Содержание

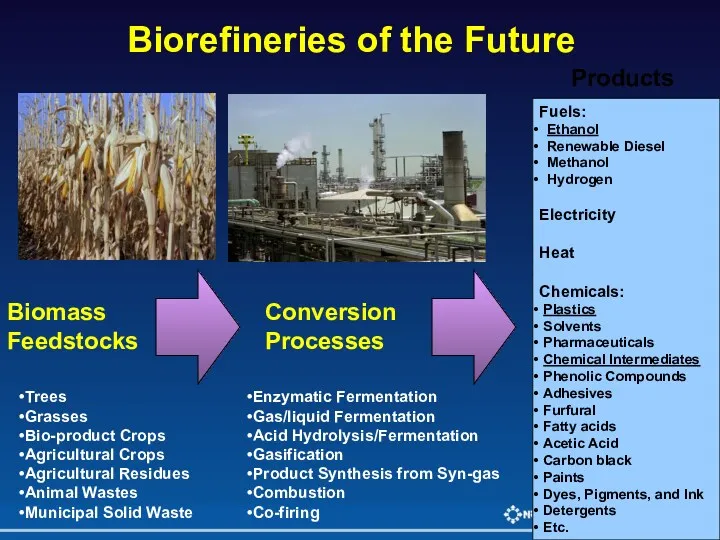

- 2. Fuels: Ethanol Renewable Diesel Methanol Hydrogen Electricity Heat Chemicals: Plastics Solvents Pharmaceuticals Chemical Intermediates Phenolic Compounds

- 3. Biodiesel (B100) ASTM PS 121 Biodiesel Fuel Standard similar to ASTM D 975 Used pure or

- 4. Handles Just Like Diesel No engine modifications required for B20, if using B100 then: rubber seals

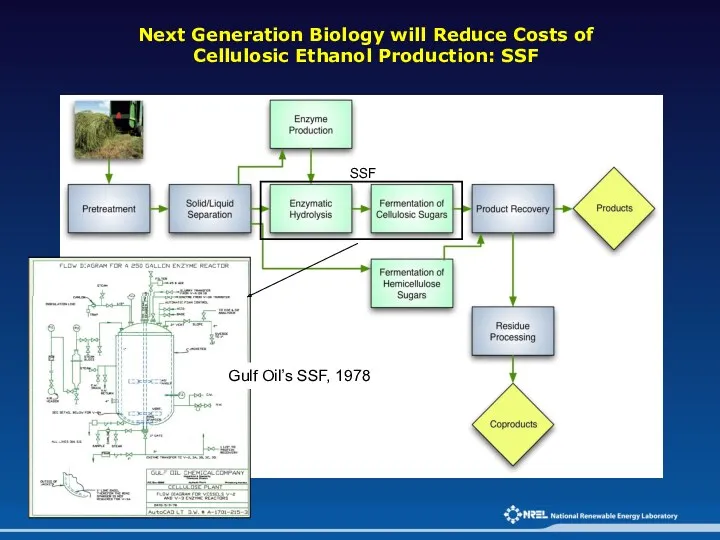

- 5. Next Generation Biology will Reduce Costs of Cellulosic Ethanol Production: SSF

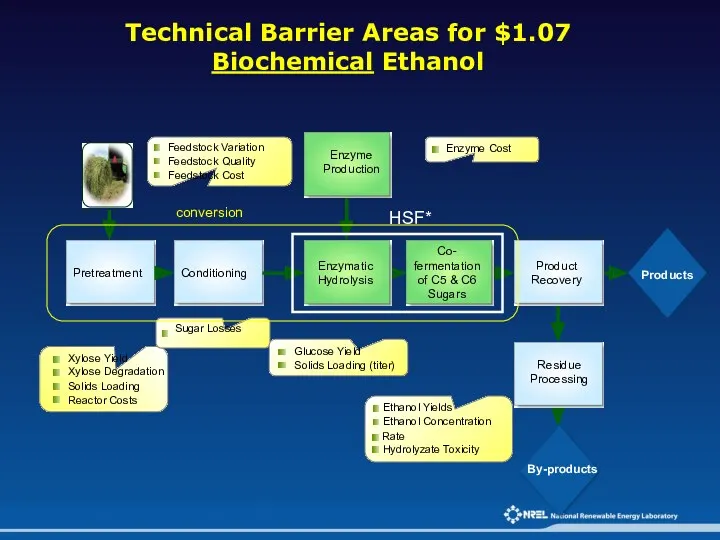

- 6. Technical Barrier Areas for $1.07 Biochemical Ethanol *Hybrid Saccharification & Fermentation - HSF Pretreatment Products By-products

