Содержание

- 2. Plan Introduction; ; ; Conclusion

- 3. Reactors. Direct-flow reactors of the cracking plants with a ball of the catalyst have six characteristic

- 4. Heavy feedstock and catalyst input unit: 1 — pipe distribution device; 2-input of raw materials; 3-input

- 5. In the reactor, the vapors of the raw material are in contact with the hot ball

- 9. Скачать презентацию

Plan

Introduction;

;

;

Conclusion

Plan

Introduction;

;

;

Conclusion

Reactors. Direct-flow reactors of the cracking plants with a ball of

Reactors. Direct-flow reactors of the cracking plants with a ball of

Cracking plant reactor with ball catalyst:I-input of raw materials; II - input of catalyst; III-output of reaction products; IV-removal of catalyst; V-input of water vapor; 1-switchgear; 2-reaction zone; 3-separation device; 4-Stripping zone; 5-precast leveling device.

Heavy feedstock and catalyst input unit:

1 — pipe distribution device;

2-input

Heavy feedstock and catalyst input unit:

1 — pipe distribution device;

2-input

From the upper hopper through the riser, the catalyst flows by gravity into the upper distribution device, which is a cylindrical shell. It is designed for uniform distribution of the catalyst flow in the reaction zone of the apparatus.

In the case of heavy raw materials, such an input design can lead to coking of the upper part of the apparatus, so the pipes of the switchgear are protected from contact with the raw material by a curtain of catalyst.

In the reactor, the vapors of the raw material are in

In the reactor, the vapors of the raw material are in

The scheme of the reactor of a catalytic cracking installation with a circulating ball catalyst

4-pressure riser, 5-fitting, 6-distribution device, 7-overhead pipes, 8-fitting for raw materials, 9-separation device, 10-pipes, 11-caps, 12-leveling device, 13 - fittings for drainage, 14-overflow pipes, 15-Stripping zone, 16-fitting for water vapor

the catalyst equalizer plate has 64 holes with a diameter of 108 mm.

Анализ проб воды

Анализ проб воды Carbohydrates and their metabolism. Digestion of carbohydrates

Carbohydrates and their metabolism. Digestion of carbohydrates Химические свойства и получение алканов

Химические свойства и получение алканов Олово и свинец

Олово и свинец Күкірт қышқылы

Күкірт қышқылы Показатели химической обстановки при авариях на химически опасных объектах

Показатели химической обстановки при авариях на химически опасных объектах Жуғыш заттар және жуғыш әсері. 2 Лекция

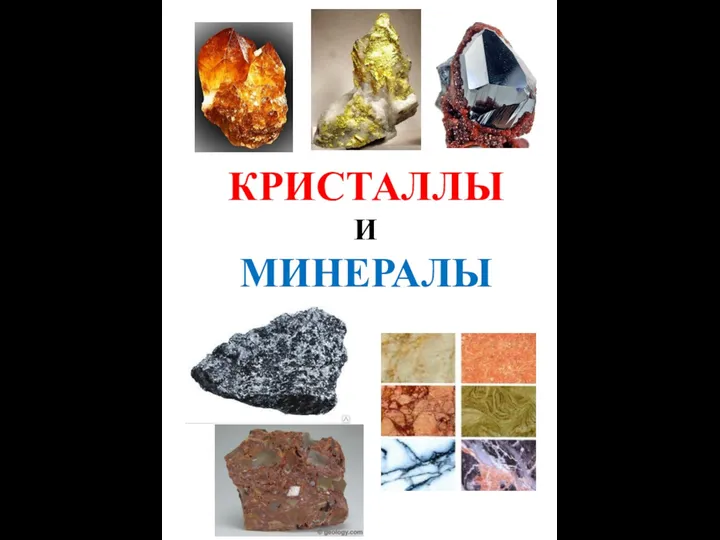

Жуғыш заттар және жуғыш әсері. 2 Лекция Кристаллы и минералы

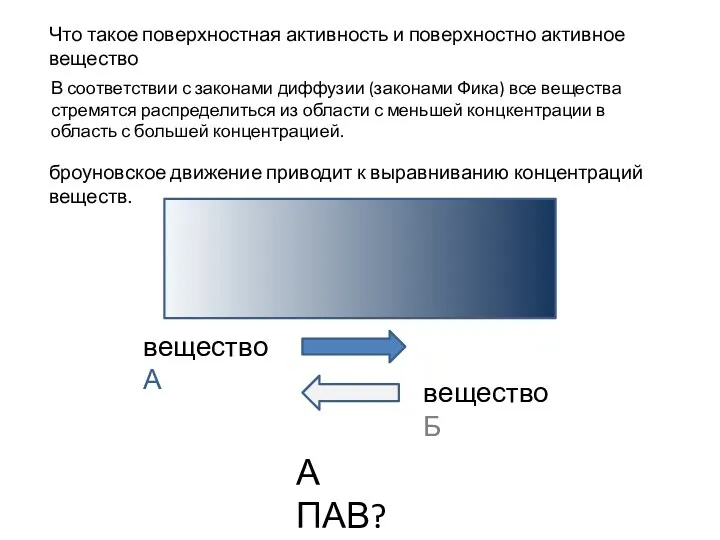

Кристаллы и минералы Поверхностная активность и поверхностно активное вещество

Поверхностная активность и поверхностно активное вещество Строение и свойства циклоалканов

