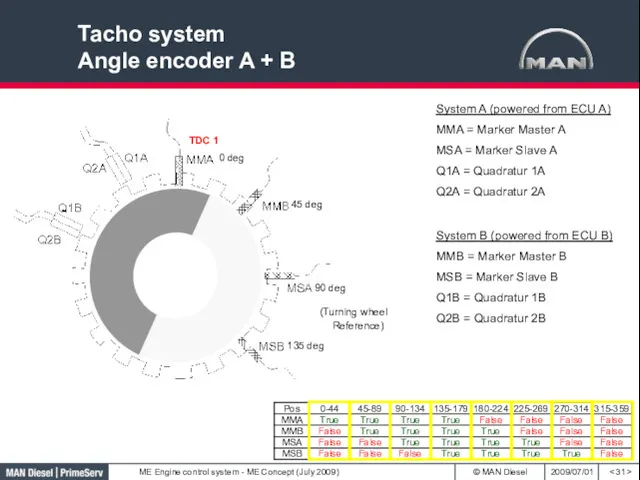

- 31. Tacho system Angle encoder A + B System A (powered from ECU A) MMA = Marker

- 32. Tacho System, Angle Encoders

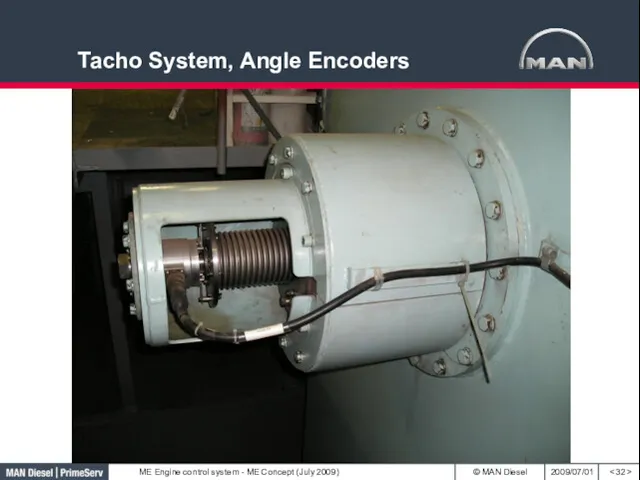

- 33. Tacho System Amplifier Boxes, TSA

- 34. Tacho System, Semicircular Ring

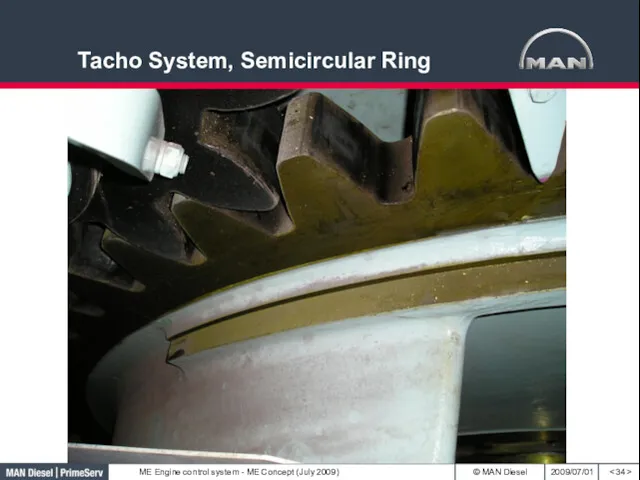

- 35. Tacho System, Master Slave A, MSA, on AFT end of Engine

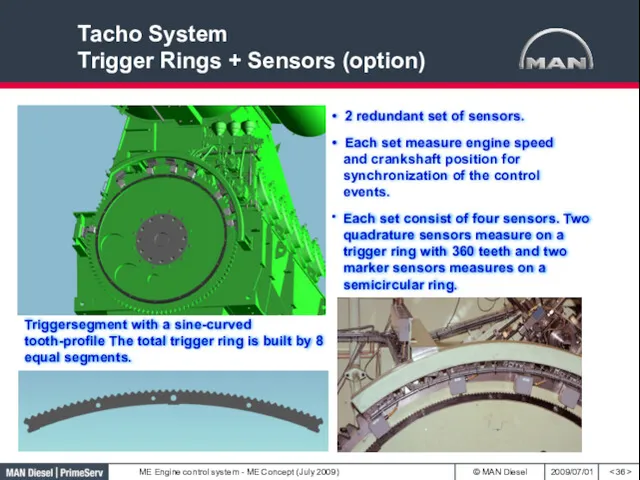

- 36. Tacho System Trigger Rings + Sensors (option) Triggersegment with a sine-curved tooth-profile The total trigger ring