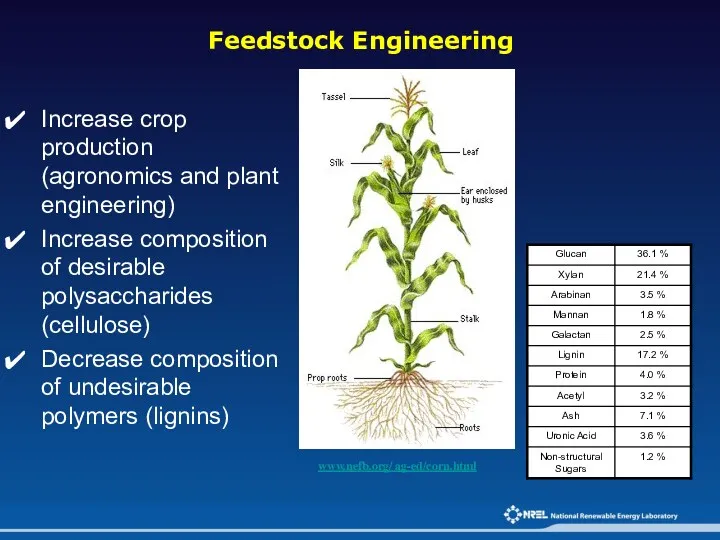

- 7. www.nefb.org/ ag-ed/corn.html Increase crop production (agronomics and plant engineering) Increase composition of desirable polysaccharides (cellulose) Decrease

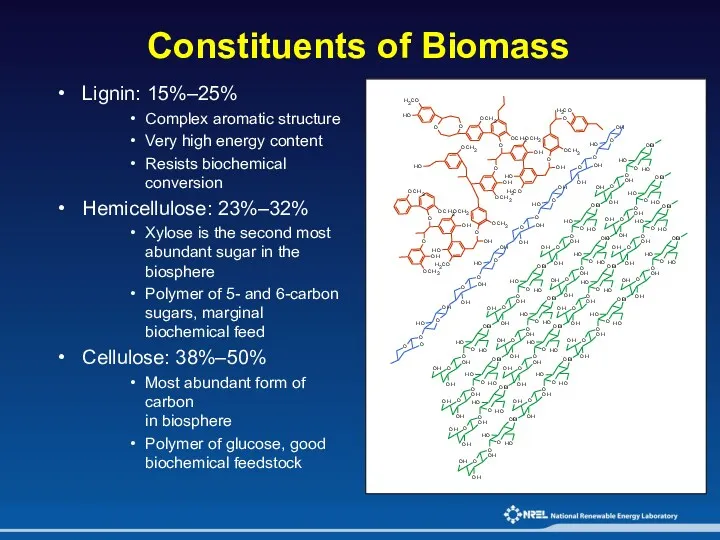

- 8. Constituents of Biomass Lignin: 15%–25% Complex aromatic structure Very high energy content Resists biochemical conversion Hemicellulose:

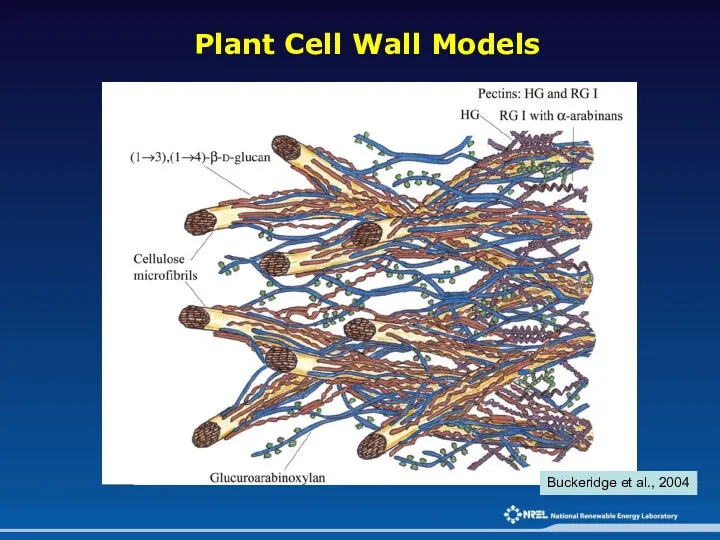

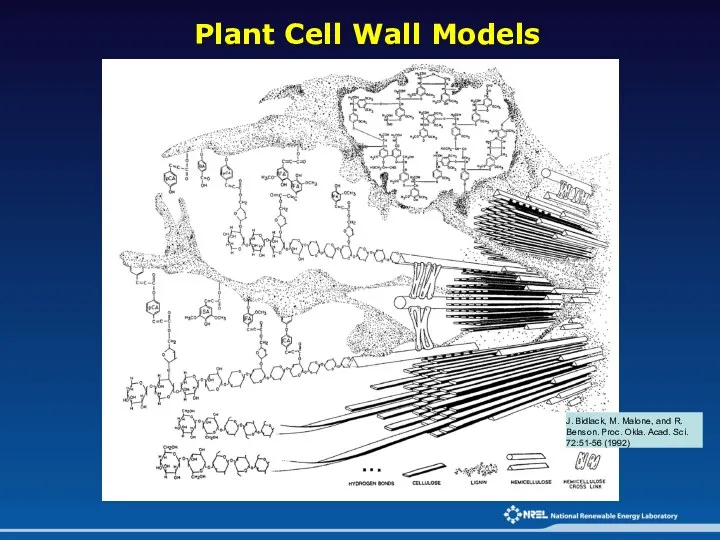

- 9. Plant Cell Wall Models Buckeridge et al., 2004

- 10. J. Bidlack, M. Malone, and R. Benson. Proc. Okla. Acad. Sci. 72:51-56 (1992) Plant Cell Wall

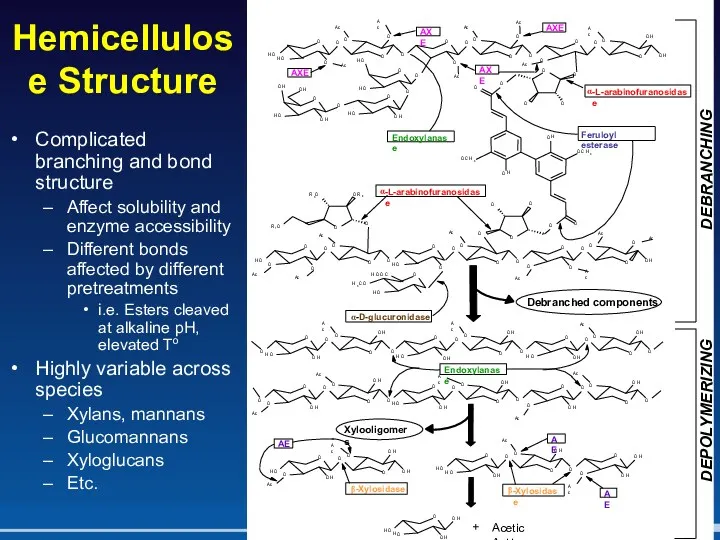

- 11. Hemicellulose Structure Complicated branching and bond structure Affect solubility and enzyme accessibility Different bonds affected by

