Содержание

- 2. The modernization of the CNC machine is usually associated with the replacement of the CNC system.

- 3. Turning-rotary double-stand machine mod. 1А563F4 is equipped with an outdated CNC system. It is made on

- 4. When installing modern CNC systems and modernized drive mechanisms of the machine tools, the following benefits

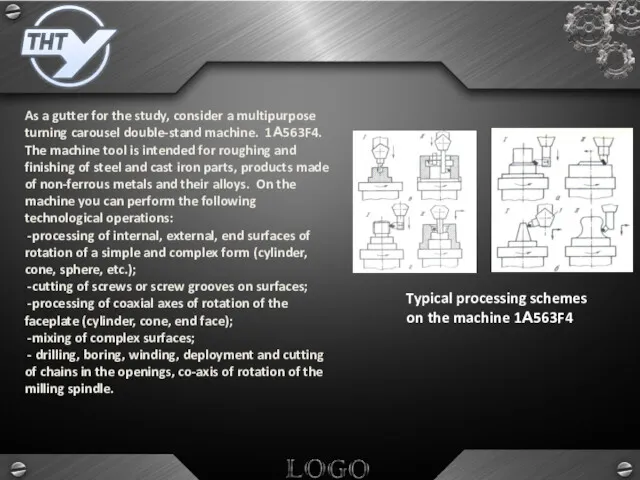

- 5. As a gutter for the study, consider a multipurpose turning carousel double-stand machine. 1А563F4. The machine

- 6. The most important trend in the design of high-tech products of modern production: aircraft, modern CNC

- 7. Along with the common industrial cylindrical, cylindrical-conical gearboxes are becoming increasingly relevant gearboxes based on planetary,

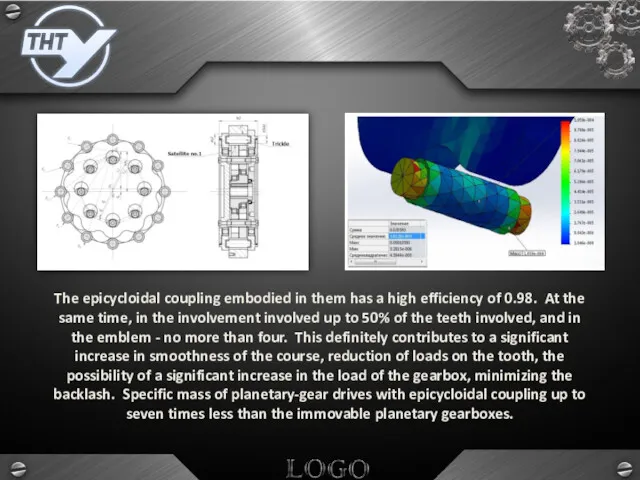

- 8. The epicycloidal coupling embodied in them has a high efficiency of 0.98. At the same time,

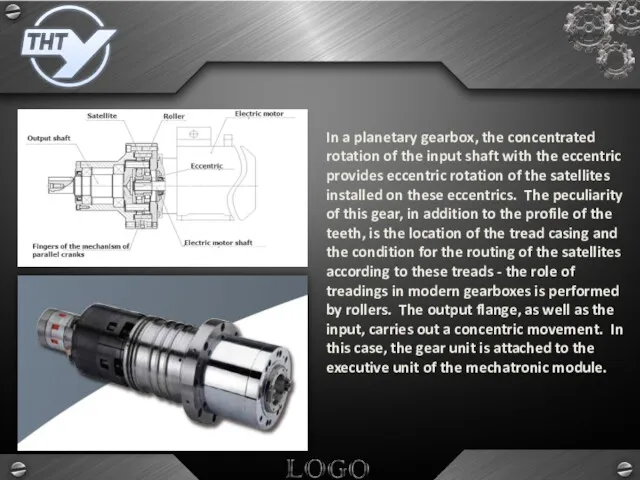

- 9. In a planetary gearbox, the concentrated rotation of the input shaft with the eccentric provides eccentric

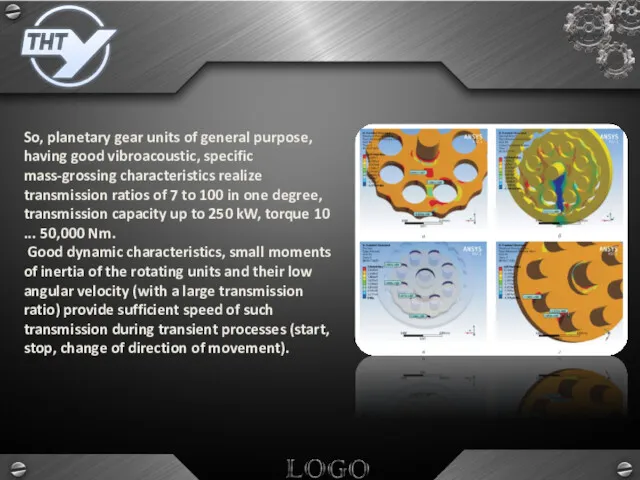

- 10. So, planetary gear units of general purpose, having good vibroacoustic, specific mass-grossing characteristics realize transmission ratios