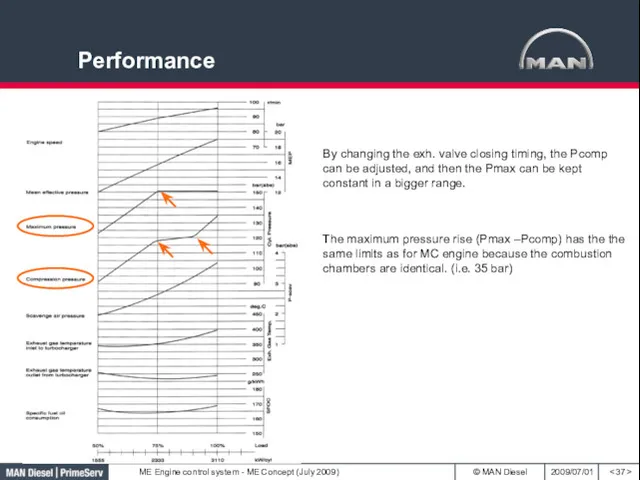

- 37. Performance By changing the exh. valve closing timing, the Pcomp can be adjusted, and then the

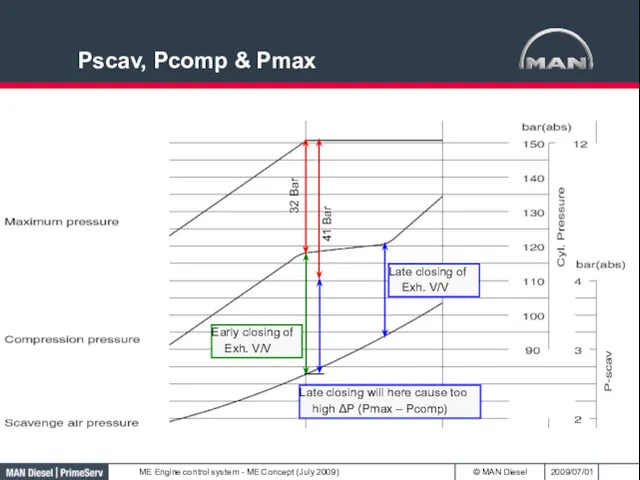

- 38. Pscav, Pcomp & Pmax

- 40. Скачать презентацию

Сказочки-шумелки. Зима в лесу

Сказочки-шумелки. Зима в лесу Контроль условий, процессов и результатов образовательной деятельности

Контроль условий, процессов и результатов образовательной деятельности Презентация- игра Гербы городов Липецкой области

Презентация- игра Гербы городов Липецкой области Презентация. Развитие мелкой моторики с помощью дидактических игр в разных областях образовательной деятельности.

Презентация. Развитие мелкой моторики с помощью дидактических игр в разных областях образовательной деятельности. Мастер-класс Силуэты

Мастер-класс Силуэты Наши права и обязанности

Наши права и обязанности Лоскутное шитье

Лоскутное шитье Проблемы управления политикой спроса

Проблемы управления политикой спроса Человеческий капитал ТЭК. Роль ТЭК в экономике страны

Человеческий капитал ТЭК. Роль ТЭК в экономике страны Познавательный проект Славяне

Познавательный проект Славяне Внеклассное занятие Легенды и мифы Санкт-Петербурга 2 класс

Внеклассное занятие Легенды и мифы Санкт-Петербурга 2 класс Ценовая эластичность спроса. Эластичность спроса и доход производителей

Ценовая эластичность спроса. Эластичность спроса и доход производителей Инвестиционная деятельность предприятия ПАО КАМАЗ Автомобильный завод

Инвестиционная деятельность предприятия ПАО КАМАЗ Автомобильный завод Что должен уметь ребенок 3-4 лет

Что должен уметь ребенок 3-4 лет Прямоугольная система координат

Прямоугольная система координат Хирургиядағы ақпаратты-компьютерлік технологиялар телемедицинасы

Хирургиядағы ақпаратты-компьютерлік технологиялар телемедицинасы Расстройства аутистического спектра

Расстройства аутистического спектра Наркомания

Наркомания Етика та естетика. Етика ділових відносин. Етикет

Етика та естетика. Етика ділових відносин. Етикет АСК 2 урок Природные особенности Смоленской области

АСК 2 урок Природные особенности Смоленской области Организация различных видов деятельности и общения детей. Практика

Организация различных видов деятельности и общения детей. Практика Презентация От Коперника до наших дней

Презентация От Коперника до наших дней презентация к родительскому собранию Агрессия детей, ее причины и предупреждение

презентация к родительскому собранию Агрессия детей, ее причины и предупреждение Проект Живая азбука

Проект Живая азбука Дружат дети всей Земли Диск

Дружат дети всей Земли Диск Презентация. Роль ИКТ в формировании познавательной сферы обучающихся, развитие логического мышления

Презентация. Роль ИКТ в формировании познавательной сферы обучающихся, развитие логического мышления Педагогические технологии

Педагогические технологии Тест по теме СОСТОЯНИЯ ВЕЩЕСТВА, 5 класс

Тест по теме СОСТОЯНИЯ ВЕЩЕСТВА, 5 класс