- 12. Biofuels from Biomass CORN SUGAR CANE SUGAR EXTRACT BIOMASS ETHANOL YEAST FERMENT CORN STOVER SUGAR CANE

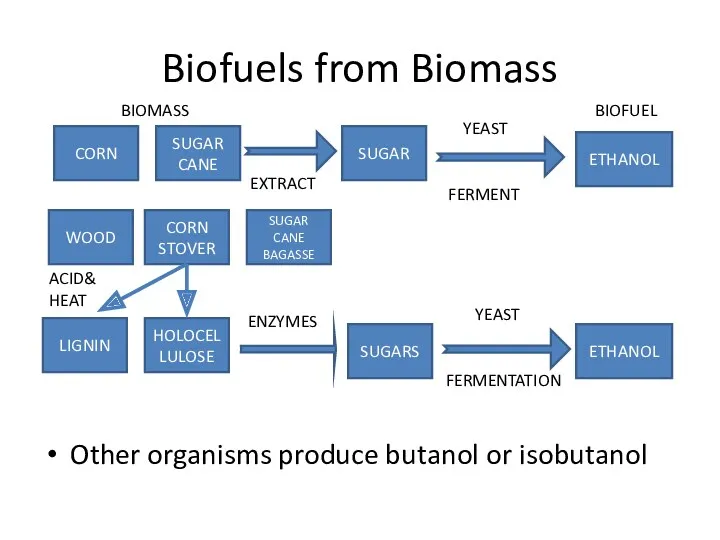

- 13. Diesel Biofuels from Biomass SOYBEAN CANOLA VEGETABLE OIL PRESS BIODIESEL (FAMES) METHANOL HEAT, BASE GREEN DIESEL

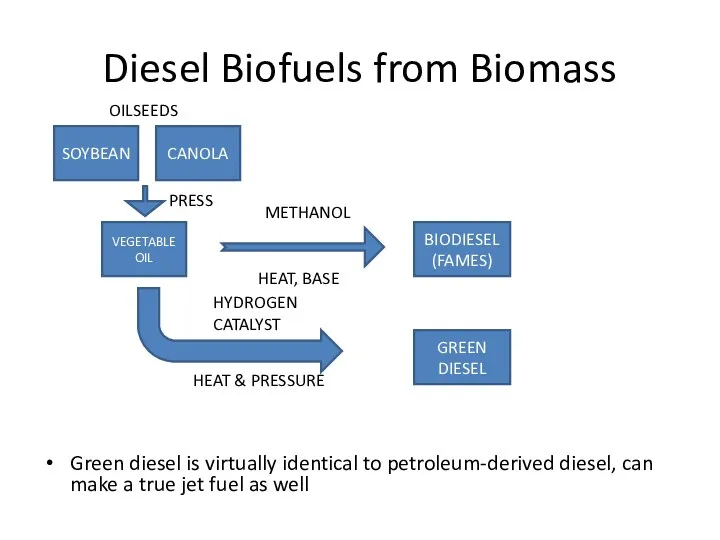

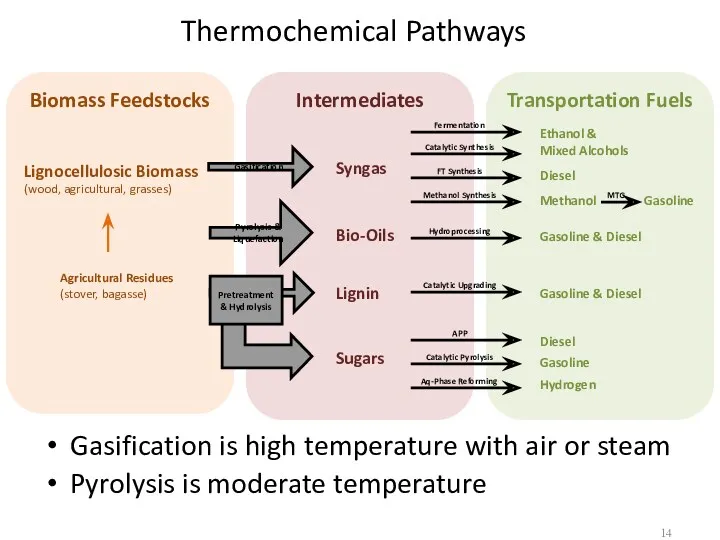

- 14. Transportation Fuels Ethanol & Mixed Alcohols Diesel Methanol Gasoline Gasoline & Diesel Gasoline & Diesel Diesel

- 15. Comparison of feeds and processes Biochemical is low temperature but long times Thermochemical is high-throughput but