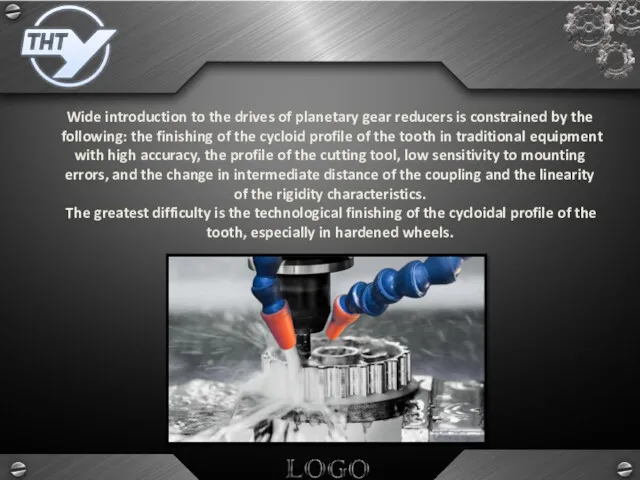

- 11. Wide introduction to the drives of planetary gear reducers is constrained by the following: the finishing

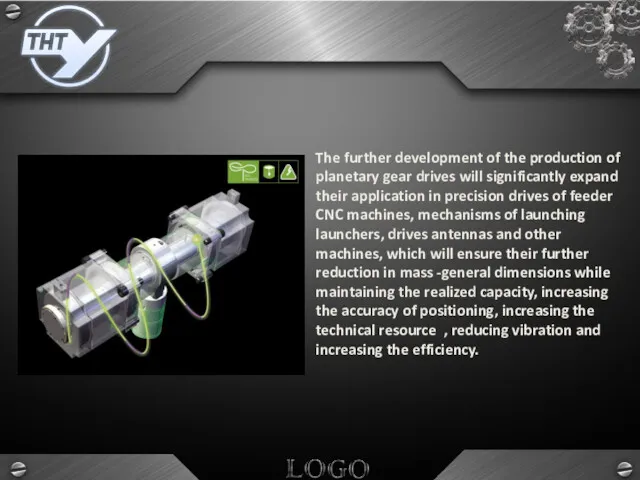

- 12. The further development of the production of planetary gear drives will significantly expand their application in

- 13. In order to create modern planetary-transmission programs that are competitive in the world market, it is

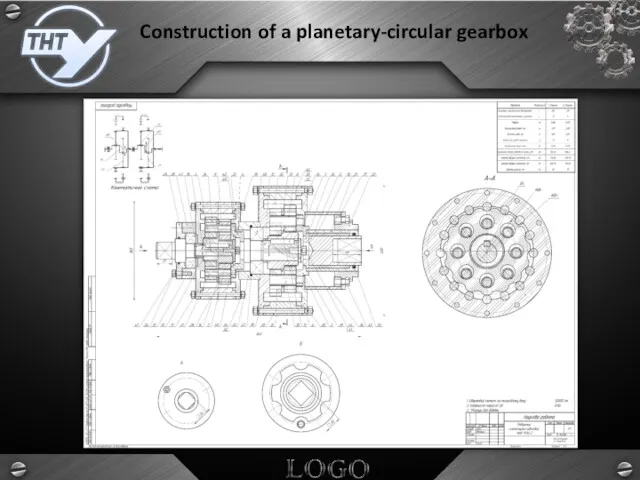

- 14. Construction of a planetary-circular gearbox First stage: From the received calculation data, a two-dimensional drawing of