Строение и свойства циклоалканов Химические реакции или химические явления

Химические реакции или химические явления Растворы ВМС

Растворы ВМС Констукционные и функциональные волокнистые композиты. Стекловолокно

Констукционные и функциональные волокнистые композиты. Стекловолокно Основные способы получения металлов

Основные способы получения металлов Расчет распределения пор по размерам из изотерм адсорбции

Расчет распределения пор по размерам из изотерм адсорбции Обчислення об'ємних відношень газів за хімічними рівняннями. Хімія. 9 клас

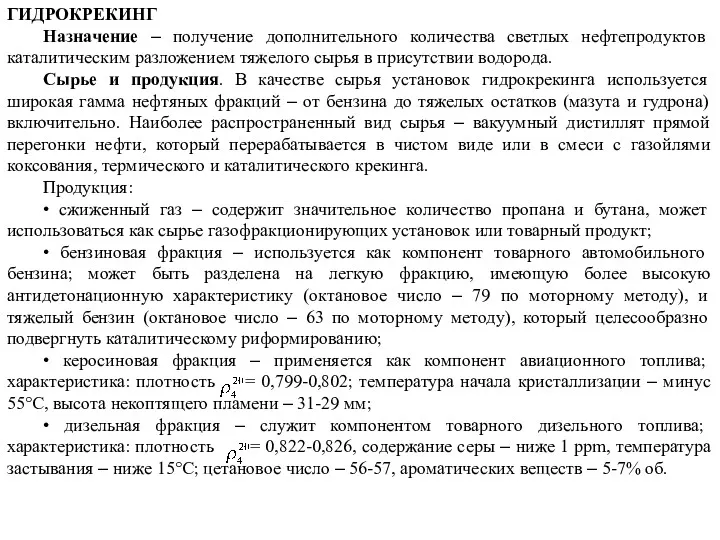

Обчислення об'ємних відношень газів за хімічними рівняннями. Хімія. 9 клас Установка гидрокрекинга

Установка гидрокрекинга Закономірності протікання хімічних реакцій

Закономірності протікання хімічних реакцій Арилалкиламины, гидроксифенилалкиламины и их производные

Арилалкиламины, гидроксифенилалкиламины и их производные Азотсодержащие органические соединения. Лекция 8

Азотсодержащие органические соединения. Лекция 8 Приёмы обращения с лабораторным оборудованием и основы техники безопасности

Приёмы обращения с лабораторным оборудованием и основы техники безопасности Особенности лантаноидов и актиноидов

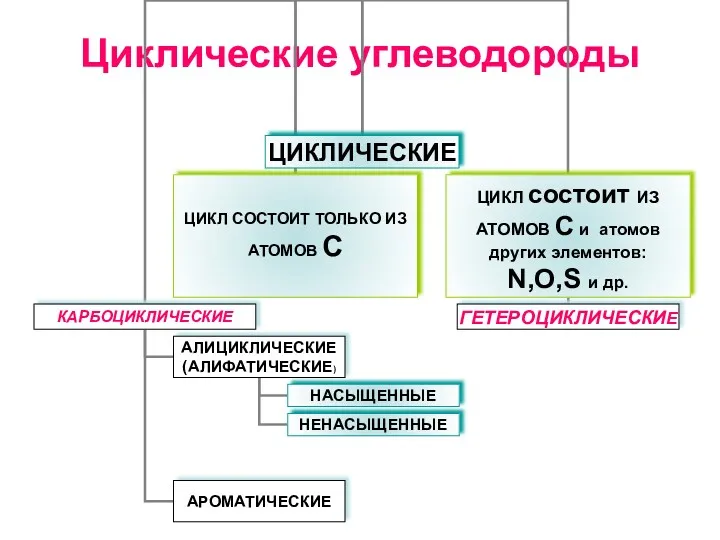

Особенности лантаноидов и актиноидов Циклические углеводороды

Циклические углеводороды Полимеры

Полимеры Кристаллические решетки

Кристаллические решетки Алкадиены: строение, номенклатура, гомологи, изомерия

Алкадиены: строение, номенклатура, гомологи, изомерия Соли, их классификация и свойства

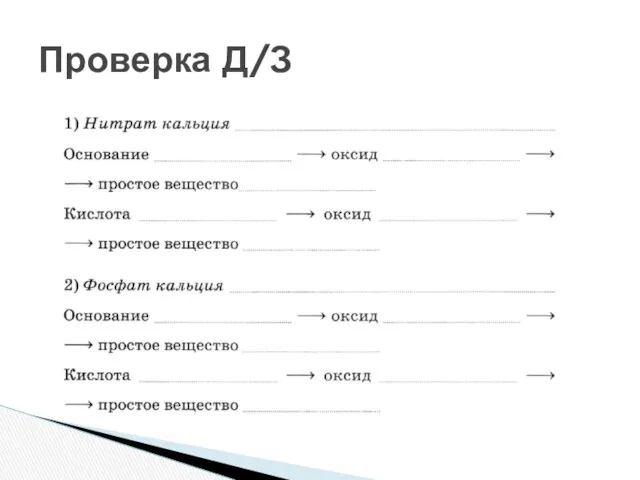

Соли, их классификация и свойства Молярная масса вещества

Молярная масса вещества