- 16. National Renewable Energy Laboratory Innovation for Our Energy Future Sustainability of Cellulosic Ethanol Requires Much Less

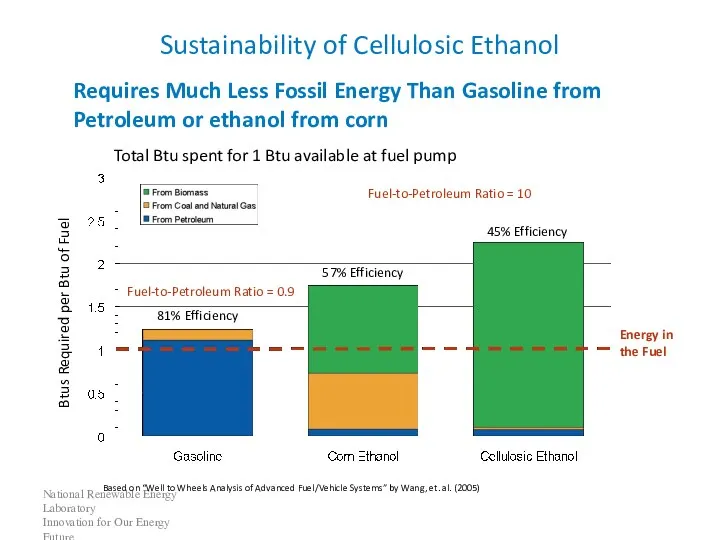

- 17. Is there enough land? If biomass competes with food crops for farm land, then food prices

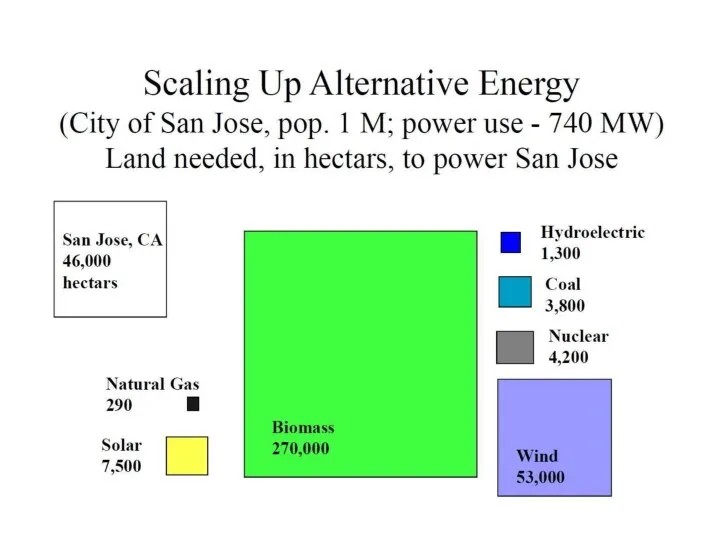

- 19. The 1.3 Billion Ton Biomass Scenario Based on ORNL & USDA Resource Assessment Study by Perlach

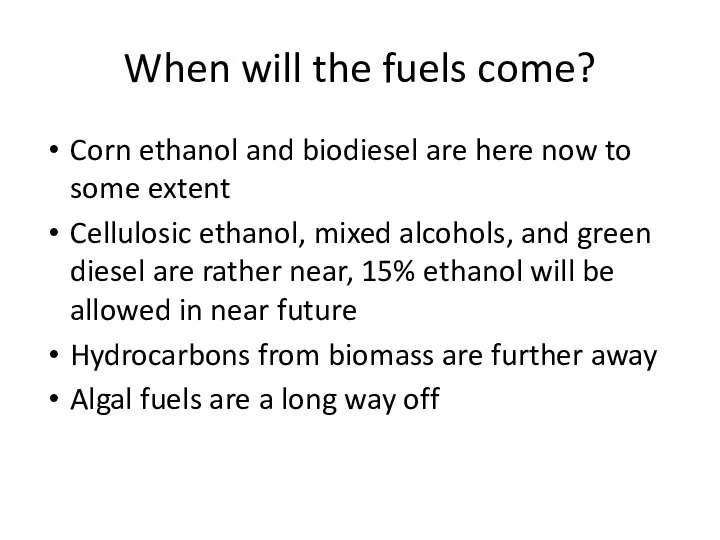

- 20. When will the fuels come? Corn ethanol and biodiesel are here now to some extent Cellulosic