- 15. Construction of a planetary-circular gearbox

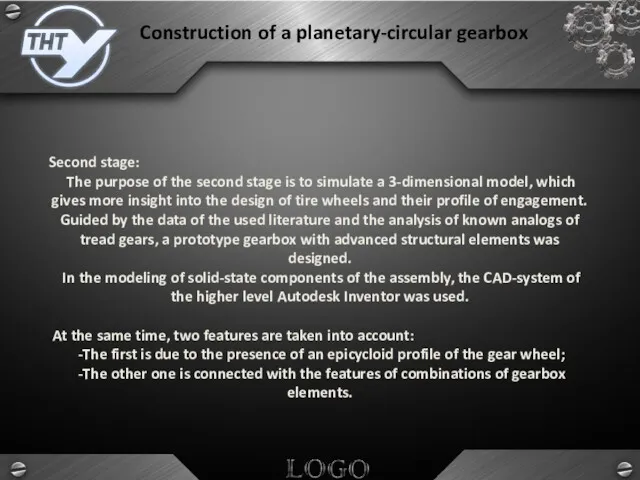

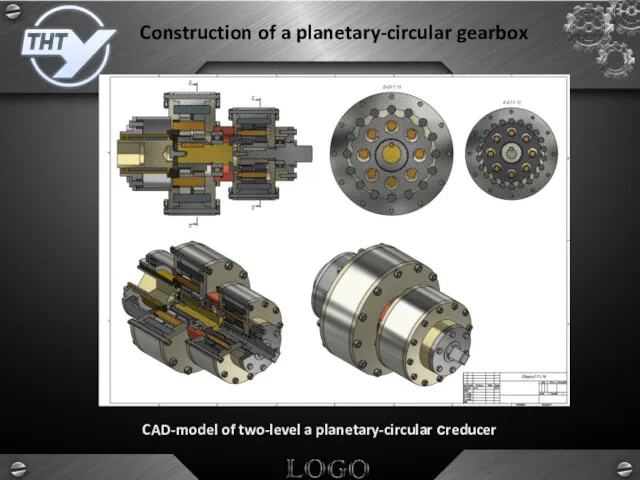

- 16. Second stage: The purpose of the second stage is to simulate a 3-dimensional model, which gives

- 17. CAD-model of two-level a planetary-circular сreducer Construction of a planetary-circular gearbox

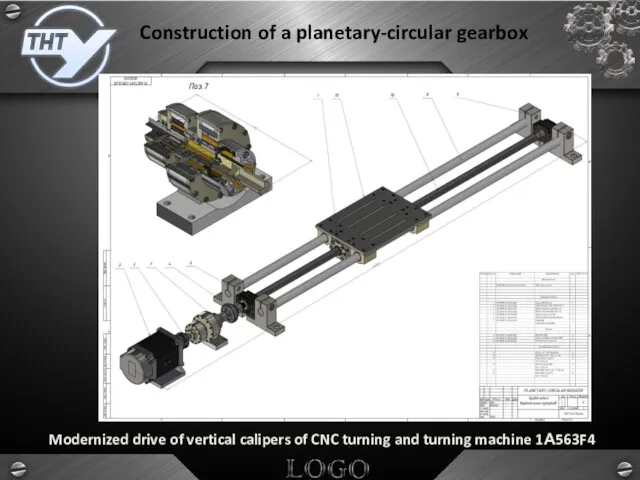

- 18. Construction of a planetary-circular gearbox Third stage: Using the characteristics of the turning-carousel machine, its drive

- 19. Construction of a planetary-circular gearbox Modernized drive of vertical calipers of CNC turning and turning machine

- 21. Скачать презентацию

Корабельные гироскопические системы. (Тема 2)

Корабельные гироскопические системы. (Тема 2) Взаимозаменяемость и нормирование точности

Взаимозаменяемость и нормирование точности Точность и погрешность измерений

Точность и погрешность измерений Основы теории подобия

Основы теории подобия Развитие средств связи

Развитие средств связи Тренажер по физике. Формулы.8 класс

Тренажер по физике. Формулы.8 класс Урок Обобщение материала по теме Силы в природе. 7 класс.

Урок Обобщение материала по теме Силы в природе. 7 класс. Плотность вещества

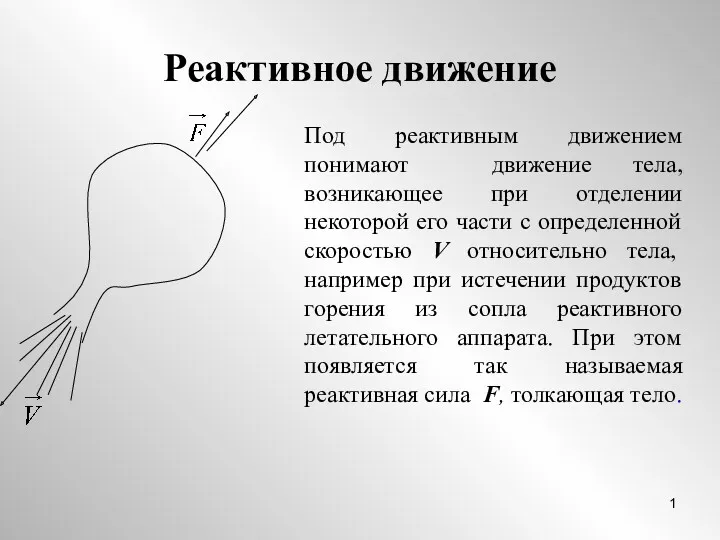

Плотность вещества Реактивное движение

Реактивное движение Пожежні автомобілі аеродромної служби

Пожежні автомобілі аеродромної служби Урок-презентация по теме Сила трения

Урок-презентация по теме Сила трения Поршневой жидкостный насос. Гидравлический пресс