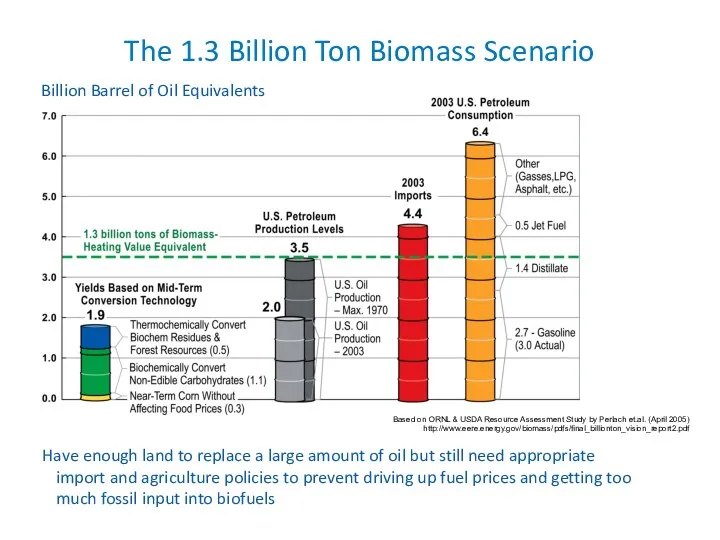

- 21. Life Cycle Assessment: Definition LCA Is a systematic analytical method Used to quantify environmental benefits and