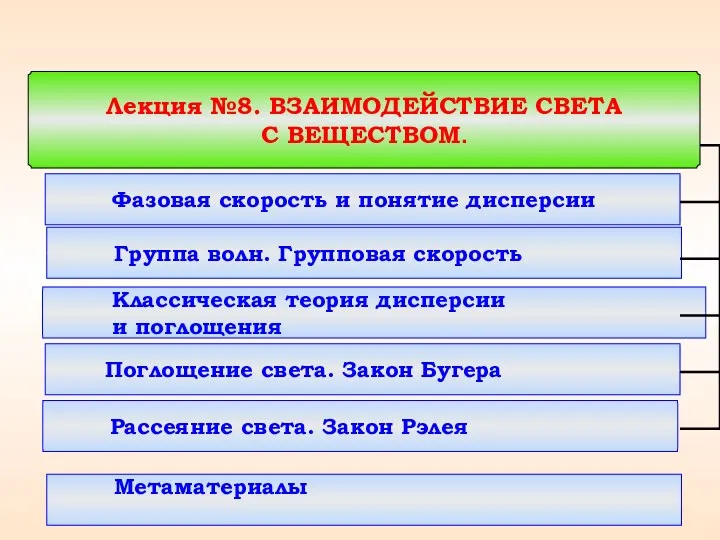

Поршневой жидкостный насос. Гидравлический пресс Взаимодействие света с веществом. Лекция №8

Взаимодействие света с веществом. Лекция №8 Свободное падение тел

Свободное падение тел Управление колебаниями системы маятник-тележка с приводом методом скоростного биградиента

Управление колебаниями системы маятник-тележка с приводом методом скоростного биградиента Плотность вещества

Плотность вещества Магнитное поле и его характеристики

Магнитное поле и его характеристики Розв'язування задач з теми Сили в природі

Розв'язування задач з теми Сили в природі Испарение и конденсация. Кипение жидкости

Испарение и конденсация. Кипение жидкости Акустика как часть физики

Акустика как часть физики Какие батарейки лучше

Какие батарейки лучше Колебательные цепи при гармонических воздействиях. Лекция 5

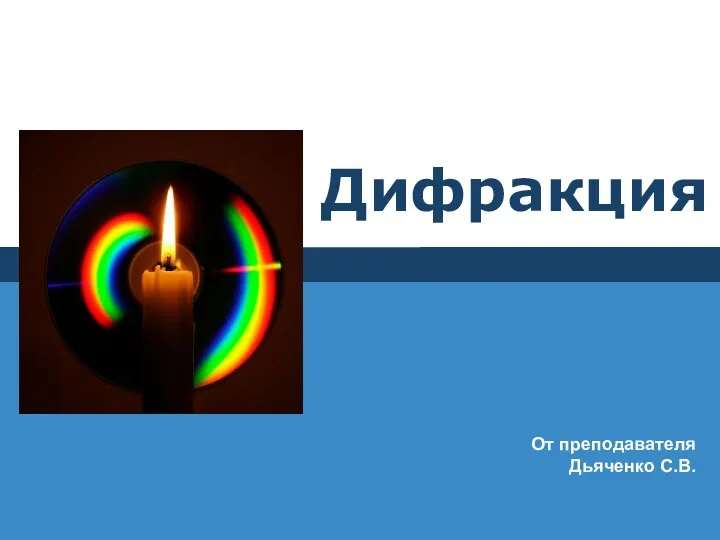

Колебательные цепи при гармонических воздействиях. Лекция 5 Дифракция

Дифракция Опыт Карла Рикке

Опыт Карла Рикке Акустика. Слух и его свойства

Акустика. Слух и его свойства способы изм. вн. эн

способы изм. вн. эн Расчет переходных процессов в электрических цепях классическим методом

Расчет переходных процессов в электрических цепях классическим методом Плоские электромагнитные волны. Устройство и параметры однородных линий передач

Плоские электромагнитные волны. Устройство и параметры однородных линий передач