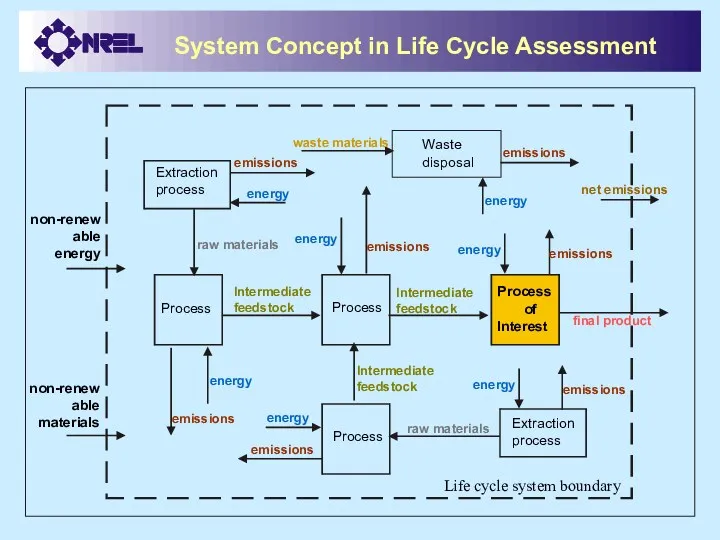

- 22. System Concept in Life Cycle Assessment Life cycle system boundary

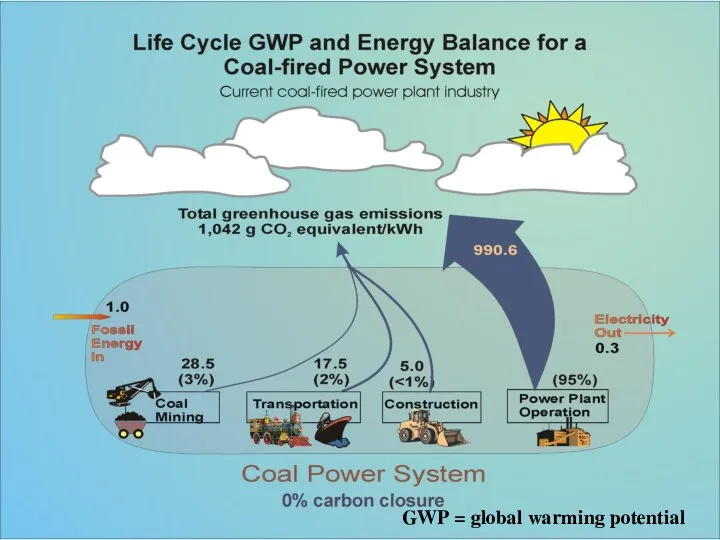

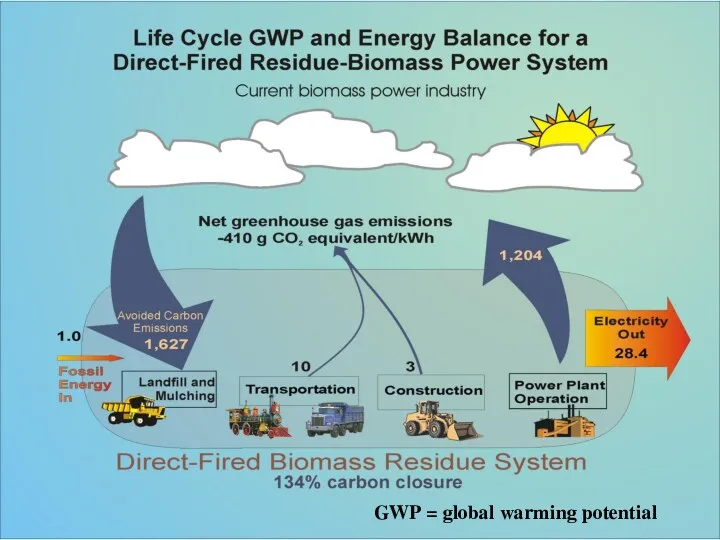

- 23. GWP = global warming potential

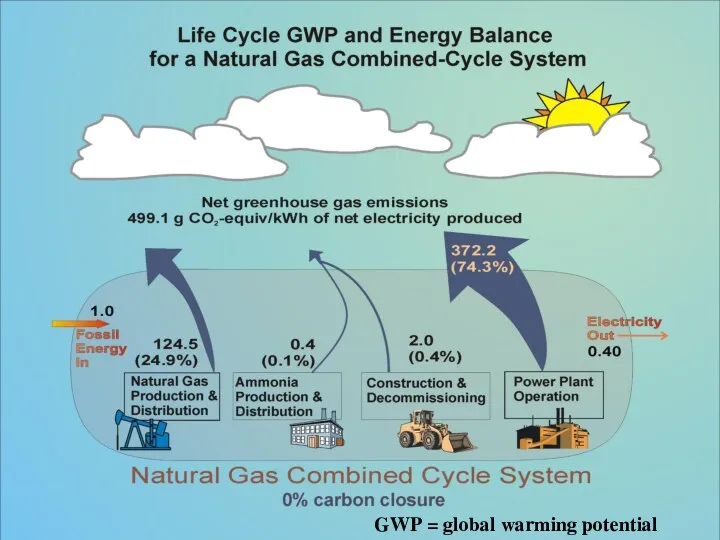

- 24. GWP = global warming potential

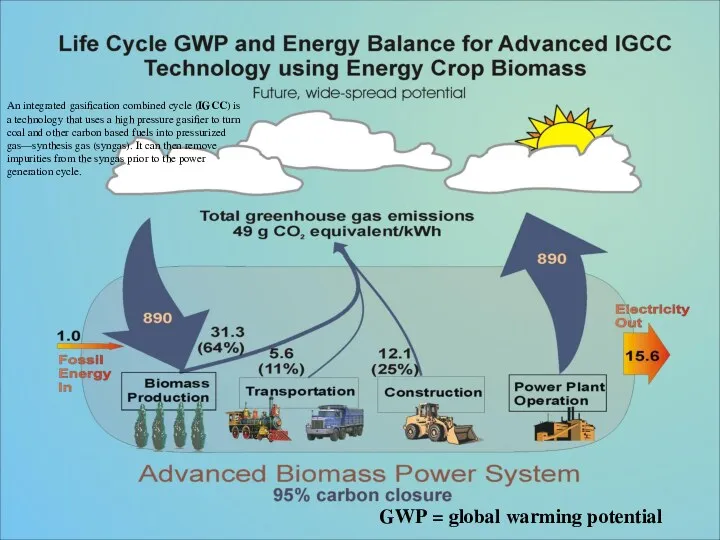

- 25. GWP = global warming potential An integrated gasification combined cycle (IGCC) is a technology that uses

- 26. GWP = global warming potential

- 28. Скачать презентацию

Значение органической химии в жизни человека

Значение органической химии в жизни человека Коррозия металлов

Коррозия металлов Водород. Изотопы водорода. Свойства, получение и применение водорода. Топливные элементы

Водород. Изотопы водорода. Свойства, получение и применение водорода. Топливные элементы Неорганические строительные материалы. Стекло

Неорганические строительные материалы. Стекло Конструкционные функциональные волокнистые композиты

Конструкционные функциональные волокнистые композиты Урок + презентация Азот. 9 класс.

Урок + презентация Азот. 9 класс. Токсическое действие диоксинов и диоксиноподоных соединений

Токсическое действие диоксинов и диоксиноподоных соединений Розчин і його компоненти

Розчин і його компоненти Ароматические углеводороды. Арены

Ароматические углеводороды. Арены Carbohydrates (sugars)

Carbohydrates (sugars) Коррозия и методы борьбы с ней

Коррозия и методы борьбы с ней Поверхностно-активные вещества (ПАВ). Классификация, свойства и условия применения

Поверхностно-активные вещества (ПАВ). Классификация, свойства и условия применения Alyuminiy_ego_soedinenia

Alyuminiy_ego_soedinenia Фосфор

Фосфор Воспламенение (зажигание) газовых смесей

Воспламенение (зажигание) газовых смесей Теоретическое и прикладное материаловедение. Занятие 2

Теоретическое и прикладное материаловедение. Занятие 2 Строение атома. Теории строения атома

Строение атома. Теории строения атома Химия в продуктах питания

Химия в продуктах питания Алкины

Алкины Silicon. Silicate minerals. Weathering

Silicon. Silicate minerals. Weathering Соли. Определение солей

Соли. Определение солей Порівняльний аналіз методів відновлення свинцево-кислотних акумуляторів

Порівняльний аналіз методів відновлення свинцево-кислотних акумуляторів Электролиты и неэлектролиты. Электролитическая диссоциация веществ в водных растворах

Электролиты и неэлектролиты. Электролитическая диссоциация веществ в водных растворах Энергетика химических процессов. Энтропия и энергия Гиббса

Энергетика химических процессов. Энтропия и энергия Гиббса Электрохимические производства

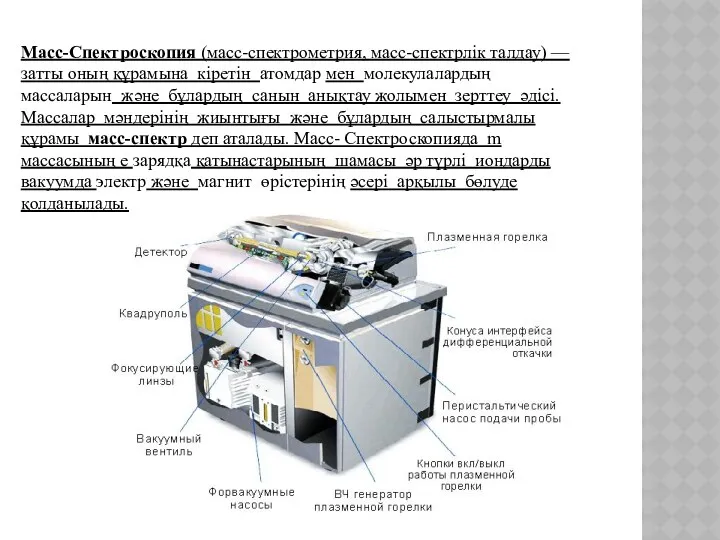

Электрохимические производства Масс-Спектроскопия

Масс-Спектроскопия Борьба с биологической коррозией

Борьба с биологической коррозией Көміртекті материалдар

Көміртекті материалдар